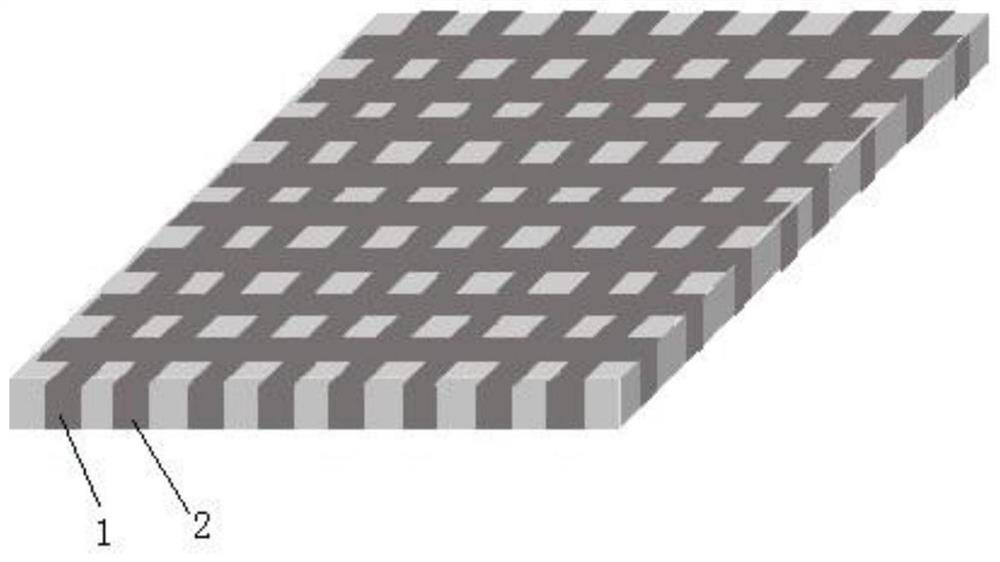

Preparation method of high-strength and high-toughness metal material with shell-like brick mud structure

A technology of imitating shell and tough metal is applied in the field of preparation of high-strength and tough metal materials, which can solve the problems of no shell structure theory and technical research, and achieve the effects of easy promotion, increased toughness, and comprehensive performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

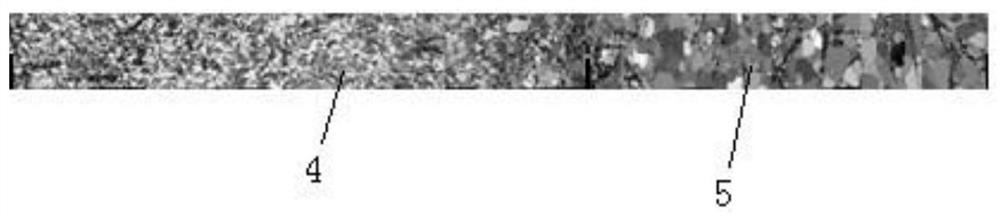

[0038] A method for preparing a high-strength and tough metal material with a shell-like brick-mud structure, the specific steps are:

[0039] 1) Select the AZ31 magnesium alloy whose length, width, and thickness are 100mm, 100mm, and 2.5mm, and perform annealing treatment first. The annealing temperature is 350°C, and the annealing time is 4h. After the annealing is completed, clean the surface of the plate with acetone and alcohol to remove oil stains , and then clean the surface of the plate with deionized water;

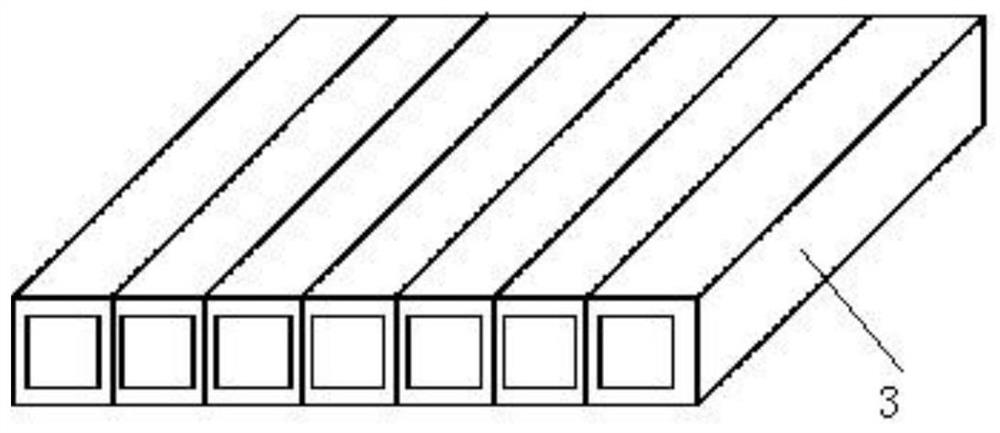

[0040] 2) Put the AZ31 magnesium alloy plate on the workbench, start the alternating cooling and heating system 3, the cooling pipe is below the welding seam, and the two sides adjacent to the cooling pipe are heating pipes, the width of the cooling pipe is 5mm, and the width of the heating pipe is 5mm. 3.5mm, the liquid nitrogen flow rate is 30mL / s, the heating temperature is 200°C and the pre-tightening force is applied to lock;

[0041] 3) The size of the sti...

Embodiment 2

[0051] A method for preparing a high-strength and tough metal material with a shell-like brick-mud structure, the specific steps are:

[0052] 1) Select the AZ91 magnesium alloy whose length, width, and thickness are 100mm, 100mm, and 4mm, respectively, and anneal the plate first. The annealing temperature is 350°C, and the annealing time is 5h. Clean the surface of the plate with deionized water;

[0053] 2) Place the AZ91 magnesium alloy plate on the workbench, and start the alternate cooling and heating system 3. It is expected that the cooling pipe is below the welding seam, and the two sides adjacent to the cooling pipe are heating pipes. The width of the cooling pipe is 6mm, and the heating pipe The width is 4mm, the liquid nitrogen flow rate is 30mL / s, the heating temperature is 200°C, and the pre-tightening force is applied to lock;

[0054] 3) The size of the stirring head for friction stir welding is: the diameter of the shaft shoulder is 16mm, the diameter of the t...

Embodiment 3

[0062] A method for preparing a high-strength and tough metal material with a shell-like brick-mud structure, the specific steps are:

[0063] 1) Select the AZ31 magnesium alloy whose length, width and thickness are 80mm, 80mm and 2.5mm, respectively, and anneal the plate first. The annealing temperature is 400°C, and the annealing time is 4h. After the annealing is completed, clean it with acetone and alcohol to remove oil stains. Then use deionized water to clean the surface of the plate;

[0064] 2) Place the AZ31 magnesium alloy plate on the workbench and start the alternating cooling and heating system 3. It is estimated that the cooling pipe is below the welding seam, and the two sides adjacent to the cooling pipe are heating pipes. The width of the cooling pipe is 4mm, and the heating pipe The width is 4mm, the liquid nitrogen flow rate is 30mL / s, the heating temperature is 200°C, and the pre-tightening force is applied to lock;

[0065] 3) The size of the stirring hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com