Powder metallurgy helical gear and manufacturing process thereof

A technology of powder metallurgy and helical gears, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of low efficiency, long cycle and high cost of gear production process, and achieve long service life, The effect of energy saving in production and improvement of friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The gear provided in this embodiment has a torque of not less than 120N / M when the engine speed is 3600 rpm and the interference fit is ≥0.06mm, which can meet the transmission requirements of the engine gear, and has low wear and long service life. .

[0046] Embodiment two

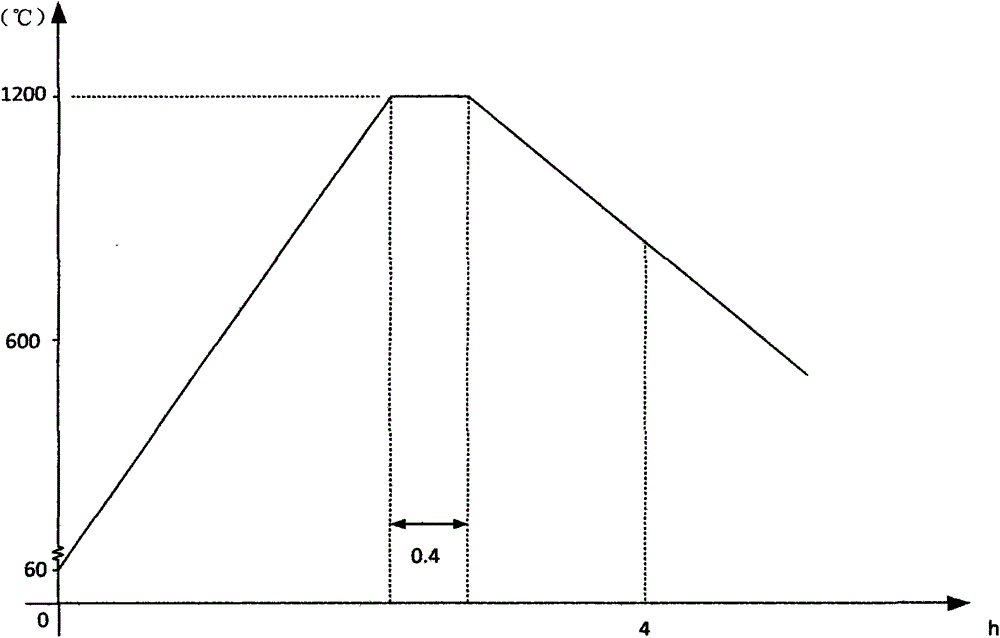

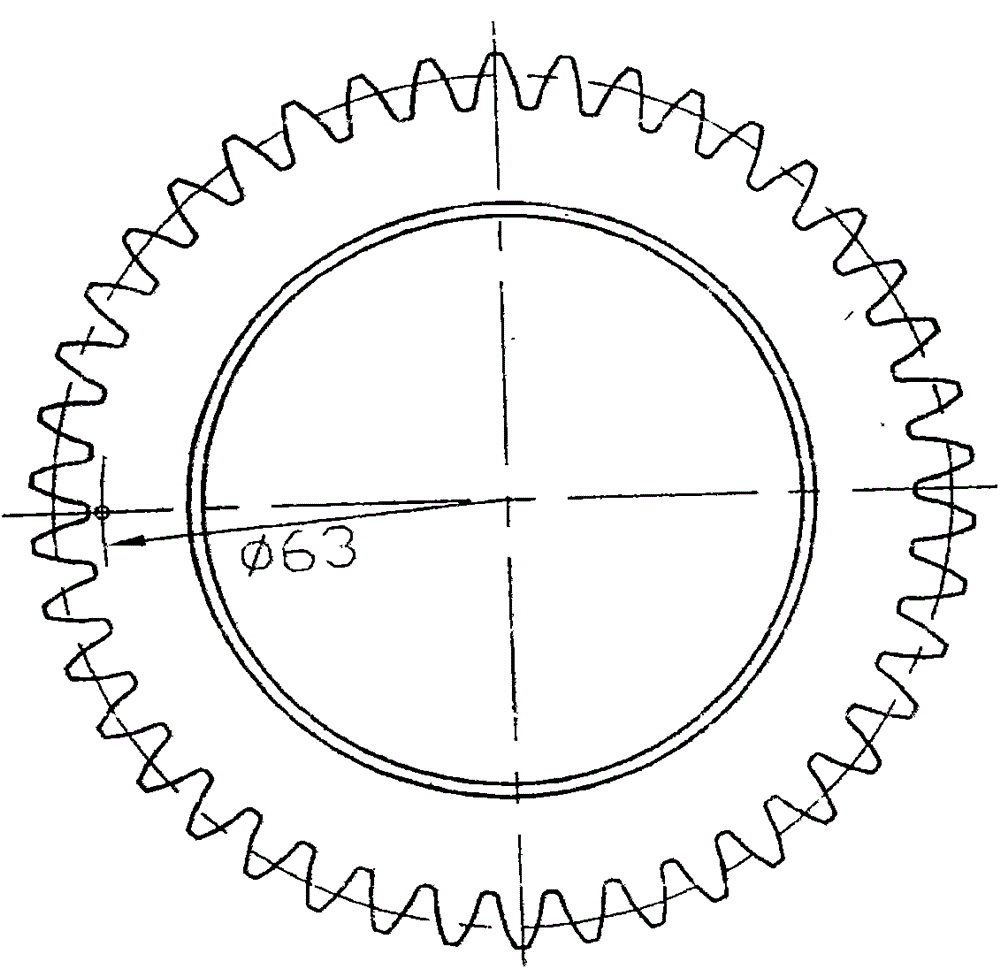

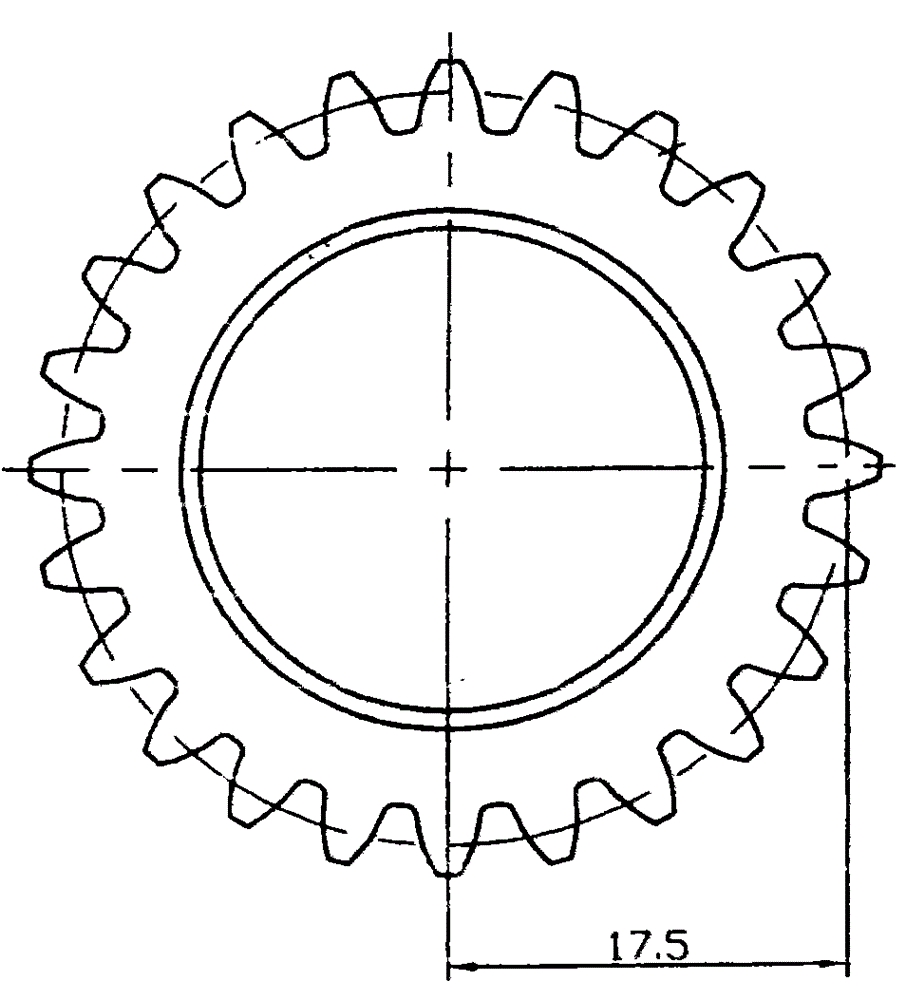

[0047] Take 606 kg of iron powder, 18 kg of copper powder, 32 kg of nickel powder, 6 kg of graphite, and 5 kg of lubricant, wherein the particle sizes of the above-mentioned powder raw materials are respectively 80 meshes of iron powder, 340 meshes of copper powder, and 300 meshes of nickel powder , 500 meshes of graphite, in addition, the purity of each of the above powder raw materials is above 98%. The gear powder raw material measured according to the above ratio is put into the mixer and mixed for 15 minutes to 45 minutes, and then the mixed raw material is put into the powder molding machine for pressing to obtain an integrally formed gear blank, and then the gear blank is taken out, And p...

Embodiment 2

[0049] The gear provided in this embodiment has a torque of not less than 120 N / M when the engine speed is 3600 rpm and maintains an interference fit of ≥0.06 mm, which can meet the transmission requirements of the engine gear, and has low wear and long service life.

