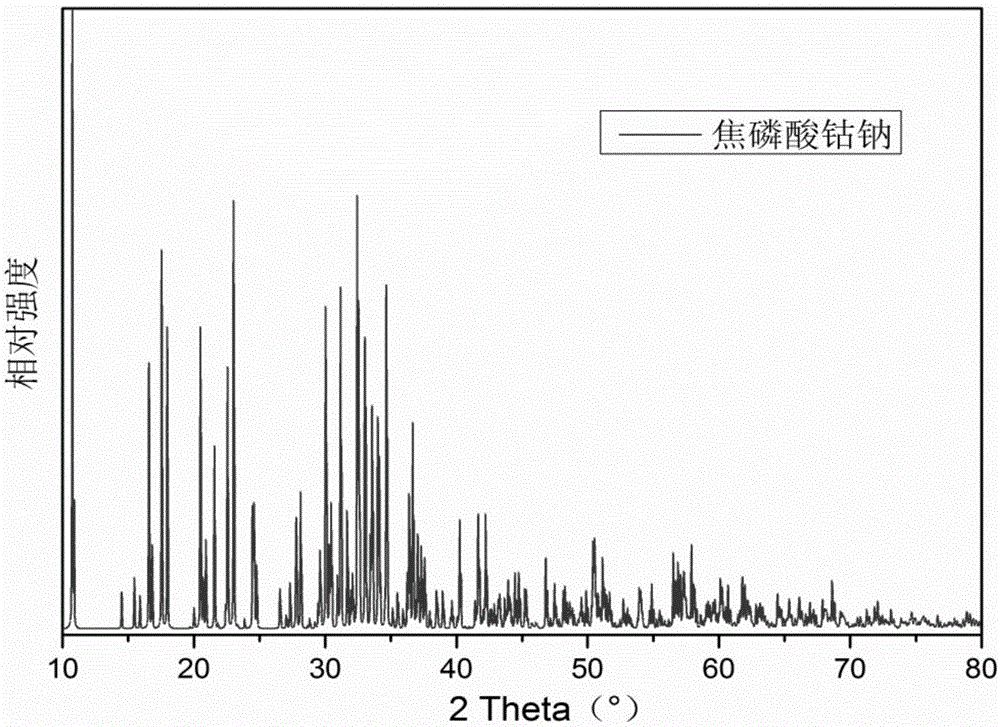

Preparation method of sodium cobalt pyrophosphate and application of sodium cobalt pyrophosphate to sodium ion battery

