Patents

Literature

51 results about "Iron pyrophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric Pyrophosphate. In the US, Ferric Pyrophosphate (ferric pyrophosphate systemic) is a member of the drug class iron products and is used to treat Anemia Associated with Chronic Renal Failure.

Fire retardant compositions with reduced aluminum corrosivity

InactiveUS6905639B2Reduced-tendency to corrode various metalBroaden applicationFireproof paintsAntifouling/underwater paintsBiopolymerFerrous Gluconate

Corrosion-inhibited fire retardant compositions and methods of making and using the same are provided. The corrosion-inhibited fire retardant compositions are comprised of at least one fire retardant component, at least one biopolymer having a particle size diameter of less than about 100 microns, and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group of compounds including azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, soluble ferric orthophosphate, insoluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxide, ferric lactate, ferric resinate and any combination thereof. In a specific embodiment, the corrosion-inhibited fire retardant composition includes a xanthan biopolymer.

Owner:PERIMETER SOLUTIONS LP

Mixture of iron and copper salts masking metallic taste

A composition comprising iron pyrophosphate and copper citrate does not exhibit the unpleasant taste and aftertaste usually found with iron supplements.

Owner:BAYER CONSUMER CARE

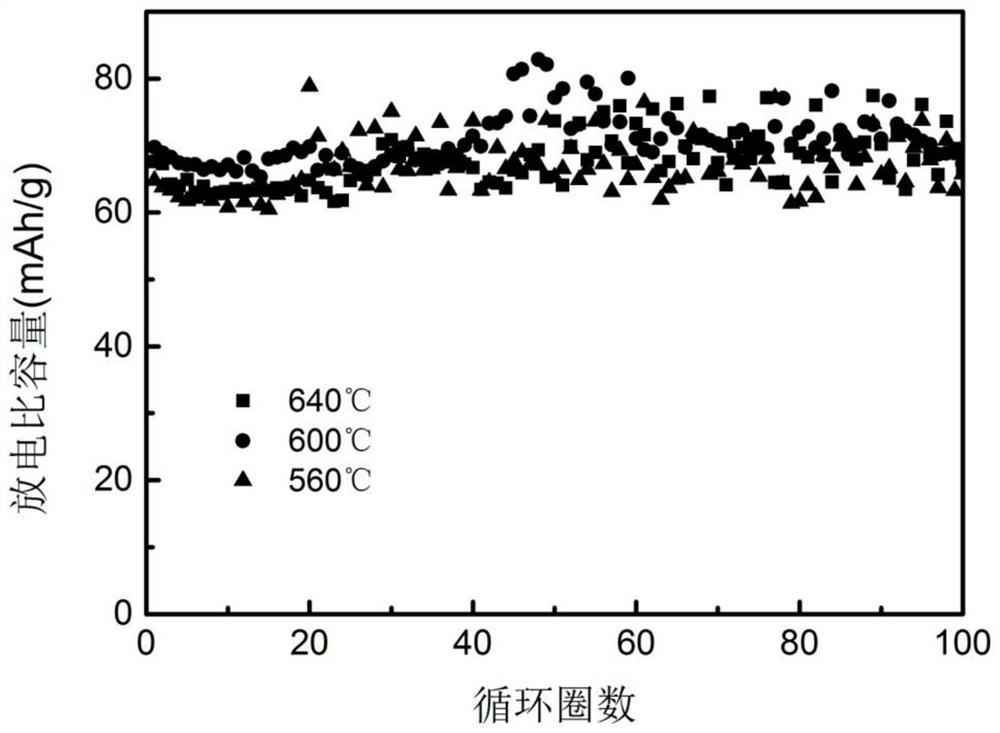

Method for preparing lithium iron pyrophosphate used as positive material for lithium ion battery

