Brazing type diamond grinding wheel used for high-precision grinding and manufacturing method

A diamond and grinding wheel technology, which is applied in the field of brazed diamond grinding wheel and its preparation, can solve the problems of low diamond holding force, poor chip removal, poor processing precision, electroplating solution, etc., and achieve energy saving and environmental protection in the preparation process, high service life, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

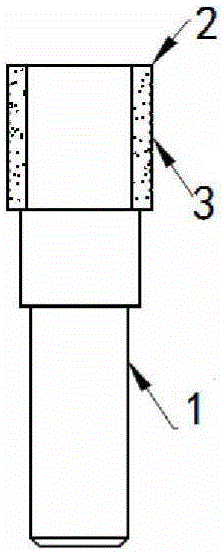

[0038] Embodiment 1: as figure 1 and figure 2 As shown, a brazed diamond grinding wheel for high-precision grinding has micro grooves 6 on the surface of the metal body, and the grooves 6 can be arranged in order or disorderly on the surface of the metal body.

[0039] Diamond abrasive grains: solder = 2:15, evenly mixed and wrapped on the metal body, after plastic treatment, multi-layer brazing of diamond abrasive grains is realized in a vacuum furnace at a temperature of 800-1100 °C.

[0040] After brazing, the workpiece is processed by electric machining or forming roller grinding to realize the machining of the outer circular groove and the later trimming.

[0041] Made of parallel grinding wheel, simple grinding wheel, single bevel grinding wheel, double bevel grinding wheel, cup grinding wheel, bowl grinding wheel, trapezoidal grinding wheel and cymbal grinding wheel.

[0042] The invention has the advantage that it can solve the problems of low holding force and easy...

Embodiment 2

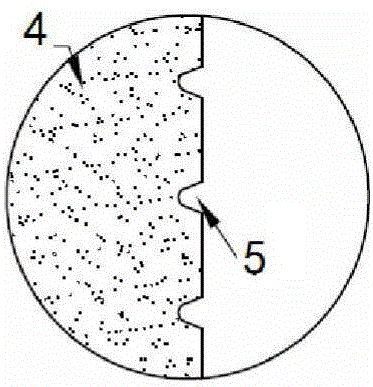

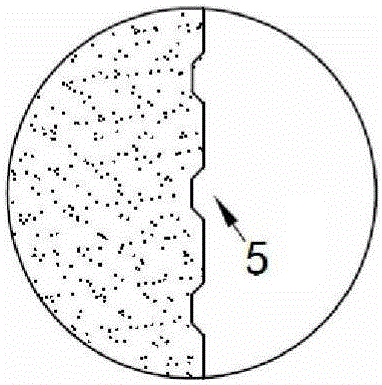

[0048] Embodiment 2: as figure 1 , figure 2 , image 3 Figure 4As shown, a brazed diamond grinding wheel for high-precision grinding is a grinding wheel with a handle, the metal body 1 is a handle type, and the upper part of the metal body 1 has a diamond brazing layer 2, and the diamond brazing layer 2 There are diamond abrasive grains 4, and there are micro grooves 6 on the surface of the metal body 1. The grooves 6 are arranged on the surface of the metal body 1 in an orderly or disorderly manner. The groove precision can be controlled within 0.01mm. There are diamond grooves in the groove 6. The brazing layer 2 and the groove 6 are rectangular, triangular, trapezoidal and arc-shaped; the outer surface of the grinding wheel 3 has a grinding groove 5, and the shape of the grinding groove 5 can be determined according to the requirements of the workpiece. The shape of the grinding groove 5 is rectangular, triangular, Trapezoidal and arc-shaped, the shape of the grinding ...

Embodiment 3

[0049] Embodiment 3: as Figure 5 and Figure 6 As shown, the structure is the same as that of Embodiment 1 and Embodiment 2. A brazed diamond grinding wheel for high-precision grinding has an outer circular, end-face, special-shaped, curved surface or cup-shaped structure; Wheels, Cup Grinding Wheels, Disc Grinding Wheels, Parallel Grinding Wheels, Simplified Grinding Wheels, Single Bevel Grinding Wheels, Double Bevel Grinding Wheels, Cup Grinding Wheels, Trapezoid Grinding Wheels and Cymbal Grinding Wheels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com