Method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate

A vinylidene chloride and acrylate technology, applied in the field of coating science, can solve the problems of adhesion, salt spray resistance, poor stability of the emulsion, easy demulsification of the emulsion, etc., to achieve good emulsification, improve Good film formation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

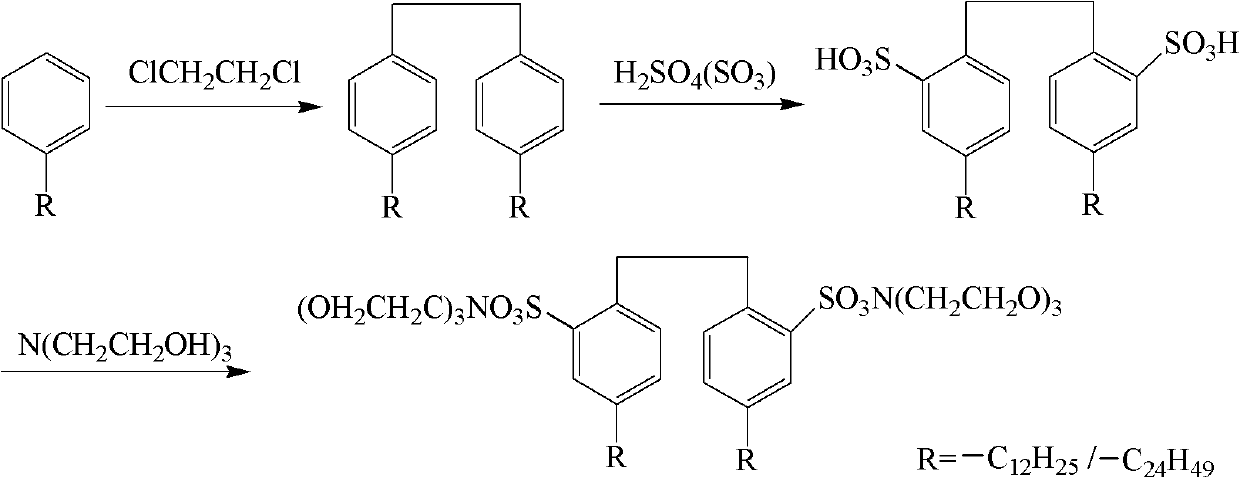

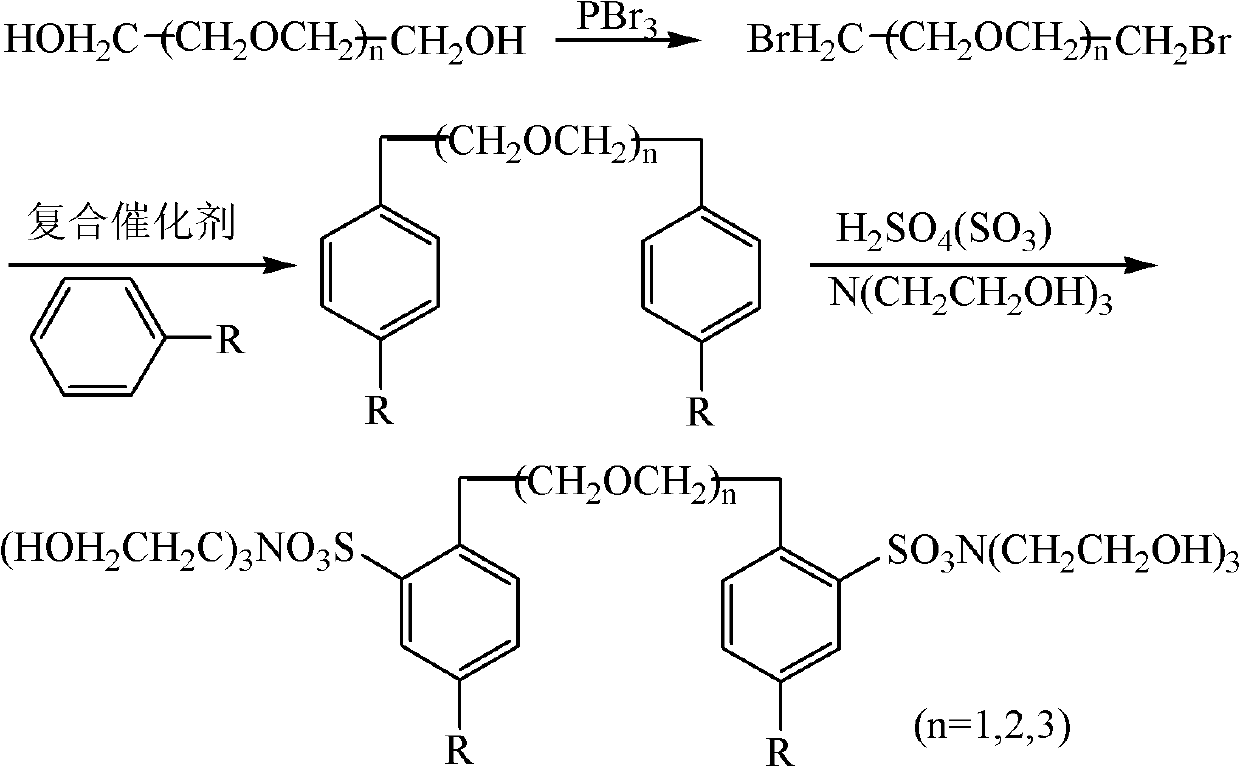

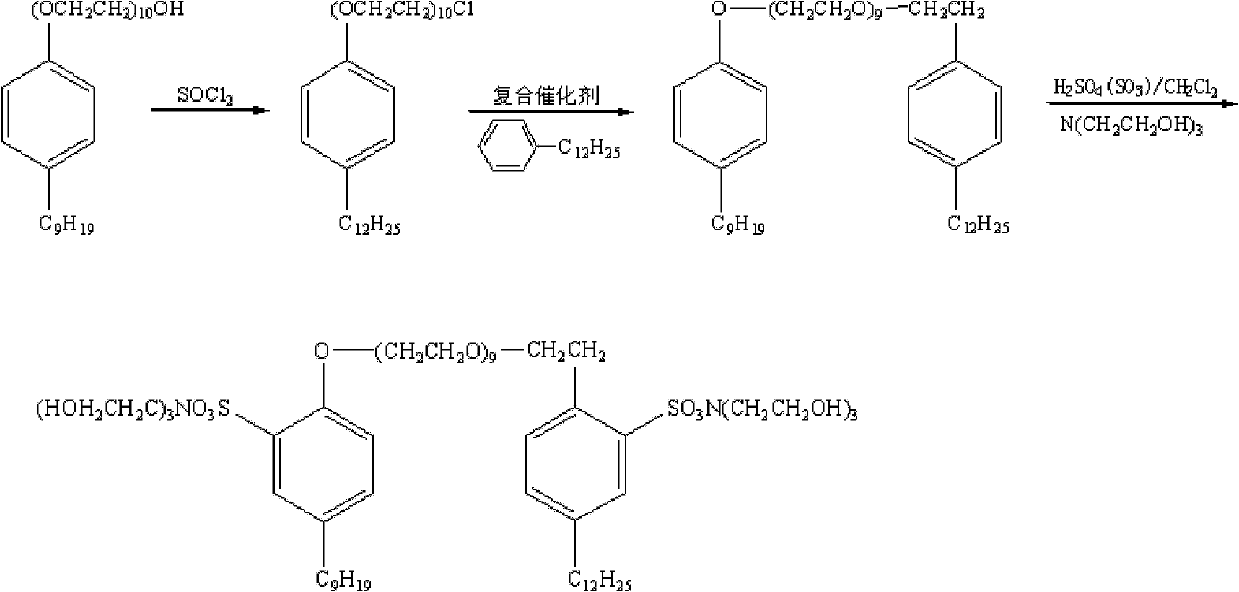

Method used

Image

Examples

Embodiment 1

[0035] Dissolve 2.6g of the asymmetric anion-nonionic Gemini surfactant synthesized as in (3) in 276g of deionized water. After the emulsifier is completely dissolved, add 28.8g of butyl acrylate and 16.8g of methyl methacrylate under ice bath conditions. Ester, 278.4g of vinylidene chloride, emulsified at high speed under ice bath for 1 hour to obtain pre-emulsion.

[0036] Add 242g of pre-emulsion into the reactor, vacuumize and fill with nitrogen three times, raise the temperature to 78°C, add 1.95g of azobisisobutyronitrile dissolved in 5mL of ethanol, keep the temperature for 15-30min, and start adding the remaining pre-emulsion dropwise. After dripping the emulsion in half an hour, react at a constant temperature for 5 hours to obtain a vinylidene chloride-acrylate emulsion: the solid content is about 55%. The emulsion has excellent storage stability, high coating film hardness, good water resistance, chemical resistance and salt spray resistance, and can be applied to w...

Embodiment 2

[0041]Dissolve 2.6g of the polyoxyethylene ether synthesized as in (2) as the linker Gemini surfactant in 276g of deionized water. After the emulsifier is completely dissolved, add 31.0g of butyl acrylate and 14.6g of methacrylic acid under ice bath conditions. Methyl ester and 278.4g of vinylidene chloride were emulsified with high-speed stirring under an ice bath for 1 hour to obtain a pre-emulsion.