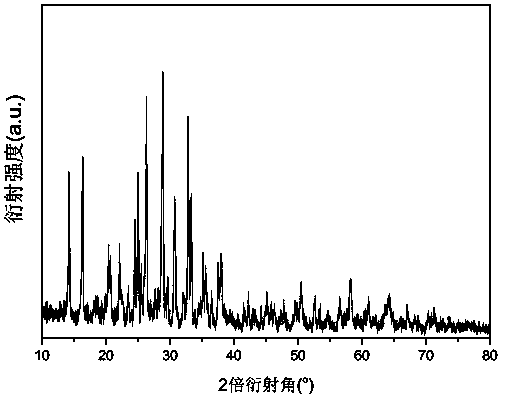

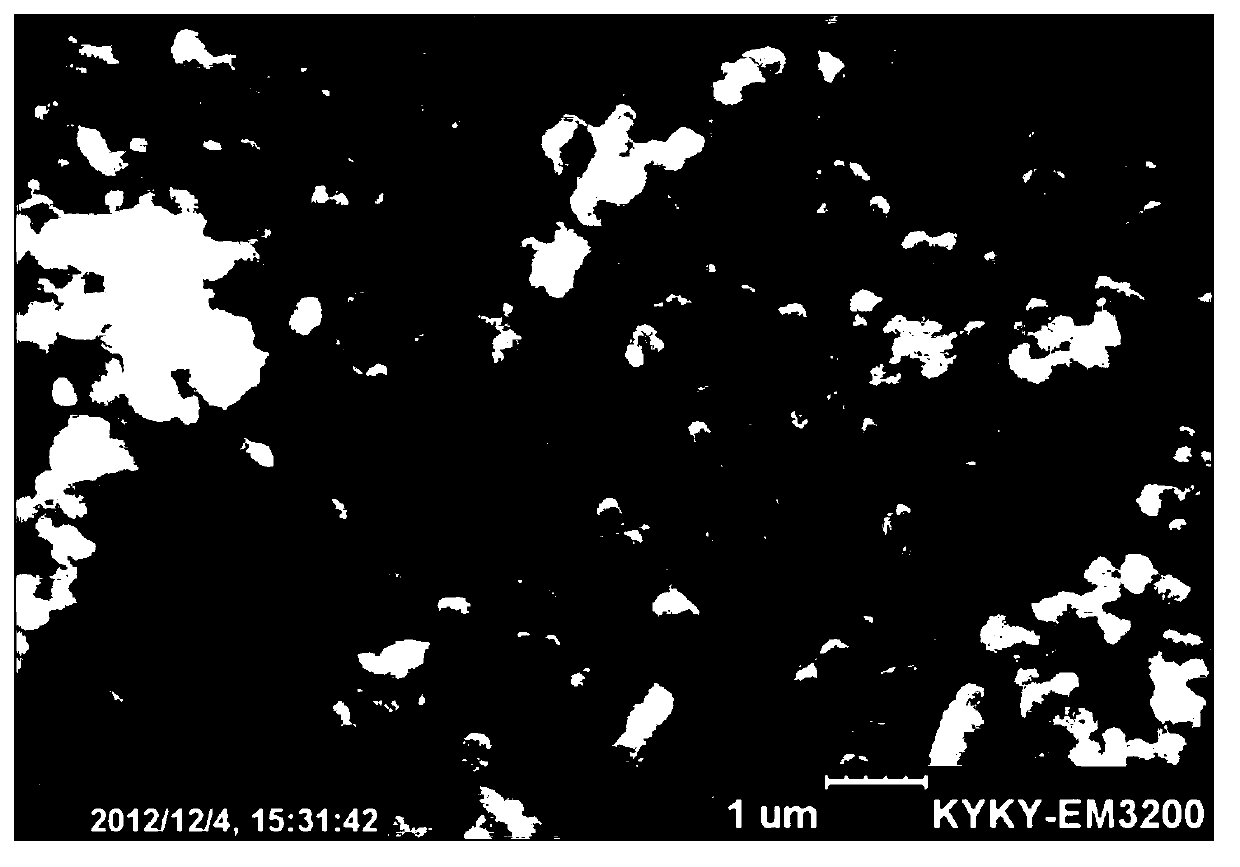

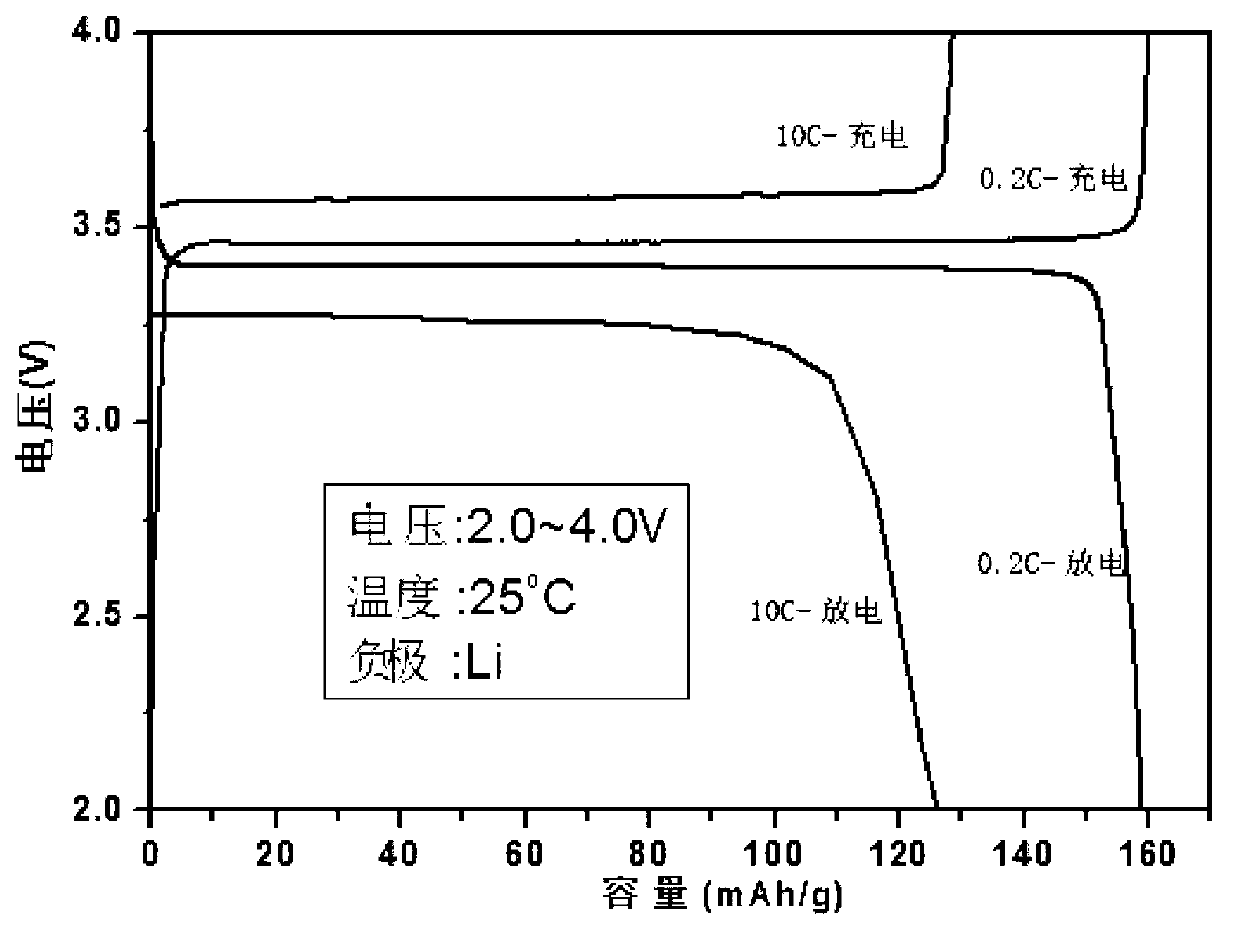

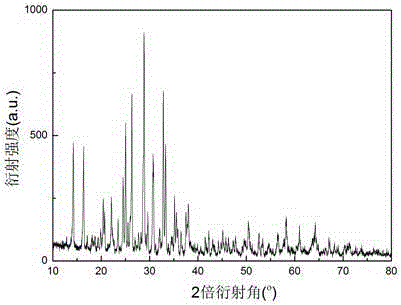

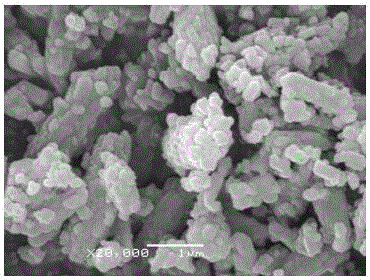

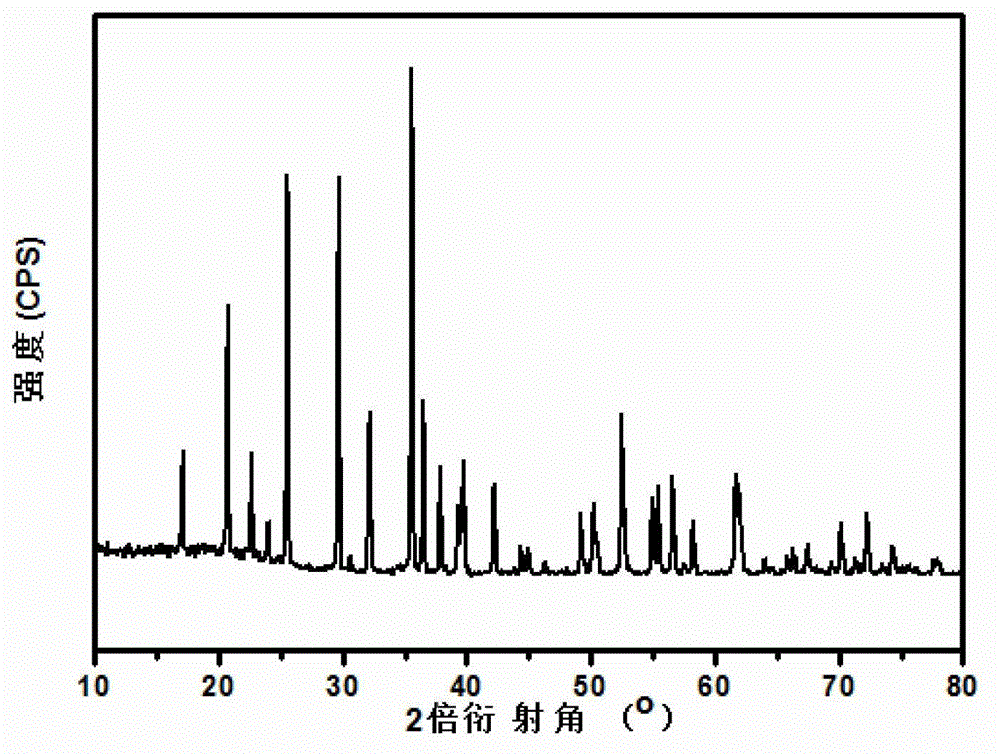

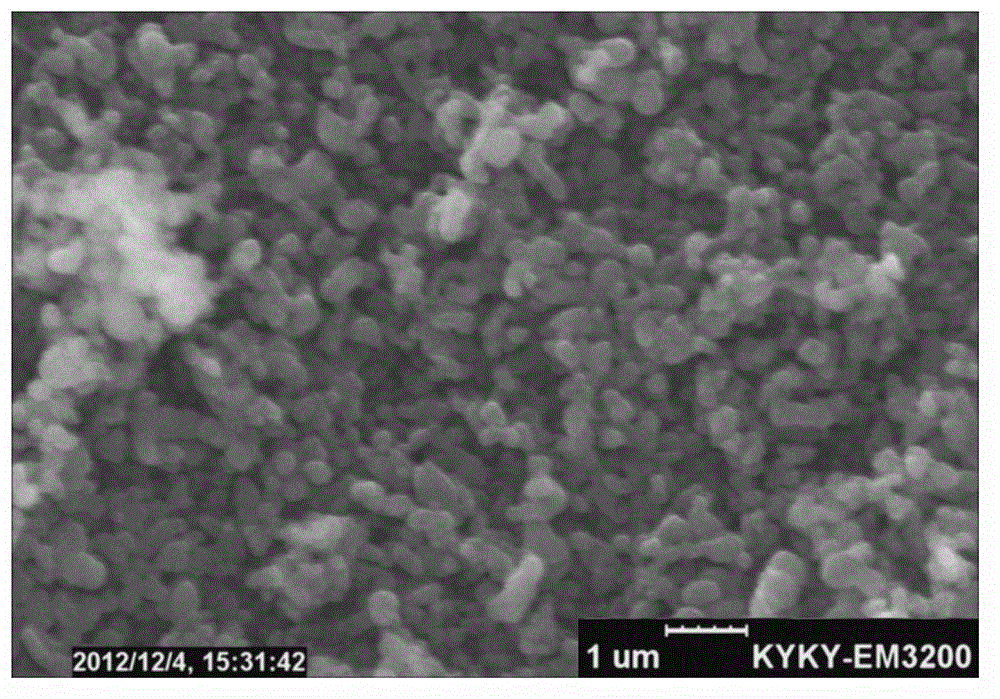

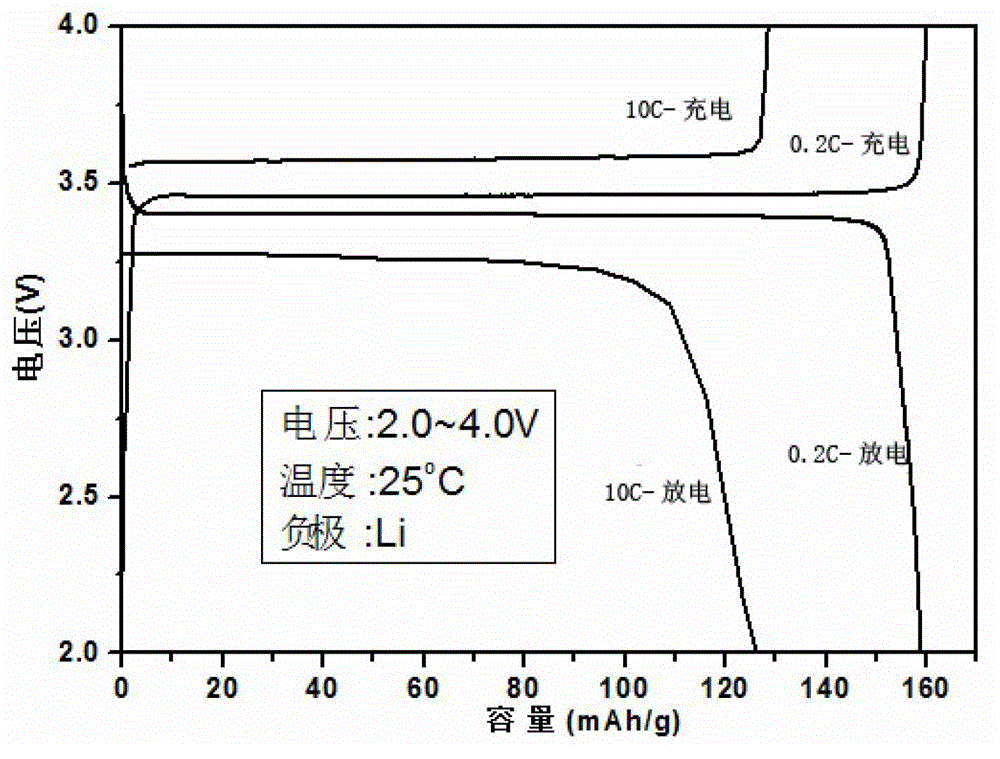

ActiveCN103825026AWide variety of sourcesBroad mixCell electrodesPhosphorus compoundsHYDROSOLCrystallinity

The invention relates to a method for preparing lithium iron pyrophosphate used as a positive material for a lithium ion battery. The method comprises the following steps: mixing a lithium source compound, an iron source compound, a phosphorus source compound and a chelating agent, used as raw materials, dissolving into water, and stirring at room temperature for 0.5-2h to obtain sol; heating to be at 50-100 DEG C and keeping the temperature for 2-10h to form gel; drying the gel in a vacuum drying oven at 100-120 DEG C to obtain dried gel; ball-milling the dried gel for 1-4h, grinding uniformly, sintering at 500-700 DEG C for 2-16h in protective atmosphere, and naturally cooling to be at room temperature to obtain the lithium iron pyrophosphate. The prepared lithium iron pyrophosphate particles are uniform, have high crystallinity degree and good dispersibility; the battery manufactured by the lithium iron pyrophosphate has high charging and discharging capacity and charging platform and good cycle life, and can meet various requirements of the lithium ion battery in practical application.

Owner:CENT SOUTH UNIV

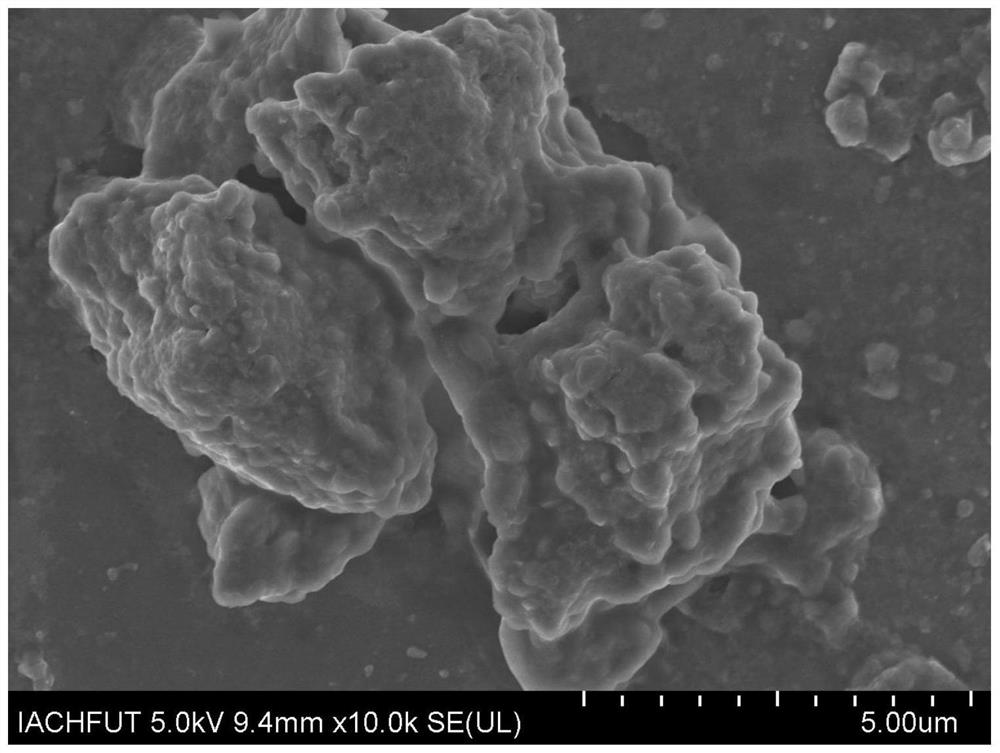

LFP (lithium iron phosphate) positive electrode material with excellent low-temperature property and preparation method thereof

