Patents

Literature

61results about How to "Energy saving and environmental protection in the preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

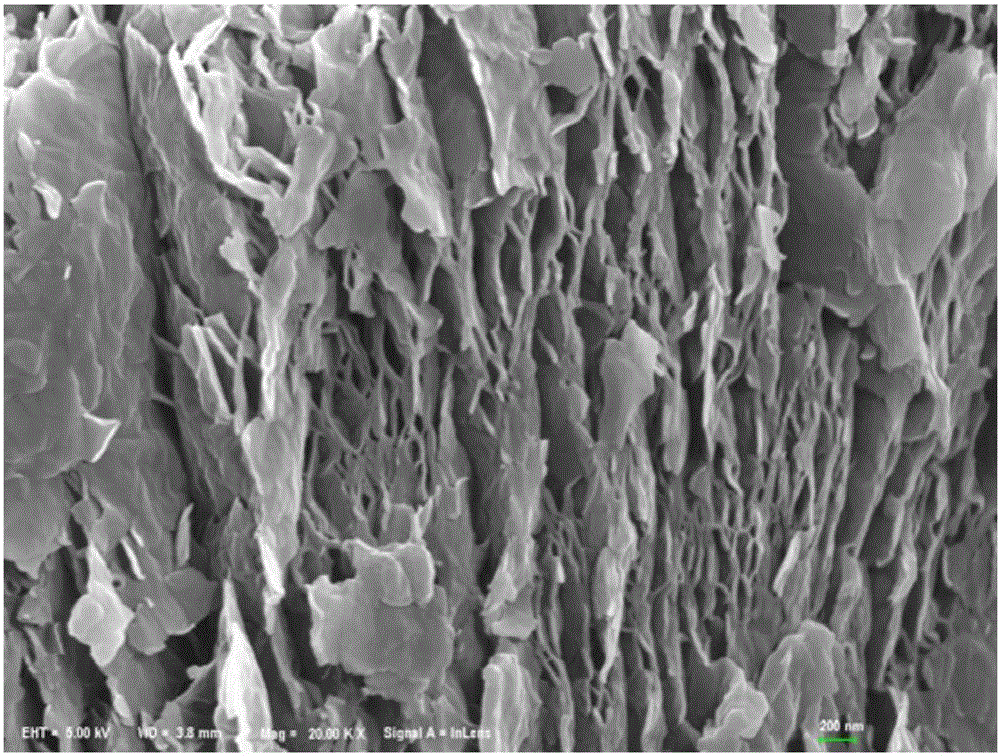

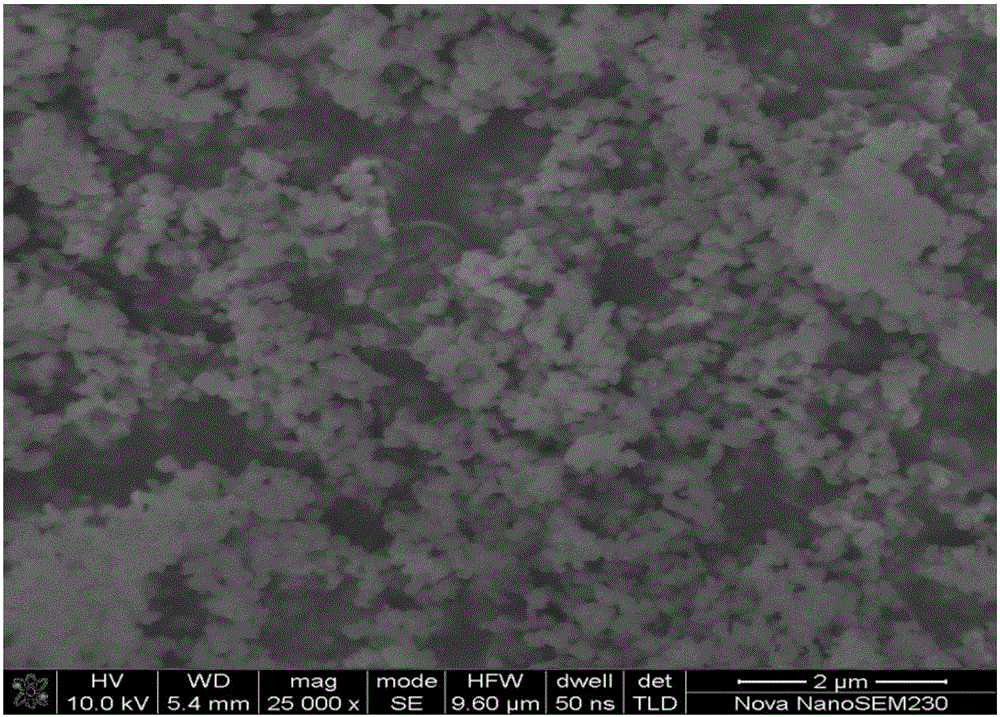

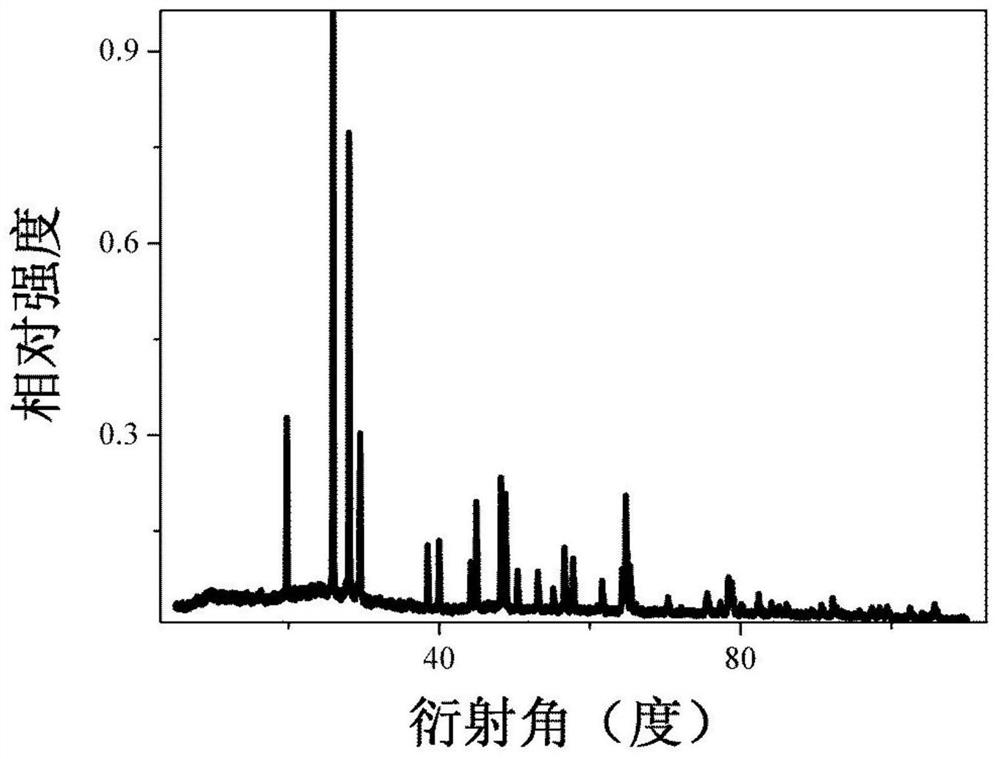

Composite positive electrode material for sodium-ion battery and preparation method of composite positive electrode material

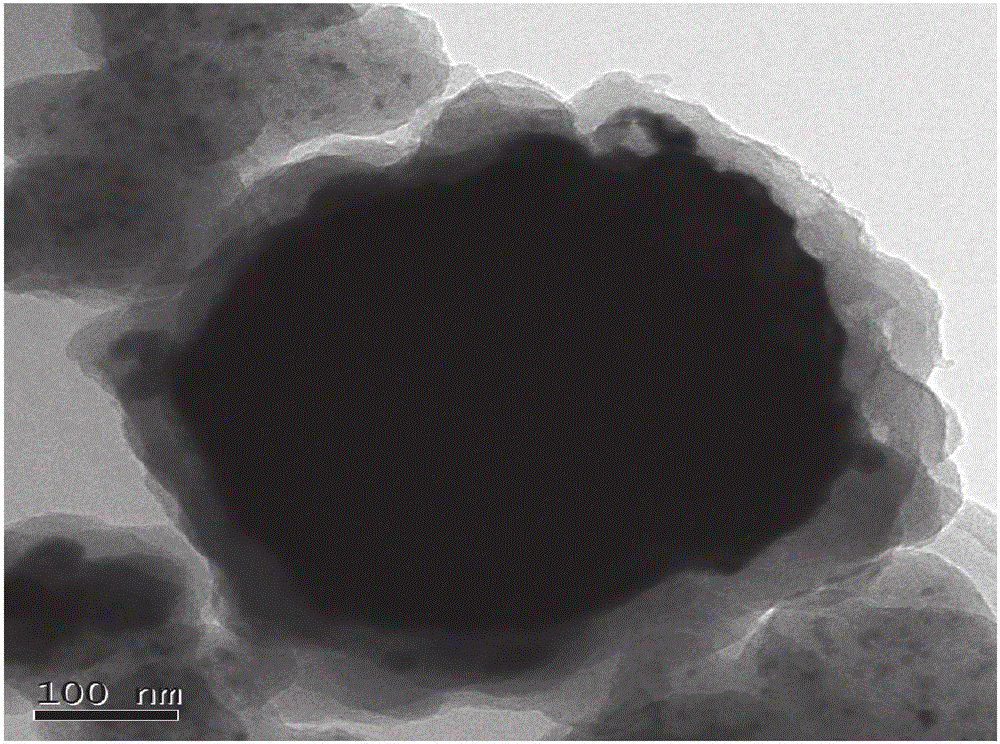

ActiveCN105938904AImproved high-magnification cycle performanceEvenly distributedCell electrodesSecondary cellsSynthesis methodsNanoparticle

