Hydrogen purification and transportation method

A technology of hydrogen and mixed gas, applied in chemical instruments and methods, separation methods, hydrogen separation, etc., can solve the problems of complex equipment, large investment, high energy consumption, etc., and achieve extended regeneration time, high safety, and simple system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

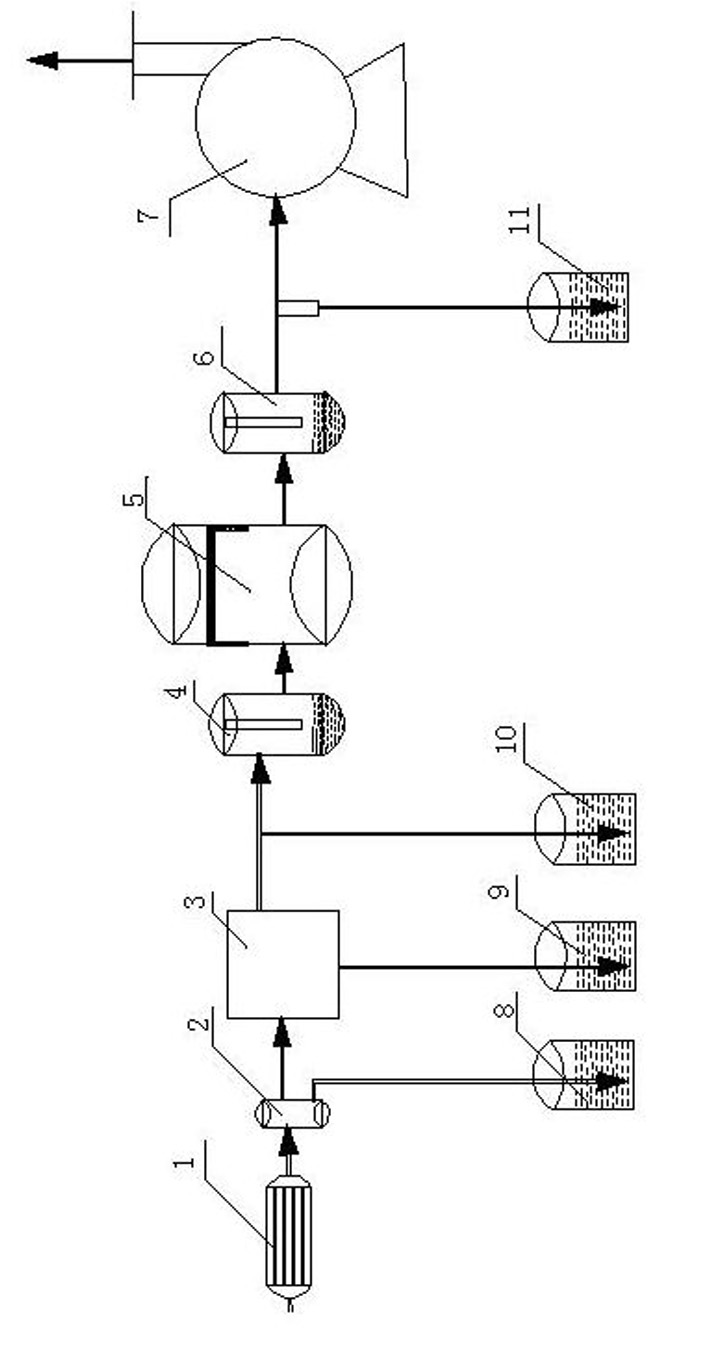

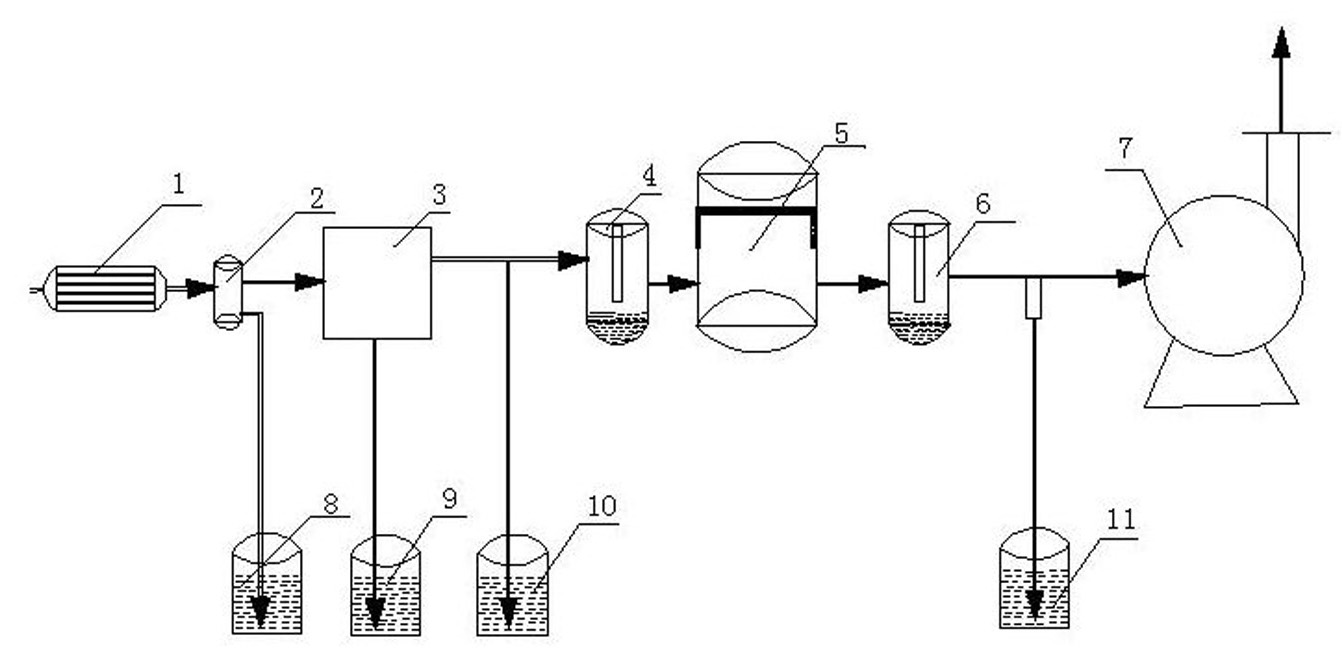

Image

Examples

Embodiment 1

[0016] The hydrogen mixed gas containing water vapor obtained from the upstream sodium chlorate production process enters the chilled water cooler at a pressure of 15-25KPa, and the chilled water cooler is fed with cooling water at 3°C to reduce the temperature of the mixed gas to 5 ℃, the cooled mixed gas enters the gas-liquid separator, the water vapor is condensed and separated from the mixed gas, and the condensed water is discharged into the water seal. At the lowest point of the gas transportation pipelines, a condensed water discharge pipe is installed, and the pipes The condensed water in the road is discharged into the water seal to further reduce the moisture content in the gas; the mixed gas after cooling and dewatering by the chilled water cooler enters the activated carbon adsorption device to further absorb moisture and impurities; after the above treatment, it enters the dry gas It is stored in a cabinet. There are water seals on the inlet and outlet pipes of t...

Embodiment 2

