Thermal sensitive ceramic material and preparation method thereof

A technology of heat-sensitive ceramics and rare earth oxides, applied in the field of materials, can solve the problems of narrow temperature range and restricted use, and achieve the effect of wide operating temperature range, stable performance and good sensitivity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

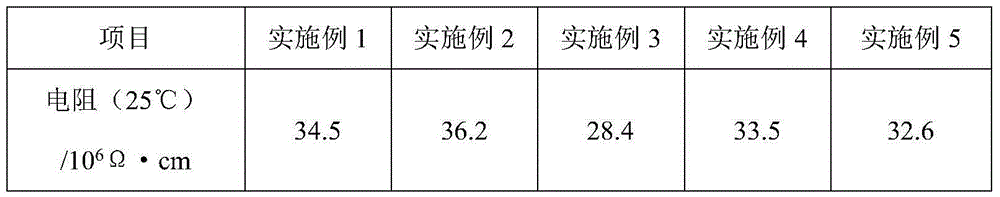

Examples

Embodiment 1

[0028] According to the preparation method of the heat-sensitive ceramic material provided by the present invention, the heat-sensitive ceramic material is prepared, and the preparation steps are as follows:

[0029] (1) Weigh Co 3 o 4 , Fe 2 o 3 、Ni 2 o 3 , SnO 2 、TiO 2 , Li 2 O and La 2 o 3 , the purity of the material is 99.99%;

[0030] The material ratio of each component is Co:Fe:Ni:Sn:Ti:Li:La is 1:1:0.3:0.01:0.02:0.01:0.1;

[0031] (2) mixing each component together for grinding and dispersing;

[0032] (3) put the above mixture into a ball mill and carry out ball milling, and dry after mixing;

[0033] (4) After ball milling, put the mixture into a mold and perform high-temperature calcination at a temperature of 1250° C., a pressure of 4 GPa, and a time of 3 hours;

[0034] (5) After the calcination is finished, cool to room temperature with the furnace, and take it out;

[0035] (6) After performing a slicing process on the block material, the electrod...

Embodiment 2

[0037] (1) Weigh Co 3 o 4 , Fe 2 o 3 、Ni 2 o 3 , SnO 2 、TiO 2 , Li 2 O and La 2 o 3 , the purity of the material is 99.99%;

[0038] The material ratio of each component is Co:Fe:Ni:Sn:Ti:Li:rare earth is 1:3:0.7:0.05:0.05:0.03:0.3;

[0039] (2) mixing each component together for grinding and dispersing;

[0040] (3) put the above mixture into a ball mill and carry out ball milling, and dry after mixing;

[0041] (4) After ball milling, put the mixture into a mold and perform high-temperature calcination at a temperature of 1350° C., a pressure of 4 GPa, and a time of 4 hours;

[0042] (5) After the calcination is finished, cool to room temperature with the furnace, and take it out;

[0043] (6) After performing a slicing process on the block material, the electrode material is coated to obtain a heat-sensitive ceramic material.

Embodiment 3

[0045] (1) Weigh Co 3 o 4 , Fe 2 o 3 、Ni 2 o3 , SnO 2 、TiO 2 , Li 2 O, Nd 2 o 3 and Y 2 o 3 , the purity of the material is 99.99%;

[0046] The material ratio of each component is Co:Fe:Ni:Sn:Ti:Li:rare earth is 1:2:0.5:0.03:0.04:0.02:0.28;

[0047] Wherein the material ratio of Nd and Y is 0.4:1;

[0048] (2) mixing each component together for grinding and dispersing;

[0049] (3) put the above mixture into a ball mill and carry out ball milling, and dry after mixing;

[0050] (4) After ball milling, put the mixture into a mold and perform high-temperature calcination at a temperature of 1450° C., a pressure of 6 GPa, and a time of 2 hours;

[0051] (5) After the calcination is finished, cool to room temperature with the furnace, and take it out;

[0052] (6) After performing a slicing process on the block material, the electrode material is coated to obtain a heat-sensitive ceramic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com