A ternary blend alloy material with balanced rigidity and toughness and preparation method thereof

A gold material and toughness technology, applied in the field of ternary blended gold materials and their preparation, can solve the problems of low notched impact strength and flexural modulus of POK materials, achieve easy control of technology, increase toughness, high strength and modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

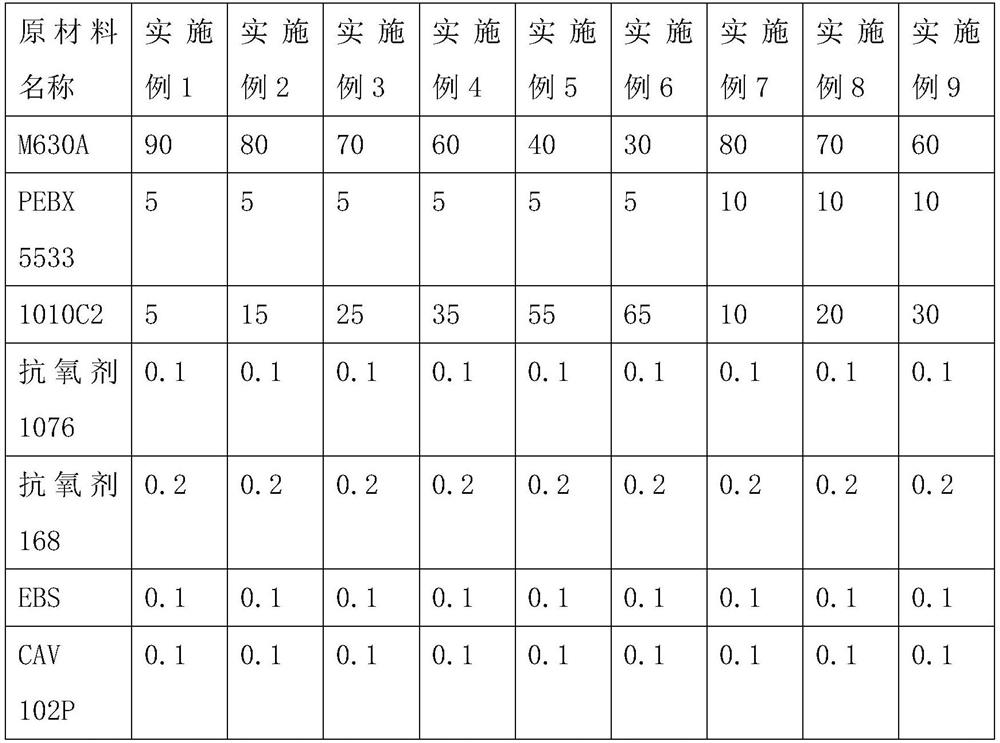

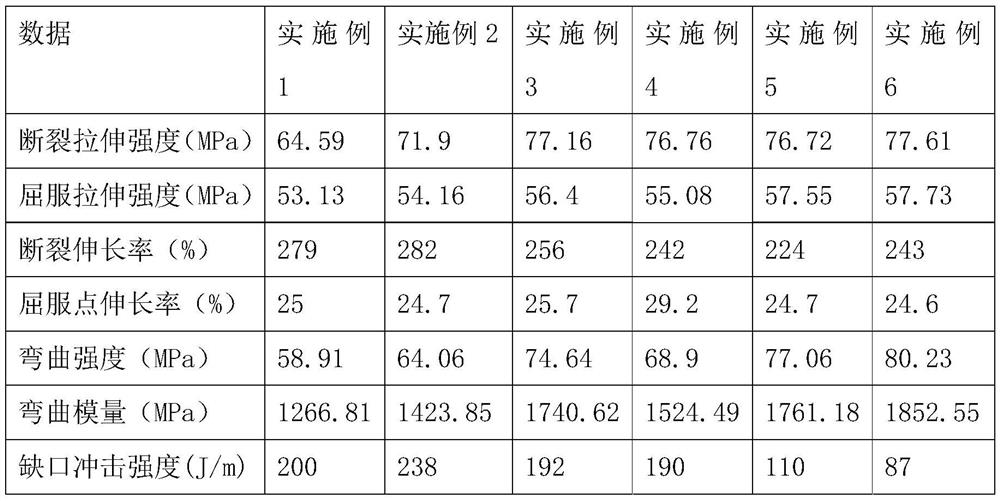

Embodiment 1

[0039] Bake 90 parts by weight of polyketone POK (M630A, Hyosung Korea) at 100-110°C for 4-6 hours, and 5 parts by weight of nylon elastomer (PEBAX 5533, Arkema) at 90-100°C for 4- After 6 hours, 5 parts by weight of nylon 6 (1010C2, DSM) was baked at 100-110°C for 4-6 hours, mixed with 0.1 parts by weight of primary antioxidant 1076, 0.2 parts by weight of auxiliary antioxidant 168, and 0.1 parts by weight Parts of lubricant EBS (ethylene bis stearamide), 0.1 parts by weight of nucleating agent CAV102P of Clariant, Germany. Add it to a high-speed mixer and mix evenly. The mixing temperature does not exceed 90°C and the mixing time is less than 30 minutes. Put the uniformly mixed material into the co-rotating twin-screw extruder, melt and extrude, the extrusion temperature is 230-260°C, the screw speed is 300-500r / min, the vacuum degree is -0.04MPa~-0.1MPa; Cool in a sink and chop into pieces. The prepared raw material is a ternary blend alloy material with balanced rigidity...

Embodiment 2