ActiveCN103107332AImprove ionic conductivityAvoid conductive propertiesCell electrodesPhosphorus compoundsCarbon layerLithium iron phosphate

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

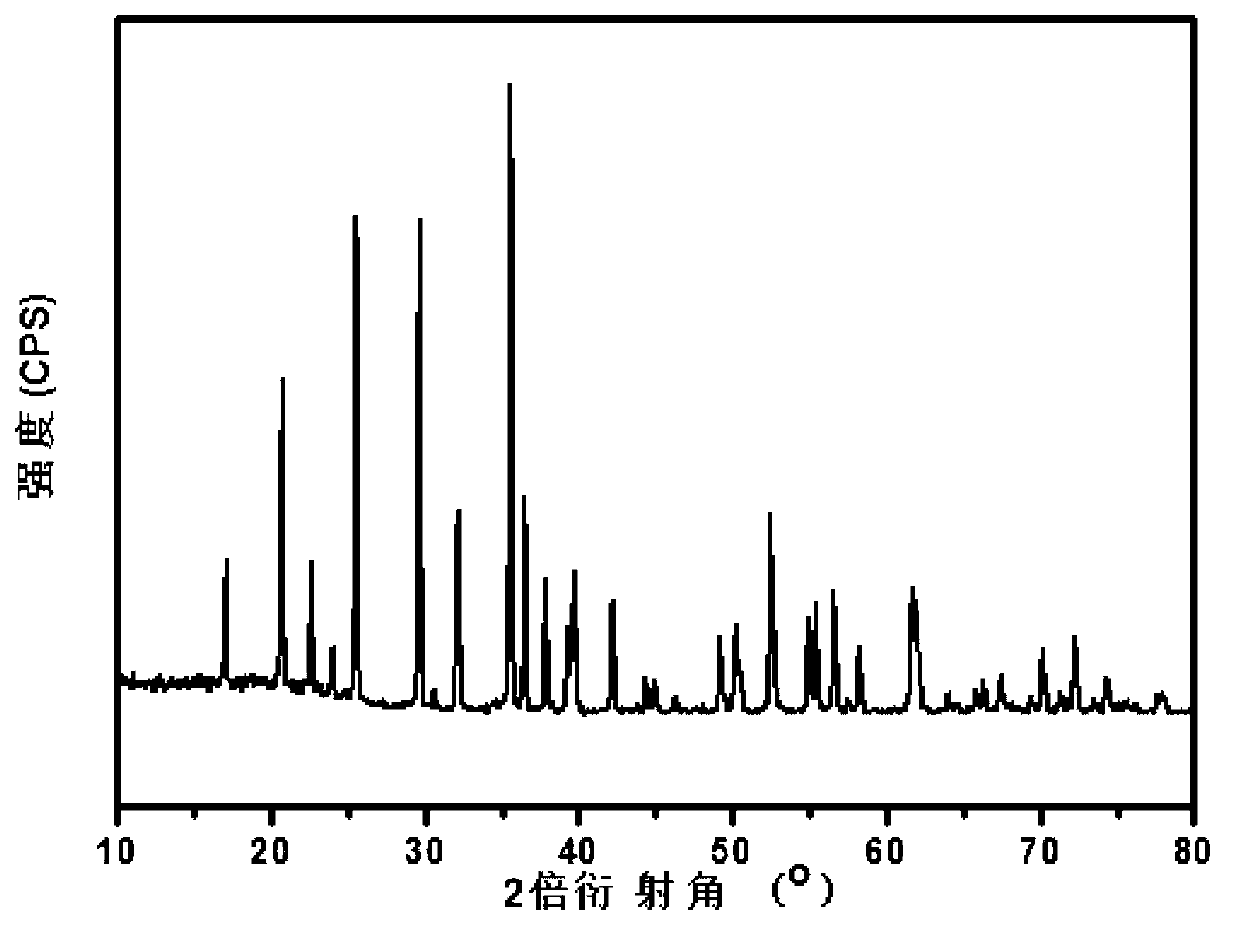

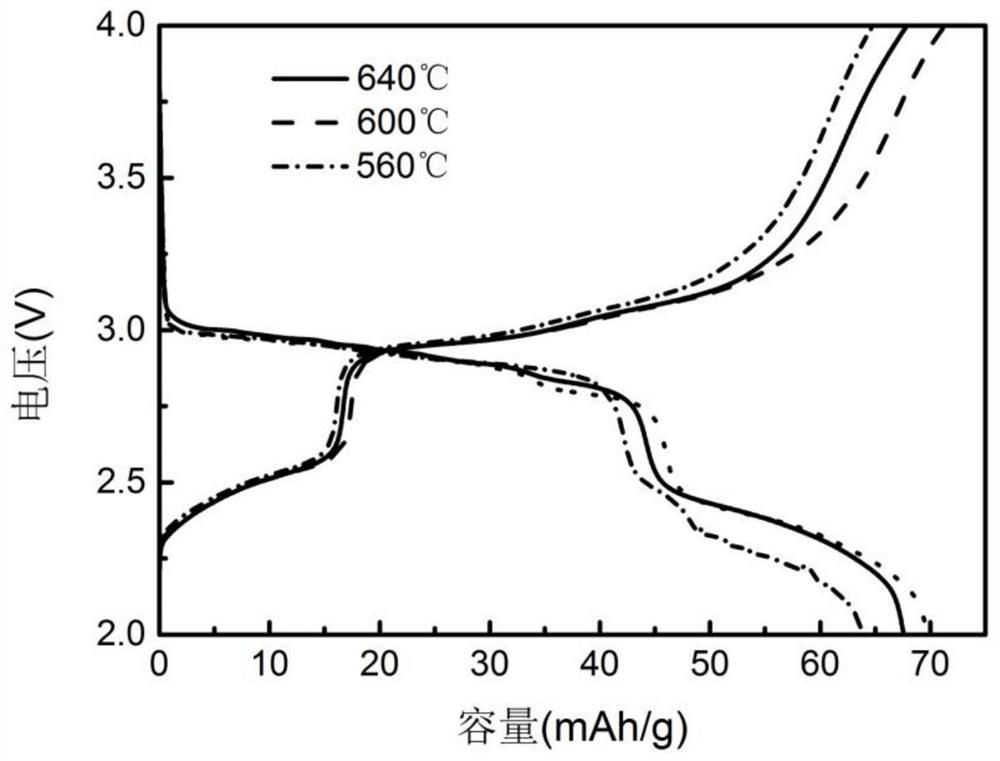

Sodium fluoride impregnated and coated vanadium-doped porous structure sodium ferric pyrophosphate positive electrode material and preparation method thereof

InactiveCN112909232AImprove stabilityPromote circulationSecondary cellsPositive electrodesVanadium dopingPhysical chemistry

The invention discloses a sodium fluoride impregnated and coated vanadium-doped porous structure sodium ferric pyrophosphate positive electrode material and a preparation method thereof, the positive electrode material is obtained by impregnating and coating sodium fluoride on the surface of sodium ferric pyrophosphate doped with vanadium in situ, and the structural general formula is NaF (at) Na2Fe1-1.5 xVxP2O7. The Na2FeP2O7 material is coated with a proper amount of sodium fluoride and doped with a proper amount of vanadium, so that the crystal structure of the ferric sodium pyrophosphate with a triclinic crystal structure can keep high stability in the process of embedding and de-embedding sodium ions, and the material has excellent cycle performance and good coulombic efficiency; sharp reduction of circulation caused by structure collapse after sodion deintercalation is effectively avoided,the stability of the material is improved, the conductivity is improved to a certain extent, thereby being beneficial to improving the electrochemical performance of the material.

Owner:HEFEI UNIV OF TECH

Method for preparing lithium iron phosphate and lithium iron pyrophosphate by taking mineral leaching tail liquor as iron source

InactiveCN104555974ARealize resource utilizationWide variety of sourcesPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a method for preparing lithium iron phosphate and lithium iron pyrophosphate by taking mineral leaching tail liquor as an iron source. The method comprises the following steps: spraying a phosphate or pyrophosphate solution into the mineral leaching tail liquor, adding an organic flocculant after complete precipitation, and dehydrating and drying the precipitate to obtain ferric phosphate or ferric pyrophosphate; uniformly mixing ferric phosphate with lithium formate, or lithium acetate, or lithium oxalate, grinding the mixture, heating the ground mixture in a protective atmosphere, and cooling to obtain lithium iron phosphate or lithium iron pyrophosphate; and uniformly mixing ferric pyrophosphate with sodium pyrophosphate and lithium formate, or lithium acetate, or lithium oxalate, grinding the mixture, drying the ground mixture in a drying oven, heating the dried mixture in a protective atmosphere, cooling to the room temperature, leaching, and drying to obtain lithium iron pyrophosphate. The method realizes recycling of dissolved iron while achieving harmless disposal of mineral leaching tail liquor, and the prepared lithium iron phosphate and lithium iron pyrophosphate are easy for precipitation and recovery, are materials for manufacturing zincodes, are not cheap and have a wide market prospect.

