A kind of sodium ion battery positive electrode na2fe2(so4)3@alumina composite material and preparation method thereof

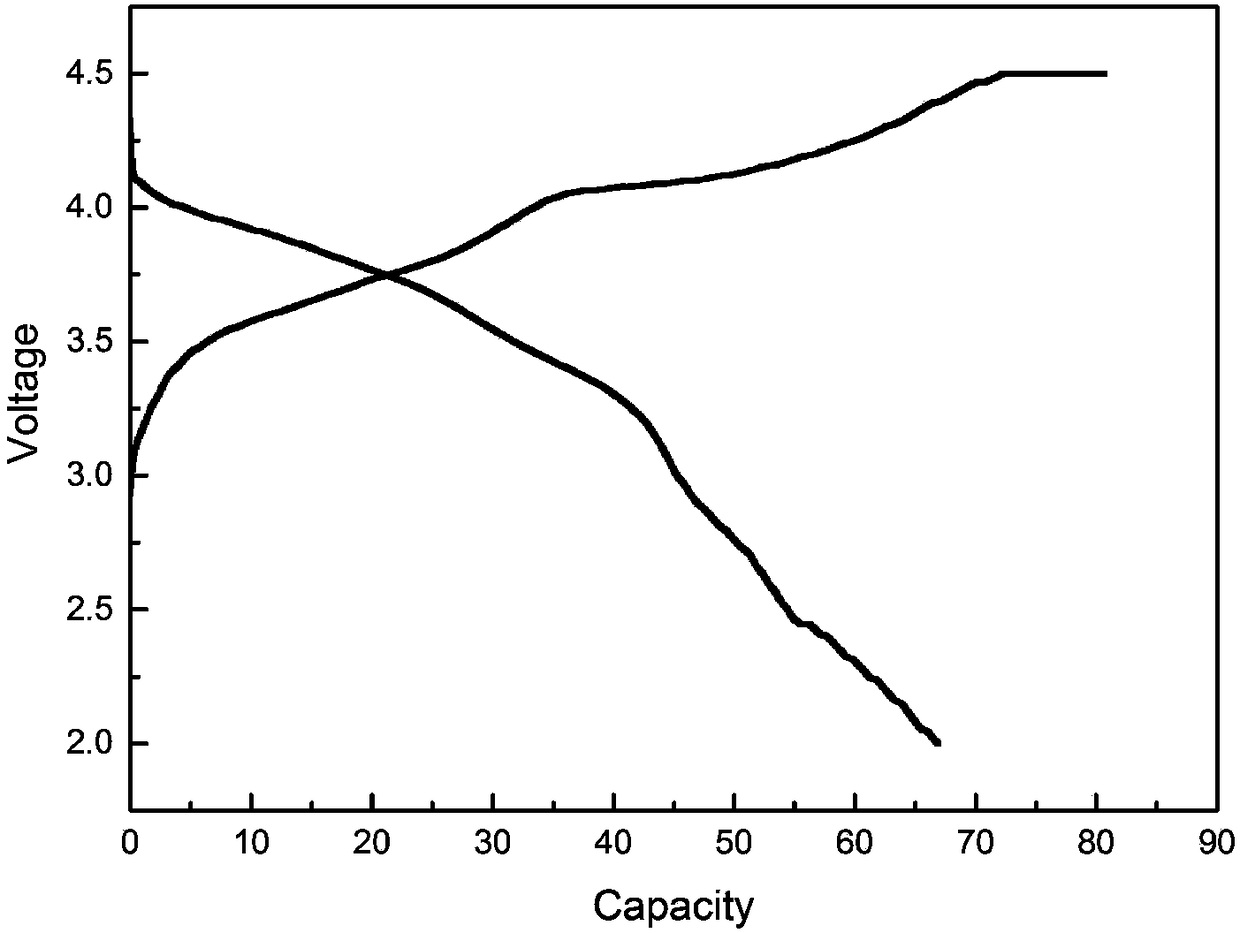

A technology of sodium ion battery and composite material, which is applied in the field of Na2Fe23@alumina composite material and its preparation of the positive electrode of sodium ion battery, can solve the problems of difficulty in realizing large-scale production, harsh production environment requirements, short cycle life and the like, and achieves good cycle Stable performance, inhibition of surface poisoning effect, good material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This embodiment includes the following steps:

[0075] Step (1): This embodiment design generates 0.03mol target product Na 2 Fe 2 (SO 4 ) 3 @Alumina composite material, prepare 50mL of solution, weigh 0.03mol of sodium sulfate and 0.06mol of ferrous sulfate in 50mL of deionized water, stir to dissolve;

[0076] Step (2): Stir the solution treated in step (1) in an 80°C oil bath until the solution is evaporated to dryness, and the obtained solid powder is Na 2 Fe 2 (SO 4 ) 3 precursor products;