[0042] Bake 80 parts by weight of polyketone POK (M630A, Hyosung Korea) at 100-110°C for 4-6 hours, and 5 parts by weight of nylon elastomer (PEBAX 5533, Arkema) at 90-100°C for 4- After 6 hours, 15 parts by weight of nylon 6 (1010C2, DSM) was baked at 100-110°C for 4-6 hours, mixed with 0.1 parts by weight of primary antioxidant 1076, 0.2 parts by weight of auxiliary antioxidant 168, and 0.1 parts by weight The lubricant EBS (ethylene bis stearamide) of part, the nucleating agent CAV 102P of German Clariant company of 0.1 weight part. . Add it to a high-speed mixer and mix evenly. The mixing temperature does not exceed 90°C and the mixing time is less than 30 minutes. Put the uniformly mixed material into the co-rotating twin-screw extruder, melt and extrude, the extrusion temperature is 230-260°C, the screw speed is 300-500r / min, the vacuum degree is -0.04MPa~-0.1MPa; Cool in a sink and chop into pieces. The prepared raw material is a ternary blend alloy material with bal...

Embodiment 3

[0044] Bake 70 parts by weight of polyketone POK (M630A, Hyosung Korea) at 100-110°C for 4-6 hours, and 5 parts by weight of nylon elastomer (PEBAX 5533, Arkema) at 90-100°C for 4- After 6 hours, 25 parts by weight of nylon 6 (1010C2, DSM) was baked at 100-110°C for 4-6 hours, mixed with 0.1 parts by weight of primary antioxidant 1076, 0.2 parts by weight of auxiliary antioxidant 168, and 0.1 parts by weight The lubricant EBS (ethylene bis stearamide) of part, the nucleating agent CAV 102P of German Clariant company of 0.1 weight part. Add it to a high-speed mixer and mix evenly. The mixing temperature does not exceed 90°C and the mixing time is less than 30 minutes. Put the uniformly mixed material into the co-rotating twin-screw extruder, melt and extrude, the extrusion temperature is 230-260°C, the screw speed is 300-500r / min, the vacuum degree is -0.04MPa~-0.1MPa; Cool in a sink and chop into pieces. The prepared raw material is a ternary blend alloy material with balanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com