Owner:ZHEJIANG UNIV

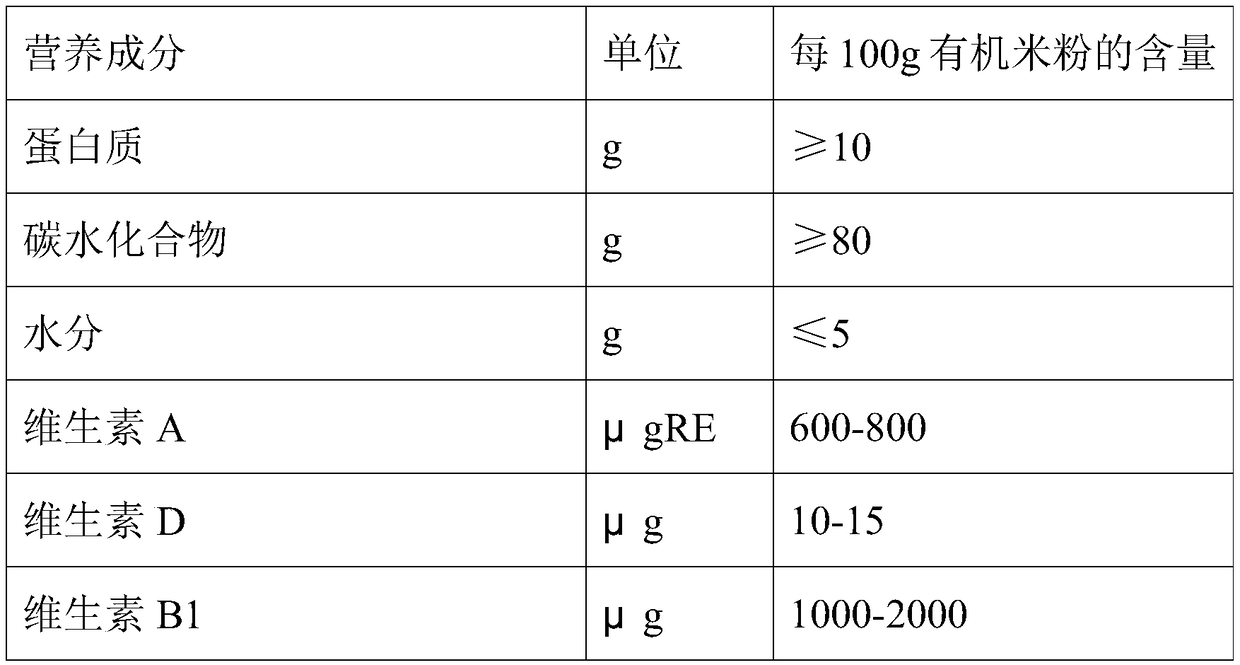

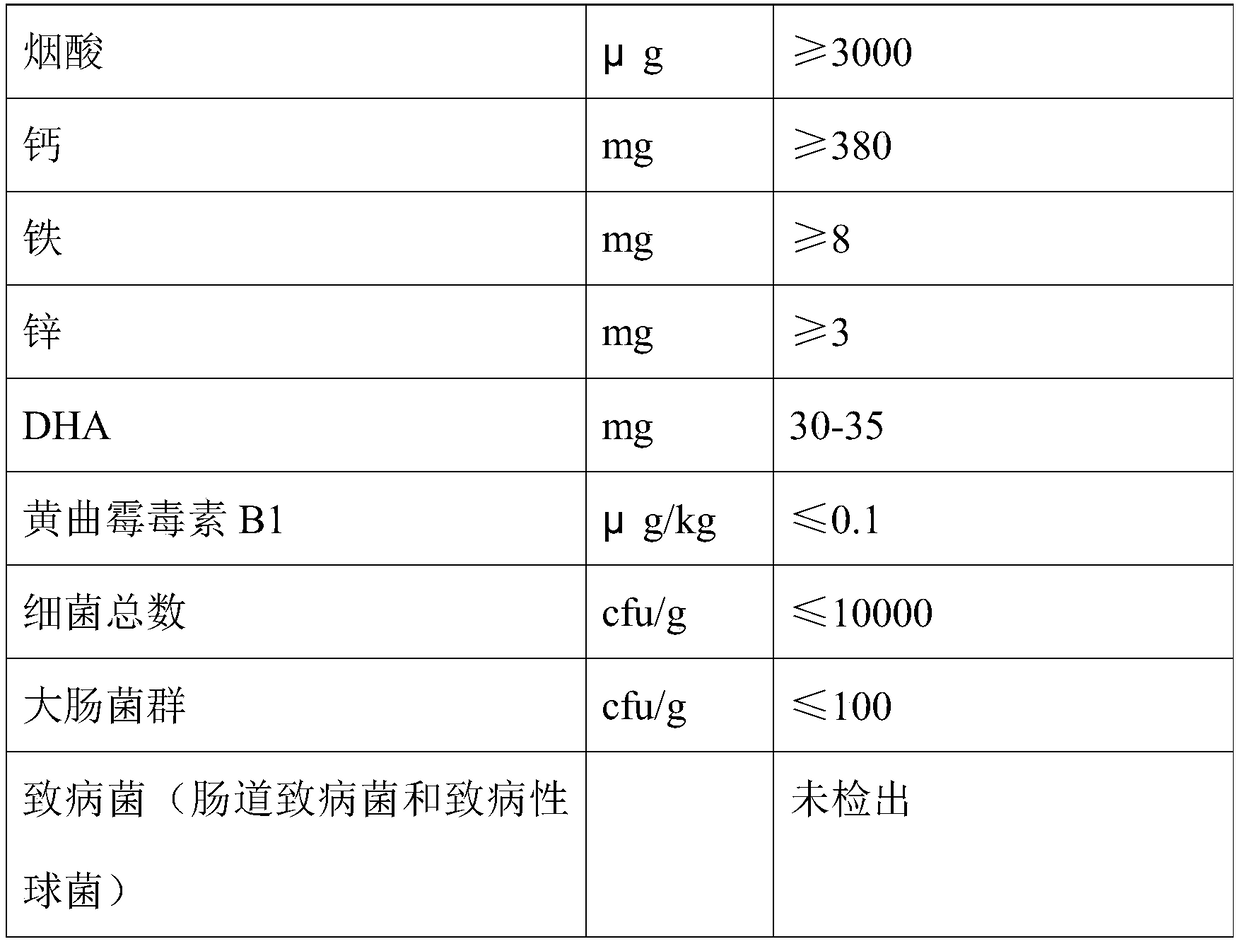

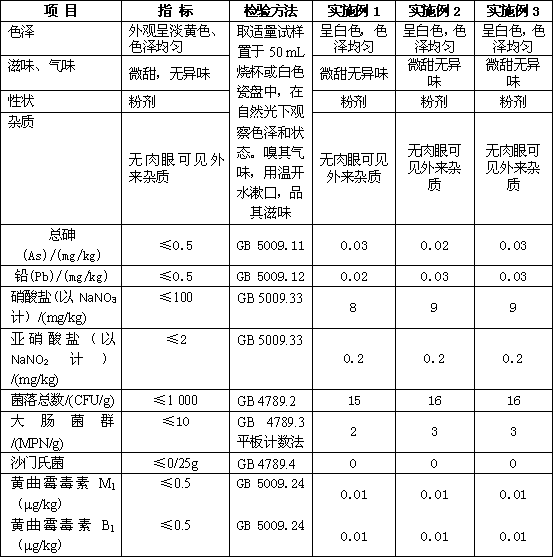

DHA calcium-iron-zinc nutritional organic rice flour used for infants and capable of promoting intelligence development

InactiveCN109105737AChanging the mononutrient structureFull of nutritionLactobacillusBifidobacteriumAdditive ingredientGluconic acid

Owner:安徽金源药业有限公司

Electric calcination furnace and application of electric calcination furnace in preparing industrial-grade phosphoric acid

ActiveCN103274378AReduce energy consumptionSimple processChemical industryPhosphoric acidHydrogen fluorideO-Phosphoric Acid

Owner:SICHUAN SHANGZHOU IND

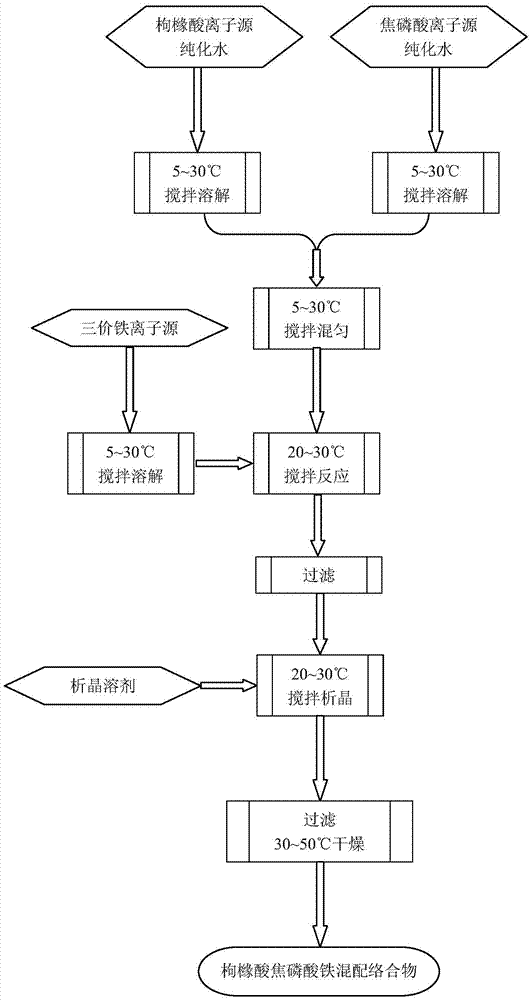

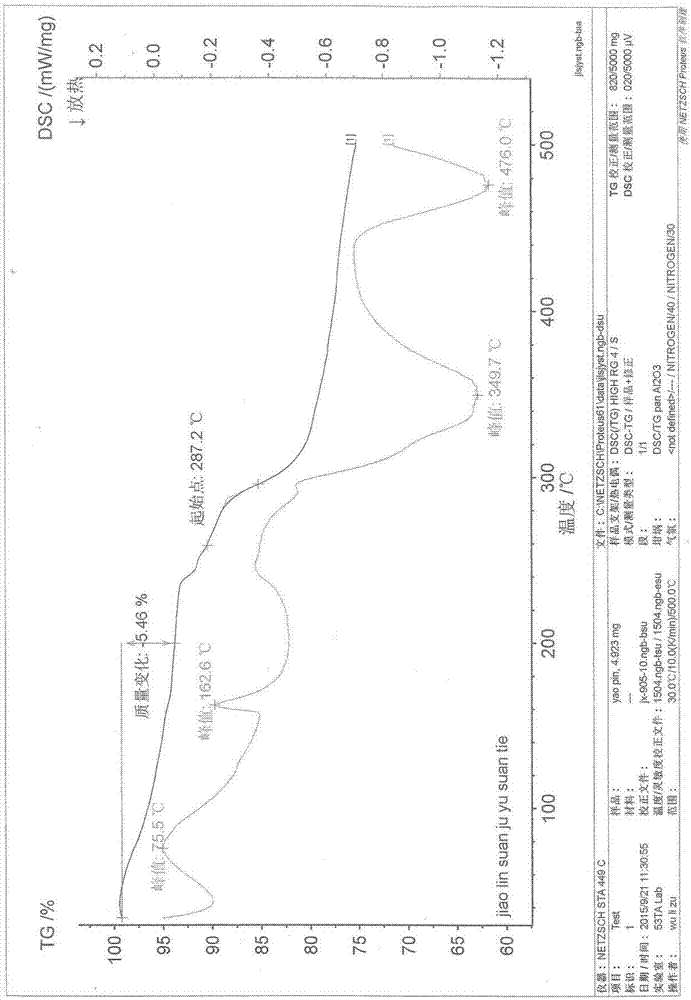

Ferric pyrophosphate citrate mixed complex preparation method

ActiveCN106977552AAvoid decompositionAvoid destructionIron organic compoundsPhosphateIron pyrophosphate

The invention discloses a ferric pyrophosphate citrate mixed complex preparation method, which comprises: (1) preparing an aqueous solution containing trivalent iron cations; (2) respectively preparing an aqueous solution containing citric acid anions and an aqueous solution containing pyrophosphoric acid anions, slowly adding the aqueous solution containing pyrophosphoric acid anions into the aqueous solution containing citric acid anions in a dropwise manner, and uniformly stirring and mixing to obtain a mixed aqueous solution; (3) slowly adding the aqueous solution prepared in the step (1) into the mixed aqueous solution prepared in the step (2) while stirring, carrying out a stirring reaction for 1-2 h after completing the adding to obtain a dark green solution, filtering out insoluble matters, and taking the filtrate; and (4) adding the filtrate obtained in the step (3) into a crystallization solvent in a dropwise manner, continuously stirring for 1-2 h after completing the adding to obtain a slight green precipitate, filtering, and drying the obtained solid so as to obtain the ferric pyrophosphate citrate mixed complex. According to the present invention, with the preparation method, the high-yield phosphate-radical-free ferric pyrophosphate citrate having the low organic impurity content can be stably obtained.