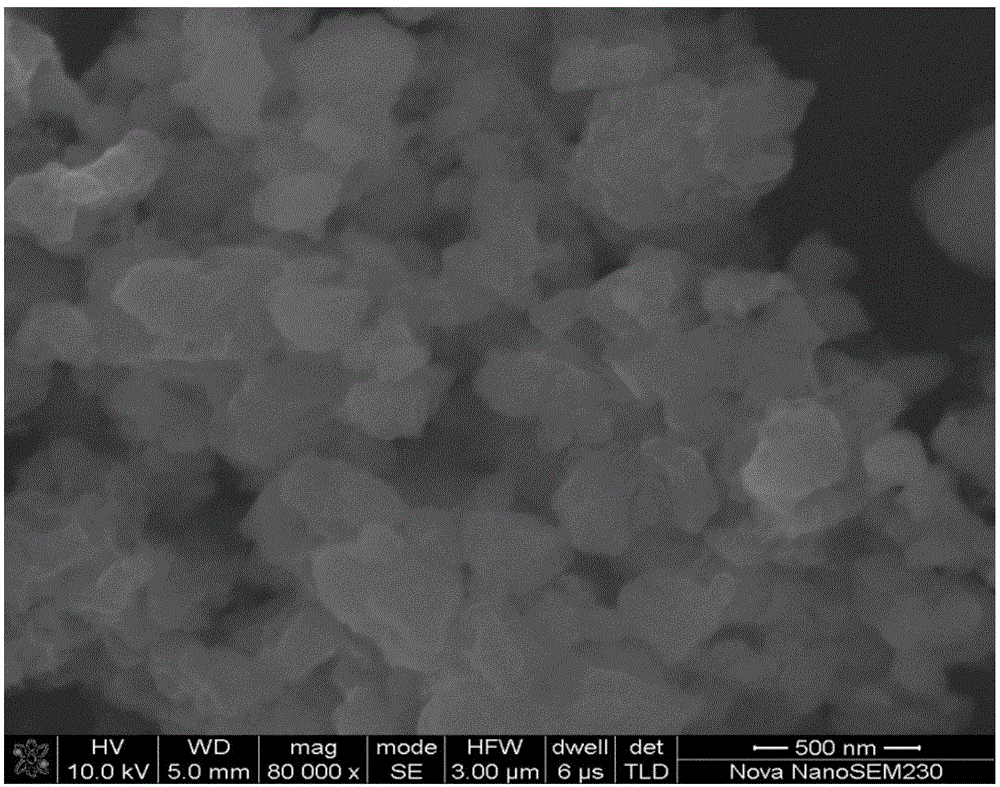

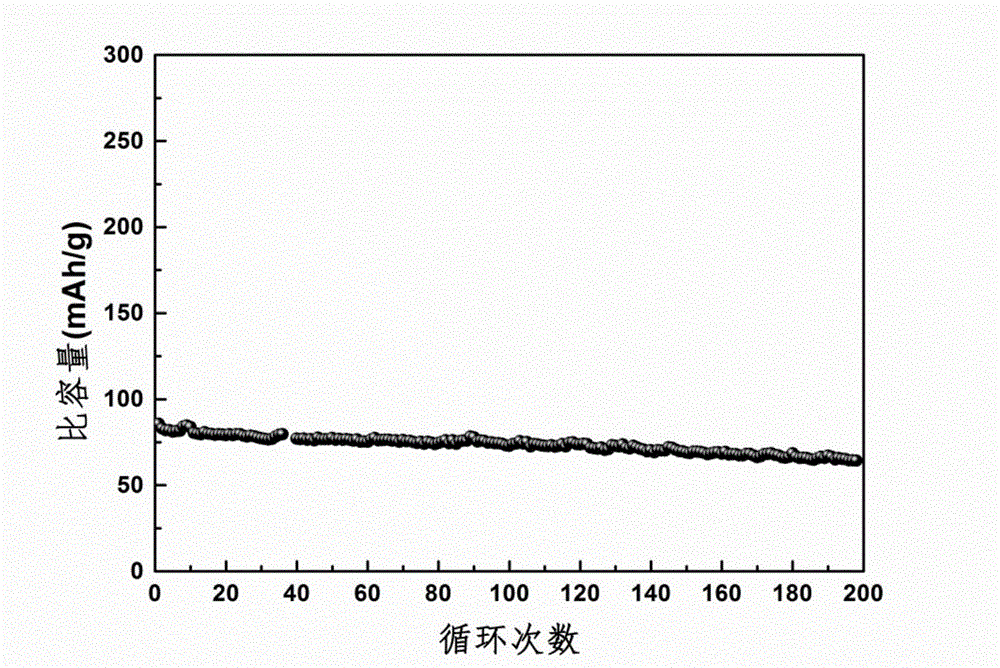

A technology of sodium cobalt pyrophosphate and hydrated cobalt pyrophosphate, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the difficulty in regulating the morphology and crystal phase of sodium cobalt pyrophosphate products, and it is difficult to obtain stable performance and high rate performance. Poor and other problems, to achieve the effect of excellent electrochemical performance, excellent electrochemical performance, uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The present embodiment is designed to generate 0.03mol target product sodium cobalt pyrophosphate, and cobalt chloride hexahydrate and potassium pyrophosphate are respectively prepared into a solution with a concentration of 0.5mol / L. Under stirring conditions, 60mL cobalt chloride solution is slowly Add 60 mL of potassium pyrophosphate solution, adjust the pH of the mixed solution to 3.5 with hydrochloric acid solution with a concentration of 1 mol / L, age at room temperature for 3 days, filter and dry to obtain cobalt pyrophosphate hexahydrate;

[0038](2) 0.0315mol sodium carbonate and the cobalt pyrophosphate hexahydrate obtained in the above steps are uniformly mixed by solid-phase ball milling to obtain the sodium cobalt pyrophosphate precursor;

[0039] (3) The precursor is placed in an argon atmosphere, heated to 650°C at a rate of 5°C / min for sintering for 3 hours, then cooled to 550°C for 1 hour at a rate of 2°C / min, and then sintered at 2°C / min The tempera...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] (1) This embodiment is designed to generate 0.03 mol of the target product sodium cobalt pyrophosphate, cobalt chloride hexahydrate and potassium pyrophosphate are respectively prepared into a solution with a concentration of 1 mol / L, and 30 mL of cobalt chloride solution is slowly added under stirring conditions 30mL of potassium pyrophosphate solution, the obtained mixed solution was adjusted to pH 3 with hydrochloric acid solution with a concentration of 1mol / L, aged at room temperature for 4 days, filtered and dried to obtain cobalt pyrophosphate hexahydrate;

[0047] (2) 0.0315mol sodium carbonate and the cobalt pyrophosphate hexahydrate obtained in the above steps are uniformly mixed by solid-phase ball milling to obtain the sodium cobalt pyrophosphate precursor;

[0048] (3) The precursor is placed in an argon atmosphere, heated to 620°C for 3 hours at a rate of 7°C / min for sintering, then cooled to 550°C for...

Embodiment 3

[0051] This embodiment includes the following steps:

[0052] (1) The present embodiment is designed to generate 0.03mol target product sodium cobalt pyrophosphate, and cobalt chloride hexahydrate and potassium pyrophosphate are respectively prepared into a solution with a concentration of 0.5mol / L. Under stirring conditions, 60mL cobalt chloride solution is slowly Add 60 mL of potassium pyrophosphate solution, adjust the pH of the mixed solution to 3.5 with hydrochloric acid solution with a concentration of 1 mol / L, age at room temperature for 3 days, filter and dry to obtain cobalt pyrophosphate hexahydrate;

[0053] (2) 0.03mol sodium carbonate and the cobalt pyrophosphate hexahydrate obtained in the above steps are uniformly mixed by solid-phase ball milling to obtain the sodium cobalt pyrophosphate precursor;

[0054] (3) The precursor is placed in an argon atmosphere, heated to 680°C at a rate of 5°C / min for sintering for 3 hours, then cooled to 550°C for 1 hour at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com