Method for predicting, controlling and improving efficiency of thermal power unit steam turbine by using steam pressure

A steam turbine efficiency and predictive control technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of errors, low steam turbine efficiency, and low control accuracy, achieve stable and safe production, reduce labor intensity, and improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further understand the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the protection scope of the present invention.

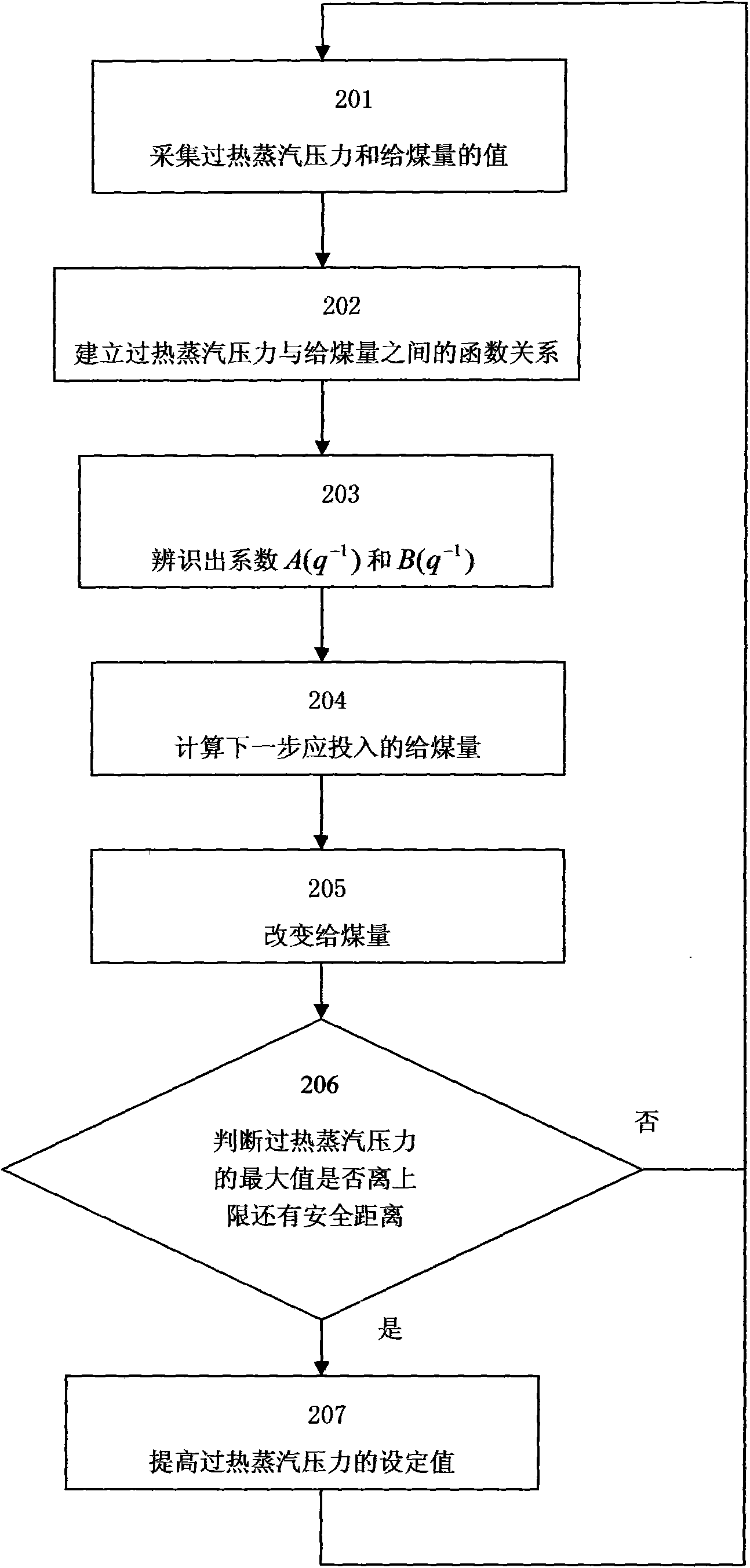

[0053] Such as figure 2 Shown, for the present invention uses steam pressure predictive control to improve the method flowchart of steam turbine efficiency of thermal power unit:

[0054] Step 201: The sensor collects the values of superheated steam pressure and coal feed rate in the boiler. In one embodiment of the present invention, the sampling time interval is set at 2 seconds, that is, a pair of values of superheated steam pressure and coal feed rate are collected every 2 seconds, and a total of 10,000 sets of data are collected.

[0055] Step 202: Establish the functional relationship between the superheated steam pressure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com