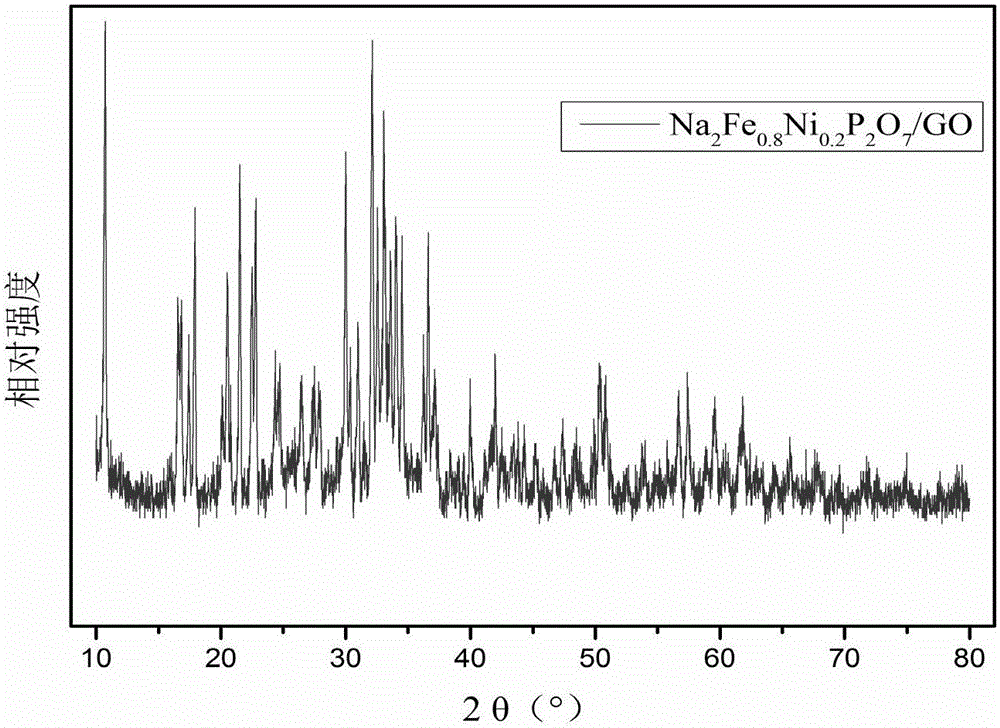

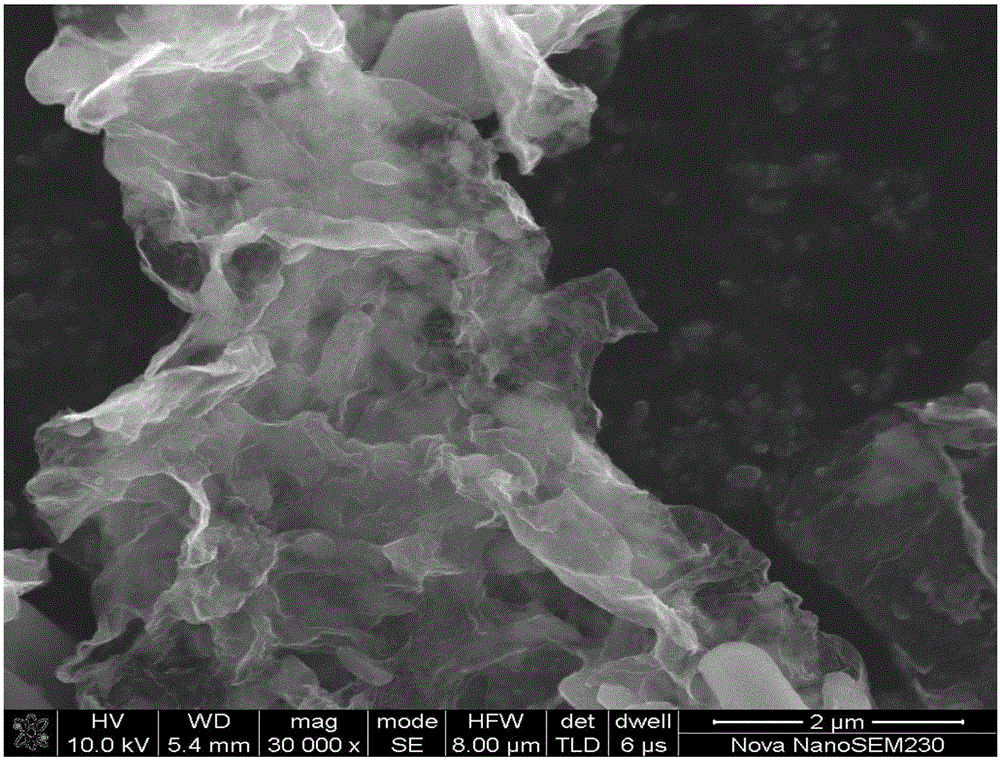

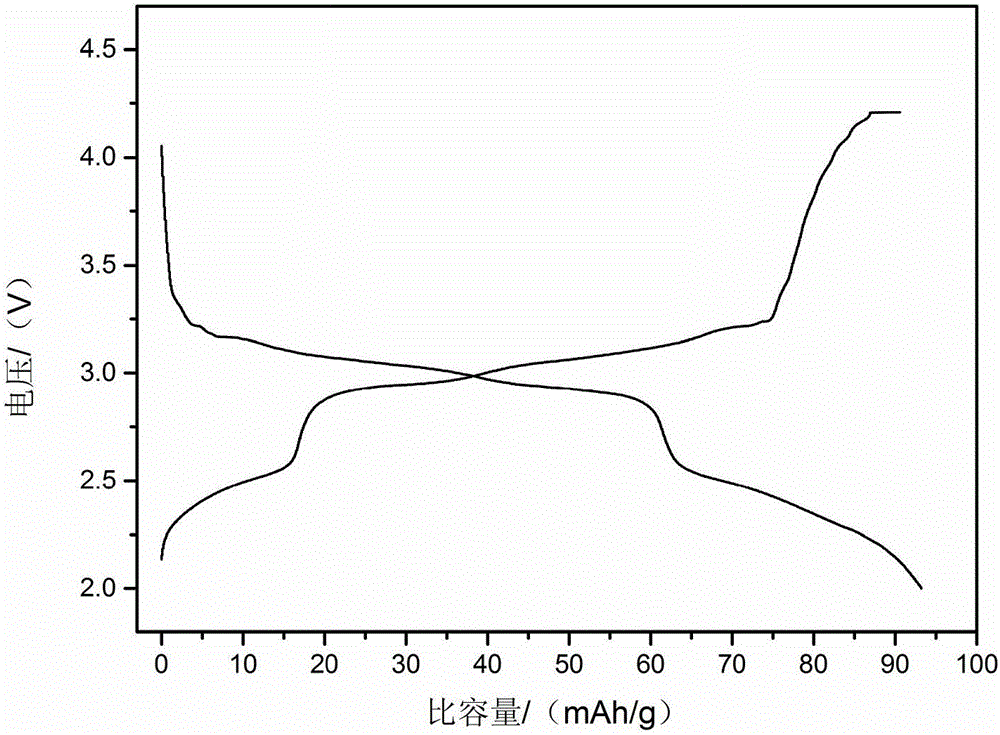

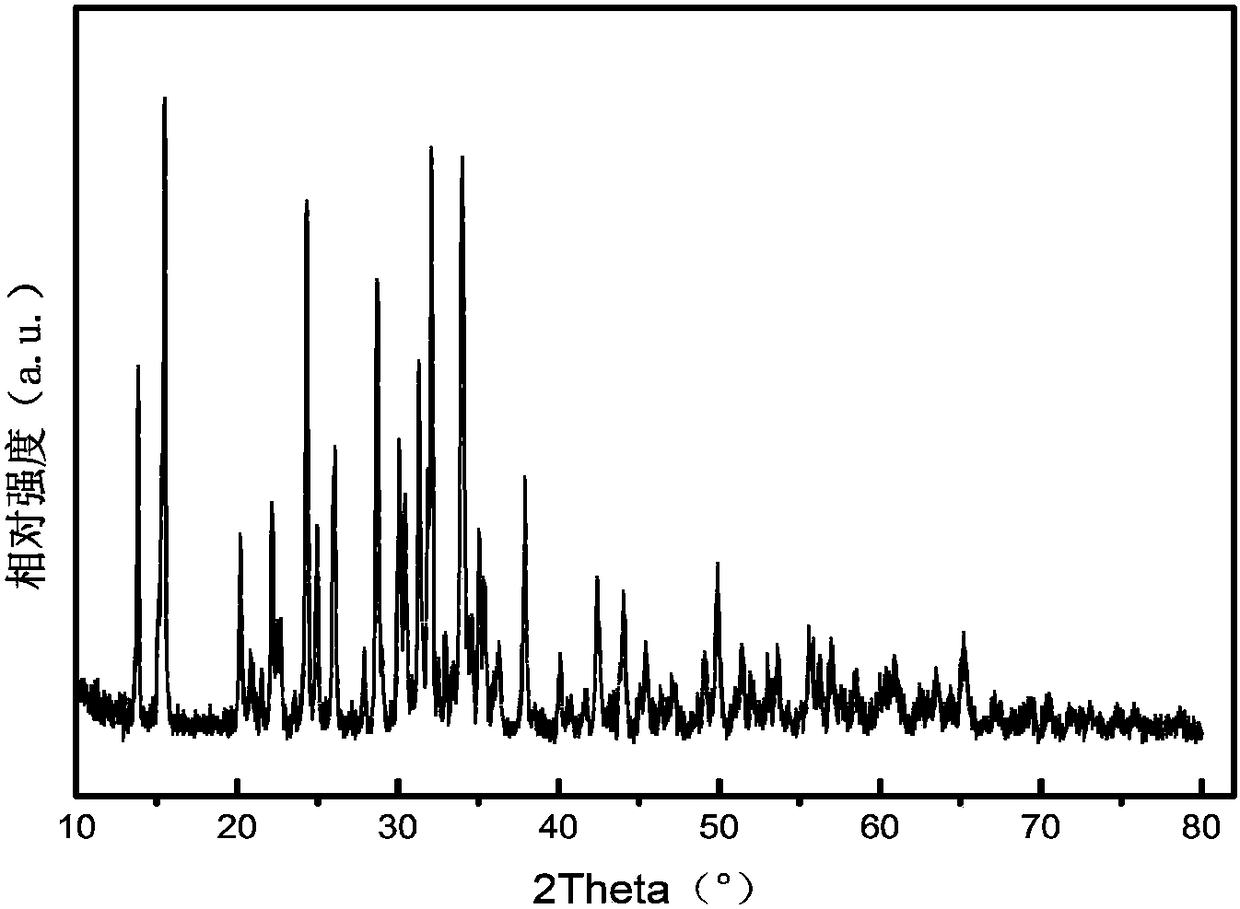

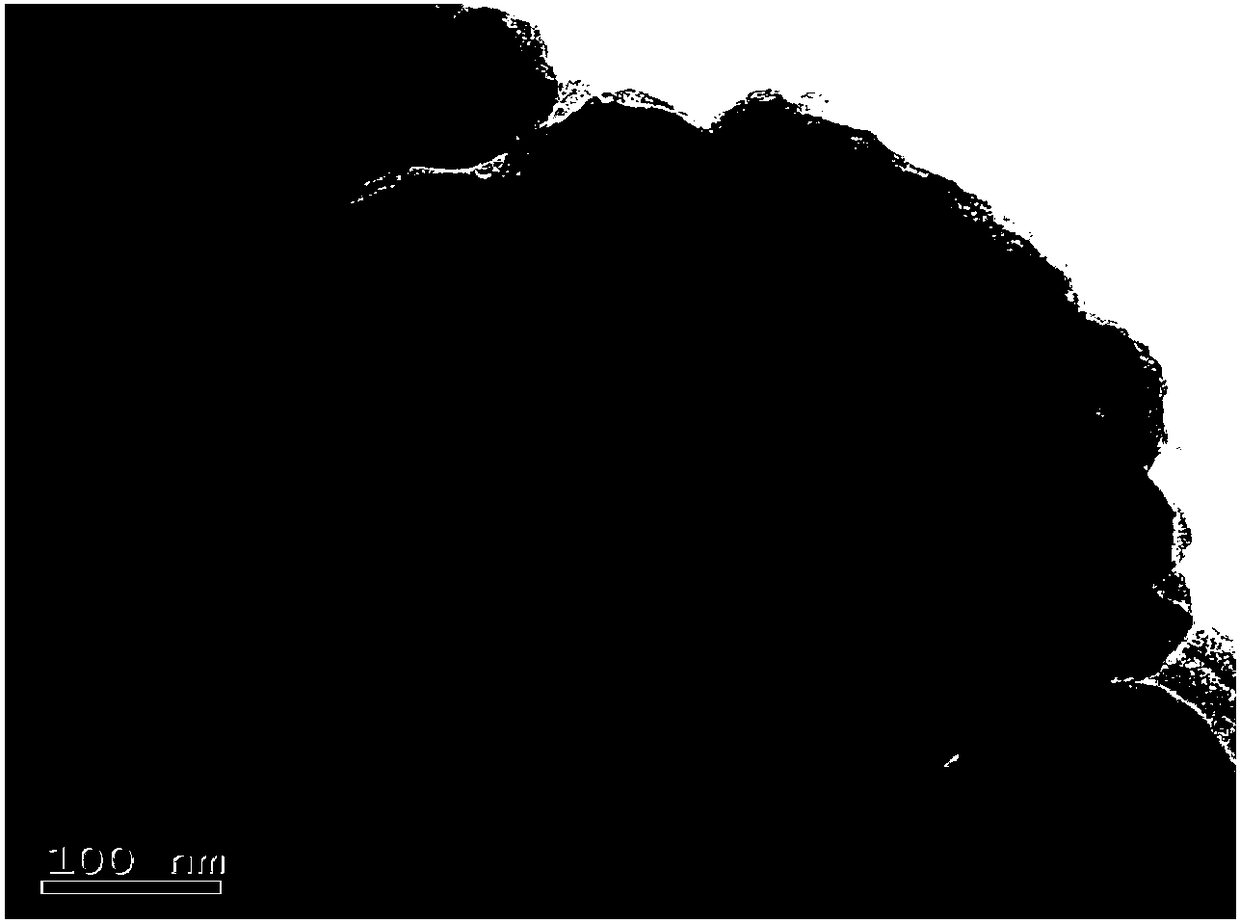

The invention discloses a composite positive electrode material for a sodium-ion battery and a preparation method of the composite positive electrode material. An Na<2>Fe<1-x>Ni<x>P<2>O<7> precursor grows in a graphene oxide (GO) solution by a coprecipitation method in situ; and graphene oxide is reduced when Na<2>Fe<1-x>Ni<x>P<2>O<7> nanoparticles are obtained in a calcining manner, thereby obtaining a vegetable sponge-shaped Na<2>Fe<1-x>Ni<x>P<2>O<7> / reduced graphene oxide nanocomposite material. The synthesis method is simple; the conditions are mild; and the yield is high. In the prepared composite material, active materials are dispersed uniformly; and the composite positive electrode material has high specific capacity, high working voltage, good cycling stability and excellent rate capability when used as a sodium-ion positive electrode material.

Owner:CENT SOUTH UNIV

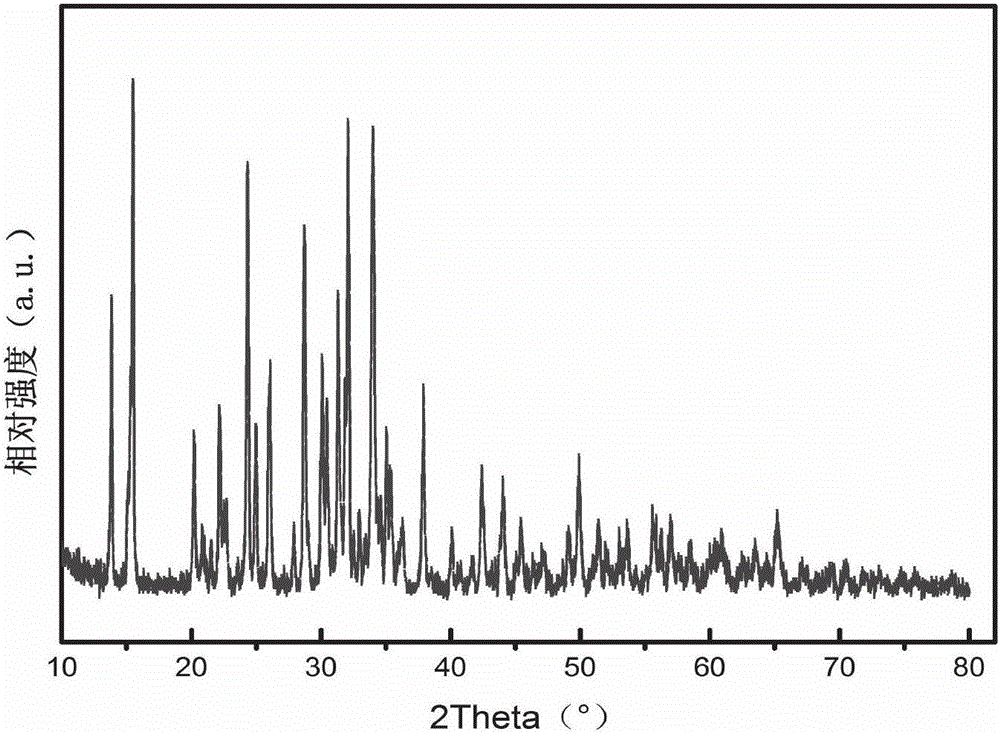

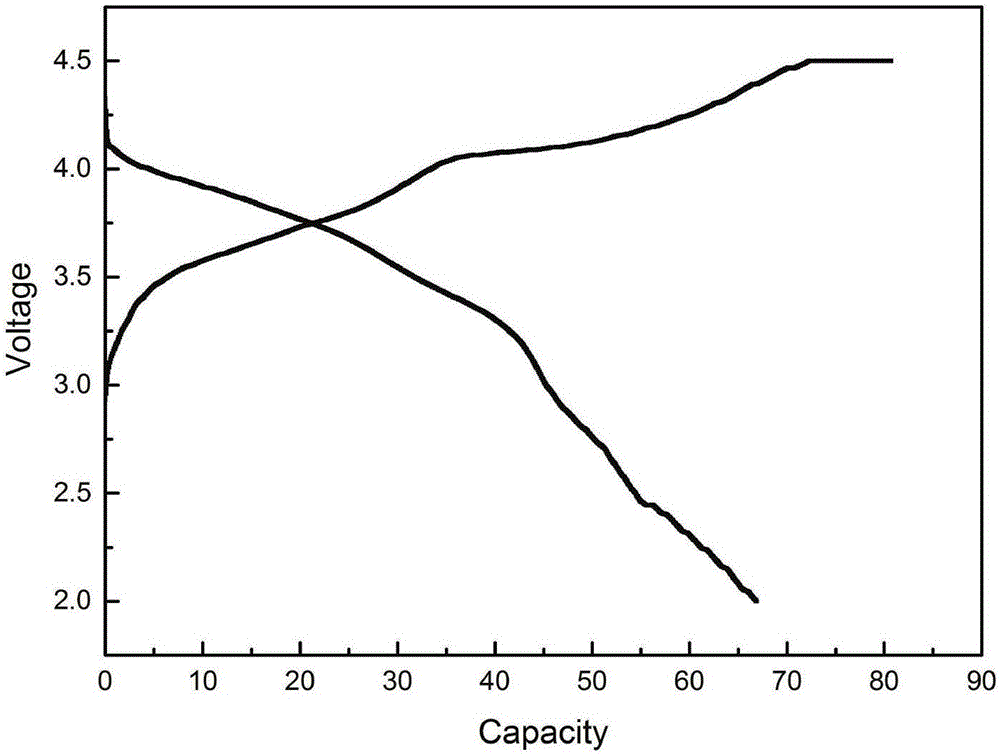

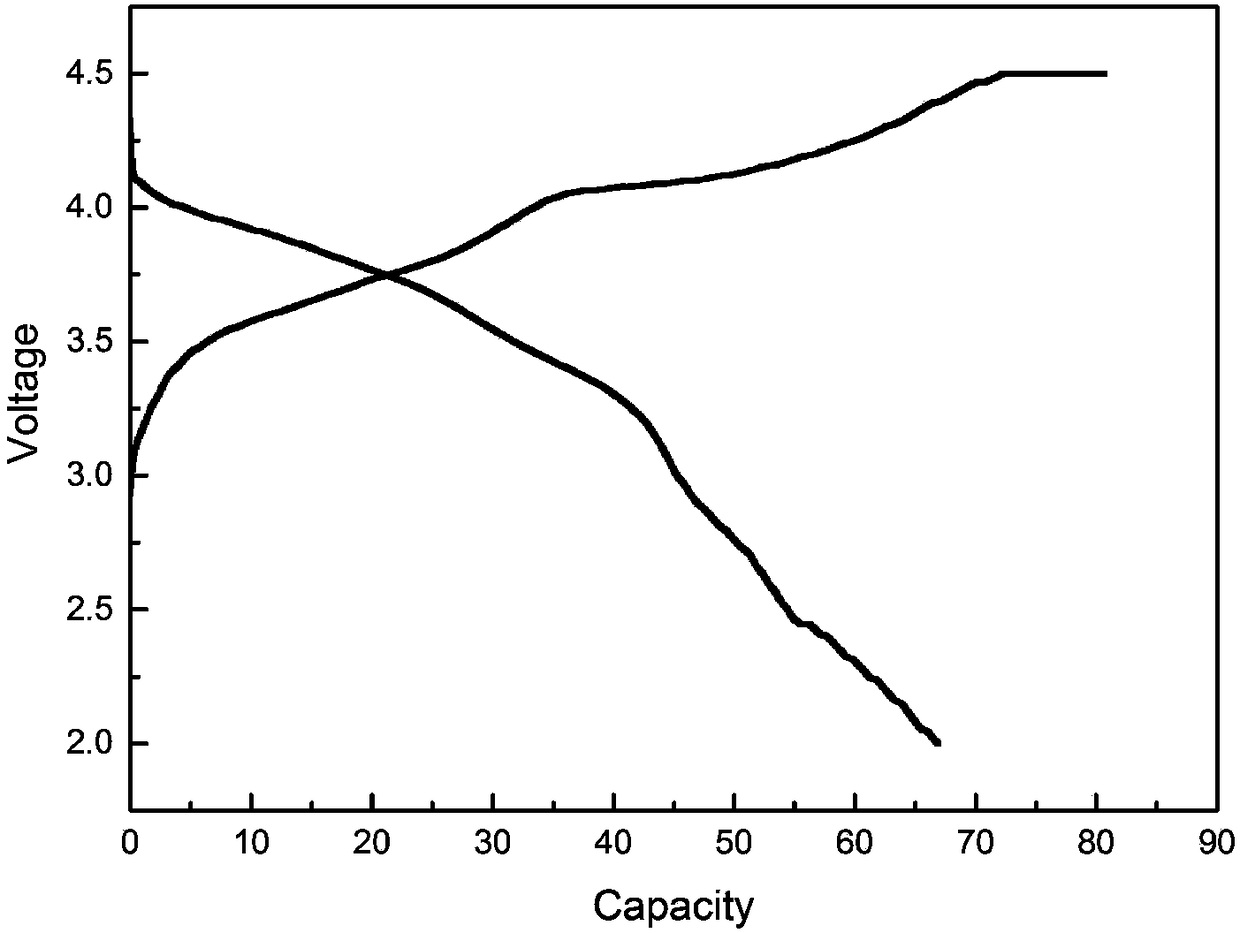

Sodium ion battery positive electrode Na2Fe2(SO4)3@alumina composite material and preparation method thereof

ActiveCN106058251AInhibition of surface poisoning effectsHigh specific capacityCell electrodesSecondary cellsSynthesis methodsAlumina composite

The invention discloses a Na2Fe2(SO4)3@alumina composite material having a core-shell structure and a preparation method and an application thereof. The material is a composite material having the core-shell structure and prepared by coating the surface of Na2Fe2(SO4)3 particles with alumina. The Na2Fe2(SO4)3 is pyrolytically coated with an organic aluminum salt, the problems that Na2Fe2(SO4)3 is dissolved in water and is difficultly coated by alumina via a traditional hydrolysis method are overcome, the synthesis method is simple, conditions are mild, and the yield is high; the prepared composite material can effectively suppress a 'surface poisoning effect' of the material, and has the advantages of high specific capacity, high work voltage, good cyclic stability and excellent rate performance when applied as a sodium ion battery positive electrode material.

Owner:CENT SOUTH UNIV

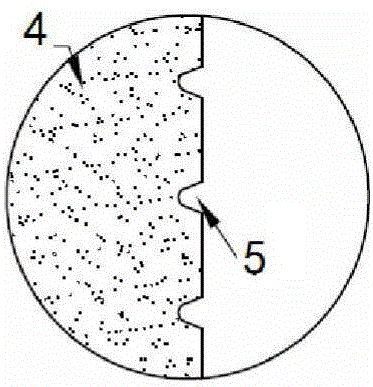

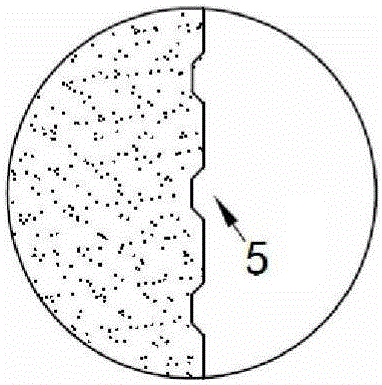

Porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and preparation method thereof

InactiveCN102515828AEmission reduction benefits are obviousImprove absorbencySolid waste managementCeramicwareMineralogyMining engineering

The invention relates to a porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and a preparation method of the porous heat-insulation material. The porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings is characterized by being prepared from the following components in percentage by weight: 30-60% of iron tailing powder, 20-50% of iron ore surrounding rock powder, 0.5-10% of foaming agent, 0-1% of cosolvent and 0.1-9% of foam stabilizer by uniformly mixing, then adding water, mixing and pulping, carrying out microwave calcining and cooling. The preparation method of the porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings has high utilization rates of iron ore surrounding rock and iron tailings; and the prepared porous heat-insulation material has low density and excellent heat-insulation performance.