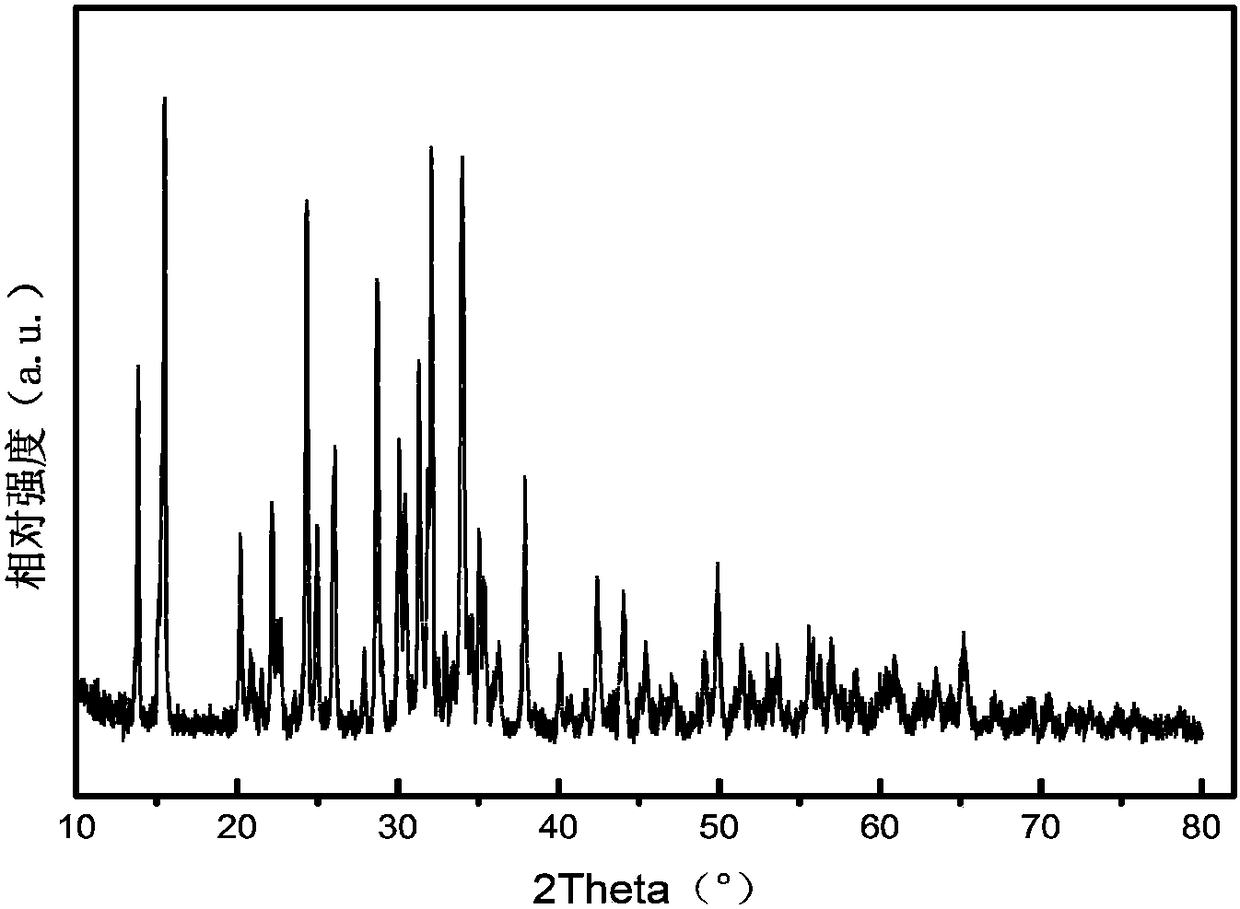

[0077] Step (3): The obtained precursor solid phase product is mixed with hydrogen and argon (5% H 2 +95% Ar) under the protection of the atmosphere, the temperature was raised to 350 ° C, sintered for 24 hours, the heating rate was 5 ° C / min, and the product Na 2 Fe 2 (SO 4 ) 3 ;