[0050] Embodiment Three

[0051]Take 777 kg of iron powder, 22 kg of copper powder, 24 kg of nickel powder, 5 kg of graphite, and 6 kg of lubricant, wherein the particle sizes of the above-mentioned powder raw materials are respectively 100 meshes of iron powder, 300 meshes of copper powder, and 500 meshes of nickel powder , graphite 300 mesh, in addition, the purity of each of the above-mentioned powder raw materials is above 98%. The gear powder raw material measured according to the above ratio is put into the mixer and mixed for 15 minutes to 45 minutes, and then the mixed raw material is put into the powder molding machine for pressing to obtain an integrally formed gear blank, and then the gear blank is ta...

Embodiment 3

[0053] The gear provided in this embodiment has a torque of not less than 120N / M when the engine speed is 3600 rpm and an interference fit of ≥0.06mm is maintained, and its high-temperature performance is stable, wear is low, and its service life is long, which can meet the requirements of engine gears. transmission requirements.

[0054] Embodiment four

[0055] Take 238 kilograms of iron powder, 4 kilograms of copper powder, 4 kilograms of nickel powder, 2 kilograms of graphite, and 2 kilograms of lubricant, wherein the particle sizes of the above-mentioned powder raw materials are respectively 100 meshes of iron powder, 320 meshes of copper powder, and 400 meshes of nickel powder , graphite 400 mesh, in addition, the purity of each of the above-mentioned powder raw materials is above 98%. The gear powder raw material measured according to the above ratio is put into the mixer and mixed for 15 minutes to 45 minutes, and then the mixed raw material is put into the powder mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com