Owner:WUHAN UNIV OF TECH

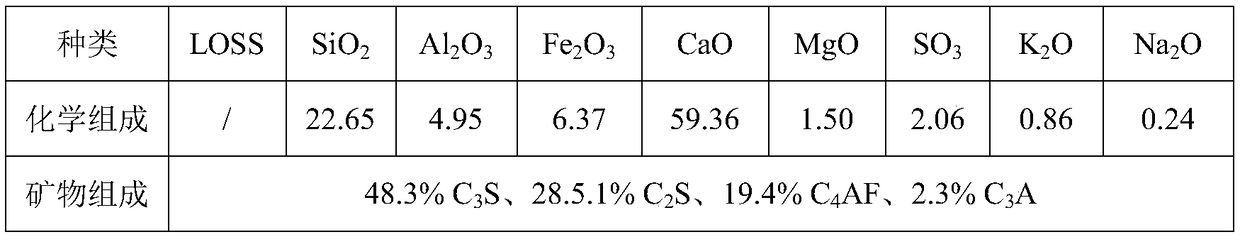

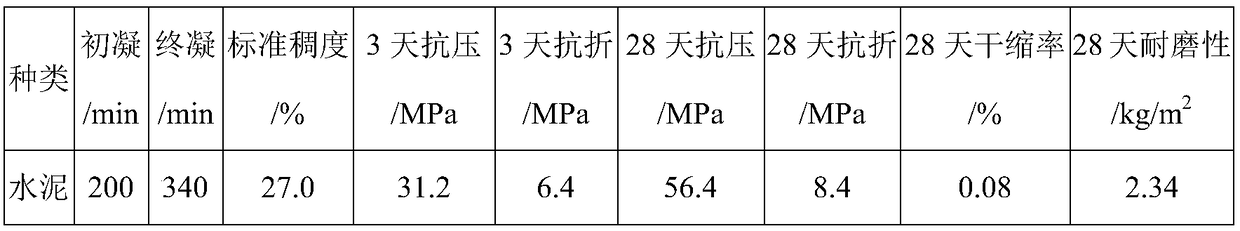

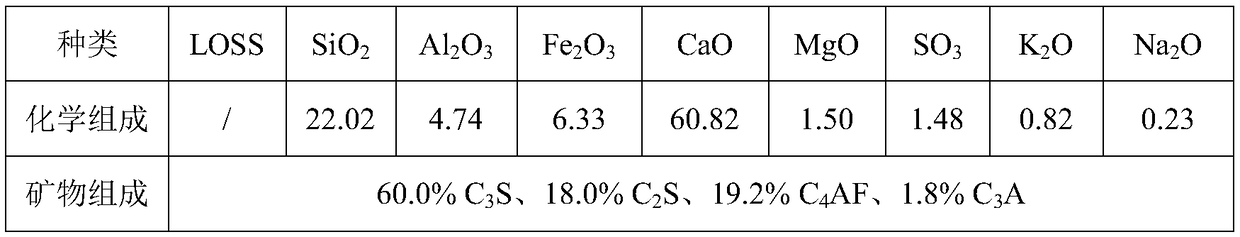

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

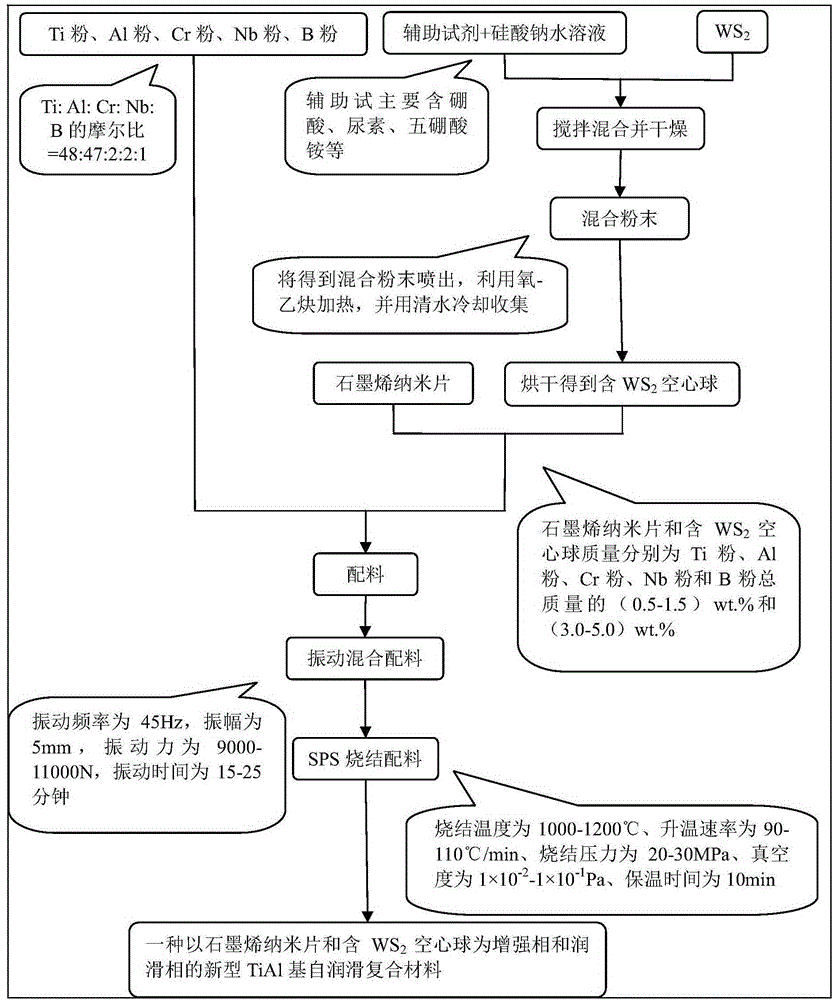

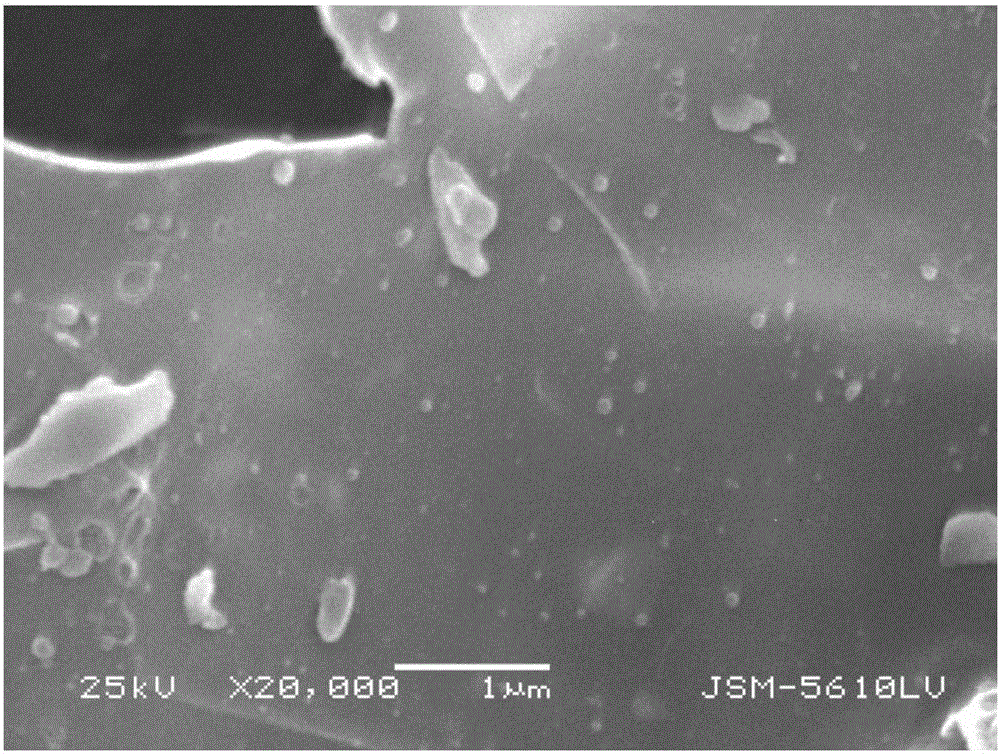

Novel TiAl base self-lubricating composite and preparing method

InactiveCN105861876AImprove mechanical propertiesGood wear reductionGraphene nanoplateletMechanical property

The invention relates to a novel TiAl base self-lubricating composite. The novel TiAl base self-lubricating composite is characterized in that a TiAl base serves as a matrix, and graphene nanosheets and hollow spheres containing WS2 serve as an enhancing phase and a lubricating phase. The graphene nanosheets account for 0.5-1.5 wt.% of the matrix by mass, and hollow spheres containing WS2 account for 3.0-5.0 wt.% of the matrix by mass. A preparing method of the novel TiAl base self-lubricating composite comprises the following steps that elementary substance powder is weighed according to the mole ratio of elements contained in the TiAl base to serve as matrix materials, the graphene nanosheets and the hollow spheres containing WS2 are weighed according to the proportion, the materials are evenly mixed and then subjected to spark plasma sintering, and the novel TiAl base self-lubricating composite is obtained. With the graphene nanosheets and the hollow spheres containing WS2 as the enhancing phase and the lubricating phase, the TiAl base self-lubricating composite is high in compactness, good in mechanical property and high in abrasion relieving and resisting performance.

Owner:WUHAN UNIV OF TECH

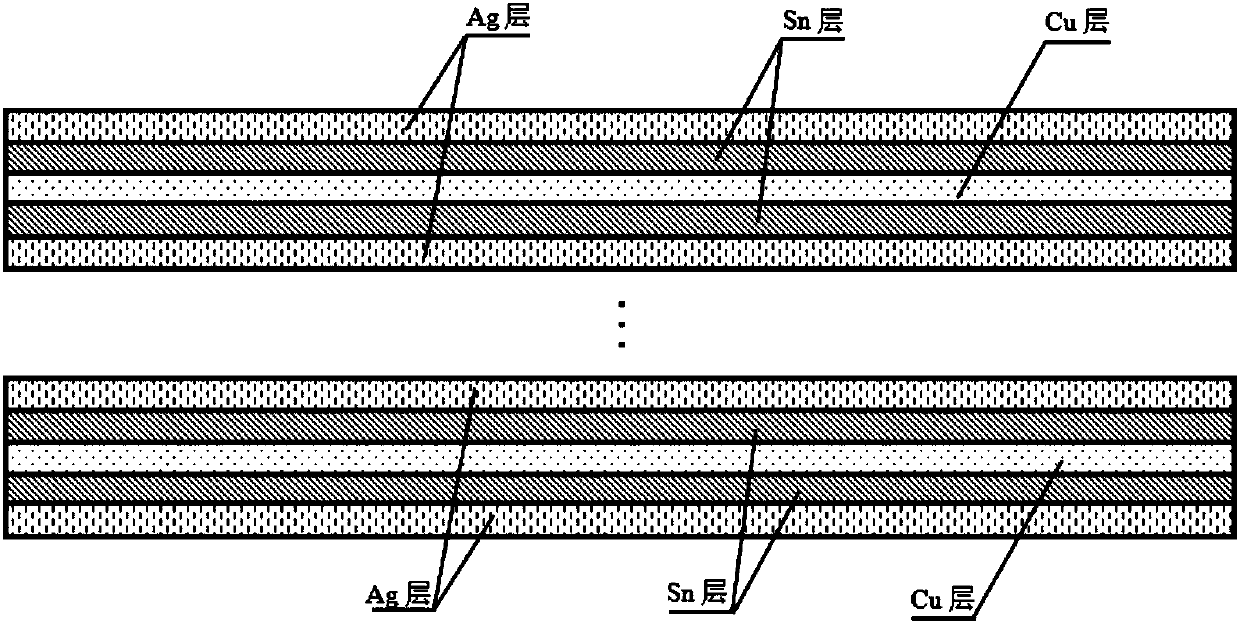

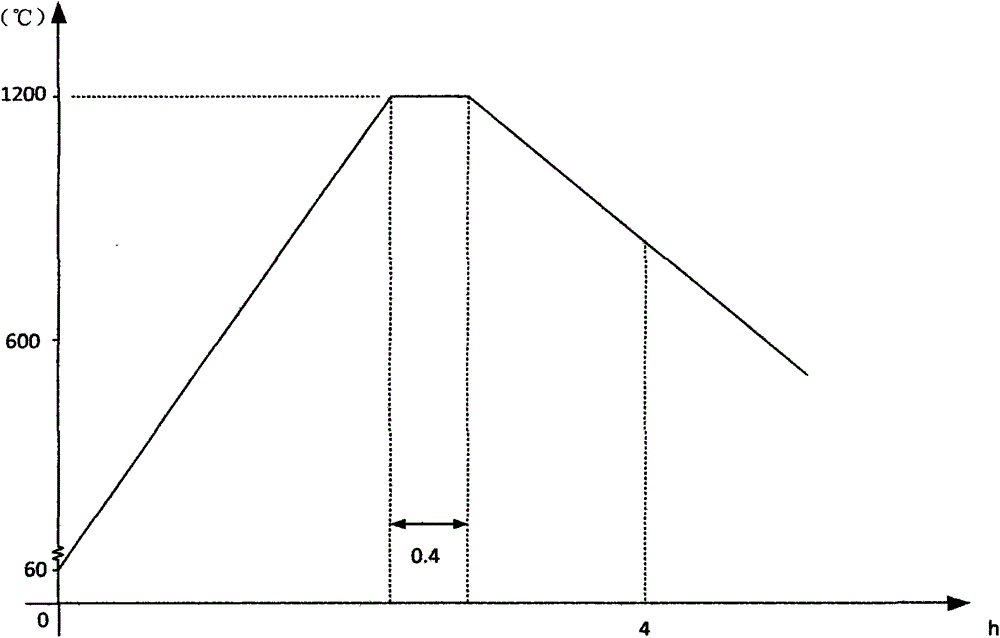

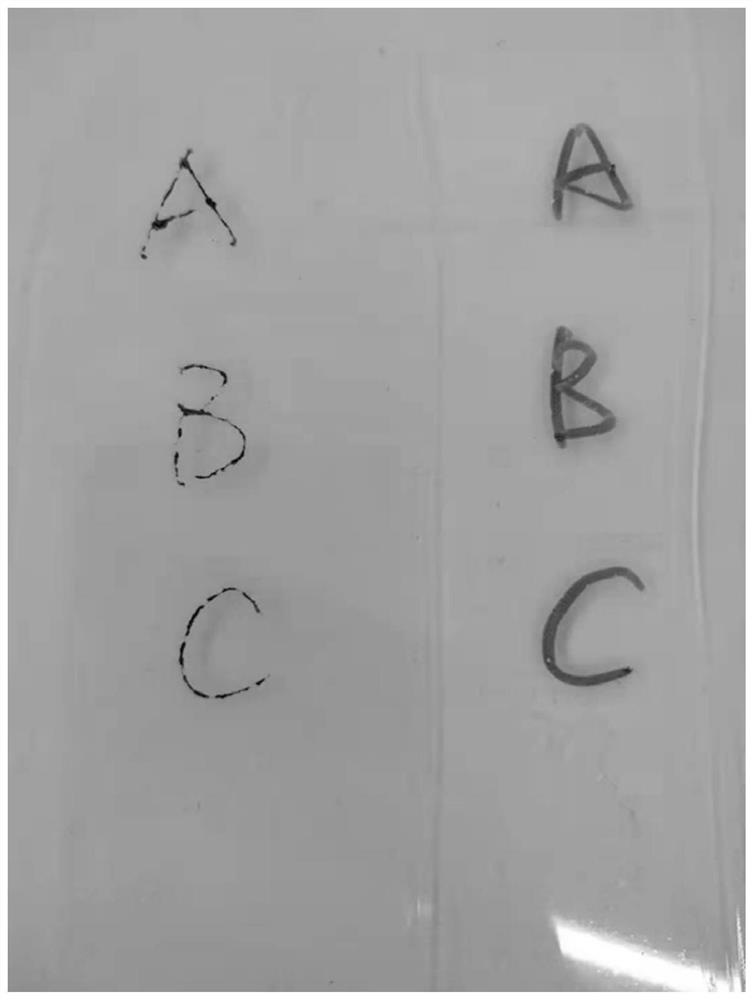

Ag-based composite brazing foil and preparing method thereof

ActiveCN107695559AImprove toughness and plasticityEnergy saving and environmental protection in the preparation processWelding/cutting media/materialsSoldering mediaPre compressionCopper

The invention discloses Ag-based composite brazing foil and a preparing method thereof, which is used for brazing electric vacuum components. The thickness of the Ag-based composite brazing foil is 0.05-1mm, the Sn content is 19-21%, the Cu content is 21-23%, and the rest is Ag. The preparing method of the Ag-based composite brazing foil comprises the following steps: orderly stacking Ag layers, Cu layers and Sn layers which are the same in size and 0.05-0.5mm in thickness according to the structure mode of Ag / Sn / Cu / Sn / Ag / ... / Ag / Sn / Cu / Sn / Ag; making an Ag-Cu-Sn multi-layer composite blank of which the total layer number is 5-30 through pre-compression; then carrying out rolling to make Ag-Cu-Sn foil of which the thickness is 0.05-1mm; and after the following heat treatment, obtaining the Ag-based composite brazing foil. The prepared foil product has great tenacity and ductility, can be made into various sizes of premolding soldering lugs through cold blanking, and has great wetting property and welding property on base materials, such as copper, nickel, high-temperature alloy and kovar alloy.

Owner:SINO PLATINUM METALS CO LTD

Method for recycling waste FCC catalyst

ActiveCN108993531AImprove pore structureLarger than surfaceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationResource utilizationCatalytic oxidation

The invention discloses a method for recycling a waste FCC catalyst. The method comprises the following technical scheme: taking 50 to 70 wt% of the waste FCC catalyst, 25 to 45 wt% of clay and 2 to 5wt% of TiO2 as catalyst materials, mixing the raw materials, drying a mixture, and grinding the mixture; placing the mixture into a disc granulator, spraying 10 to 15% by weight of a transition metalsalt aqueous solution of the catalyst raw material while rotating, rotating a disk grain making machine to form spherical catalyst particles having a particle diameter of 3 to 5 mm; and drying and sintering the material at 1080 to 1200 DEG C for 15 to 30 minutes to prepare an ozone catalyst. A catalytic oxidation tower or a reaction tank is filled with an ozone catalyst according to a filling volume of the ozone catalyst being 45 to 60% of the effective volume of the catalytic oxidation tower or the reaction tank, the dosage of ozone is 50-75 mg / L, the reaction is 15-30min, and the COD of difficultly degraded industrial wastewater after deep treatment is subjected to standardized discharge. The method has the advantages of simple process, low cost and high degree of resource utilization,and the prepared ozone catalyst has stable catalytic performance and high catalytic activity.

