Instrument fault elimination method used for ABS composite material production device

A troubleshooting method and production device technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as emergency shutdown and loss of ABS composite material production devices, and achieve the effect of eliminating instrument failures and ensuring safe and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

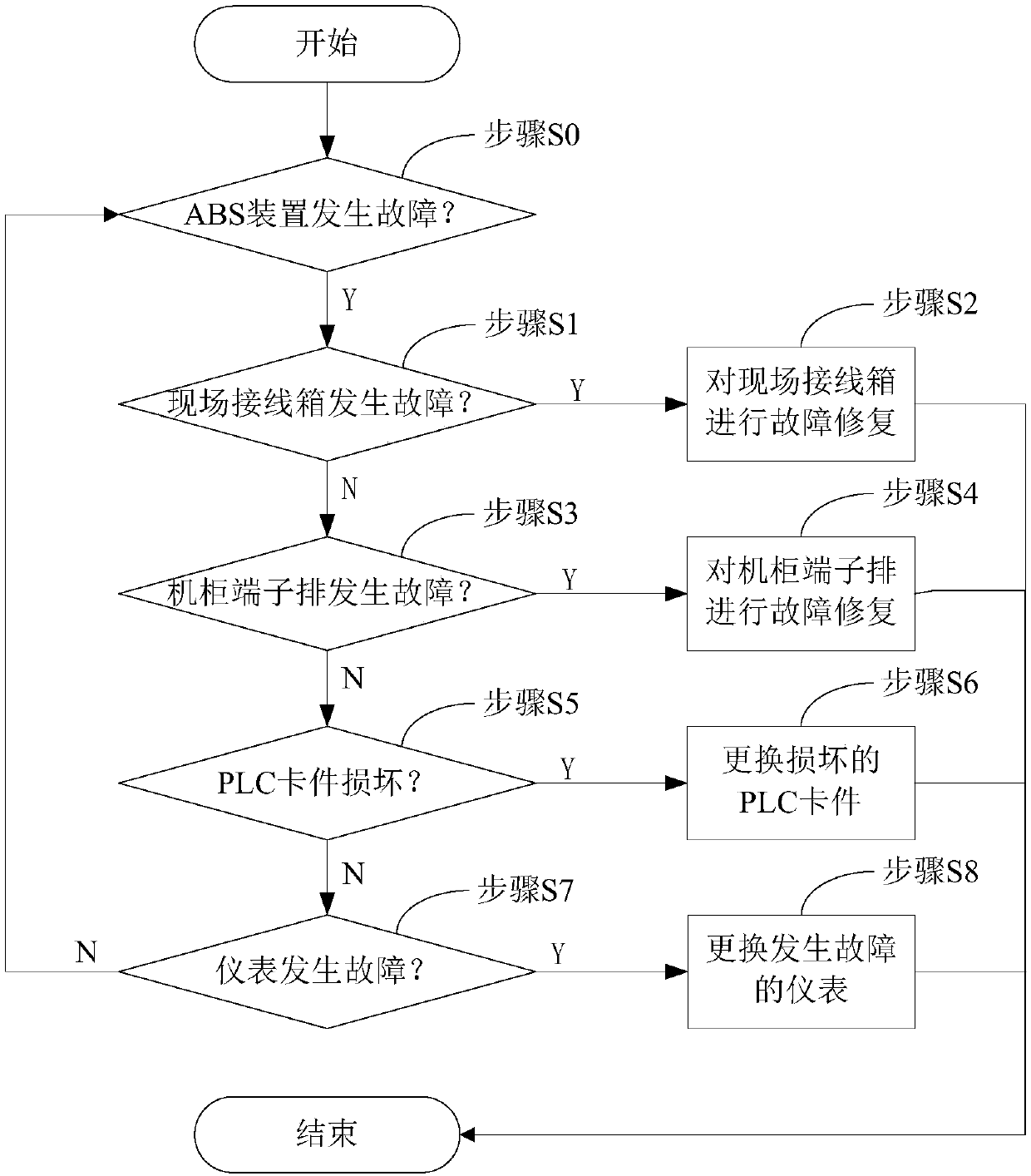

[0029] based on the following Figure 1 to Figure 5 , specifically explain the preferred embodiment of the present invention.