[0018] The hydrogen mixed gas containing water vapor obtained from the upstream sodium chlorate production process enters the chilled water cooler at a pressure of 15-25KPa, and the chilled water cooler is fed with cooling water at 5°C to reduce the temperature of the mixed gas to 9 ℃, the cooled mixed gas enters the gas-liquid separator, the water vapor is condensed and separated from the mixed gas, and the condensed water is discharged into the water seal. At the lowest point of the gas transportation pipelines, a condensed water discharge pipe is installed, and the pipes The condensed water in the road is discharged into the water seal to further reduce the moisture content in the gas; the mixed gas after cooling and dewatering by the chilled water cooler enters the activated carbon adsorption device to further absorb moisture and impurities; after the above treatment, it enters the dry gas It is stored in a cabinet. There are water seals on the inlet and outlet pipes of the...

Embodiment 3

[0020] The hydrogen mixed gas containing water vapor obtained from the upstream sodium chlorate production process enters the chilled water cooler at a pressure of 15-25KPa, and the chilled water cooler is fed with cooling water at 4°C to reduce the temperature of the mixed gas to 7 ℃, the cooled mixed gas enters the gas-liquid separator, the water vapor is condensed and separated from the mixed gas, and the condensed water is discharged into the water seal. At the lowest point of the gas transportation pipelines, a condensed water discharge pipe is installed, and the pipes The condensed water in the road is discharged into the water seal to further reduce the moisture content in the gas; the mixed gas after cooling and dewatering by the chilled water cooler enters the activated carbon adsorption device to further absorb moisture and impurities; after the above treatment, it enters the dry gas It is stored in a cabinet. There are water seals on the inlet and outlet pipes of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com