Owner:WUHAN UNIV OF SCI & TECH

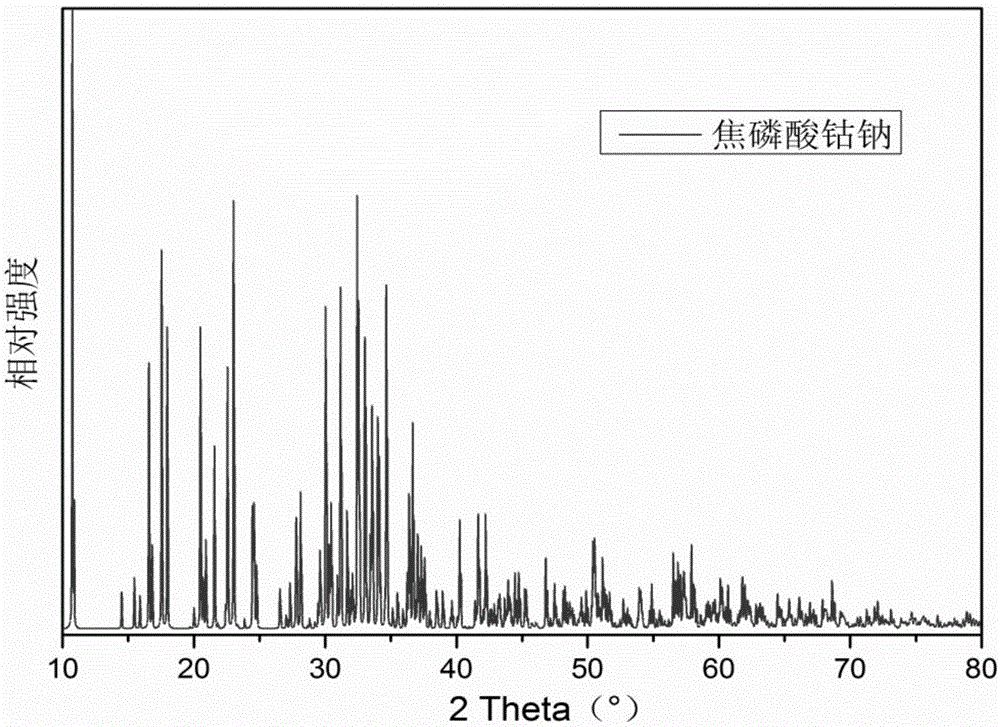

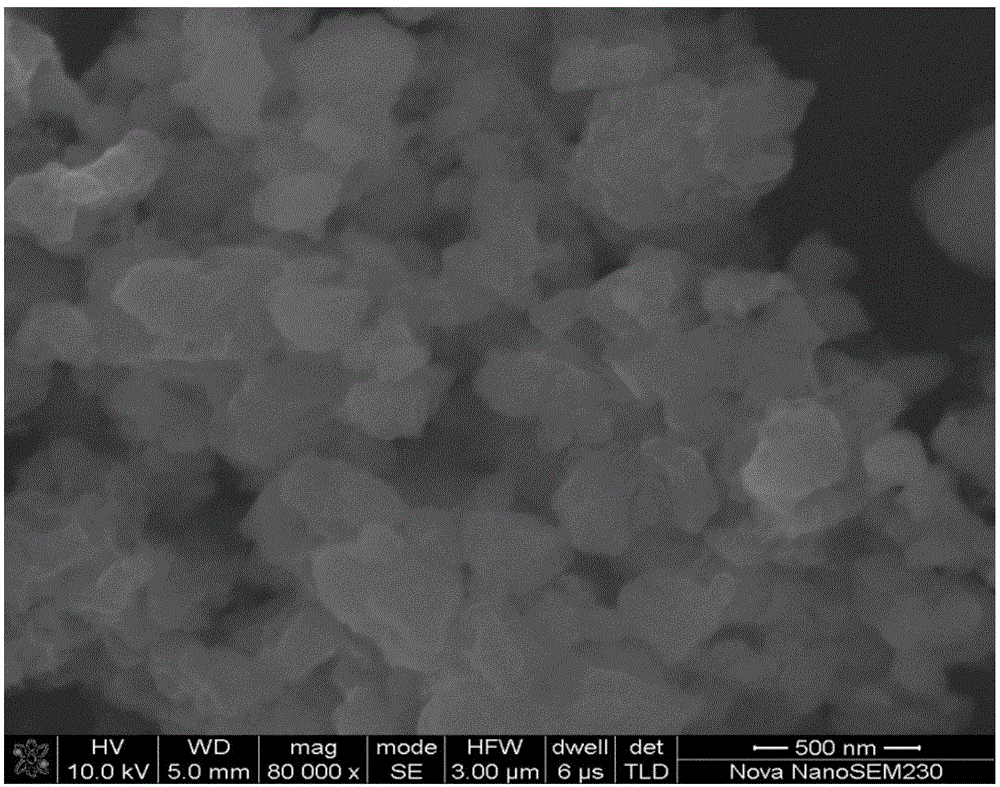

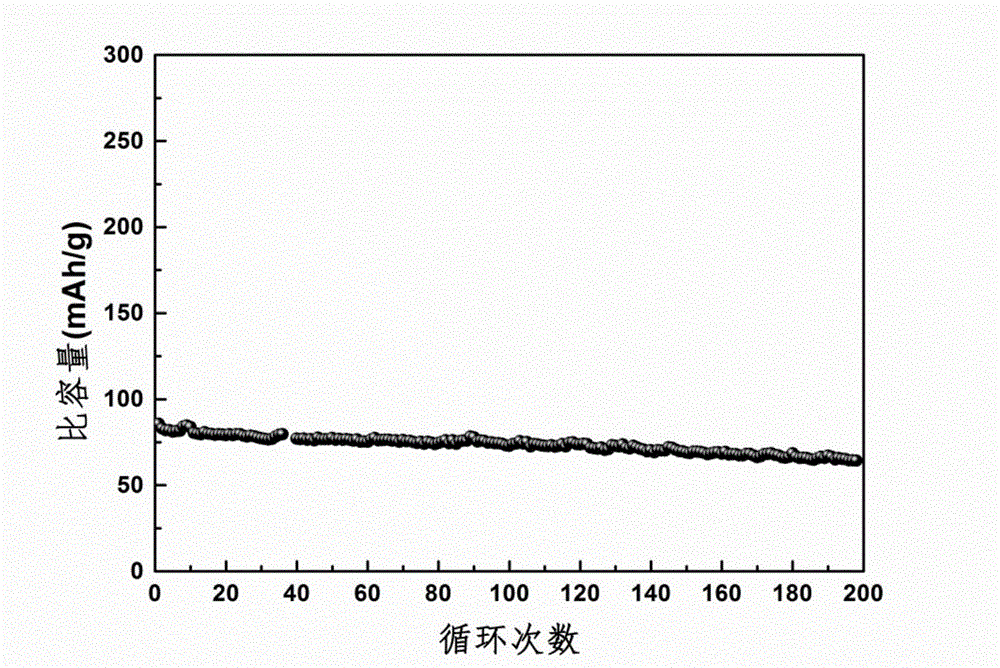

Preparation method of sodium cobalt pyrophosphate and application of sodium cobalt pyrophosphate to sodium ion battery

ActiveCN106374102AHigh purityUniform particle sizeCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a preparation method of sodium cobalt pyrophosphate and application of the sodium cobalt pyrophosphate to a sodium ion battery. The preparation method of the sodium cobalt pyrophosphate comprises the following steps: reacting a cobalt source solution with a potassium pyrophosphate solution to obtain cobalt pyrophosphate hexahydrate; mixing a sodium source and the cobalt pyrophosphate hexahydrate uniformly, putting the mixture under protective atmosphere, sintering and cooling to room temperature to obtain the sodium cobalt pyrophosphate with uniform grain size and shape, large specific surface area, single crystalline phase and high electrochemical activity. The sodium cobalt pyrophosphate serving as a sodium ion positive electrode material can show higher electrochemical property and has an exceeded 3.5V discharging platform; furthermore, the preparation method of the sodium cobalt pyrophosphate is simple and practicable in process and is convenient in large-scale production.

Owner:CENT SOUTH UNIV

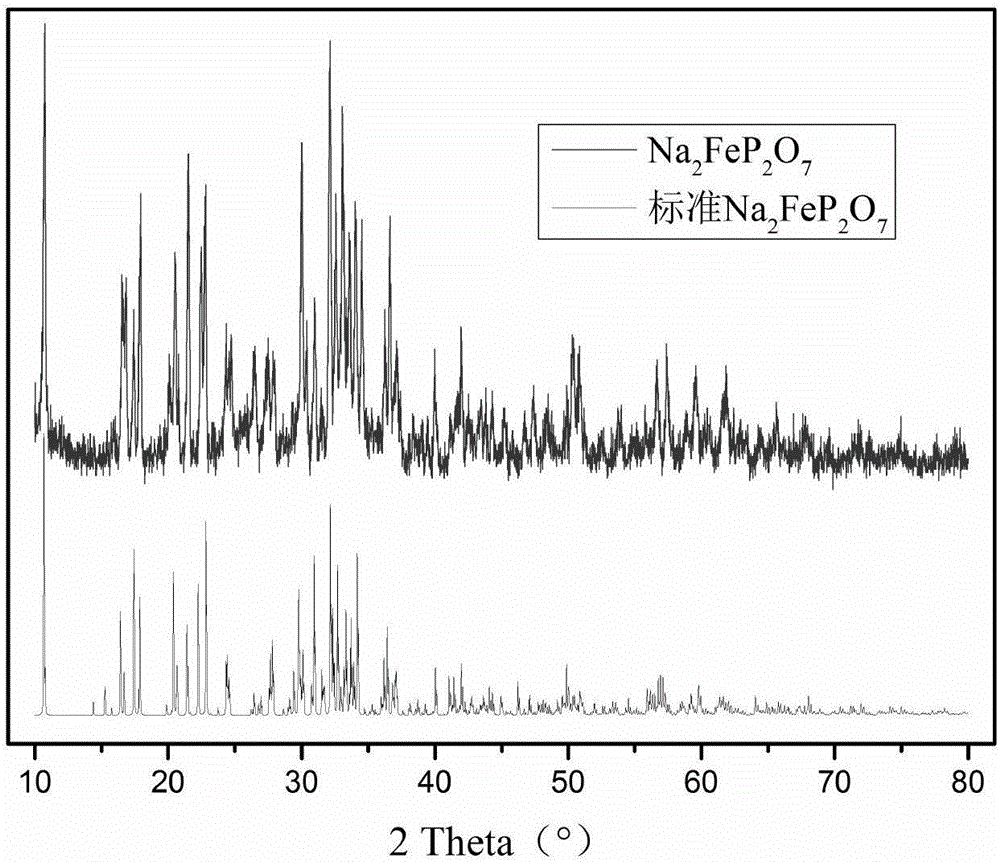

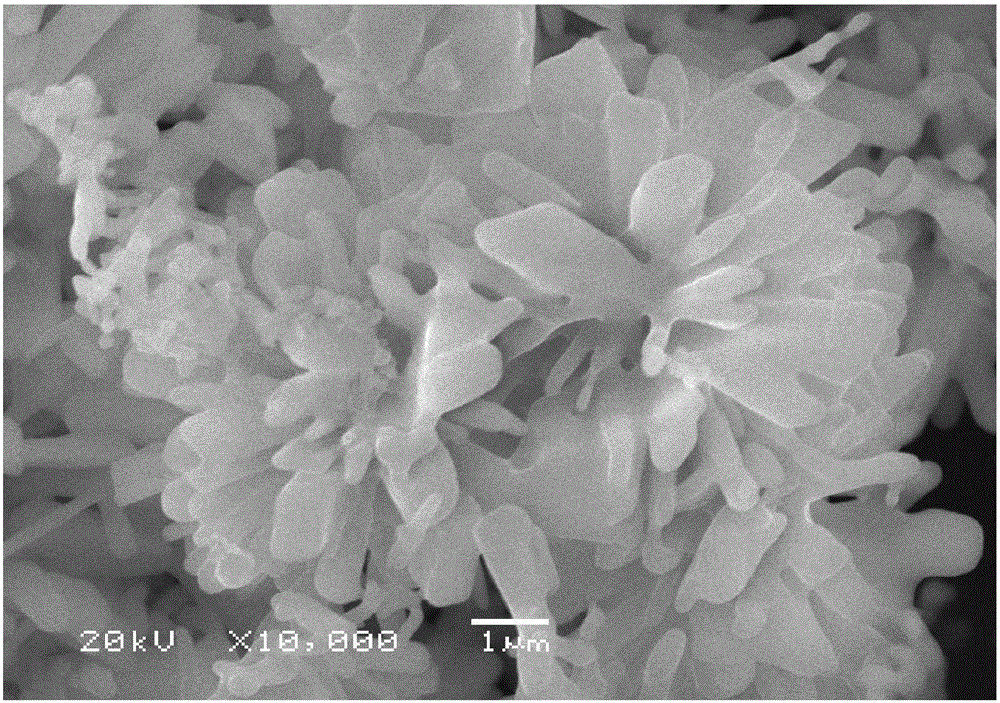

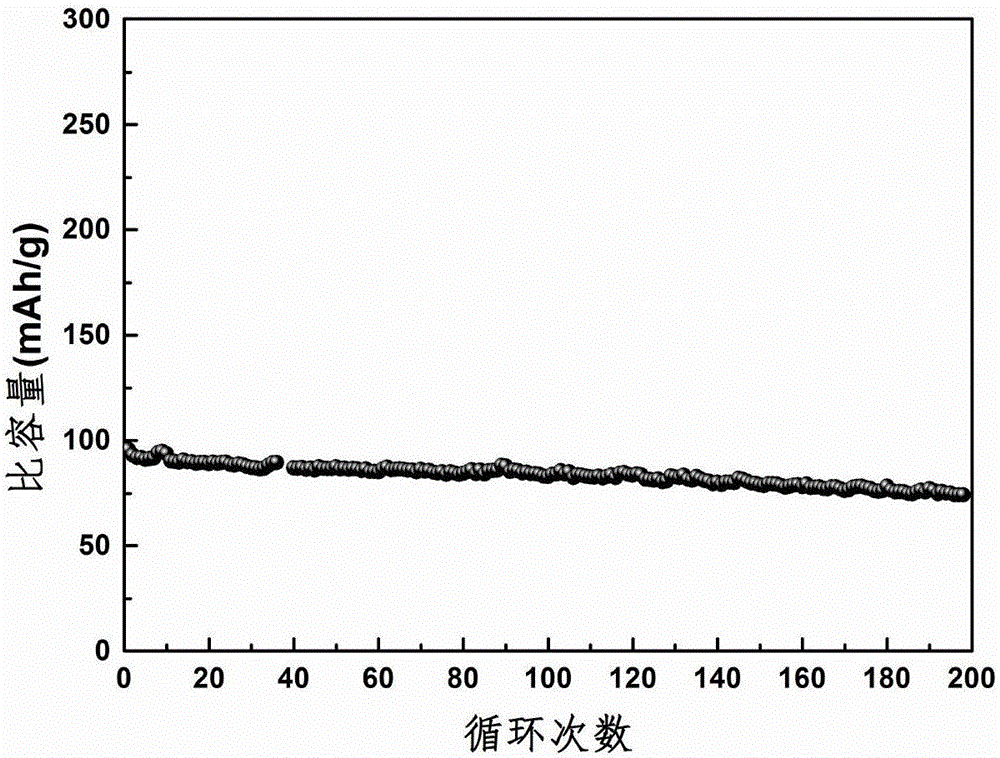

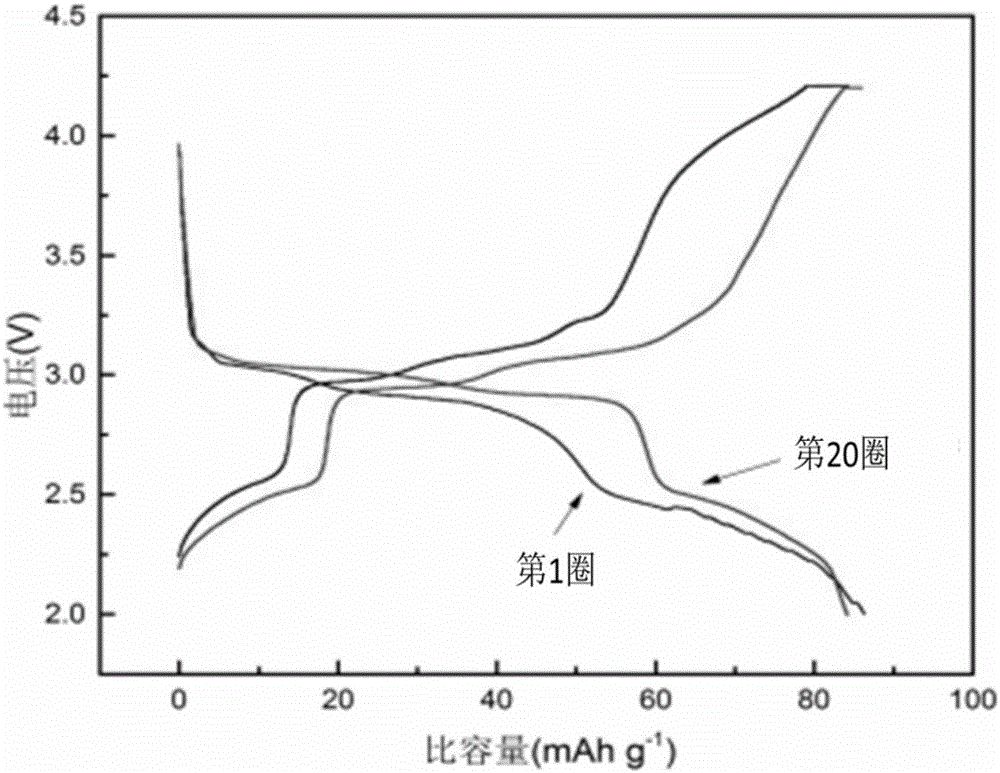

Na2Fe2P2O7 material with flower-like structure and preparation method and application thereof

ActiveCN106450300ALarge specific surface areaImprove electrochemical activityCell electrodesSecondary cellsFlower likeHigh activity

The invention discloses an Na2Fe2P2O7 material with a flower-like structure and a preparation method and application of the Na2Fe2P2O7 material with the flower-like structure. The material is formed by assembling Na2Fe2P2O7 with the flower-like structure, and the preparation method of the Na2Fe2P2O7 material comprises the following steps that a precursor is synthesized by using a hydrothermal method, and then calcined to obtain the Na2Fe2P2O7 material with the flower-like structure; the Na2Fe2P2O7 material with the flower-like structure can expose high-activity crystal faces, and has higher electrochemical activity, thereby having high specific capacity and working voltage while being used as a sodium ion anode material, and still having excellent rate capability and good cycle stability without using a carbon substrate.