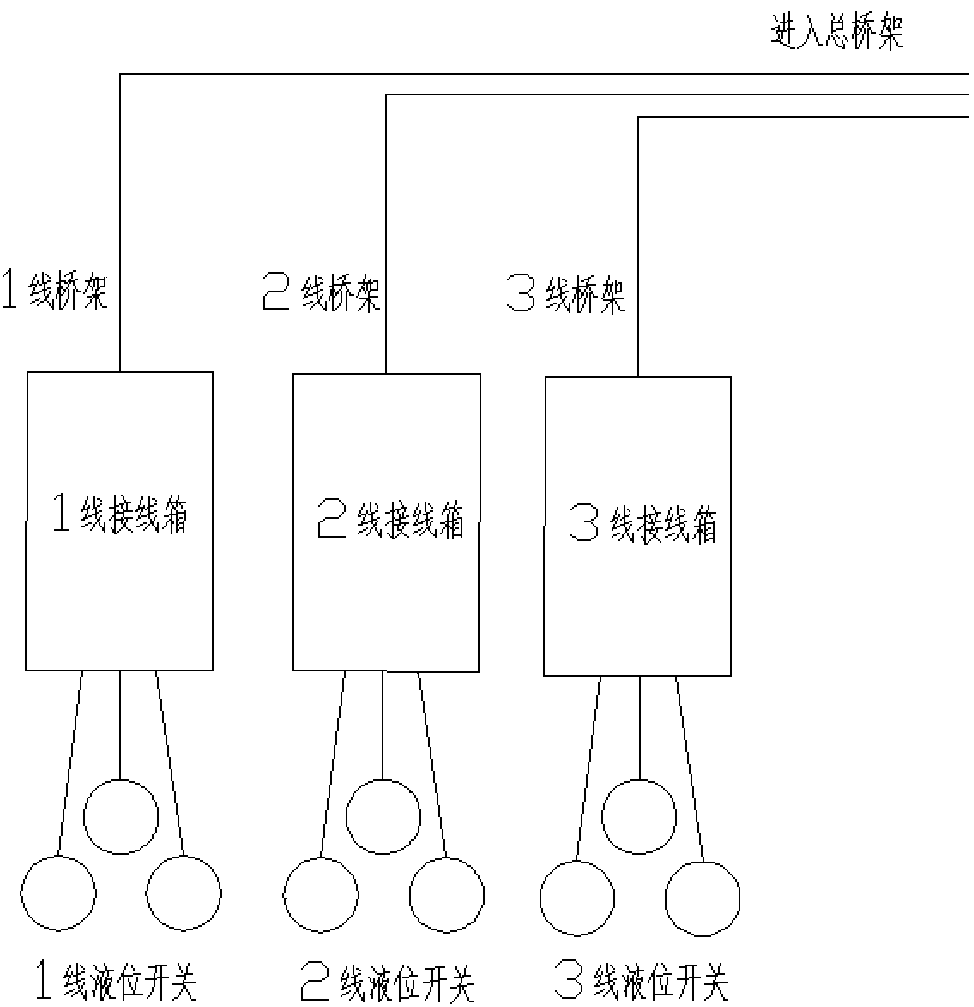

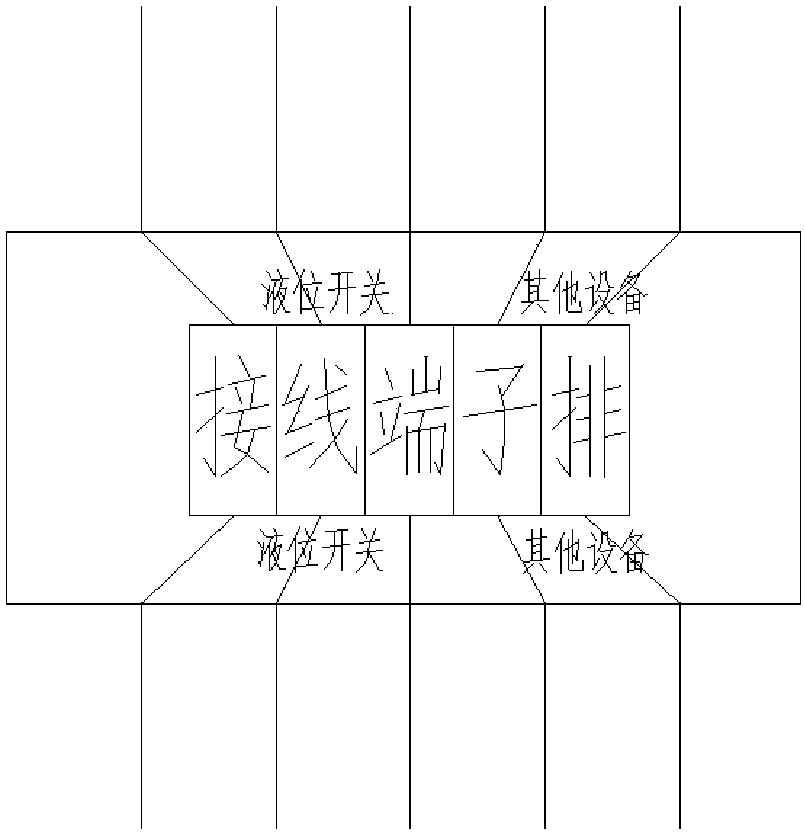

[0030] In the ABS composite material production device, the instrument cables in the two redundant vacuum systems are first connected to the field junction box, then introduced into the instrument cabinet room through the instrument bridge, then connected to the cabinet terminal block, and finally connected to the PLC card of the control system .

[0031] Such as figure 1 As shown, the present invention provides a method for troubleshooting an instrumentation of an ABS composite material production device, comprising the following steps:

[0032] Step S0, the control system judges whether the ABS composite material production device fails, and if so, proceed to step S1;

[0033] Step S1, check whether the field junction box connected to the meter is faulty, if so, go to step S2, if not, go to step S3;

[0034] Step S2, performing fault repair on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com