A kind of argon arc surfacing welding FECRC iron-based powder alloy and its preparation process

A technology of iron-based powder and preparation process, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low degree of automation in electroplating process repair, difficult repair of damaged parts of shape, high equipment and maintenance costs, etc., and achieve improvement Hardness, reduce economic loss, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

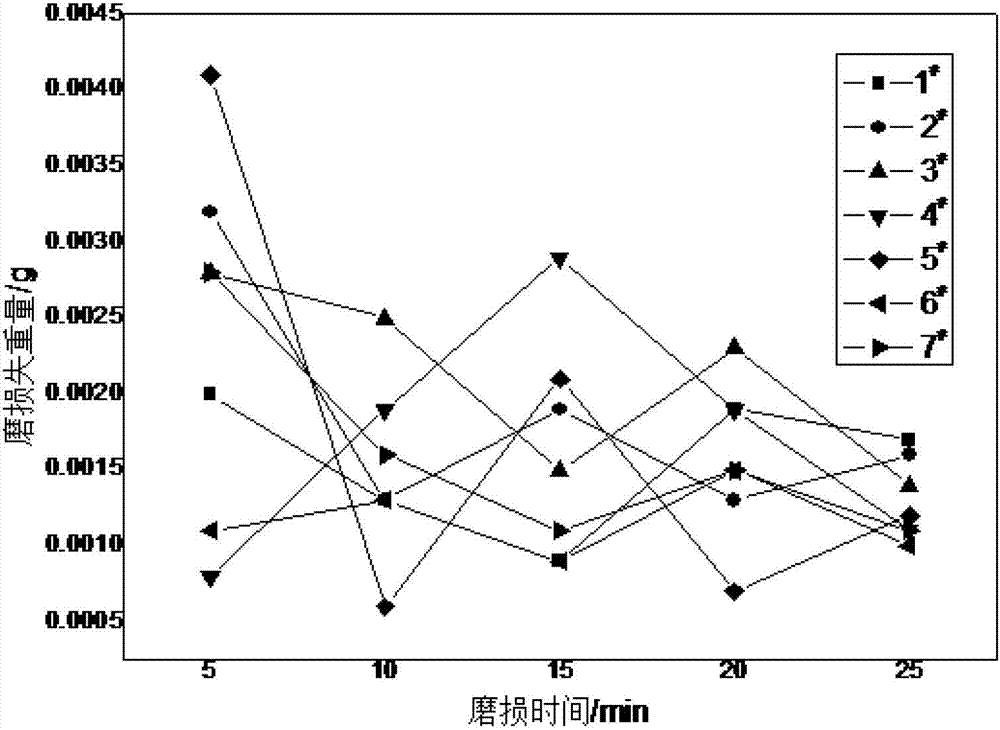

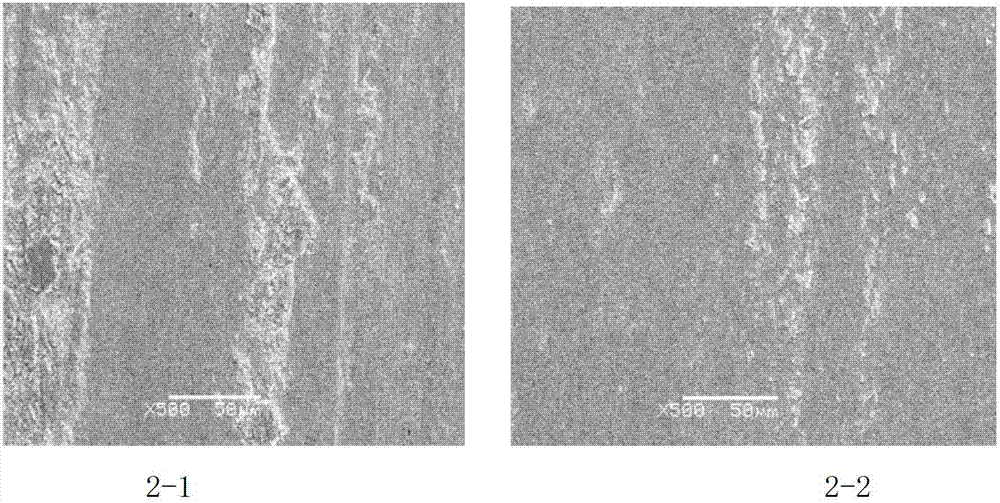

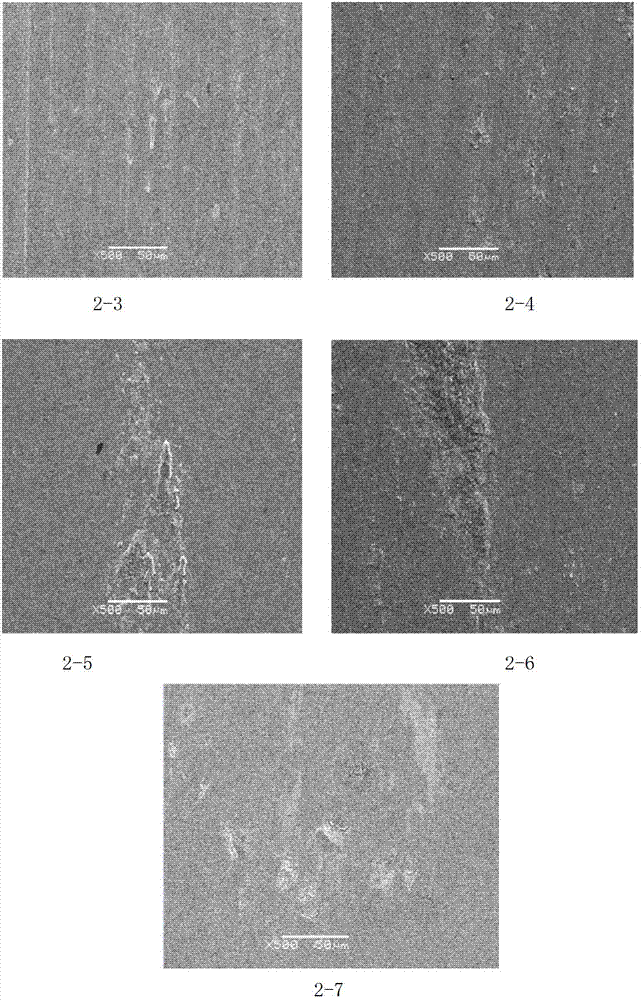

[0031] Example 1: Surfacing base material Q235, specification 200×50×10mm, argon arc surfacing welding cladding layer width 150×30×5mm.

[0032] Argon arc surfacing welding ferrochrome, graphite, reduced iron powder raw material powder particle size is 60 ~ 200 mesh ratio as follows: ferrochrome 46.125%, graphite 5%, reduced iron powder 48.875%. The iron-based powder was mixed evenly in a ball mill, stirred with a water glass binder, pressed into a 50×10×(1.2, 1.3, 1.5mm) sheet in a mold, and dried naturally for 10 hours. Place it in a drying box and heat it to 200°C, keep it warm for 1.5 hours, then cool it to 50°C with the furnace and take it out of the oven to cool. Use an angle grinder to clean the surface oil and rust of the surfacing base metal, and place a 1.2mm thin slice at the surfacing position. Argon arc surfacing process parameters are: current 120A, voltage 15V, argon gas flow rate 6L / min, welding speed 60mm / min. Surfacing arc ignition is a high-frequency argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com