Owner:CENT SOUTH UNIV

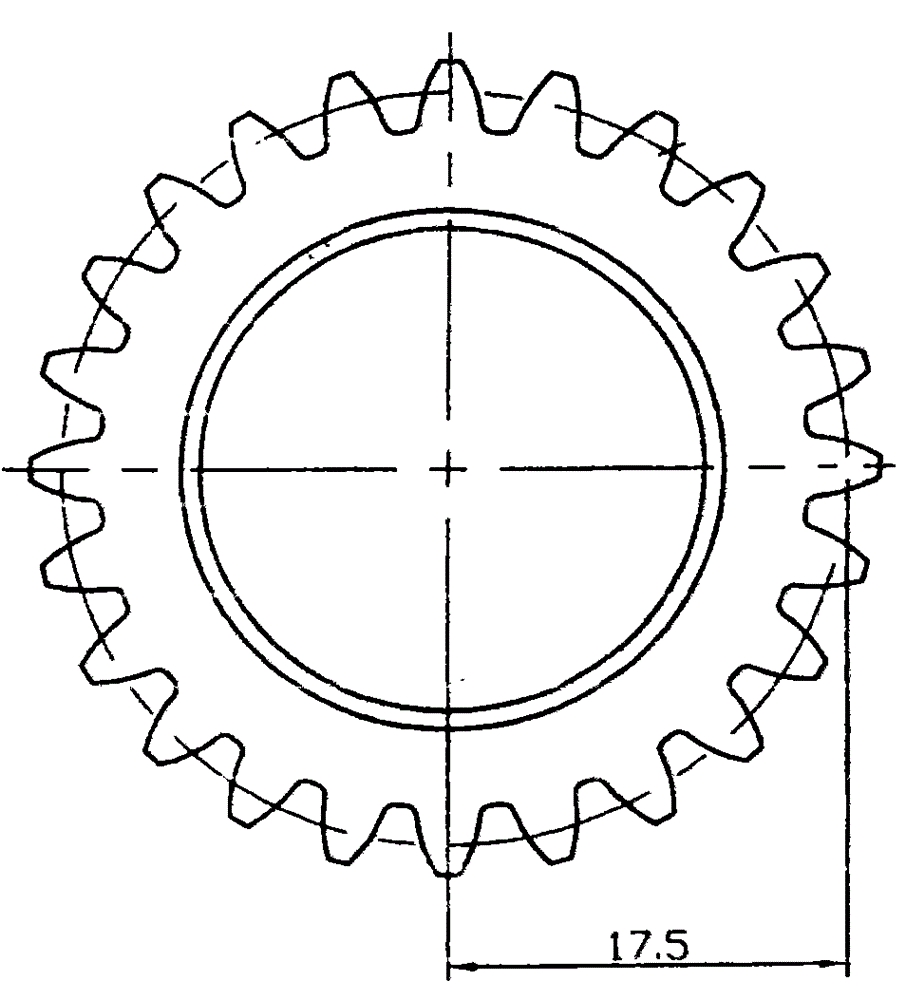

Brazing type diamond grinding wheel used for high-precision grinding and manufacturing method

InactiveCN105945737AAchieve precision machiningImprove gripBonded abrasive wheelsGrinding devicesManufacturing technologyElectroplating

The invention discloses a brazing type diamond grinding wheel used for high-precision grinding and a manufacturing method and belongs to the technical field of precise grinding of high-end glass and material grinding. A diamond brazing layer is arranged at the upper portion of a metal machine body. Diamond abrasive particles are arranged in the diamond brazing layer. Micro grooves are formed in the surface of the metal machine body and are arranged in the surface of the metal machine body in an ordered or disordered manner. The diamond brazing layer comprises an outer circle face and grinding grooves, and the shape of the grinding grooves is determined according to workpiece machining requirements. By means of the brazing type diamond grinding wheel, the number and the diameter of the grooves can be customized at will; and the diamond abrasive particles are subjected to multi-layer brazing; the diamond abrasive particles maintain high holding force in the highly-bare state, and the service life is long. Compared with sintering type and electroplating type manufacturing technologies, the service life is greatly prolonged, and the machining quality is greatly improved; and the diamond abrasive particles still have the high holding force in the highly-bare state, a collapse opening of an outer circle of ground glass is smaller, and the service life is obviously prolonged.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

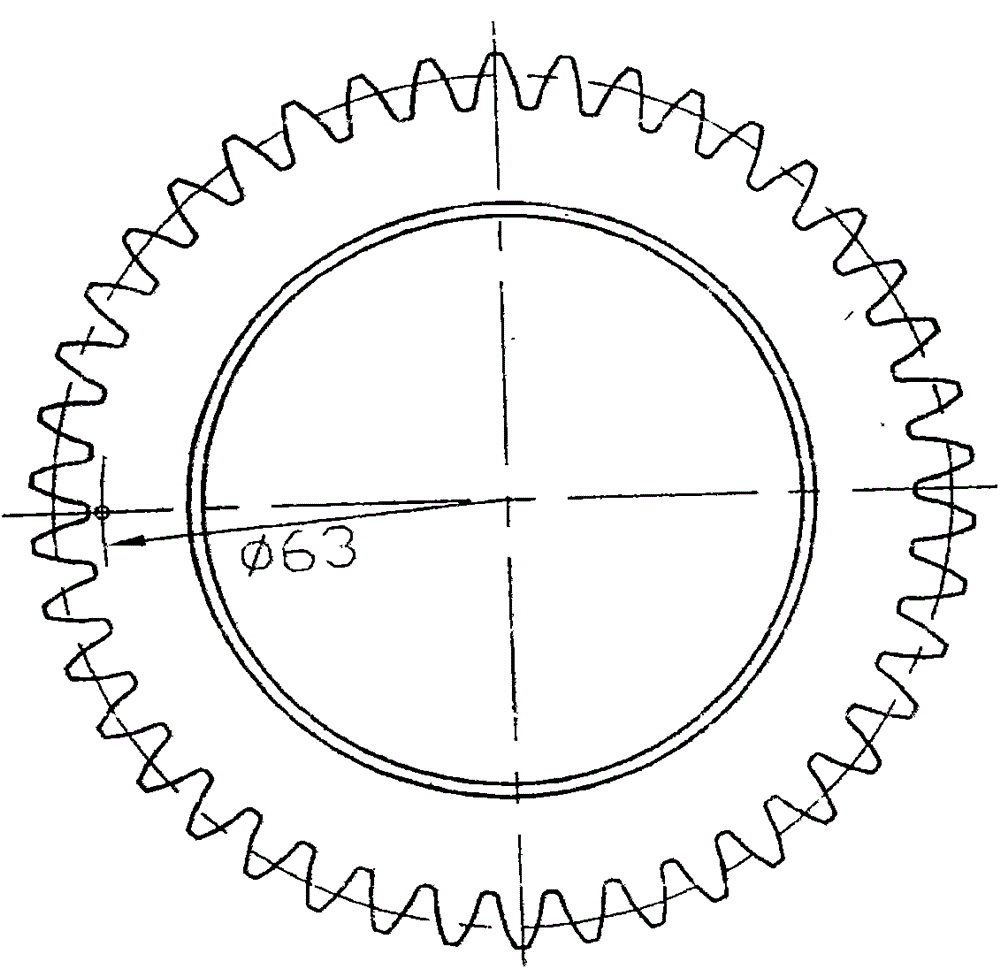

Powder metallurgy helical gear and manufacturing process thereof

InactiveCN105312553AChange hardnessChange resiliencePortable liftingGearing elementsManufacturing technologyIron powder

The invention discloses a powder metallurgy helical gear and a manufacturing process thereof. The gear is made of, by weight, powder raw materials including 0.7-1.0 parts of graphite, 0.5-3.0 parts of copper powder, 1.0-5.0 parts of nickel powder, 0.5-0.8 part of lubricating agents, iron powder and certain inevitable impurities; besides, the manufacturing process of the powder metallurgy helical gear includes the steps of raw material mixing, compressing, sintering, oil immersing and the like. The powder metallurgy helical gear and the manufacturing process thereof have the advantages that with respect to process, compared with a manufacturing process of an existing product, waste of raw materials is reduced, and the whole production energy consumption is saved by 1 / 4; besides, with respect to gear performance, the gear has the good performance that the torsion is over 120 N / M, and the hardness HRB is larger than 70, and the gear can well meet the requirement of a power device.

Owner:重庆道宇机电制造有限公司

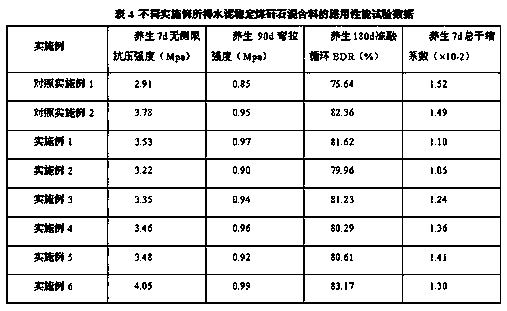

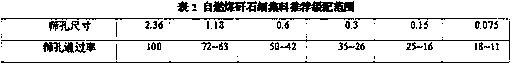

Composite admixture modified cement-stabilized gangue mixture and preparation method thereof

The invention discloses a composite admixture modified cement-stabilized gangue mixture and a preparation method thereof. The mixture is prepared from the following raw materials in parts by weight: 55-65 parts of coarse aggregates of gangue, 45-35 parts of fine aggregates of gangue, 4-6 parts of cement, 11-15 parts of coal ash, 0.02-0.04 part of crack-resistant fibers, 0.02-0.04 part of reinforced fibers and 0.12-0.18 part of improving agent. The composite admixture modified cement-stabilized gangue mixture prepared by using the preparation method disclosed by the invention is good in pavement performance, excellent in compressive strength, crack resistance and durability and significant when being applied to a high-grade road base layer; and the composite admixture modified cement-stabilized gangue mixture disclosed by the invention belongs to a non-toxic and non-corrosive composite and is wide in raw material source, low in cost, environment-friendly and energy-saving in productionprocess and high in economic and social benefits.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Rubber material for fire-proof anti-aging water-proof air-proof cable sealing part and preparation method of rubber material

InactiveCN110117387AGood fire resistance, aging resistance and waterproof performanceExtended service lifeChemical industryRubber materialStearic acid

The invention provides a rubber material for a fire-proof anti-aging water-proof air-proof cable sealing part and a preparation method of the rubber material. The rubber material is prepared from, byweight, 50-60 parts of natural rubber, 10-20 parts of epoxy acrylate rubber, 10-15 parts of an ethylene-propylene-diene monomer, 5-10 parts of nanometer zinc oxide, 5-10 parts of nanometer magnesium oxide, 5-10 parts of nanometer calcium oxide, 10-15 parts of stearic acid modified kieselguhr, 5-10 parts of phthalic acid diallyl ester, 5-10 parts of organic modified montmorillonite, 1-5 parts of ananti-aging agent, 1-5parts of a fire retardant, 1-5 parts of an accelerant, 1-5 parts of a coupling agent and 1-5 parts of a vulcanizing agent. The rubber material for the fire-proof anti-aging water-proof air-proof cable sealing part is reasonable in component composition design, is good in fire-proof, anti-aging and water-proof performance, long in service life and low in production cost, the preparation technology saves energy and is friendly to the environment, no toxic and side effects are generated, and the physical health of production workers is ensured.

Owner:EAST SEALING TECH (JIANGSU) CO LTD

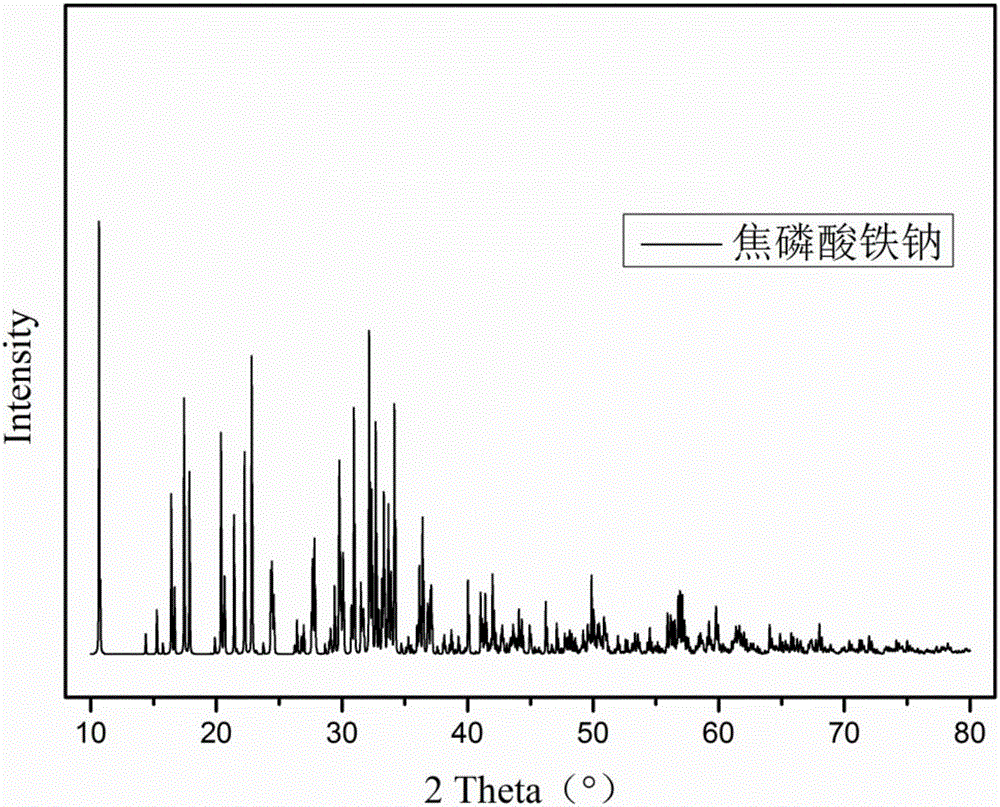

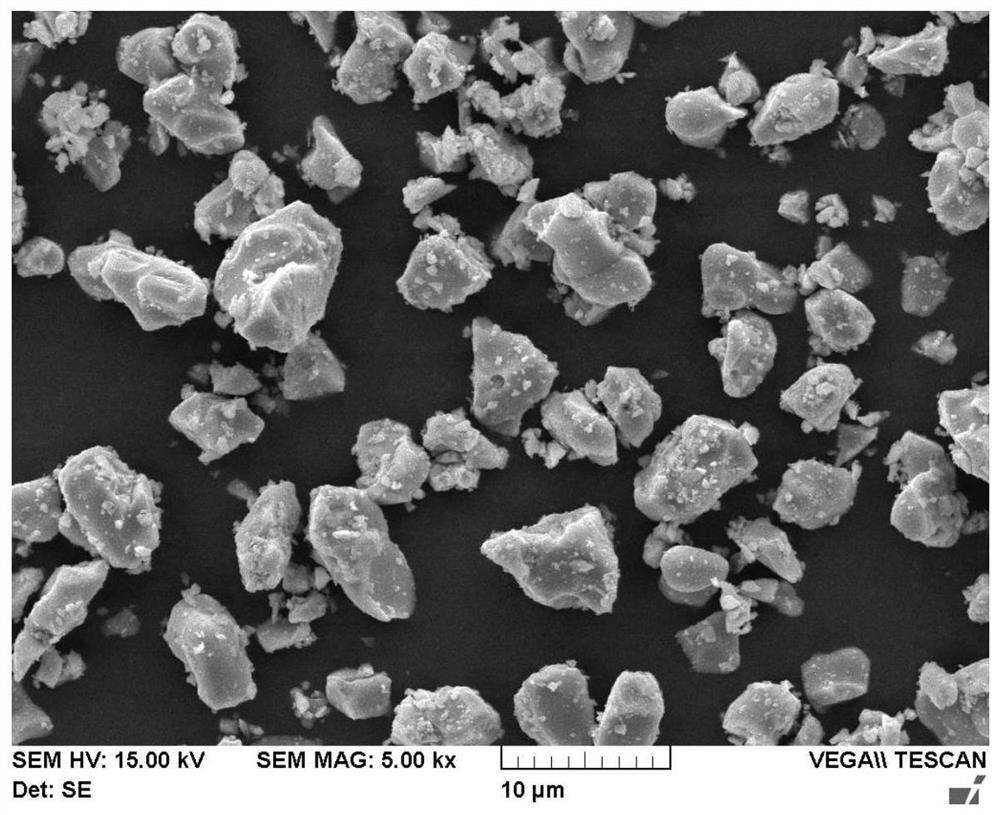

Preparation method of ferric pyrophosphate and application of ferric pyrophosphate in sodium-ion batteries

ActiveCN106340650ASmall particle sizeUniform shapePhosphatesCell electrodesSodium-ion batteryTwo step

The invention discloses a preparation method of ferric pyrophosphate and application of the ferric pyrophosphate in sodium-ion batteries. The preparation method of the ferric pyrophosphate comprises two steps that FeH2P2O7 is firstly prepared through a liquid phase method and is evenly mixed with a sodium source, and then calcination is performed to obtain the ferric pyrophosphate. The method is simple in process, facilitates large-scale production, the prepared ferric pyrophosphate is uniform in particle size distribution, low in impurity content and superior in electrochemical performance and can serve as an anode material for preparing high-performance sodium-ion batteries.