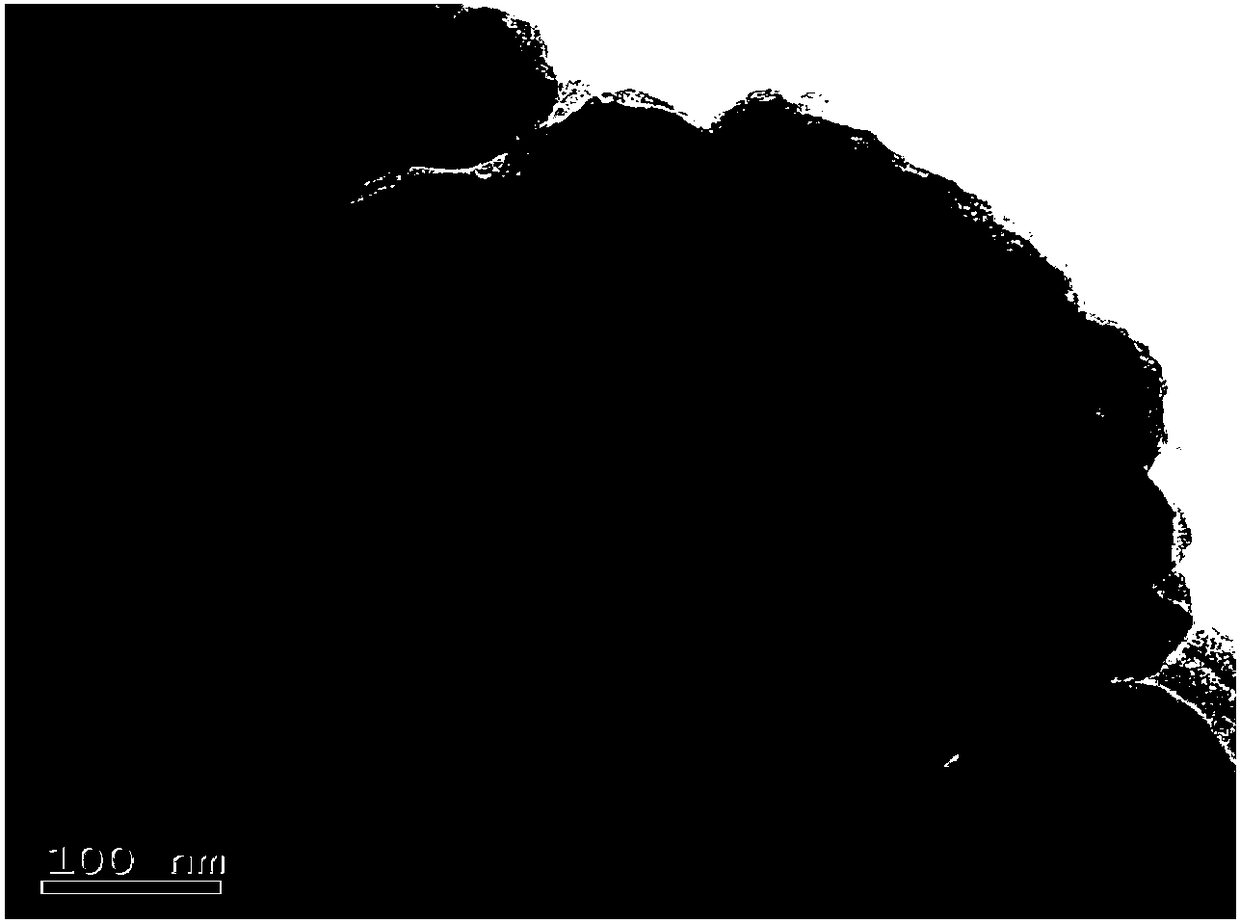

[0078] Step (3): the Na obtained in step (3) 2 Fe 2 (SO 4 ) 3 With 0.201g of aluminum isopropoxide, using acetone as the grinding medium, the ball-to-material ratio is 10:1, ball ...

Embodiment 2

[0084] This embodiment includes the following steps:

[0085] Step (1): This embodiment design generates 0.03mol target product Na 2 Fe 2 (SO 4 ) 3 @Alumina composite material, prepare 50mL of solution, weigh 0.03mol of sodium sulfate and 0.06mol of ferrous sulfate in 50mL of deionized water, stir to dissolve;

[0086] Step (2): Stir the solution treated in step (1) in an oil bath at 100°C until the solution is evaporated to dryness, and the obtained solid powder is Na 2 Fe 2 (SO 4 ) 3 precursor products;

[0087] Step (3): The obtained precursor solid phase product is mixed with hydrogen and argon (5% H 2 +95% Ar) under the protection of the atmosphere, the temperature was raised to 350 ° C, sintered for 24 hours, the heating rate was 5 ° C / min, and the product Na 2 Fe 2 (SO 4 ) 3 ;

[0088] Step (4): the Na obtained in step (3) 2 Fe2 ( SO 4 ) 3 With 0.201g of aluminum isopropoxide, using acetone as the grinding medium, the ball-to-material ratio is 10:1, b...

Embodiment 3

[0091] Step (1): This embodiment design generates 0.03mol target product Na 2 Fe 2 (SO 4 ) 3 @Alumina composite material, prepare 50mL of solution, weigh 0.03mol of sodium sulfate and 0.06mol of ferrous sulfate in 50mL of deionized water, stir to dissolve;

[0092] Step (2): Stir the solution treated in step (1) in an oil bath at 100°C until the solution is evaporated to dryness, and the obtained solid powder is Na 2 Fe 2 (SO 4 ) 3 precursor products;

[0093] Step (3): The obtained precursor solid phase product is mixed with hydrogen and argon (5% H 2 +95% Ar) under the protection of the atmosphere, the temperature was raised to 350 ° C, sintered for 24 hours, the heating rate was 5 ° C / min, and the product Na 2 Fe 2 (SO 4 ) 3 ;

[0094] Step (4): the Na obtained in step (3) 2 Fe 2 (SO 4 ) 3 With 0.268g of aluminum isopropoxide, using acetone as the grinding medium, the ball-to-material ratio is 10:1, ball milling for 6h, and drying the obtained powder in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com