Waste limestone environmentally-friendly reuse dry sand making method

A technology of limestone and environmental protection, which is applied in the field of waste limestone environmental protection and reuse dry sand making, can solve the problems of easy generation of dust, deterioration of mine ecological environment, low recovery efficiency, etc., and achieve safe and stable production process, advanced production technology, and reduce dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

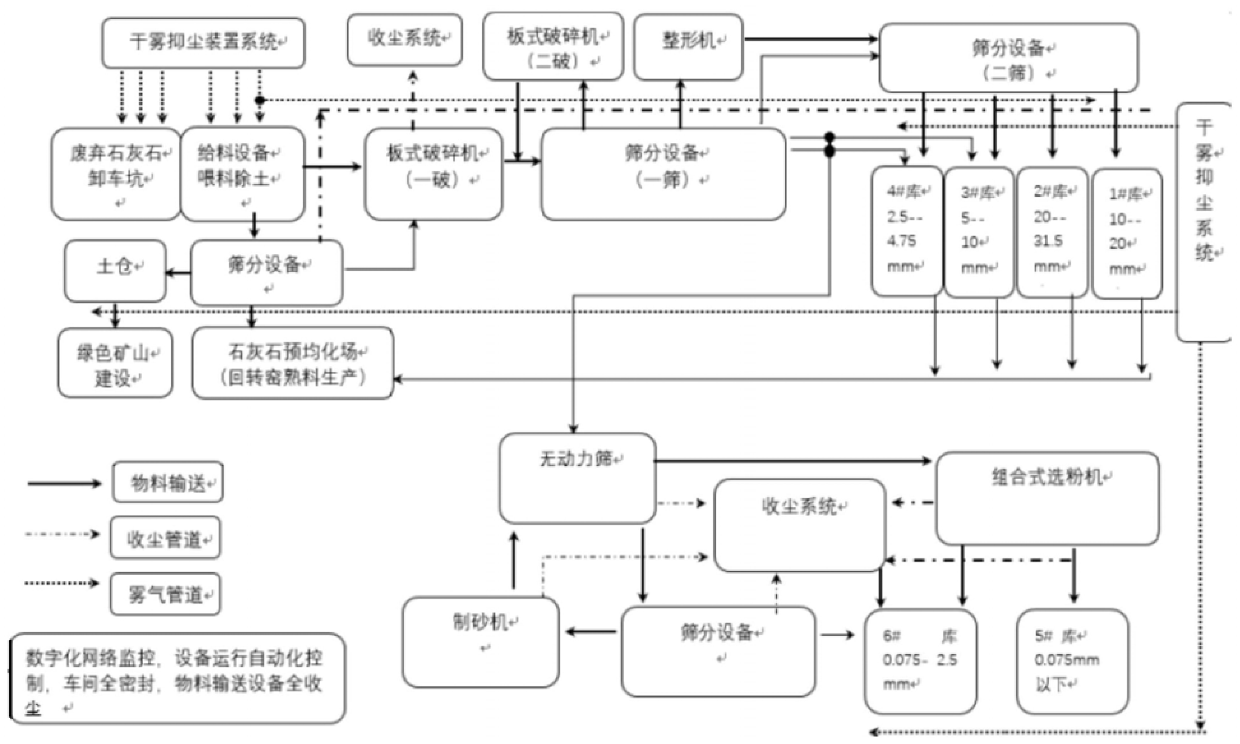

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0020] see figure 1 , the present invention provides the following technical solutions: a dry sand making method for environmental protection and reuse of waste limestone, comprising the following steps:

[0021] Step 1: Transport the waste limestone to the inside of the material bin by a transport vehicle, and the limestone that enters the inside of the material bin is evenly conveyed to the inside of the plate crusher through a screen feeder with a gap of 150 mm;

[0022] Materials with a particle size of less than 150 mm are screened out by a feeding machine with a screen, and then transported to a soil removal sieve with an aperture of 20 mm by a belt conveyor. The materials below 20 mm are screened out and sent to the waste pile by a belt conveyor. , Green mine construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com