Owner:CENT SOUTH UNIV

A kind of preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

Hydraulic steel pipe inner wall ceramic material good in comprehensive performance

The invention discloses a hydraulic steel pipe inner wall ceramic material good in comprehensive performance. The hydraulic steel pipe inner wall ceramic material is prepared from, by weight, 54-56 parts of pure aluminum powder, 159-162 parts of iron oxide red, 18-19 parts of cobalt nitrate, 18-19 parts of nickel chloride, 37-38 parts of tetraethyl orthosilicate, 74-76 parts of absolute ethyl alcohol, 10-11.5 parts of nano Y-ZrO2 powder, 8.5-9.5 parts of sodium tetraborate, 2-3 parts of ferromolybdenum powder, 3-4 parts of montmorillonite, 4-5 parts of coal ash, 1-1.3 parts of ammonium chloride, 1.5-2 parts of calcium oxide, 2-3 parts of cuprous oxide and a proper amount of deionized water. According to the hydraulic steel pipe inner wall ceramic material good in comprehensive performance, the proper amount of coal ash is added so as to serve as a component, and the production cost is reduced; in cooperation with adding of the calcium oxide and the cuprous oxide, crystals of the material are further refined; and the ceramic material which is even in organization structure, low in porosity and good in combination with a pipe wall is formed on the inner wall of a hydraulic steel pipe through the self-propagating synthetic technology.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

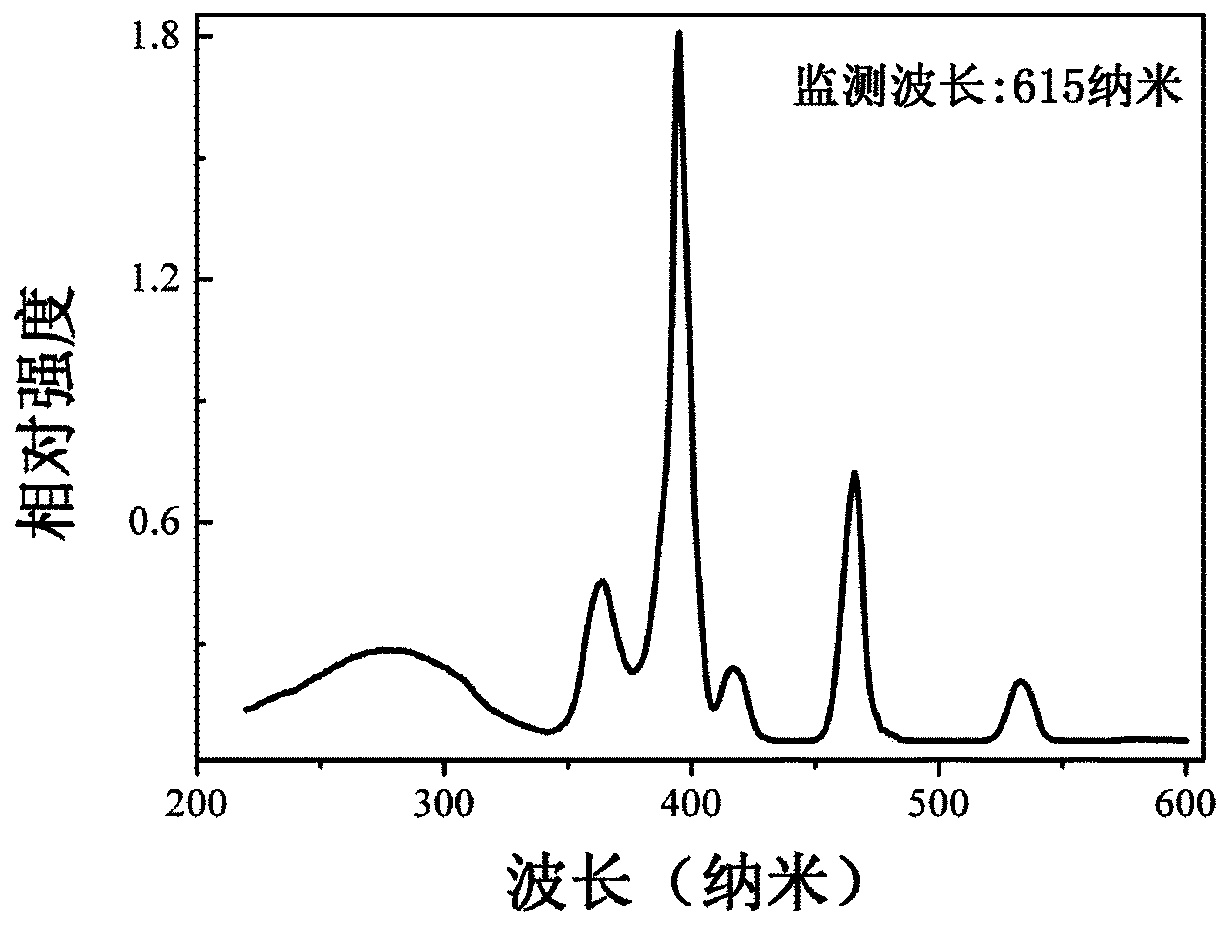

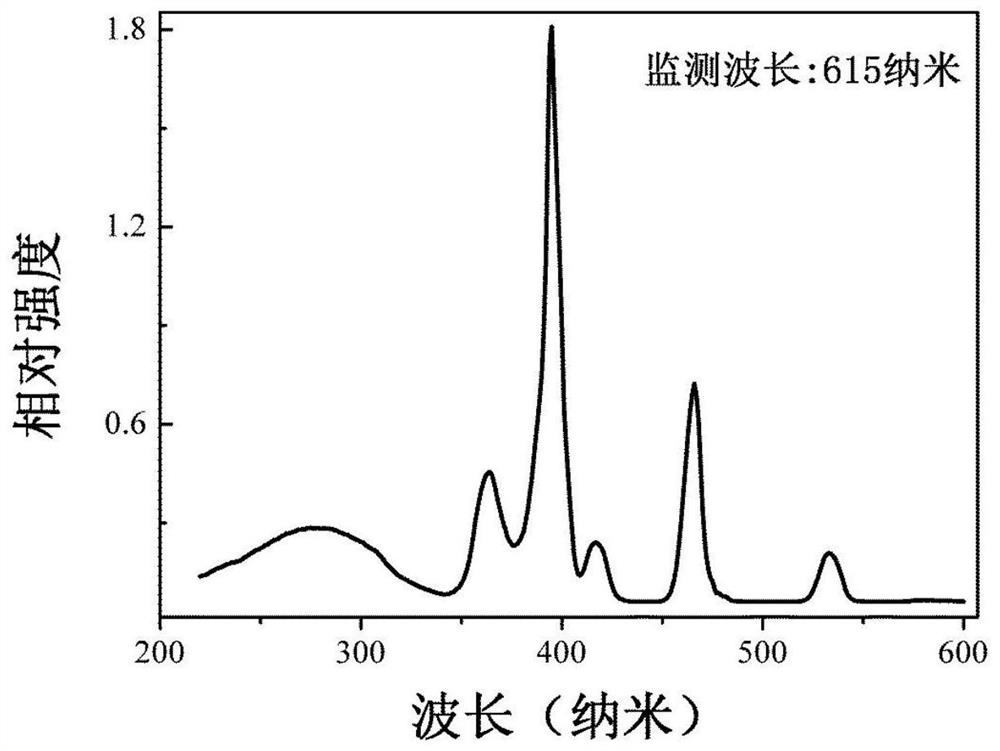

Eu<3+> ion activated vanadate-phosphate-niobate red fluorescent powder, and preparation method and application thereof

ActiveCN109988575AHigh strengthImprove thermal stabilityEnergy efficient lightingLuminescent compositionsAir atmospherePhosphate

The invention discloses Eu<3+> ion activated vanadate-phosphate-niobate red fluorescent powder, and a preparation method and application thereof. The chemical general formula of the fluorescent powderis Ca<1-x>Eu<x>Nb<2-x>Ti<x>V<2>P<4>O<21>, wherein x is the molar ratio of Eu<3+> ions and tetravalent Ti<4+> ions to respectively substituted Ca<2+> and Nb<5+>, and x is greater than or equal to 0.001 and less than or equal to 0.3. The fluorescent powder is synthesized by adopting a solid-phase reaction method, and is synthesized in an air atmosphere by a plurality of times, so that operation isconvenient, the requirement for equipment is low, the preparation process saves energy and is environmentally friendly, and the obtained fluorescent powder particles are uniform in particle size and good in thermal stability. The fluorescent powder provided by the invention has strong absorption capability on near ultraviolet and blue light wave bands, can emit red light with a wavelength of 615 nm after being excited, and is high in luminescence efficiency, so that the Eu<3+> ion activated vanadate-phosphate-niobate red fluorescent powder can be well matched with near-ultraviolet and blue-light semiconductor light-emitting diode (LED) chips, and can be matched with the LED chips to prepare white light LED lighting assemblies.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

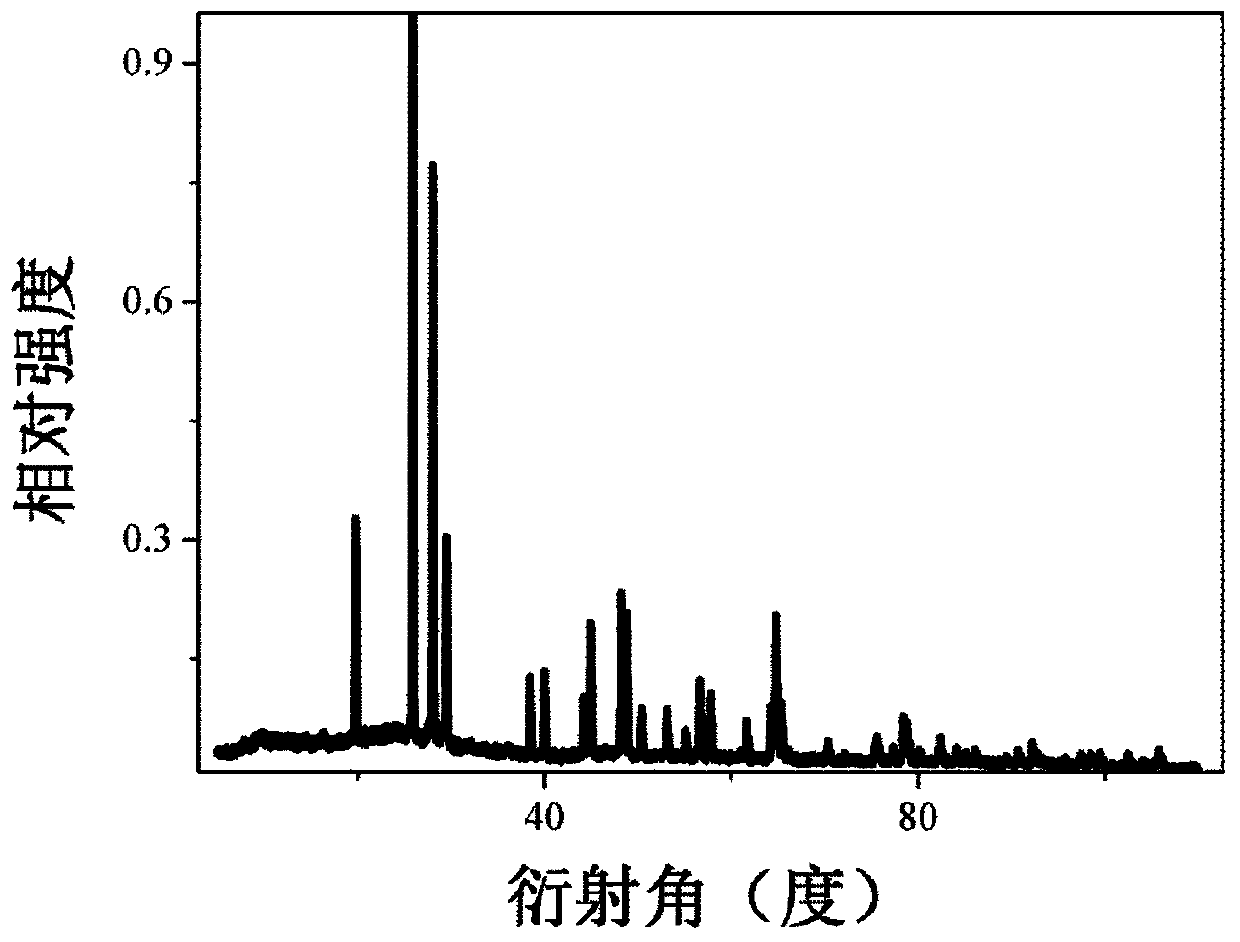

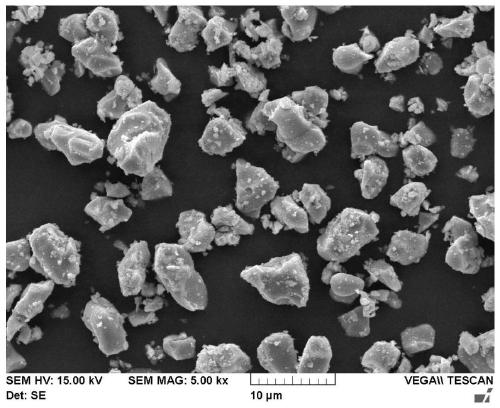

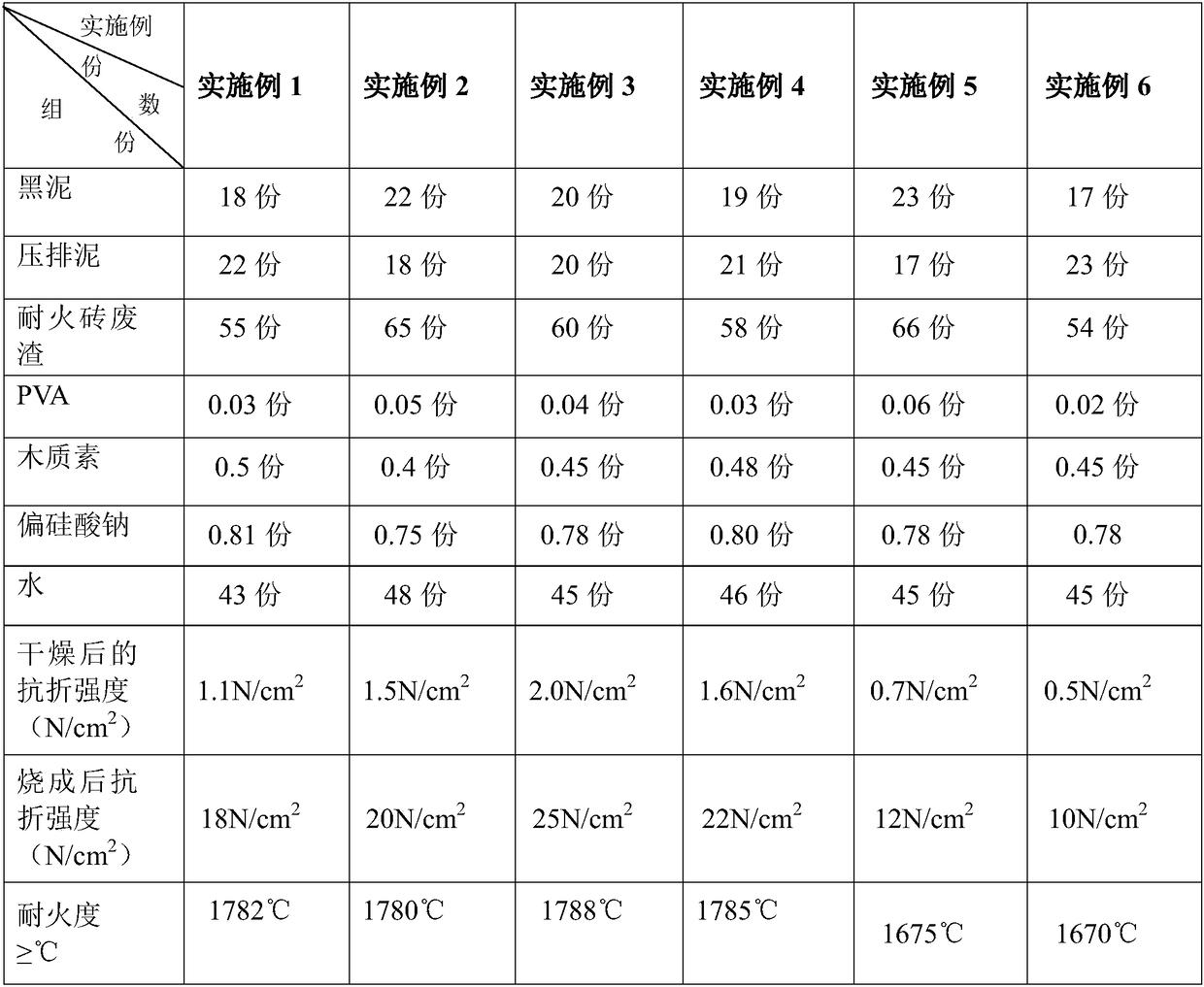

Low-cost preparation process of environment-friendly high-temperature brick and the high-temperature brick

ActiveCN108516847AEnergy saving and environmental protection in the preparation processHigh strengthCeramic materials productionClaywaresSodium metasilicateFire brick

A low-cost preparation process of an environment-friendly high-temperature brick and the high-temperature brick. The preparation process includes steps of: 1) mixing the raw materials including, by weight, 18-22 parts of black mud, 18-22 parts of pressure-discharged mud, 55-65 parts of waste residue of refractory bricks, 0.03-0.05 parts of PVA, 0.4-0.5 parts of lignin, 0.75-0.81 parts of sodium metasilicate and 43-48 parts of water, ball-milling the mixture to form slurry, and spray-drying the slurry to obtain a high-temperature brick powder material; 2) placing the high-temperature brick powder material in a pressing mould to press-shape the high-temperature brick powder material, and sintering the material in a kiln to obtain a finish product. The high-temperature brick not only has high-temperature fireproof effect but also is higher in strength, can be repeatedly used, is greatly reduced in preparation cost, is more environment-friendly and energy-saving, and has simple preparationprocess.

Owner:FOSHAN DONGPENG CERAMIC +2

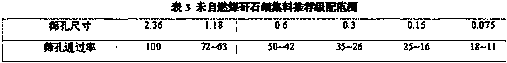

Environment-friendly high-performance coal gangue mixture base layer and preparation method thereof

The invention relates to the technical field of road engineering materials, in particular to an environment-friendly high-performance coal gangue mixture base layer and a preparation method thereof. The mixture base layer is prepared from the following raw materials in parts by weight: 72-81 parts of an unspontaneous-combustion coal gangue coarse aggregate, 12.7-18.7 parts of a spontaneous combustion coal gangue fine aggregate, 6.3-9.3 parts of an unspontaneous-combustion coal gangue fine aggregate, 3-4 parts of cement, 0.1-0.2 part of a curing accelerator, 5-9 parts of a filler and 0.02-0.04part of anti-cracking fibers. According to the invention, road performance of the inorganic binder stabilized coal gangue mixture is ensured, the technical problems of low early strength, serious shrinkage cracking and poor durability of inorganic binder stabilized coal gangue mixture road base layers in the prior art are solved, and construction cost is reduced.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

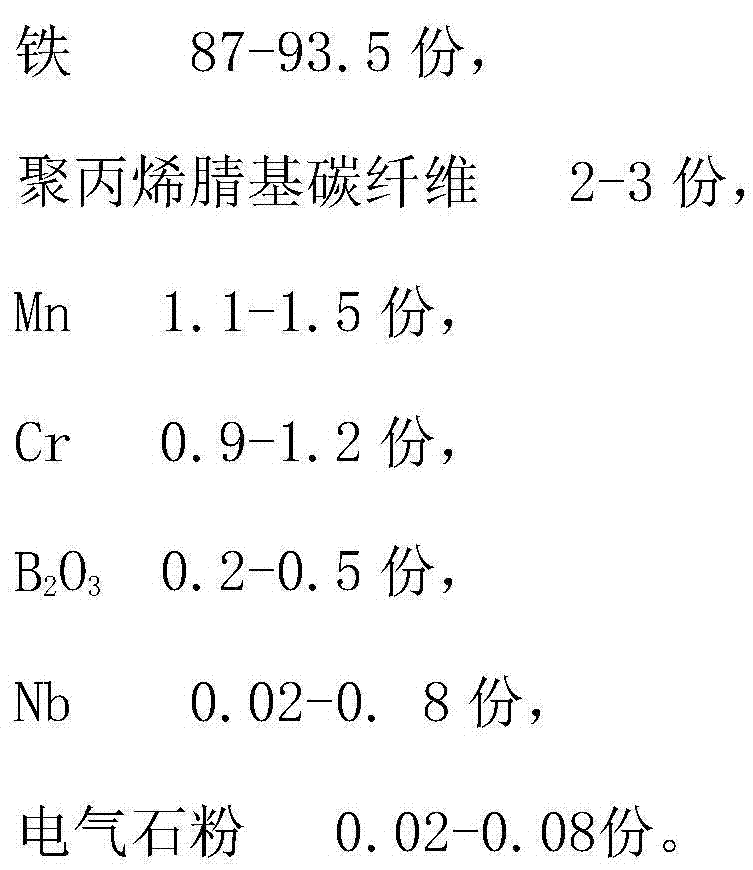

Spring steel material for elevator and preparation method of spring steel material

The invention discloses a spring steel material for an elevator and a preparation method spring steel material. The spring steel material for the elevator comprises the following components in parts by weight: 87-93.5 parts of iron, 2-3 parts of polyacrylonitrile-based carbon fiber, 1.1-1.5 parts of Mn, 0.9-1.2 parts of CrO, 0.2-0.5 part of B2O3, 0.02-0.8 part of Nb and 0.02-0.08 part of electric rock flour. The invention further provides a preparation method of the spring steel material for the elevator.