Owner:SHANDONG CHENGCHUANG BLUE OCEAN PHARM TECH CO LTD

Ceramic dielectric material with large sintering shrinking percentage

The invention discloses a ceramic dielectric material with a large sintering shrinking percentage. The ceramic dielectric material is characterized by comprising, by weight, 11-36 parts of ferric sodium pyrophosphate, 20-34.6 parts of sodium carbonate, 1-19 parts of borax, 10-31 parts of zirconium dioxide, 5-19 parts of chromic oxide, 24-69 parts of magnesite, 12.4-35.8 parts of magnesium oxide, 21-38 parts of kaolin, 14-79 parts of chinastone, 2-18 parts of ferric oxide, 0-27 parts of sericite, 10-34 parts of aluminum oxide and 2-17 parts of butyl rubber. The ceramic dielectric material is low in sintering temperature, high in dielectric constant, low in dielectric loss, wide in sintering shrinking percentage range and capable of cofiring with a silver inner electrode with high conductivity.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

High-temperature-resistant and corrosion-resistant paint for instrument shell, and preparation method thereof

InactiveCN104449196AImprove corrosion resistanceImprove high temperature resistanceRosin coatingsAnti-corrosive paintsButenedioic acidFumed silica

The invention discloses a high-temperature-resistant and corrosion-resistant paint. The high-temperature-resistant and corrosion-resistant paint is characterized by comprising the following raw materials in parts by weight: 30 to 35 parts of cyanamide resin, 1 to 2 parts of ferric pyrophosphate, 5 to 6 parts of iron oxide red, 2 to 4 parts of glycolic acid, 3 to 5 parts of glass flake, 5 to 8 parts of polycarbonate, 3 to 5 parts of silicon-aluminum oxide powder, 2 to 3 parts of epoxidized soybean oil, 12 to 16 parts of rosin cis-butenedioic acid glyceride, 1 to 2 parts of coconut oil diethanolamine, 0.5 to 1.0 part of ozocerite oxide, 0.5 to 1.0 part of dicumyl peroxide, 0.5 to 0.7 part of fumed silica, 3 to 4 parts of aluminum dihydrogen tripolyphosphate, 2 to 4 parts of quartz powder, 7 to 9 parts of acetone, 12 to 16 parts of butyl acetate and 4 to 7 parts of an additive. Aluminum dihydrogen tripolyphosphate added into the paint disclosed by the invention has high corrosion resistance and high high-temperature resistance; the glass flake serving as a filler is added into the paint, so that the paint has high chemical resistance, high anti-aging resistance, high cohesiveness and high corrosion resistance; the added additive promotes the uniform dispersion of the filler in the paint; moreover, damping and noise reducing functions to some extent are also realized, and the damage of noises to human bodies is weakened.

Owner:王小波

Total-nutrient meal replacement powder containing secoisolariciresinol diglucoside and preparation method of total-nutrient meal replacement powder

InactiveCN111671077AImprove non-specific immunityPrevent diabetesFood scienceBiotechnologyPolygonum fagopyrum

The present invention relates to the field of food processing. Total-nutrient meal replacement powder containing secoisolariciresinol diglucoside comprises the following raw materials in parts by weight: secoisolariciresinol diglucoside, oat, quinoa, buckwheat, barley, black rice, millet, red beans, white kidney beans, chickpeas, mung beans, konjac gum, resistant dextrin, soy protein powder, soy peptides, wolfberry powder, flaxseed microcapsule powder, medium chain fatty acid powder, erythritol, stevioside, silicon dioxide, Vitamin A, Vitamin E, Vitamin B1, Vitamin B2, Vitamin B6, folic Acid,Vitamin C, niacin, pantothenic acid, calcium ascorbate, zinc gluconate, iron pyrophosphate and magnesium gluconate. The prepared total-nutrient meal replacement powder containing the secoisolariciresinol diglucoside has the effects of anti-tumor and increasing satiety.

