High-precision five-axle argon arc welding machine

A kind of argon arc welding machine, high-precision technology, applied in the direction of arc welding equipment, welding equipment, welding equipment, etc., can solve the problems of high scrap rate, extremely high requirements for workers' proficiency, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

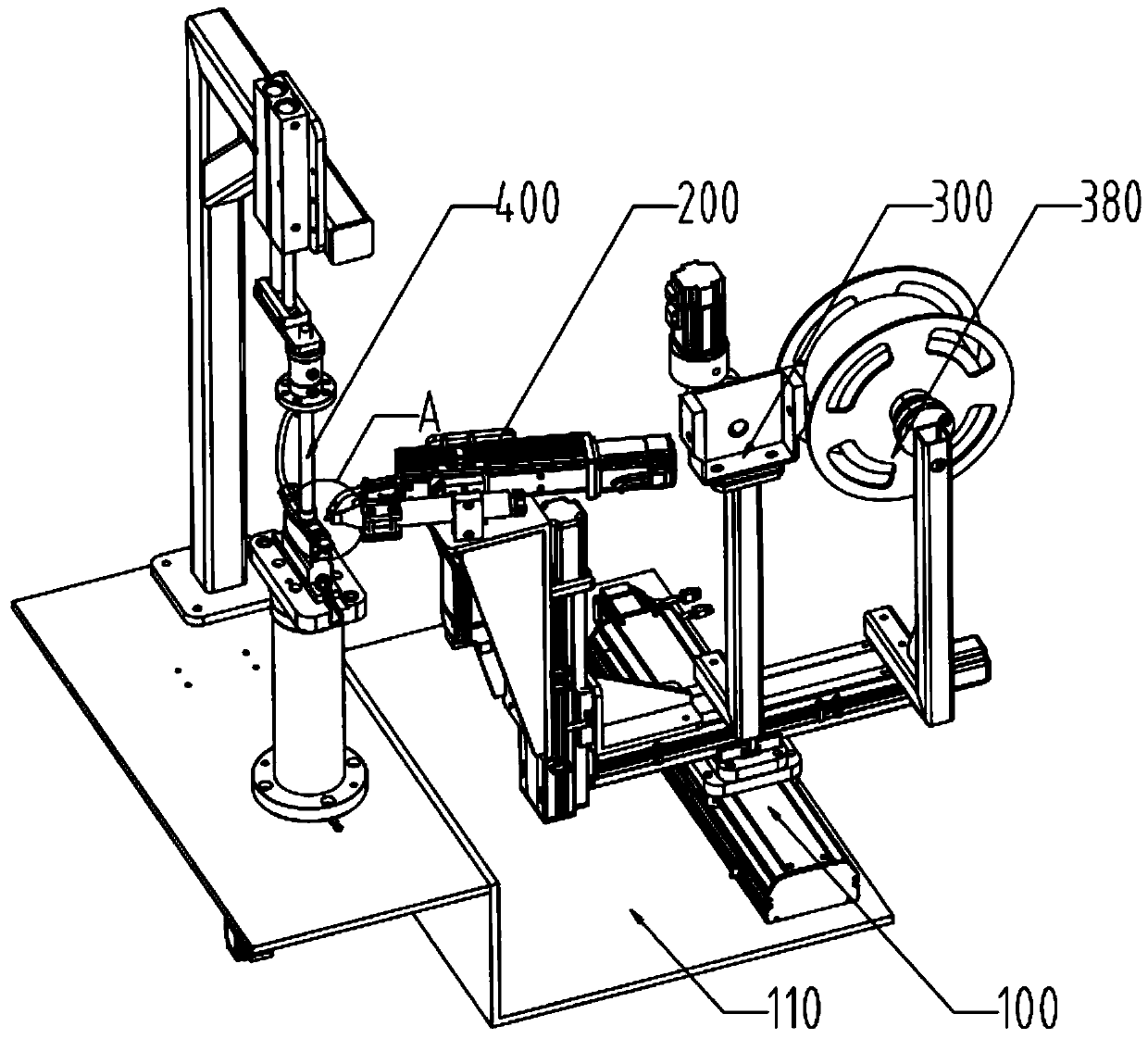

[0061] This embodiment provides a high-precision five-axis argon arc welding machine, which includes a four-axis coordinate assembly 100 , a welding torch assembly 200 , a wire filling assembly 300 , a tooling assembly 400 and an auxiliary assembly 500 .