Owner:SUZHOU MAYFORD ELEVATOR

Preparation method of modified marble powder low-temperature sintering artificial stone

InactiveCN107879715ALower sintering temperatureSmall particle gapCeramic materials productionClaywaresNano al2o3Surface modified

The invention discloses a preparation method of modified marble powder low-temperature sintering artificial stone. The method comprises the following steps that 1, marble powder is dried, then, a surface modifier, sodium carbonate, barium sulfate, tealeaf residues and cement are added for performing ball milling, and then mixing and stirring are performed to obtain modified marble powder; 2, coalash, kieselguhr, crosslinked rectorite, clay, zinc oxide and tourmaline powder are added into the modified marble powder and mixed and stirred to obtain a mixture; 3, the mixture is mixed with nanometer aluminum oxide, titanium dioxide and sodium carboxymethylcellulose are mixed, the mixture is subjected to compression molding and drying, then, low-temperature sintering under the temperature of 300-400 DEG C for 1-2 h, and the artificial stone is obtained. Marble is modified, the marble powder sintering temperature can be effectively lowered, and the preparation technology has the advantages of saving energy and being environmentally friendly; the marble powder is small in particle interval, and the artificial stone sintering density and mechanical strength can be remarkably improved.

Owner:ZAOZHUANG BOYUAN ARTIFICIAL STONE CO LTD

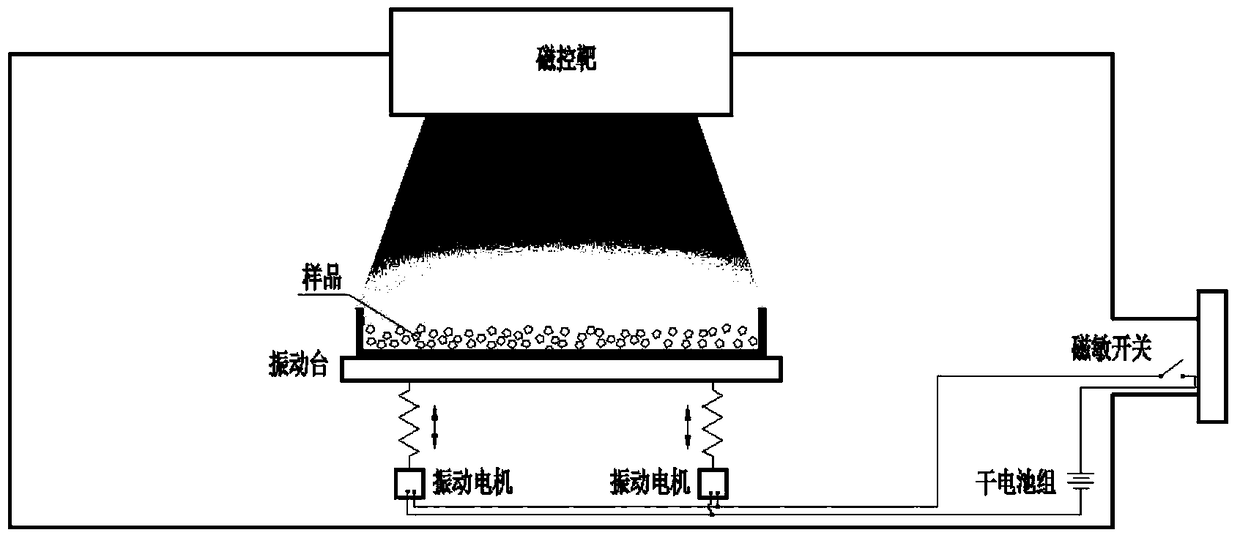

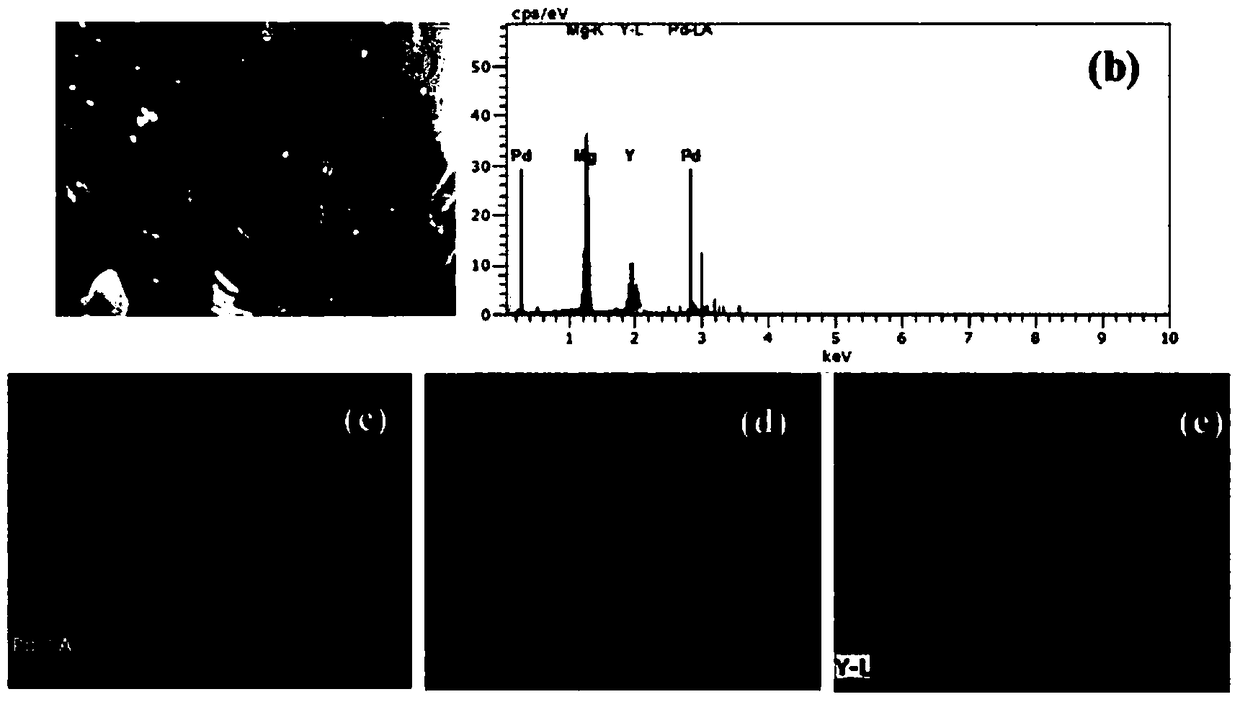

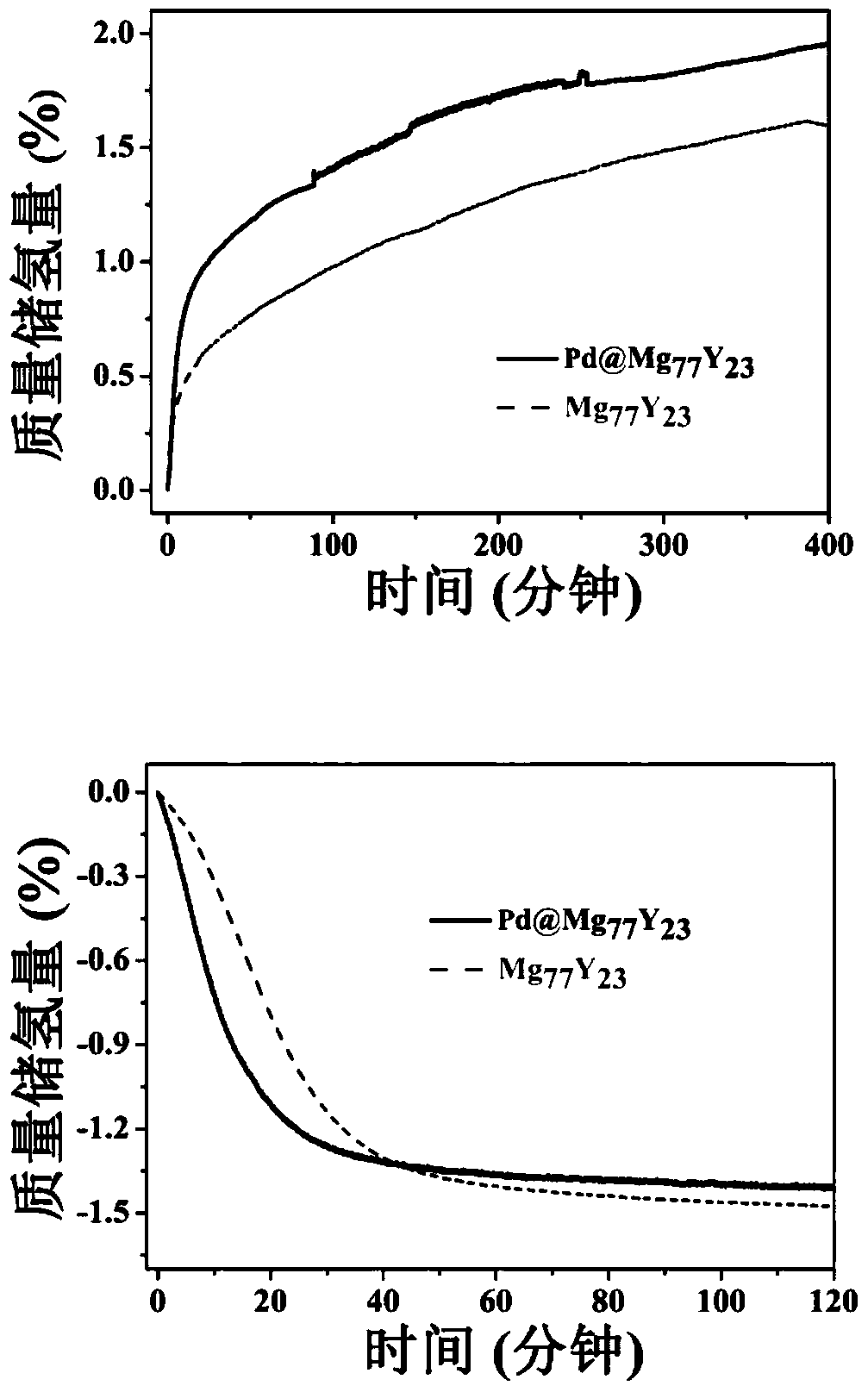

A kind of high-performance hydrogen storage alloy and preparation method thereof

ActiveCN105755302BQuality is easy to controlImprove performanceVacuum evaporation coatingSputtering coatingMechanical crushingIngot

The present invention discloses a high-performance hydrogen-storage alloy and a preparation method thereof, the high-performance hydrogen-storage alloy Pd @ Mg-Y is obtained by coating Pd with Mg100-xYx (x = 20-25) alloy particles, the particles size of the alloy particle is 50 to 150 microns, and Pd film thickness is 5-30nm. The preparation method is as follows: a Mg100-xYx (x = 20-25) master alloy ingot is prepared by vacuum melting method, hydrogen storage alloy inner-core particles with a particle size of 50 to 150 microns are obtained by mechanical crushing, and the surface of the Mg100-xYx (x = 20-25) inner-core particles is uniformly coat-plated with a Pd film by magnetron sputtering coating technology. Experimental results show that: hydrogen absorption and desorption rates of the hydrogen-storage alloy Pd @ Mg-Y obtained by the method are significantly faster than the hydrogen absorption and desorption rates of pure Mg of same size, so that the large particle size Pd @ Mg77Y23 hydrogen storage alloy has a good use prospect in hydrogen storage materials, as well as simplification of the preparation process.

Owner:STATE GRID CORP OF CHINA +2

Walnut milk and preparation method thereof

InactiveCN101971883AMeeting nutritional needsPromote absorptionMilk preparationLactalbuminPasteurization

The invention discloses walnut milk. The walnut milk comprises 89.47 to 93.23 weight percent of fresh milk, 1 to 2 weight percent of lactalbumin, 2 to 3 weight percent of cold-pressed walnut oil, 3.5 to 5 weight percent of sweeting agent, 0.1 to 0.2 weight percent of calcium carbonate, 0.02 to 0.03 weight percent of ferrous sulfate, 0.05 to 0.1 weight percent of zinc sulfate and 0.1 to 0.2 weight percent of emulsion stabilizer; and the preparation method comprises the following steps of: heating refrigerated fresh milk subjected to pasteurization to 48 to 52 DEG C according to the weight percentage; adding the lactalbumin which is preheated to 48 to 52 DEG C with stirring; reheating the lactalbumin to 75 to 80 DEG C; adding the cold-pressed walnut oil, the sweeting agent, the calcium carbonate, the ferrous sulfate, the zinc sulfate and the emulsion stabilizer; and homogenizing, sterilizing and cooling to prepare the walnut milk. The milk product of the invention has balanced nutrition, contains sufficient polyunsaturated fatty acid, has an important promotion effect on brain development of fetus, and is convenient to drink and can be easily absorbed and utilized by human bodies; and the preparation method is simple and practical and is energy-saving and environment-friendly.

Owner:HEBEI BROS ILONG FOOD TECH LLC

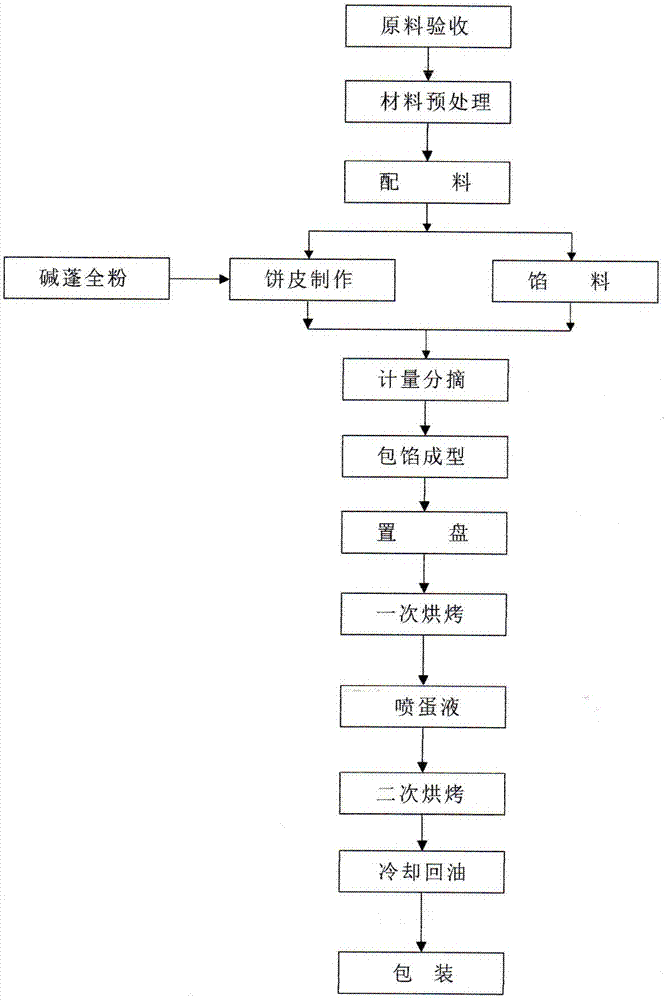

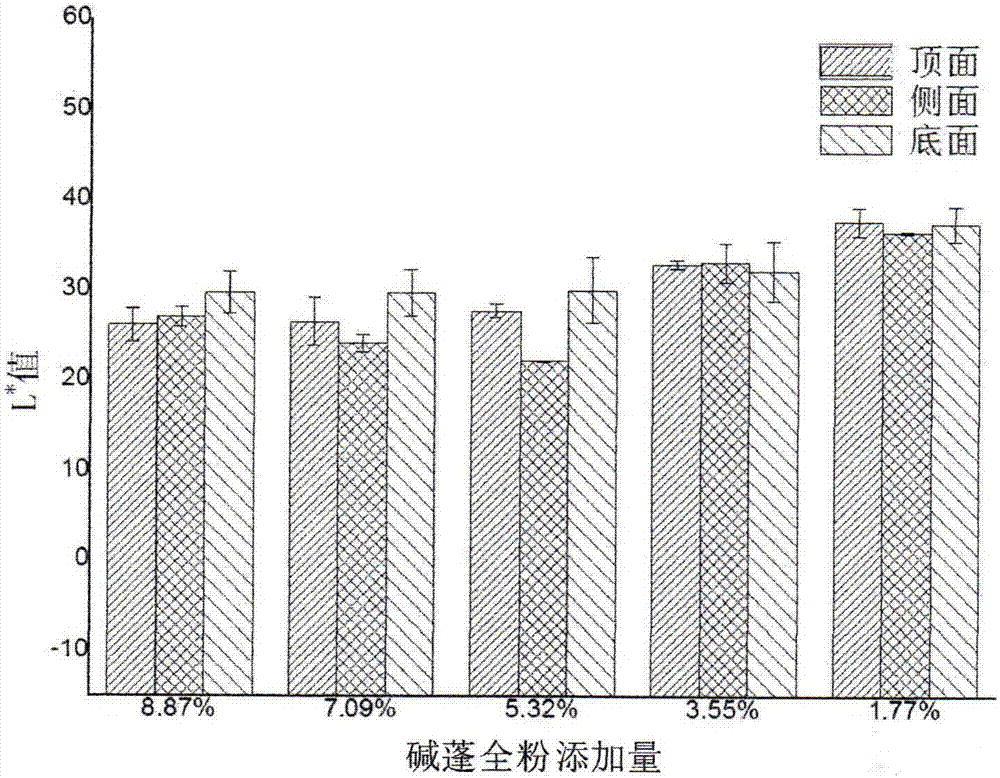

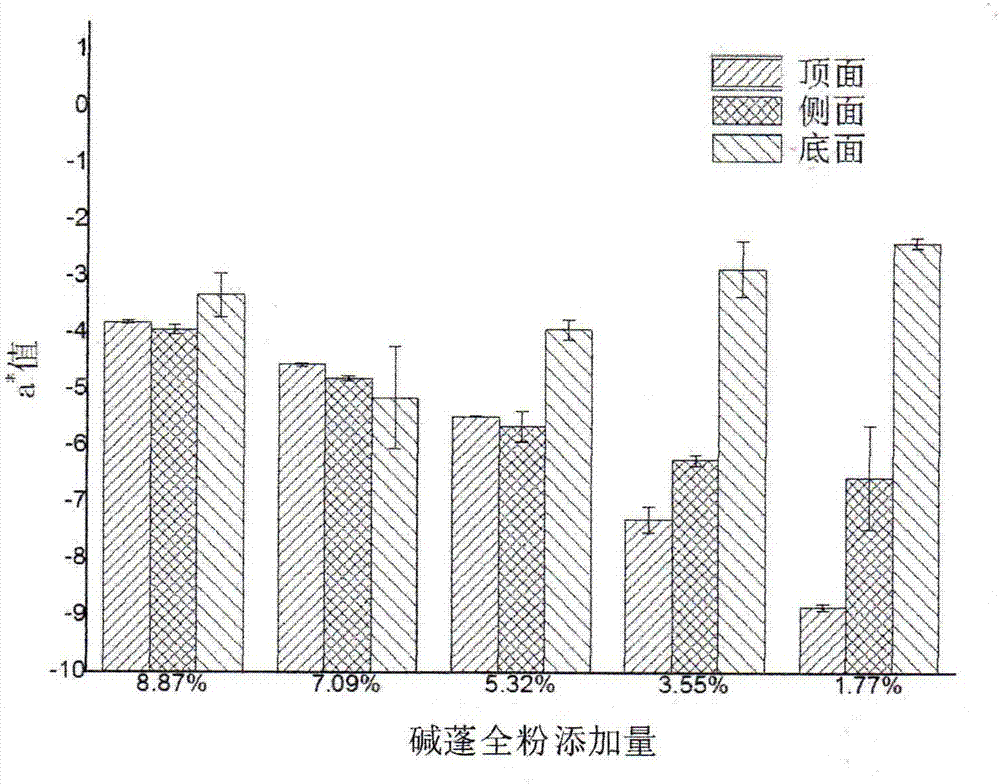

Low-oil high-quality suaeda salsa health-care moon cakes

ActiveCN107494673AReduced fat additionShorten oil return timeDough treatmentModified nutritive productsVegetable oilGluten