Owner:宁夏君星坊食品科技有限公司

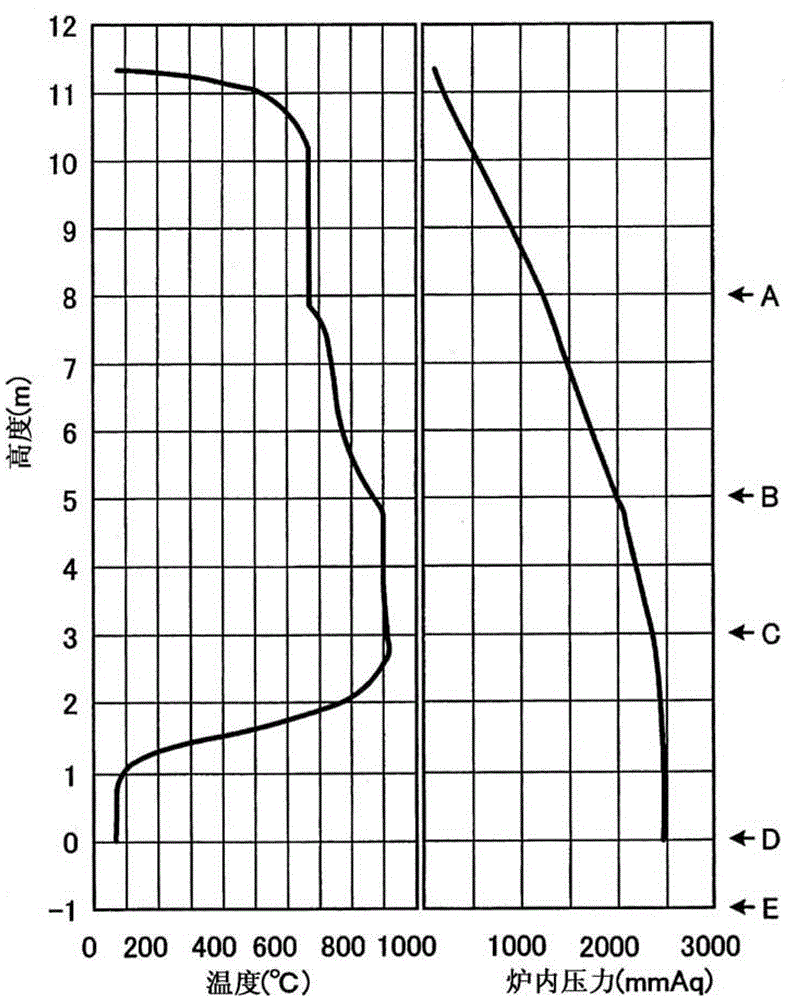

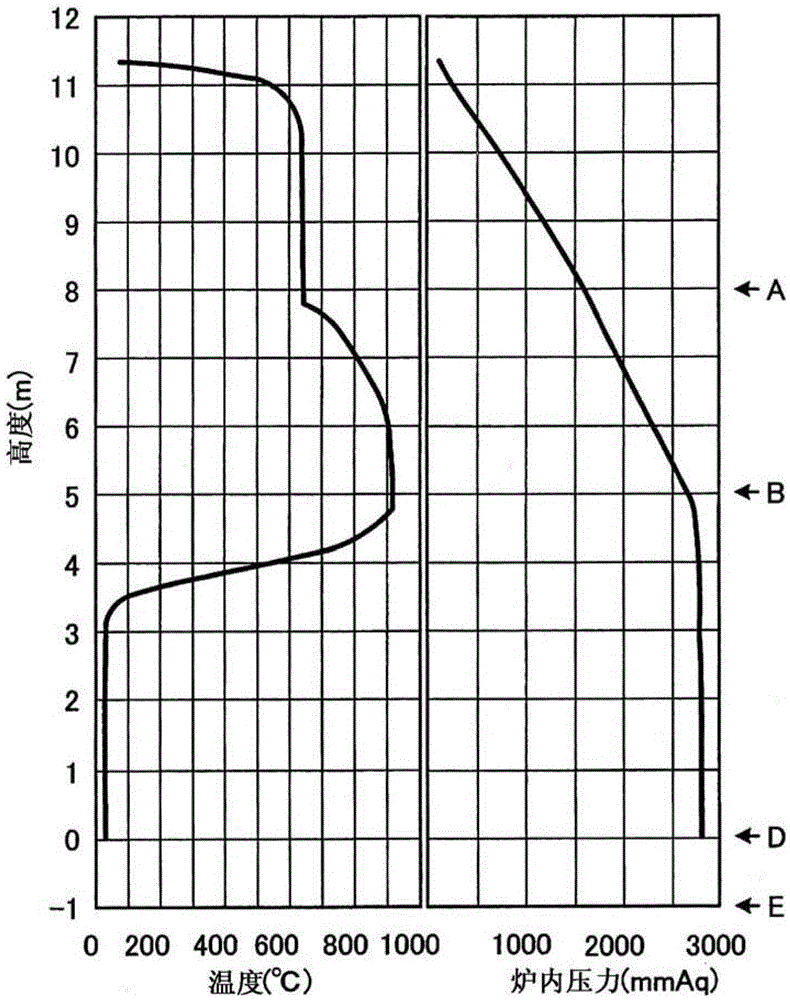

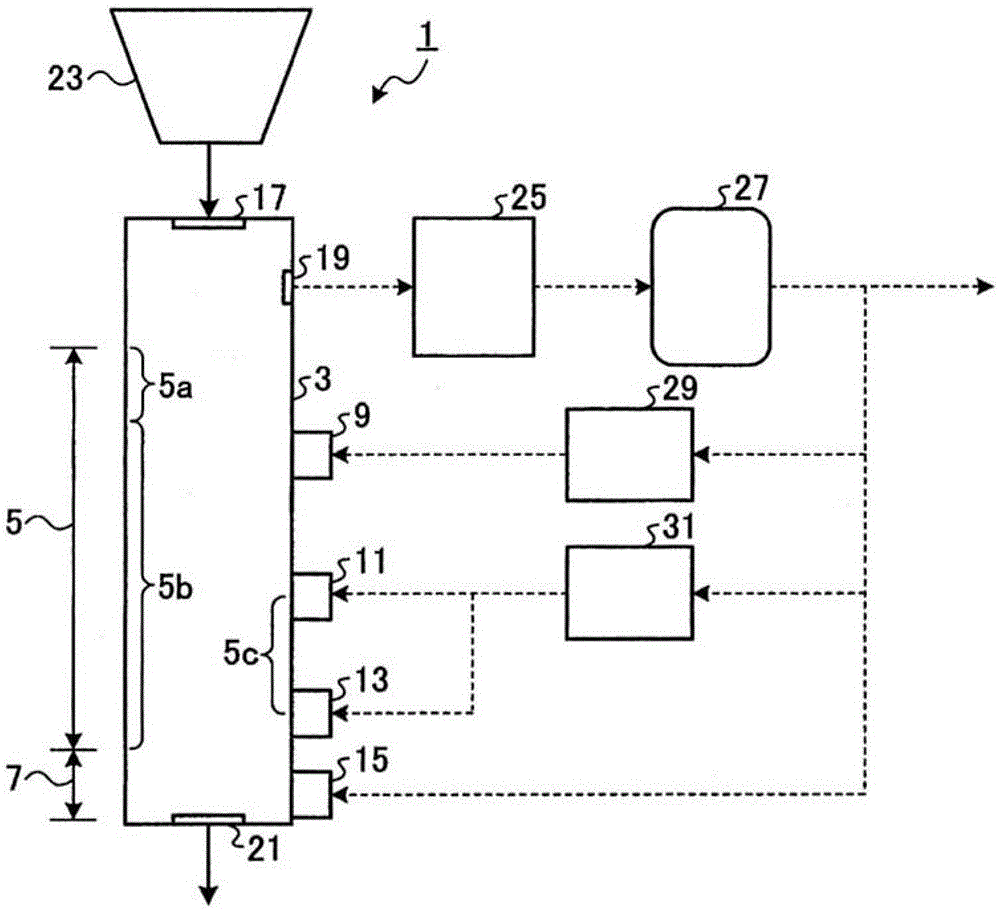

Vertical shaft furnace, iron coke manufacturing equipment and iron coke manufacturing method

ActiveCN102822315BDoes not complicate operating conditionsSimple equipmentVertical chamber coke ovensDirect heating destructive distillationCombustionCarbonization

The object of the present invention is to provide a vertical shaft furnace, which can simplify the equipment and not complicate the operating conditions; A vertical shaft furnace for continuously producing target products through combustion, gasification, dry distillation, or reduction. It is characterized in that two high-temperature soaking zones are installed in the length direction of the furnace in order to form a high-temperature soaking zone of a predetermined length below the center position in the length direction of the furnace. Gas is blown into the tuyeres 11 and 13.

Owner:JFE STEEL CORP +1

Iron phosphate feed additive, preparation method and uses thereof

InactiveCN106173197ASolve reunionImprove bioavailabilityAnimal feeding stuffAquatic animalFeed additive

The invention relates to an iron phosphate feed additive, a preparation method and uses thereof, and belongs to the field of feed additive manufacture. The iron phosphate feed additive is an iron phosphate salt supported on a porous mineral material, and accounts for 1-10% of the weight of the porous mineral material. According to the preparation method, a porous mineral material is used as a dispersing agent, iron phosphate salt micro-particles synthesized by a chemical method are supported on the porous mineral material, and dry crushing or spray drying is performed to prepare the iron phosphate feed additive. According to the present invention, the iron phosphate feed additive has narrow particle size distribution, the iron pyrophosphate salt micro-particle agglomeration problem is well solved, and the prepared supported iron pyrophosphate salt has high bioavailability, can be used as the feed additive in iron supplementing of livestock and poultry, aquatic animals and the like, and can further be used for dietary phosphorus supplementing.