[0042] Add 302g of pre-emulsion into the reactor, vacuumize and fill with nitrogen three times, heat up to 75°C, add 1.95g of azobisisobutyronitrile dissolved in 5mL of ethanol, keep the temperature for 15-30min, and start adding the remaining pre-emulsion dropwise. After dripping the emulsion in half an hour, react at a constant temperature for 5 hours to obtain a vinylidene chloride-acrylate emulsion: the solid content is about 55%. The emulsion has excellent storage stability, high coating film hardness, good water resistance, chemical resistance and salt spray resistance, a...

Embodiment 3

[0044] Dissolve 2.6g of the polyoxyethylene ether synthesized as in (2) as the linker Gemini surfactant in 276g of deionized water. After the emulsifier is completely dissolved, add 27.0g of butyl acrylate and 15.0g of methacrylic acid under ice bath conditions. Methyl ester and 282.0 g of vinylidene chloride were emulsified with high-speed stirring under an ice bath for 1 hour to obtain a pre-emulsion.

[0045] Add 280g of pre-emulsion into the reactor, vacuumize and fill with nitrogen three times, heat up to 75°C, add 1.95g of azobisisobutyronitrile dissolved in 5mL of ethanol, keep the temperature constant for 15-30min, and start adding the remaining pre-emulsion dropwise. After dripping the emulsion in half an hour, react at a constant temperature for 5 hours to obtain a vinylidene chloride-acrylate emulsion: the solid content is about 55%. The emulsion has excellent storage stability, high coating film hardness, good water resistance, chemical resistance and salt spray re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com