The invention provides low-oil high-quality suaeda salsa health-care moon cakes, and relates to moon cakes. The cake crusts of the moon cakes consist of the following components in parts by weight: 48-56 parts of low-gluten flour, 2.3-11 parts of whole suaeda salsa powder, 29-37 parts of invert sugar syrup, 3-11 parts of vegetable oil and 0.6-0.8 part of detergent granules. According to the low-oil high-quality suaeda salsa health-care moon cakes disclosed by the invention, through careful modern processing, extremely green suaeda salsa is obtained, natural probiotic functional factors of the suaeda salsa are reserved, the natural whole suaeda salsa powder is added to the cake crusts of the moon cakes, the high-oil abuse of conventional moon cakes is changed, the addition quantity of oil and fat in the cake crusts is reduced by 30-72%, besides, low oil and high quality are uniquely given to the conventional moon cakes through the green suaeda salsa, based on low oil, the original mouth feel and the original characteristics of the moon cakes are guaranteed, and the moon cakes have health-care effects and conform to the pursuit of people at the large health era.

Owner:福建一品居生物科技有限公司

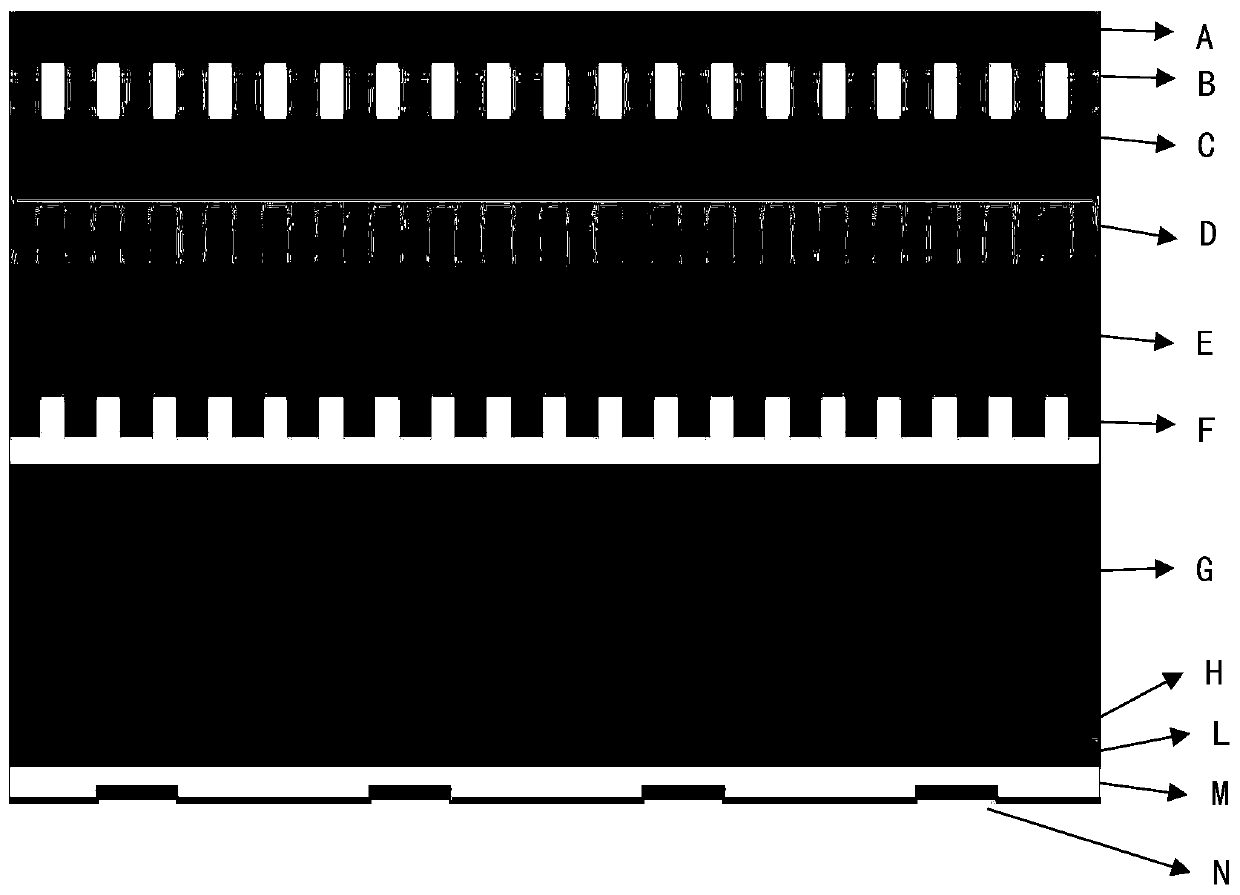

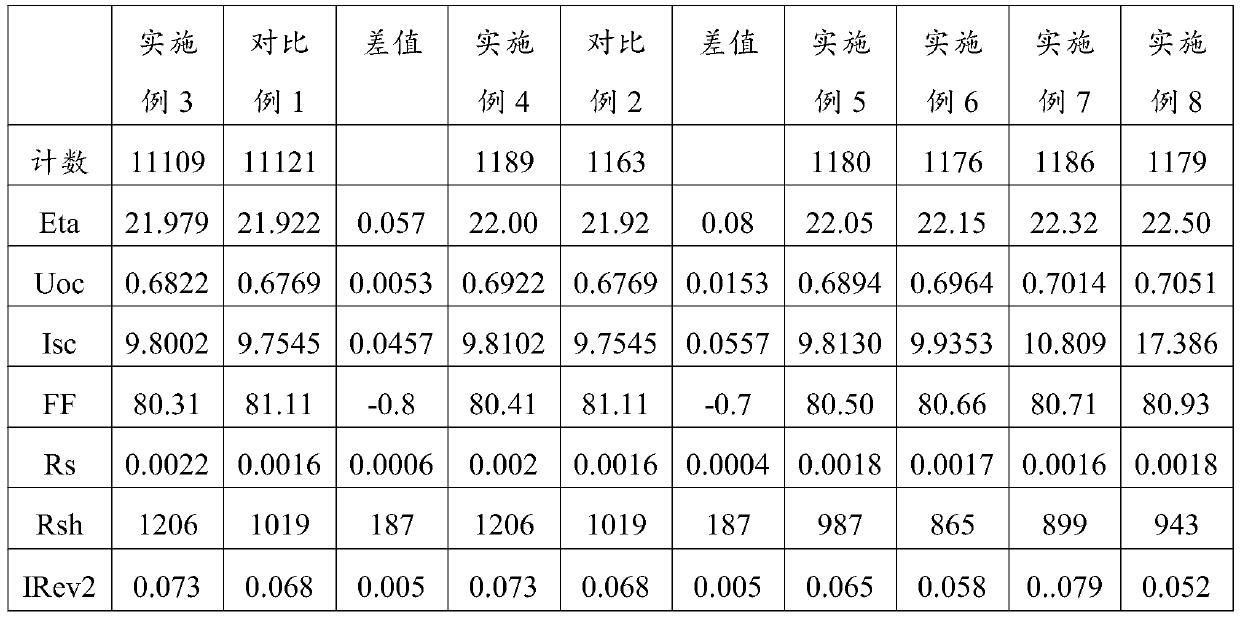

Photovoltaic SE battery and preparation method thereof

ActiveCN110993701AIncrease the open circuit voltageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a photovoltaic SE battery. The photovoltaic SE battery comprises a back field electrode, a back electrode, a protective film, a passivation layer, a P-type silicon substrate, aPN junction layer, an SE laser propulsion layer, an oxidation repair layer, an antireflection film layer, an auxiliary grid line electrode and a main grid line electrode, and a high solar cell conversion rate can be obtained through mutual cooperation of the structures of all the layers. Moreover, the invention discloses a preparation method of the photovoltaic SE battery, the whole preparation process is simple, the raw materials are simple and easy to obtain, and the production cost can be obviously reduced.

Owner:晋能光伏技术有限责任公司

Low-temperature-resistant environment-friendly tire sealant and manufacturing method thereof

InactiveCN109423250AWide variety of sourcesImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPolyvinyl alcohol

The invention relates to a low-temperature-resistant environment-friendly tire sealant and a manufacturing method thereof. The tire sealant comprises water-based polyurethane resin, polyvinyl alcohol,propylene glycol and a fluorocarbon surfactant. The preparation method comprises the following steps: step 1, adding vacuum dehydrated oligomer polyol, isocyanate, a catalyst N-methyl pyrrolidone anddibutyltin dilaurate into a reaction kettle for a reaction; step 2, adding 1,4-butanediol, dimethylolpropionic acid and trimethylolpropane for carrying out a chain extension reaction; step 3, addingtriethylamine for neutralization, and then adding the obtained material into an ethylenediamine water solution for emulsification; and step 4, slowly adding a polyvinyl alcohol water solution, propylene glycol and a fluorocarbon surfactant, meanwhile, adding a defoaming agent, a flatting agent and a tackifier, and fully carrying out stirring to obtain a final product. The low-temperature-resistantenvironment-friendly tire sealant is wide in raw material source, the preparation process saves energy and is environmentally friendly, the bonding performance and low-temperature resistance are good, and blocking performance is excellent.

Owner:成都昂多生物技术有限责任公司

A kind of sodium ion battery positive electrode na2fe2(so4)3@alumina composite material and preparation method thereof

ActiveCN106058251BLow costControl speedCell electrodesSecondary cellsComposite cathodeSynthesis methods

The invention discloses a Na2Fe2(SO4)3@alumina composite material having a core-shell structure and a preparation method and an application thereof. The material is a composite material having the core-shell structure and prepared by coating the surface of Na2Fe2(SO4)3 particles with alumina. The Na2Fe2(SO4)3 is pyrolytically coated with an organic aluminum salt, the problems that Na2Fe2(SO4)3 is dissolved in water and is difficultly coated by alumina via a traditional hydrolysis method are overcome, the synthesis method is simple, conditions are mild, and the yield is high; the prepared composite material can effectively suppress a 'surface poisoning effect' of the material, and has the advantages of high specific capacity, high work voltage, good cyclic stability and excellent rate performance when applied as a sodium ion battery positive electrode material.

Owner:CENT SOUTH UNIV

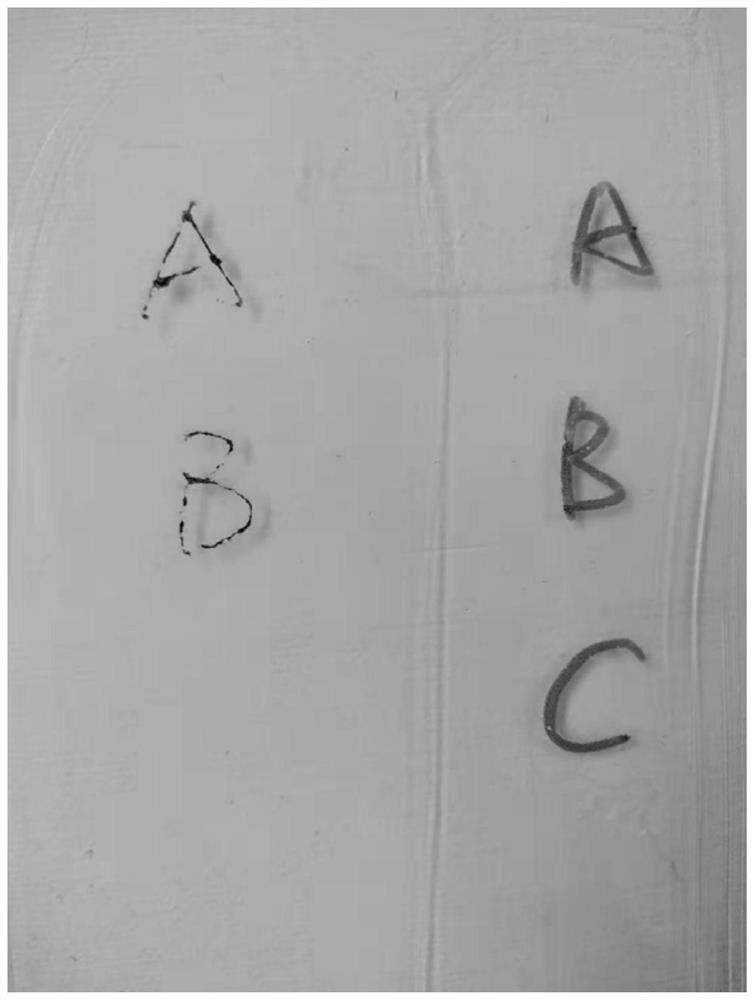

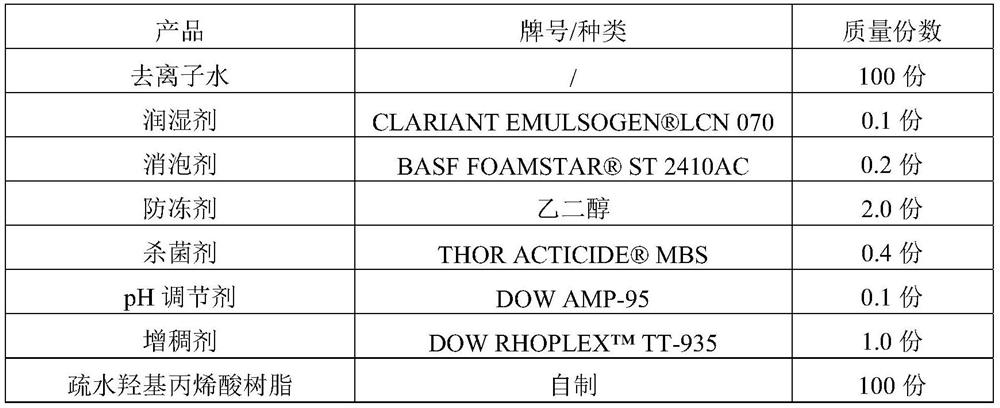

Anti-graffiti and scrubbing-resistant coating composition and preparation method thereof

ActiveCN113122091ALow VOCGood hydrophobic effectCoatingsPhotovoltaic energy generationSilicone resinActive agent

The invention relates to an anti-graffiti and scrubbing-resistant coating composition. The raw materials of the anti-graffiti and scrubbing-resistant coating composition comprise a component A and a component B, wherein the mass ratio of the component A to the component B is 100: (20-40); the component A comprises hydrophobic modified hydroxy acrylic resin, and the component B comprises a curing agent and alcohol ether esters; the hydrophobic modified hydroxy acrylic resin is prepared from hydrophobic gel, a fluorine surfactant and hydroxy acrylic resin; and the hydrophobic gel is prepared from polymethylsilane and alkoxy silicon resin. The invention also comprises a preparation method of the anti-graffiti and scrubbing-resistant coating composition. The product provided by the invention is energy-saving and environment-friendly, has low VOC, solves the problem of poor anti-graffiti effect of a water-based coating, and has a stain resistance score up to 87 scores. According to the method, the defect that the water-based coating is poor in stain resistance stability is overcome, after 10000 times of scrubbing resistance, the stain resistance still reaches 85%, and almost no attenuation exists.

Owner:HEBEI CARPOLY PAINT CO LTD +1

a kind of EU 3+ Ion activated vanadium phosphoniobate red phosphor, preparation method and application thereof

ActiveCN109988575BHigh strengthImprove thermal stabilityEnergy efficient lightingLuminescent compositionsAir atmosphereO-Phosphoric Acid

The invention discloses a Eu 3+ Ion-activated vanadium phosphoniobate red phosphor, preparation method and application thereof, its general chemical formula is Ca 1‑x Eu x Nb 2‑x Ti x V 2 P 4 o 21 , x is trivalent Eu 3+ ions and tetravalent Ti 4+ ions respectively replace Ca 2+ and Nb 5+ The number of moles of x is in the range of 0.001≤x≤0.3. The invention is synthesized by a solid-phase reaction method, and is synthesized by multiple calcining in an air atmosphere. The operation is convenient and the requirements for equipment are low. The preparation process is energy-saving and environment-friendly. The fluorescent powder provided by the present invention has a strong absorption capacity for near-ultraviolet and blue light bands, can emit red light with a wavelength of 615 nanometers after excitation, and has high luminous efficiency. Therefore, the Eu 3+ The ion-activated vanadium phosphoniobate phosphor can be well matched with near-ultraviolet and blue light semiconductor LED chips, and can be used to prepare white light LED lighting devices in combination with it.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com