Owner:扬州中微生物技术有限公司

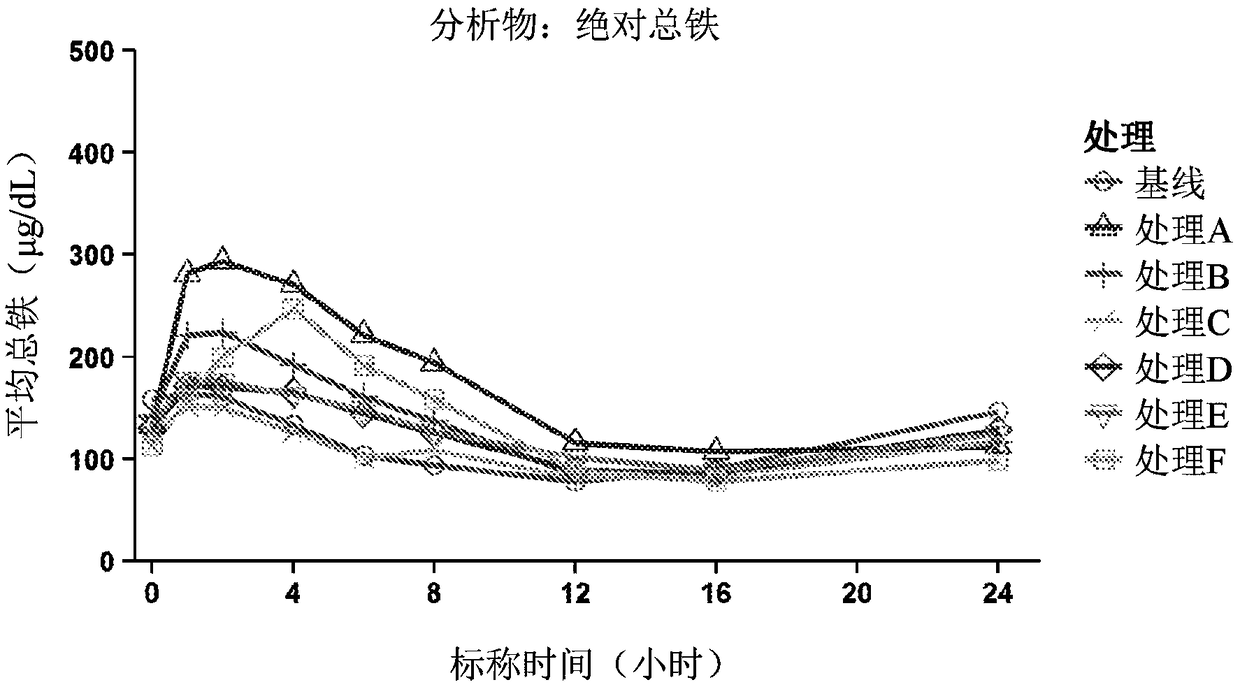

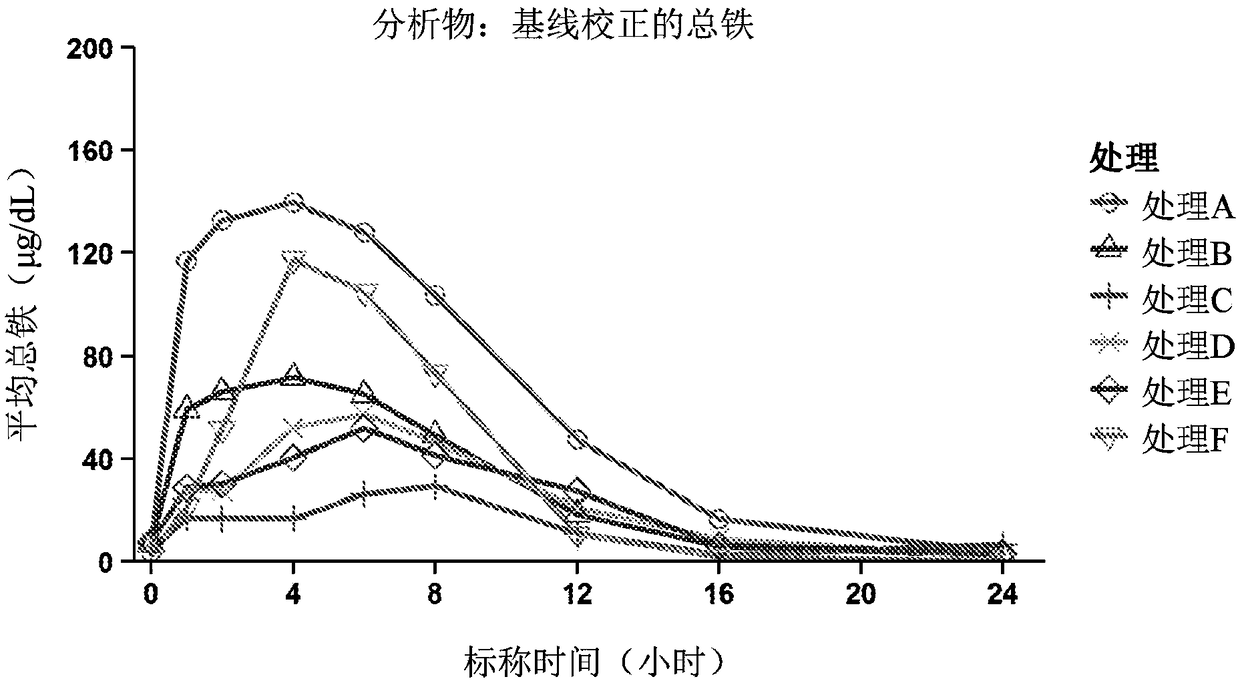

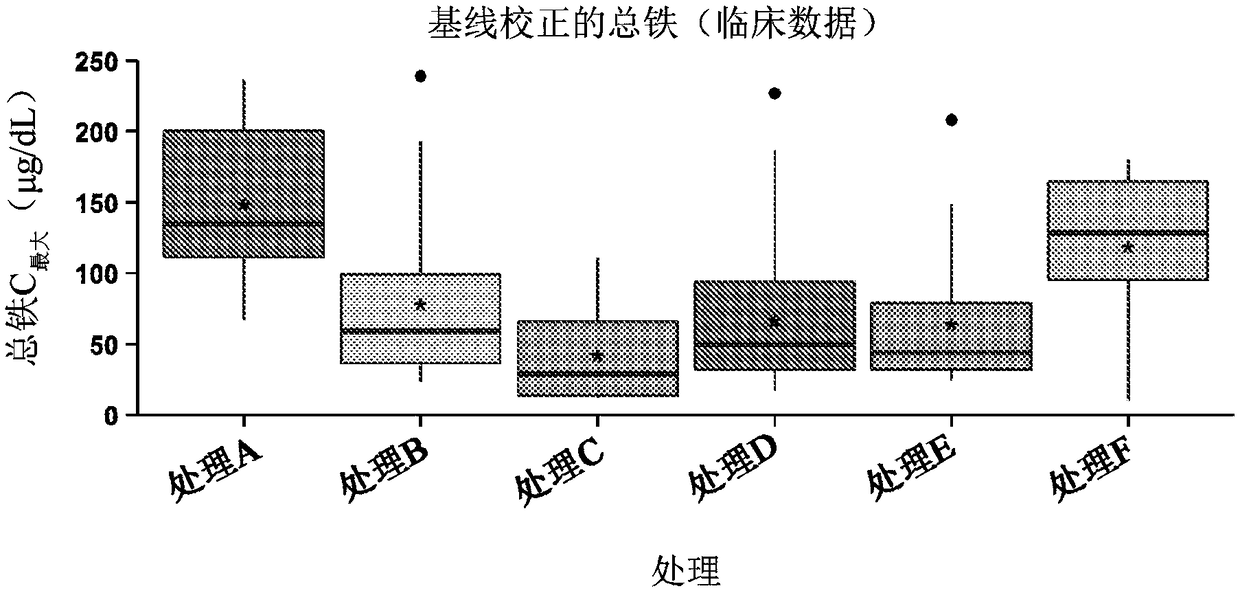

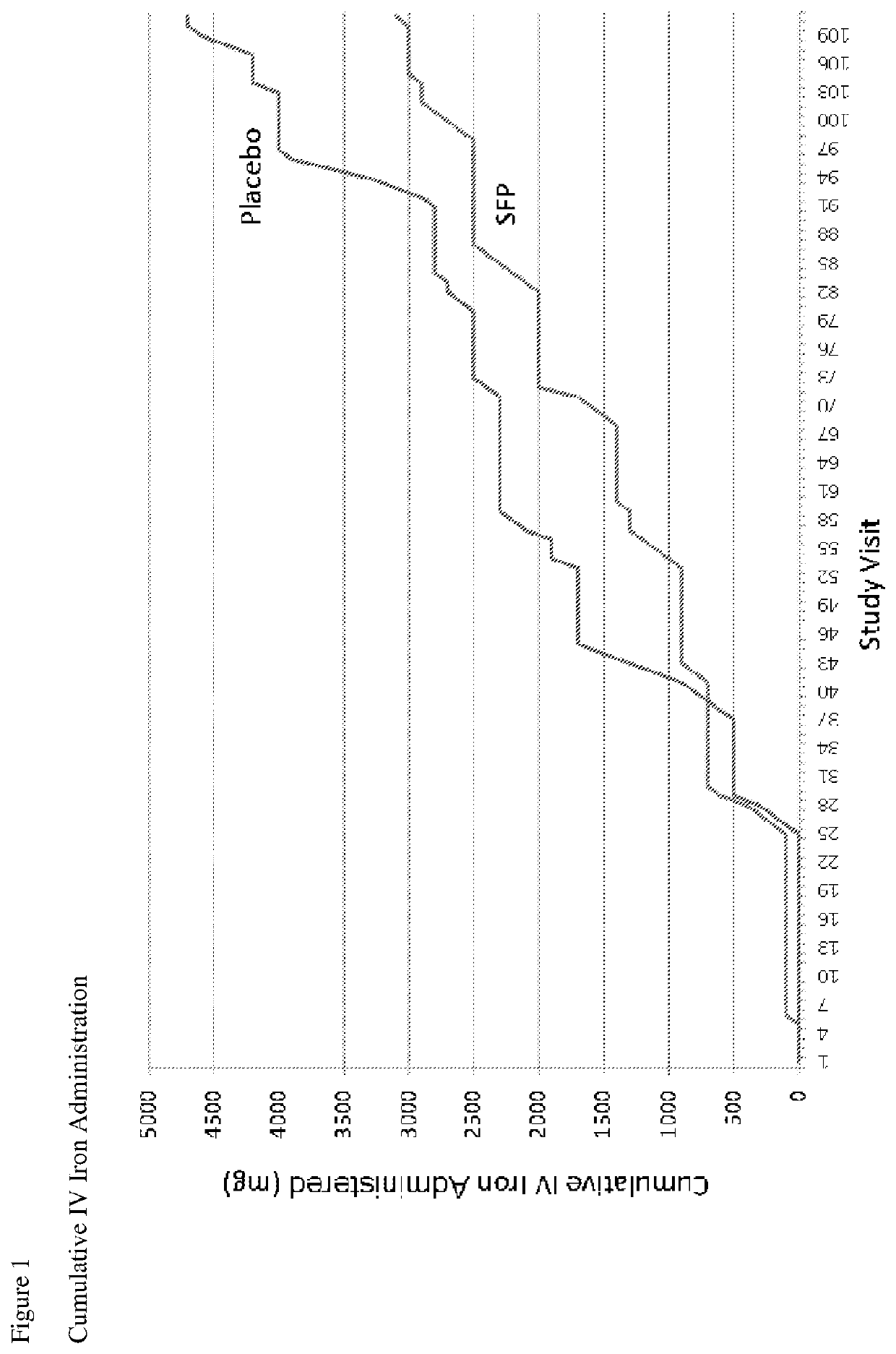

Composition therapy with iron compound and citrate compound

InactiveCN108883085AImprove bioavailabilityConvenient amountOrganic active ingredientsHeavy metal active ingredientsCITRATE ESTERMedicine

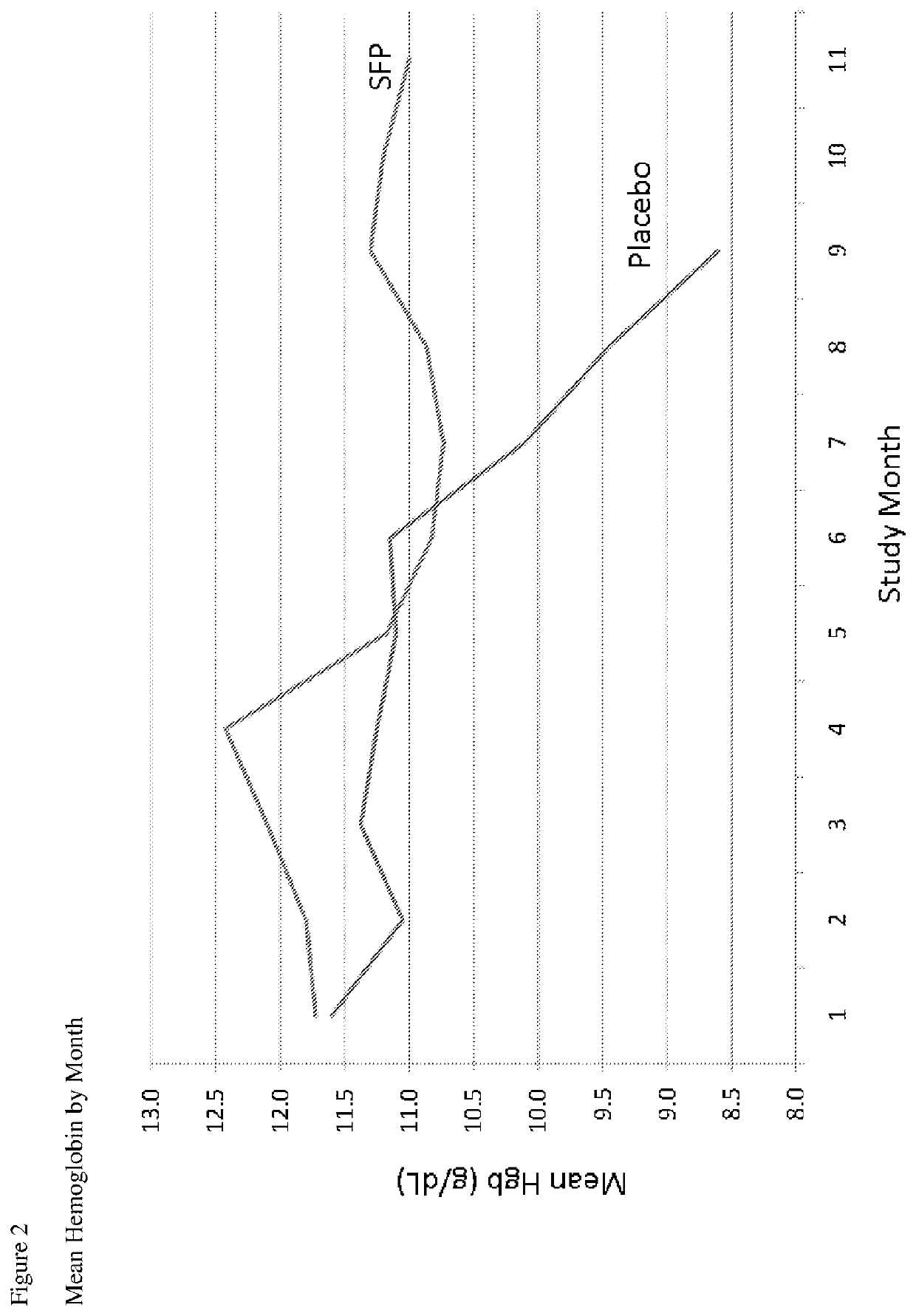

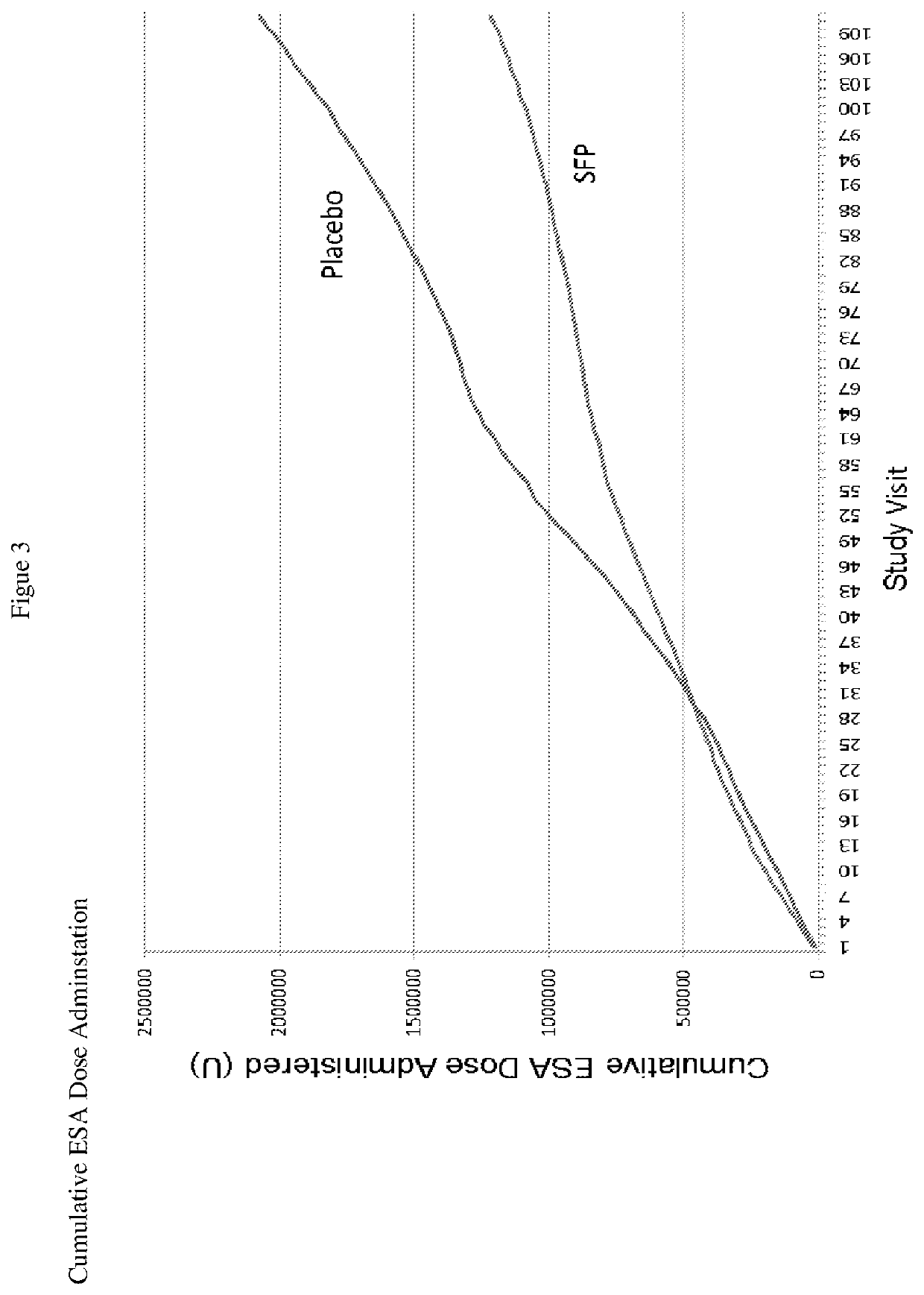

Combination therapy comprising an iron compound, preferably soluble ferric pyrophosphate (SFP), in combination with a citrate compound is disclosed. Methods of using the combination therapy in the treatment of iron deficiency, with or without anemia, including iron-refractory iron deficiency anemia and other iron-sequestration syndromes, and pharmaceutical compositions and kits comprising SFP or another iron compound and a citrate compound are also disclosed.

