High-fatigue-resistance ABS (Acrylonitrile Butadiene Styrene) resin composition and preparation method thereof

An ABS resin and fatigue-resistant technology, applied in the field of resin composition and its preparation, can solve the problems of material toughness decrease, weight increase, etc., and achieve the effect of improving fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

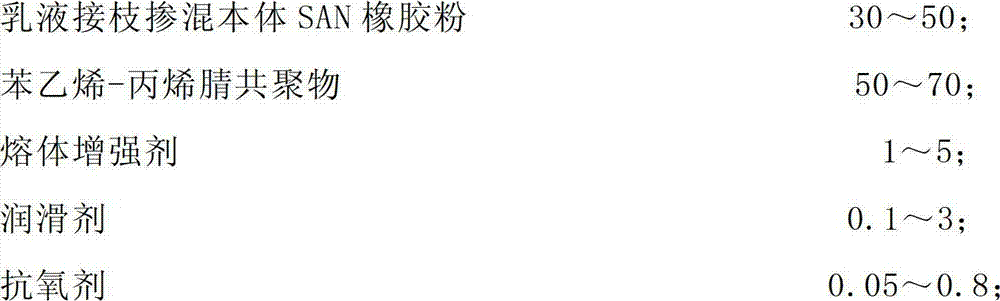

Image

Examples

Embodiment 1

[0033] Embodiment 1 Adding melt reinforcing agent to the influence of fatigue resistance of ABS resin composition

[0034] 1.1

[0035] Step 1, get following components by weight parts:

[0036] Emulsion grafting blended bulk SAN rubber powder 45

[0037] Styrene-acrylonitrile copolymer 55

[0038] Lubricant EBS 0.7

[0039] Antioxidant IG-245 0.2

[0040] Antioxidant 168 0.2.

[0041] Step 2: Add the components of Step 1 into a high-speed mixer and stir for 3 to 10 minutes, discharge the material, and then extrude and granulate in a twin-screw extruder with an aspect ratio of 36 and a diameter of 35mm, extruding The barrel temperature of the machine is 190-240° C., the screw speed is 200-600 rpm, and then cooled and granulated to obtain the ABS resin composition.

[0042] 1.2

[0043] Get following components by weight parts:

[0044] Emulsion grafting blended bulk SAN rubber powder 45

[0045] Styrene-acrylonitrile copolymer 55

[0046] Melt Enhancer 1

[0047...

Embodiment 2

[0056] Example 2 The effect of the amount of melt reinforcement added on the fatigue resistance of ABS resin compositions

[0057] The preparation method of the ABS resin composition in this embodiment is the same as that in Embodiment 1.

[0058] 2.1

[0059] Get the following components in parts by weight, then prepare the ABS resin composition:

[0060] Emulsion grafting blended bulk SAN rubber powder 45

[0061] Styrene-acrylonitrile copolymer 55

[0062] Melt Enhancer 3

[0063] Lubricant EBS 0.7

[0064] Antioxidant IG-245 0.2

[0065] Antioxidant 168 0.2.

[0066] 2.2

[0067] Get the following components in parts by weight, then prepare the ABS resin composition:

[0068] Emulsion grafting blended bulk SAN rubber powder 45

[0069] Styrene-acrylonitrile copolymer 55

[0070] Melt Enhancer 5

[0071] Lubricant EBS 0.7

[0072] Antioxidant IG-245 0.2

[0073] Antioxidant 168 0.2.

[0074] The ABS resin compositions prepared in Examples 2.1 and 2.2 wer...

Embodiment 3

[0075] Influence of AN (acrylonitrile) content on the fatigue resistance of ABS resin composition in the melt reinforcing agent of embodiment 3

[0076] The preparation method of the ABS resin composition in this embodiment is the same as that in Embodiment 1.

[0077] 3.1

[0078] Get the following components in parts by weight, then prepare the ABS resin composition:

[0079] Emulsion grafting blended bulk SAN rubber powder 45

[0080] Styrene-acrylonitrile copolymer 55

[0081] Melt enhancer (18% by weight of AN) 3

[0082] Lubricant EBS 0.7

[0083] Antioxidant IG-245 0.2

[0084] Antioxidant 168 0.2.

[0085] 3.2

[0086] Get the following components in parts by weight, then prepare the ABS resin composition:

[0087] Emulsion grafting blended bulk SAN rubber powder 45

[0088] Styrene-acrylonitrile copolymer 55

[0089] Melt enhancer (34% by weight of AN) 3

[0090] Lubricant EBS 0.7

[0091] Antioxidant IG-245 0.2

[0092] Antioxidant 168 0.2.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com