Leakage detection method for closed circulating water system of calcium carbide furnace

A technology of leakage detection and closed cycle, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the safety hazards of calcium carbide furnace, affect the reading value of the instrument, and raise the equipment parts. , to achieve the effect of improving detection accuracy and response speed, reducing system false alarm rate, and reducing the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

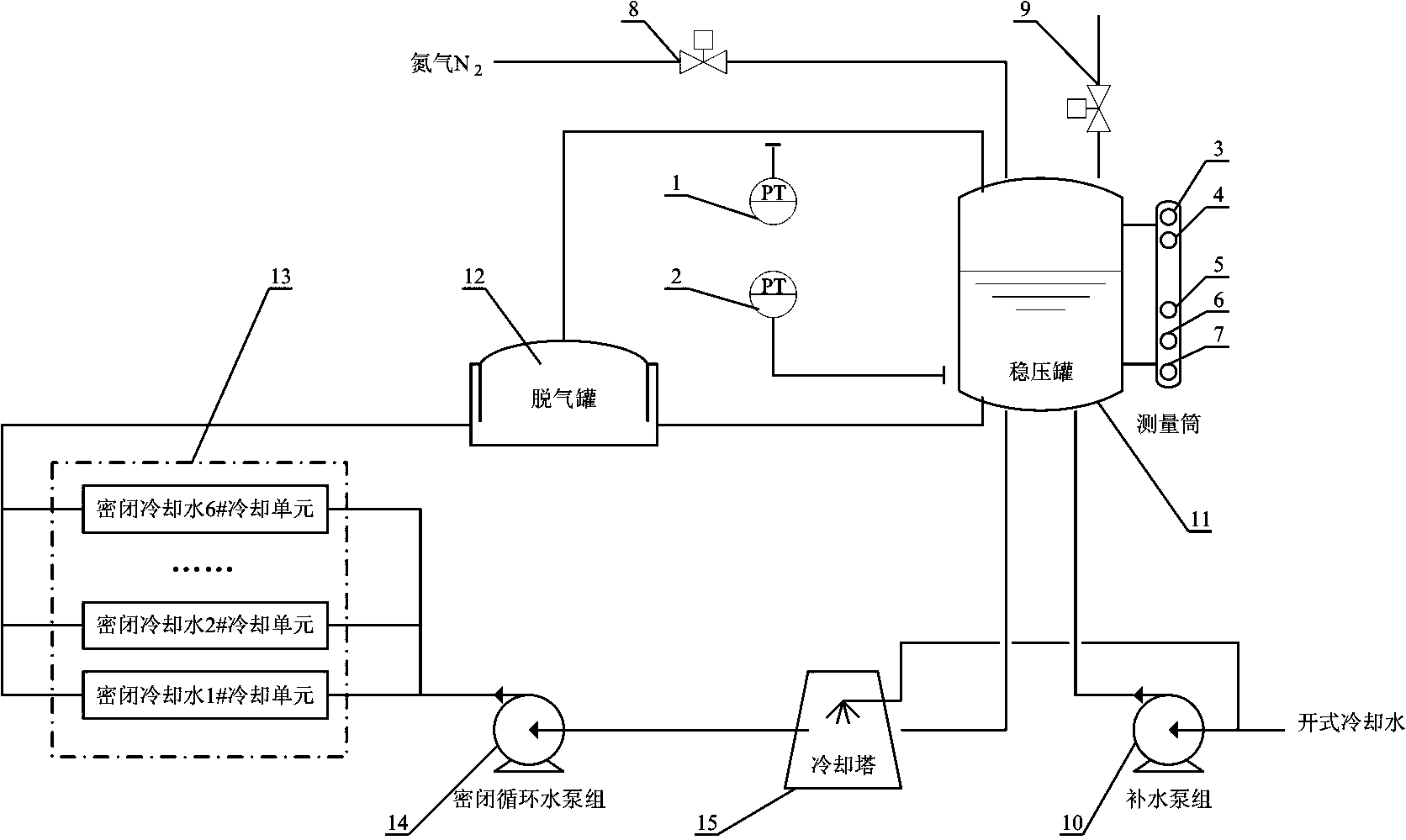

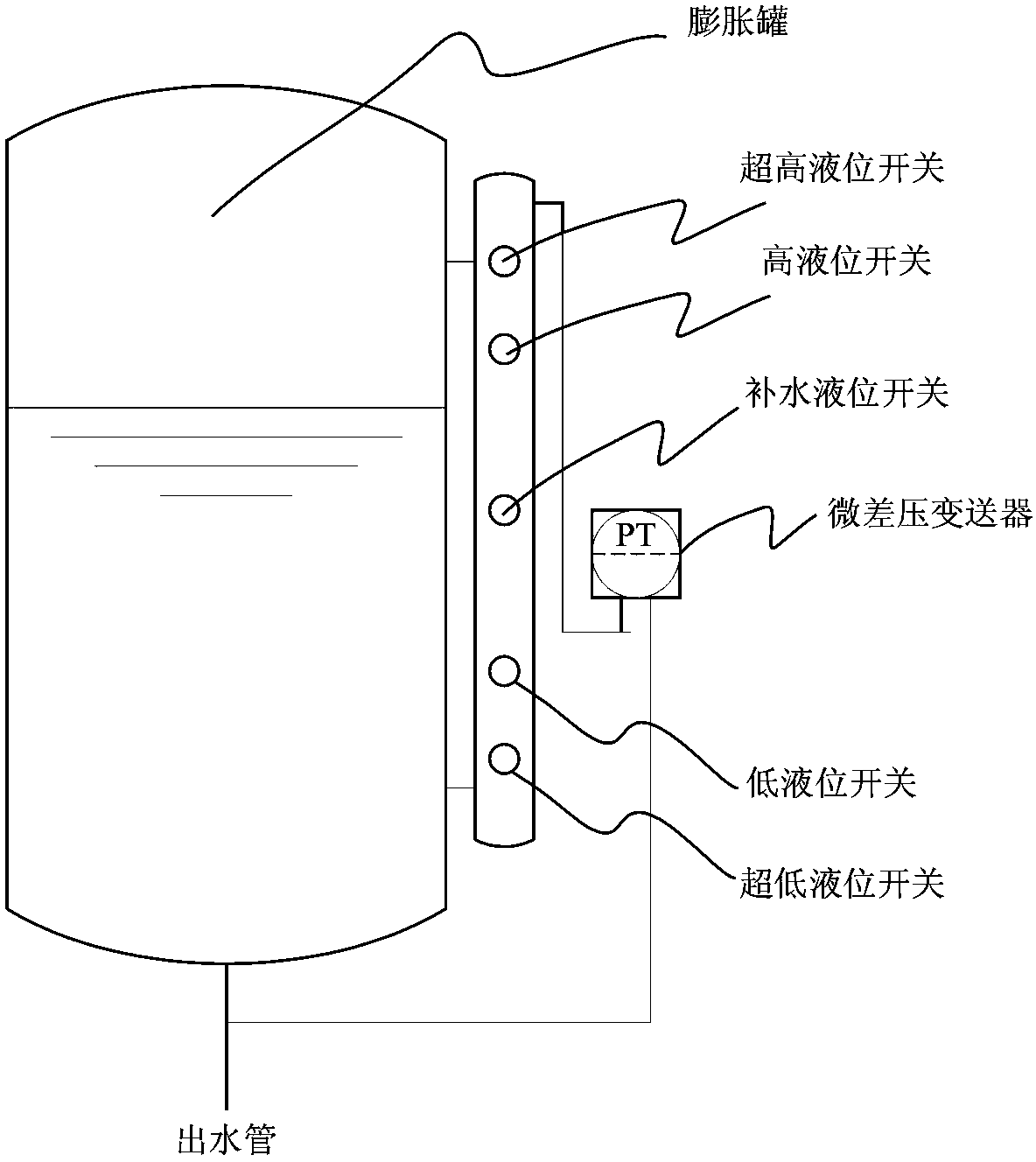

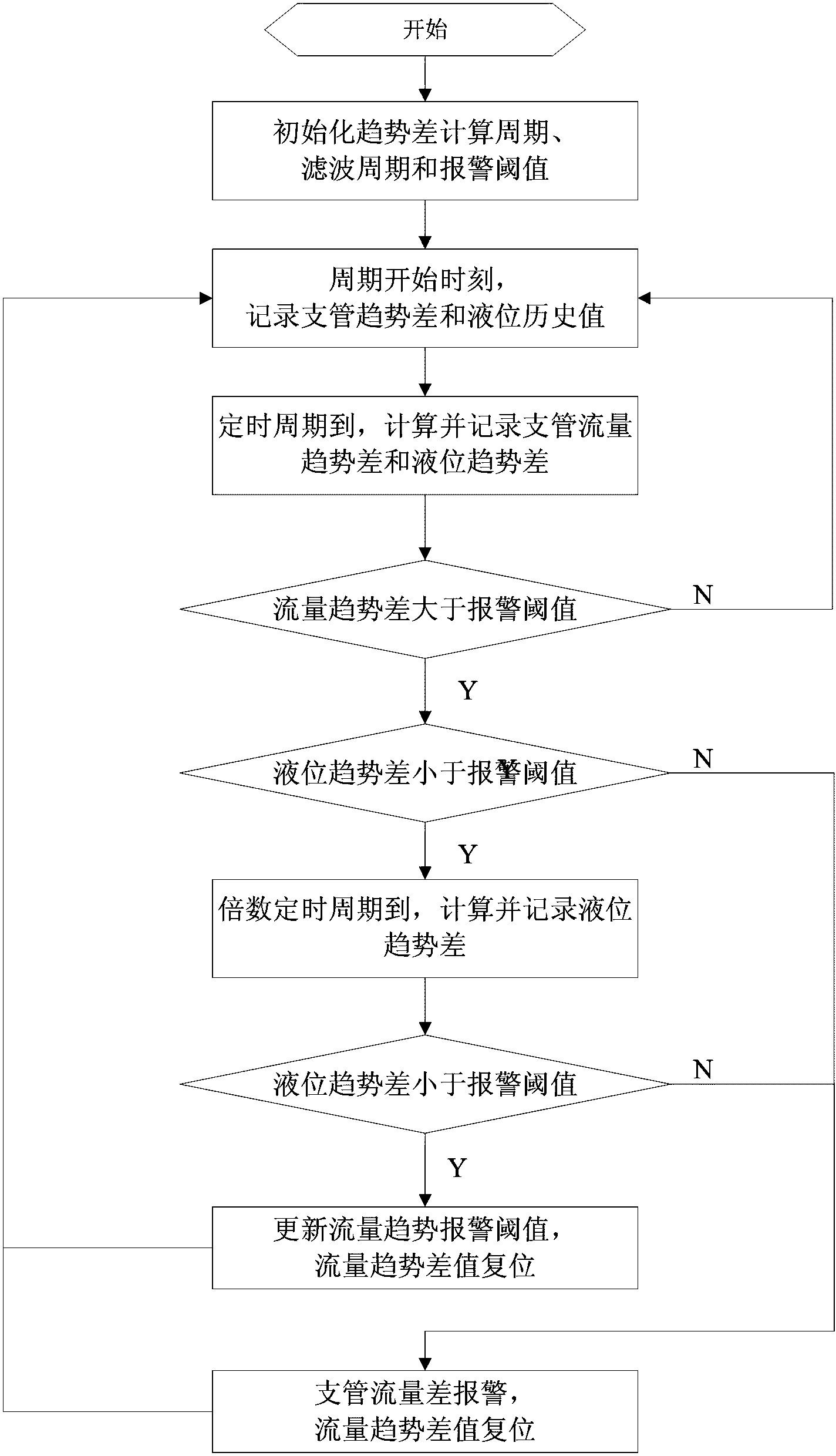

[0034] Such as figure 1 As shown, the embodiment calcium carbide furnace closed circulating water process flow chart. In order to ensure the safe and normal production of the calcium carbide furnace, it is necessary to cool the relevant parts of the calcium carbide furnace. The cooling branch pipe is divided into several closed cooling water cooling units 13, and each cooling unit 13 usually consists of a water inlet distributor, a certain number of sets The cooling water branch pipe connected to the equipment components of the calcium carbide furnace, the flow and temperature measuring device of the branch pipe, and a ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com