Production method of insulation materials used for crystal pulling furnace

A technology of thermal insulation material and production method, which is applied in the production field of thermal insulation materials for crystal pulling furnaces, can solve the problems of difficult control of production process and poor quality of finished products, and achieve the effects of shortening production cycle, low production cost, and safe and stable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

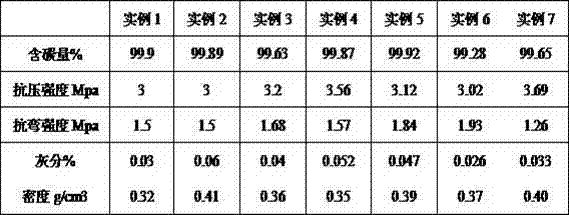

Examples

example 1

[0022] A kind of production method of thermal insulation material for crystal pulling furnace, its production process is as follows:

[0023] (1) Soak the graphitized polyacrylonitrile-based short carbon fiber composite material (0.666tex) at ∮360mm×∮390mm×115mm0 at a temperature of 2400°C for 3 hours with an organic composite resin, and dry it for later use; the organic composite resin is selected from phenolic resin, One of furfural resin, furan resin, epoxy resin, etc., preferably phenolic resin (solvent is methanol);

[0024] After curing at 150°C for 3 hours, apply a layer of sealing agent on the surface of the cured polyacrylonitrile-based short carbon fiber composite material, and dry it in the sun for later use (the sealing agent consists of 10-50wt% phenolic resin, 3-50wt% cyclic Oxygen resin, 1~10wt% furan resin, 1~10wt% furfural resin and the balance of methanol).

[0025] (2) Soak the polyacrylonitrile-based graphite fiber felt (0.666tex) after graphitization at 2...

example 2

[0032] (1) Soak ∮45mm0×∮350mm×500mm graphitized viscose-based short carbon fiber composites (0.244tex) at 2400°C in furfural resin (solvent is ethanol) for 2h, dry for later use; treat at 150°C for 3h Finally, coat a layer of phenolic resin on the surface of the short carbon fiber composite material, and let it dry for later use.

[0033] (2) Soak the viscose-based graphite fiber felt graphitized at 2400°C in furfural resin (solvent is ethanol) for 2 hours, and dry it for later use.

[0034] (3) Coating phenolic resin on the surface of the viscose-based short carbon fiber composite material coated with phenolic resin and the surface of the graphite felt; the two materials coated with the adhesive are wound and bonded together, fixed with a mold, and heated at 150~ Pressure curing at 180°C for 5 hours.

[0035] (4) Send the cured product into a high temperature furnace for graphitization at 2400°C.

[0036] (5) After graphitization, spray graphite powder or phenolic resin on ...

example 3

[0039] The carbon fiber composite material is selected from ∮400mm×∮380mm×730mm polyacrylonitrile-based short carbon fiber composite material (0.666tex) after carbonization and graphitization at 2400°C. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com