Process method for precisely machining piston rod part of aero-engine actuator cylinder

An aero-engine and precision machining technology, which is applied in the field of aero-engine actuators, can solve the problems of uneconomical further improvement of surface quality, residual processing lines on the surface of parts, wear of aprons and cylinders, etc., to improve the reliability of use and Effects of service life, improvement of surface quality, and improvement of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

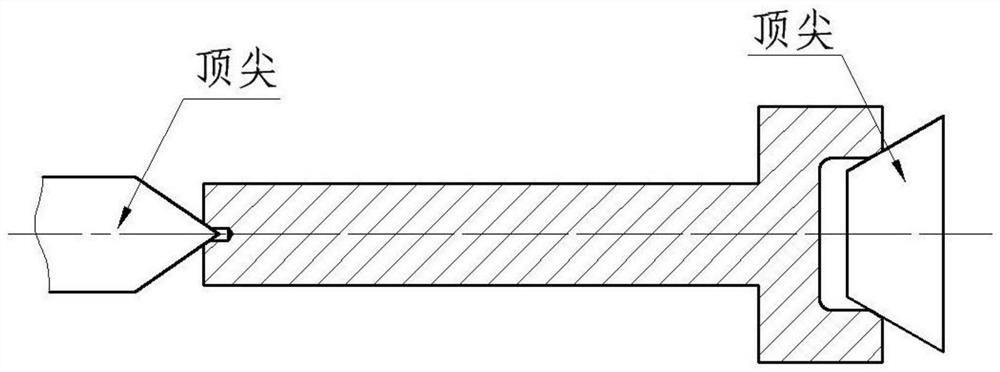

[0022] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 3 As shown, the present invention provides a process method for precision machining of the piston rod portion of an aero-engine cylinder, which is used for a lathe with Hawk energy processing equipment, comprising the following steps:

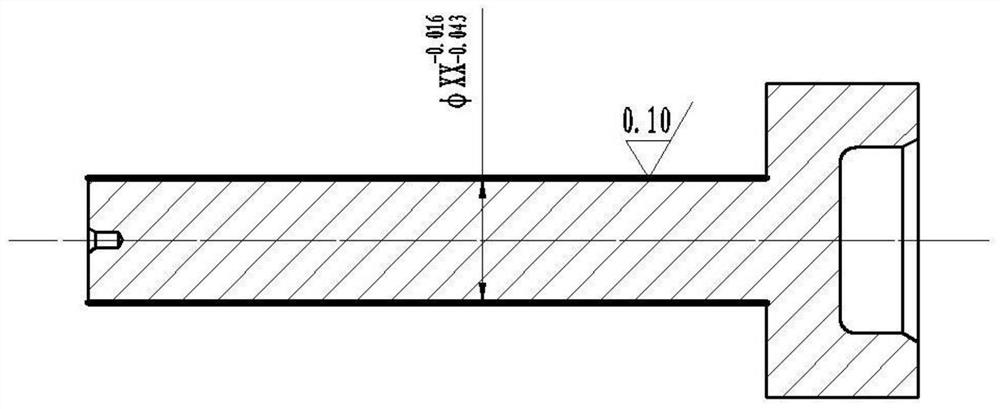

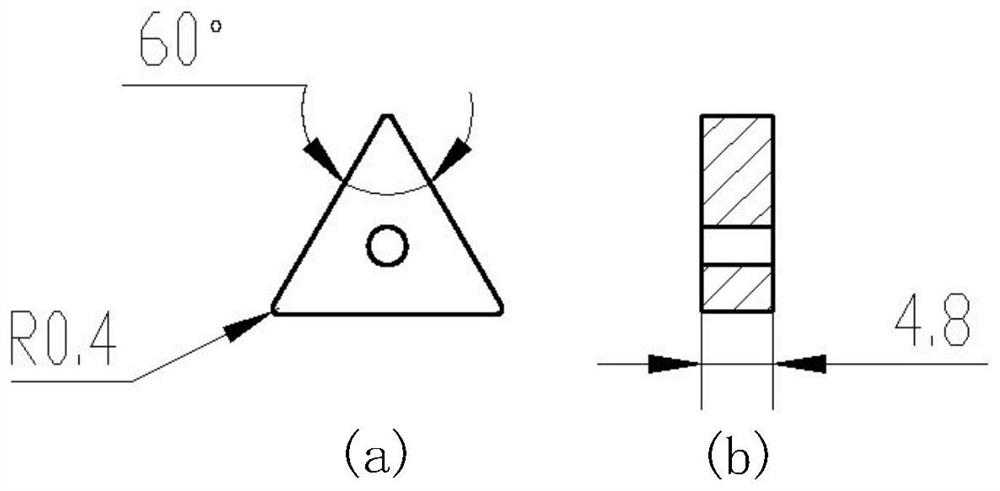

[0023] S1. Rough turning of the piston rod part, use the turning tool blade to process the outer circle of the piston rod part, and set the processing parameters of the lathe as follows: the spindle speed of the lathe is 1200r / min, the feed rate is 0.1mm / r, and the back cutting amount is 0.2mm; if figure 1 The structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com