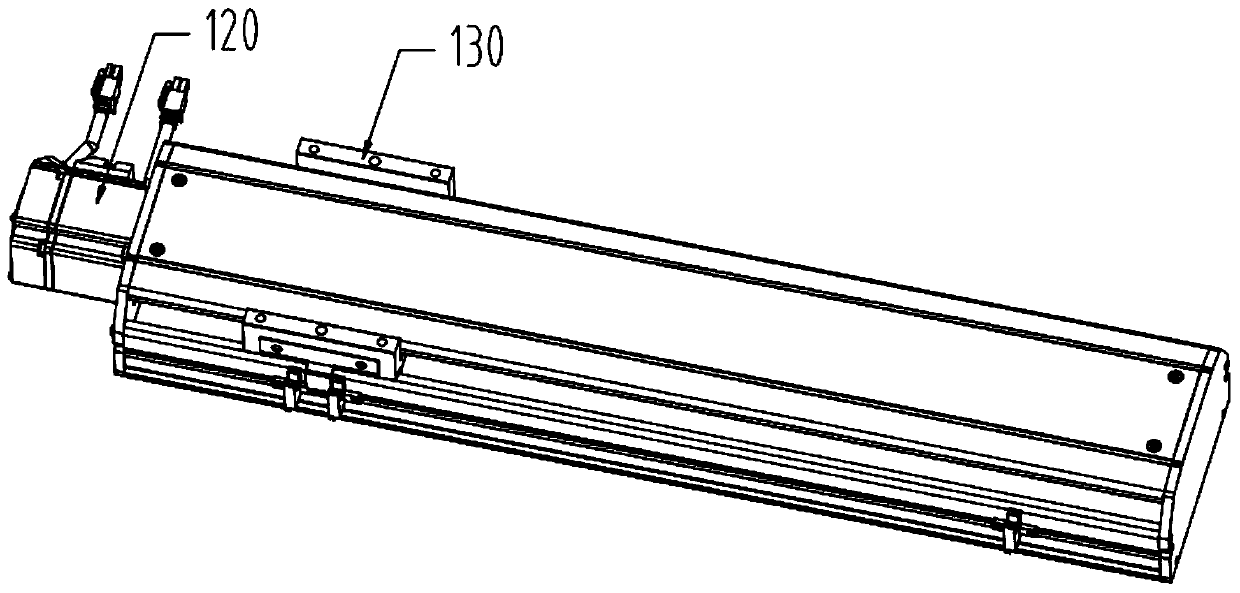

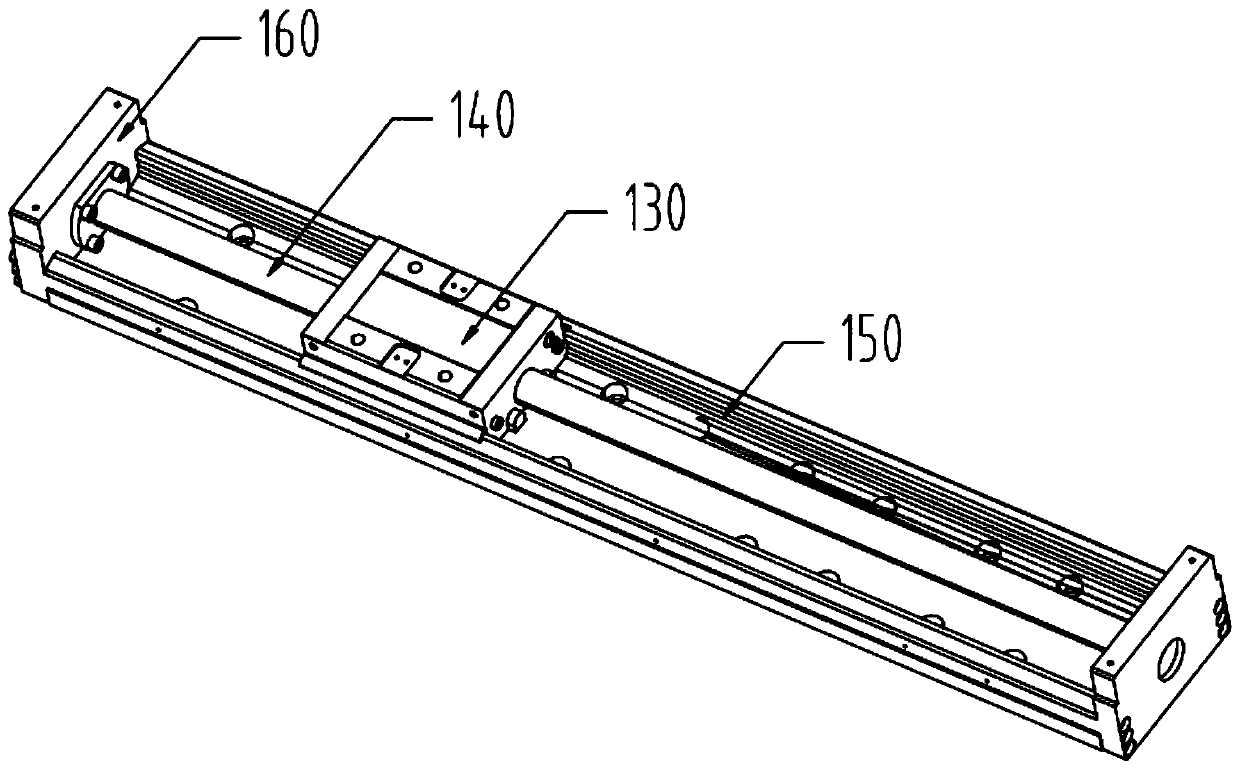

[0062] The four-axis coordinate assembly 100 includes a four-axis coordinate base 110, an A-axis rotation module, and a linear module. There are three linear modules, which are divided into an X-axis linear module, a Y-axis linear module, and a Z-axis linear module. mod. The X-axis linear module, the Y-axis linear module and the Z-axis linear module have the same configuration in structure, the plane where the X-axis and Y-axis linear modules are located is a horizontal plane, and the Z-axis linear module is vertically arranged , further, the radial direction of the X-axis linear module is the length direction of the weld and is fixedly connected to the four-axis coordinate base 110, the Y-axis linear module is slidingly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com