Insulating layer for power transmission and transformation lines

A technology for power transmission and transformation lines and insulating layers, which is applied in the direction of circuits, insulators, organic insulators, etc., and can solve problems such as burned lines and equipment, inappropriate, short circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

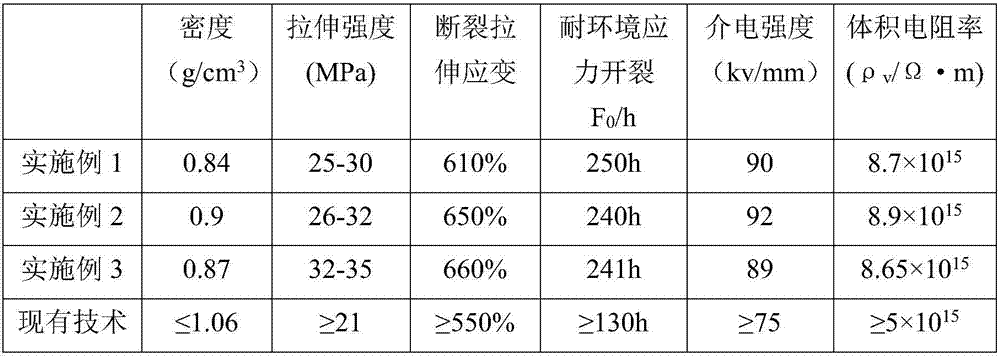

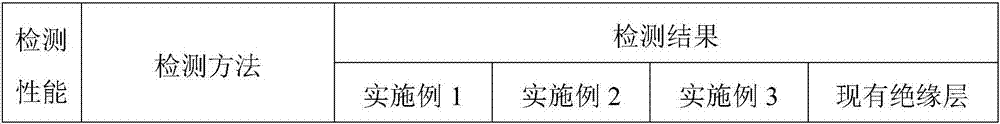

Examples

Embodiment 1

[0039] An insulating layer for power transmission and transformation lines, comprising the following raw materials in parts by weight:

[0040] polycarbonate 15 g;

[0041] Ethylene-vinyl acetate copolymer 1 g;

[0042] ABS plastic 15 grams;

[0043] Sodium dioctyl sulfosuccinate 4 grams;

[0044] Lead monoxide 2 grams;

[0045] 1 gram of graphite powder;

[0046] Rosin 1g;

[0047] 6 grams of isoprene rubber;

[0048] Mineral gum 15 grams;

[0049] Methyl vinyl silicone rubber 5 grams;

[0050] Chlorinated polyether 2 grams;

[0051] 2 grams of epoxy fatty acid octyl ester;

[0052] 2 grams of polydiallyldimethylammonium chloride;

[0053] Hexamethylenetetramine 10 grams;

[0054] 5 grams of flame retardant;

[0055] 1 gram of coupling agent;

[0057] 2 grams of diatomaceous earth;

[0058] 1 gram of wood flour;

[0059] 0.075 grams of 6-tertiary butyl-4-methylphenol;

[0060] 0.025 grams of diester thiodipropionate;

[0061] He...

Embodiment 2

[0069]An insulating layer for power transmission and transformation lines, comprising the following raw materials in parts by weight:

[0070] polycarbonate 40 g;

[0071] Ethylene-vinyl acetate copolymer 3 grams;

[0072] 20 grams of ABS plastic;

[0073] Sodium dioctyl sulfosuccinate 10 grams;

[0074] Lead monoxide 4 grams;

[0075] 3 grams of graphite powder;

[0076] Rosin 3 grams;

[0077] 15 grams of isoprene rubber;

[0078] 20 grams of mineral gum;

[0079] Methyl vinyl silicone rubber 15 grams;

[0080] Chlorinated polyether 5 grams;

[0081] 5 grams of epoxy fatty acid octyl ester;

[0082] 4 grams of polydiallyldimethylammonium chloride;

[0083] Hexamethylenetetramine 15 grams;

[0084] 15 grams of flame retardant;

[0085] 4 grams of coupling agent;

[0086] Talc powder 4 grams;

[0087] 4 grams of diatomaceous earth;

[0088] 2 grams of wood flour;

[0089] 0.15 grams of 2,6-tertiary butyl-4-methylphenol;

[0090] 0.05 grams of diester thiodipro...

Embodiment 3

[0098] An insulating layer for power transmission and transformation lines, comprising the following raw materials in parts by weight:

[0099] polycarbonate 30 g;

[0100] Ethylene-vinyl acetate copolymer 2 grams;

[0101] ABS plastic 17 grams;

[0102] Sodium dioctyl sulfosuccinate 7 grams;

[0103] 3 grams of lead monoxide;

[0104] 2 grams of graphite powder;

[0105] Rosin 2 grams;

[0106] 10 grams of isoprene rubber;

[0107] 18 grams of mineral gum;

[0108] Methyl vinyl silicone rubber 10 grams;

[0109] Chlorinated polyether 4 grams;

[0110] 4 grams of epoxy fatty acid octyl ester;

[0111] 3 grams of polydiallyldimethylammonium chloride;

[0112] Hexamethylenetetramine 12 grams;

[0113] 10 grams of flame retardant;

[0114] 2 grams of coupling agent;

[0115] 3 grams of talcum powder;

[0116] 3 grams of diatomaceous earth;

[0117] 1.5 grams of wood flour;

[0118] 0.1 grams of 2,6-tertiary butyl-4-methylphenol;

[0119] 0.05 grams of diester thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com