Owner:罗克韦尔医疗公司

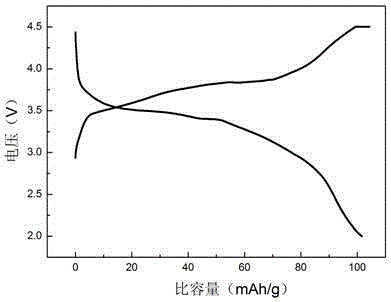

A method for synthesizing carbon-coated lithium iron pyrophosphate by hydrothermal method

ActiveCN103985870BLow costSave the wrapping processCell electrodesSecondary cellsWater bathsSynthesis methods

The invention discloses a method for synthesizing carbon-coated lithium ferrous pyrophosphate by a hydrothermal method. The method comprises the following steps of (1) weighing raw materials, dissolving a carbon source into distilled water or deionized water, and heating, stirring and dissolving in a water bath at the temperature of 50-90 DEG C; respectively dissolving a lithium source, an iron source and a phosphorus source into the deionized water, uniformly stirring the sources, sequentially adding the iron source and the lithium source into a solution dissolved with the carbon source, adding ammonia water to adjust the pH of the mixed solution to 4-6, adding the phosphorus source, heating the mixed solution in the water bath at the temperature of 50-90 DEG C, and stirring for 1-2 hours; (2) performing reaction on the mixed solution at 150-350 DEG C and the pressure of 1-10MPa for 3-10 hours, cooling to room temperature after the reaction is finished, and performing solid-liquid separation to obtain a solid which is a precursor solid-phase product; (3) drying the precursor solid-phase product, and then sintering to obtain the carbon-coated lithium ferrous pyrophosphate. The method has the advantage that the reaction temperature is relatively low, and the synthesis method is simple; the prepared carbon-coated lithium ferrous pyrophosphate serving as a positive electrode material is excellent in electrochemical performance.

Owner:CENT SOUTH UNIV

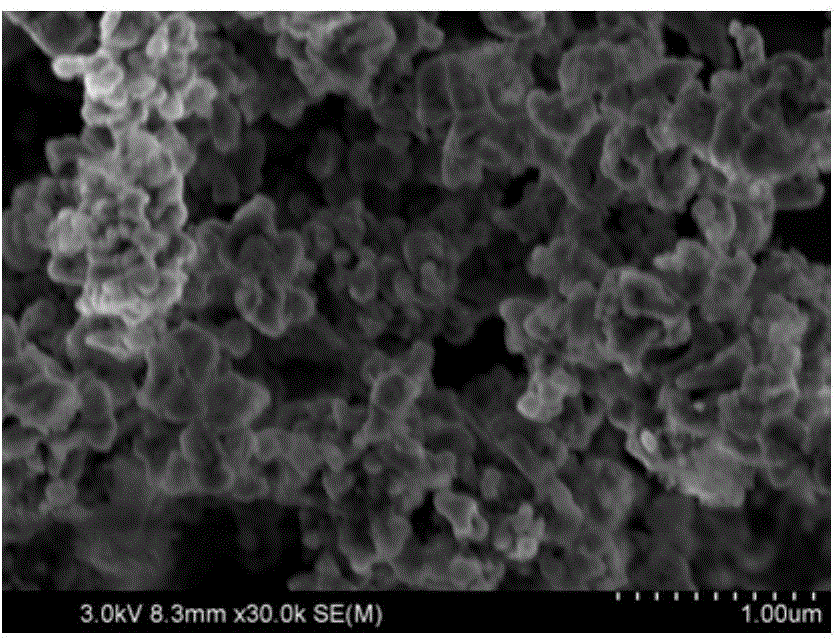

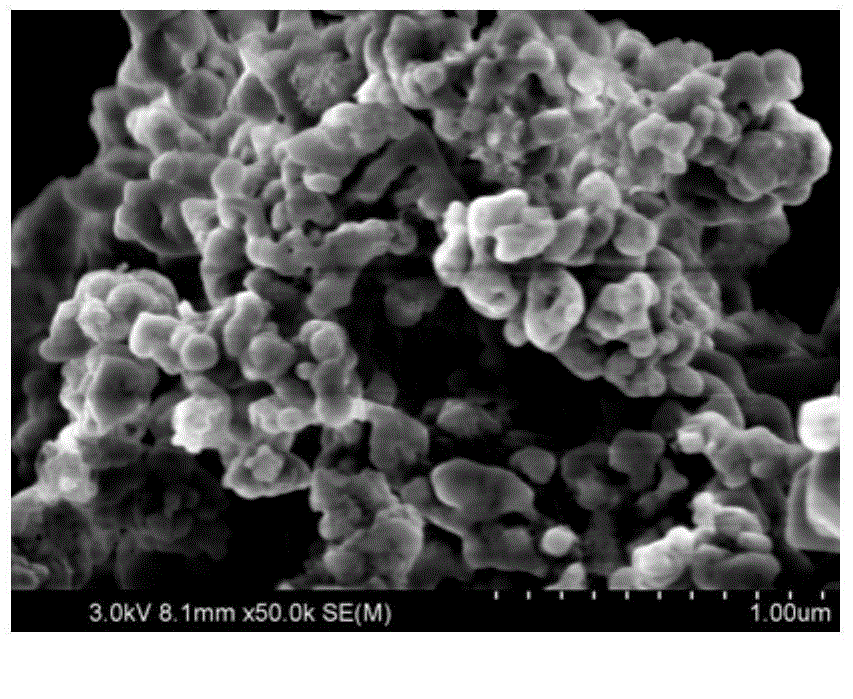

Ferric pyrophosphate microcapsule powder applied to Vc-containing series products and preparation method thereof

PendingCN113966844ALight colorGood dispersionMulti-step food processesFood ingredientsIron pyrophosphateSuccinic acid

The invention discloses ferric pyrophosphate microcapsule powder applied to Vc-containing series products and a preparation method thereof, the microcapsule powder is prepared from the following raw materials: a wall material, span 80 and ferric pyrophosphate, the mass ratio of the wall material to the ferric pyrophosphate is (1.5-2.5):1, and the addition amount of the span 80 is 0.5-2% of the total mass of the microcapsule powder; and the wall material is composed of starch sodium octenylsuccinate and maltodextrin in a mass ratio of 1:(2-4). On the basis of adopting the starch sodium octenylsuccinate and the maltodextrin, the span 80 emulsifier is also added, so that the prepared microcapsule powder is light in color and good in dispersity and flowability in water, and the blackening phenomenon generated by the microcapsule powder and Vc series products such as Vc and Vc sodium can be better delayed.

Owner:河南瑞贝佳生物科技有限公司

Metal cleaning agent

The invention discloses a metal cleaning agent. The metal cleaning agent is characterized in that the metal cleaning solution is composed of the following components by mass: 10-15 parts of citric acid, 1-3 parts of trisodium phosphate, 2-5 parts of iron pyrophosphate, 2-5 parts of nekal, 5-8 parts of tartaric acid, 2-3 parts of lauric acid, 1.2-1.6 parts of triethanolamine, 0.8-1.2 parts of sodium ethylene diamine tetracetate, 0.2-0.3 part of sodium nitrate and 40-45 parts of deionized water. The metal cleaning agent has the advantages that: the metal cleaning solution does not combust easily, is safe and reliable in use, and has no damage to metals; the use method is simple, the metal cleaning solution can be used at room temperature, has strong detergency, and can remove residual substances on the surfaces of mechanical parts; the whole technical scheme is simple and reliable in operation, and low in cost, and is conducive to reducing the production cost of enterprises; the metal cleaning solution not only can quickly clean stains on metal surfaces, but also can effectively prevent the generation of rust spots on metal surfaces, and has long-term rust protection and maintenanceefficacy on cleaned metals.

Owner:苏州瑞沁精密机械有限公司

A kind of lithium iron phosphate cathode material and preparation method thereof

ActiveCN103107332BImprove ionic conductivityImprove low temperature performanceCell electrodesPhosphorus compoundsCarbon layerLithium iron phosphate

The invention relates to an LFP (lithium iron phosphate) positive electrode material with excellent low-temperature property. The LFP positive electrode material comprises LFP particles, and lithium iron pyrophosphate covering the LFP particles. The preparation method comprises the steps of fully mixing a Li-source compound, a Fe-source compound, a P-source compound and a compound containing doped metal M in a dispersing agent according to the molar ratio of X:1:1:Y, grinding and drying to obtain a dry material A, wherein X is not less than 1.02 and not greater than 1.10, and Y is not less than 0 and not greater than 0.05; heating the material A to obtain a sintered material B; adding B, the Li-source compound, the Fe-source compound and the P-source compound into the dispersing agent, grinding, and drying to obtain a dry material C; and heating the material C to obtain the LFP particles coated with lithium iron pyrophosphate. Furthermore, a carbon layer can be generated to improve the electron conductivity. The LFP positive electrode material provided by the invention is effectively improved in the low-temperature property and the rate capability.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

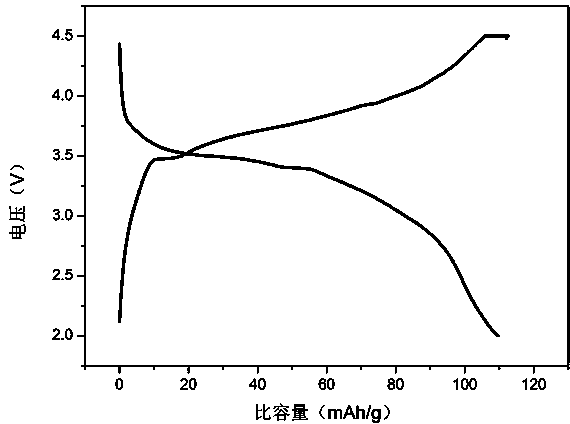

Preparation method of sodium ferric pyrophosphate electrode material coated with metal oxide, product and application of sodium ferric pyrophosphate electrode material

PendingCN114709401AImprove stabilityImprove diffusion abilitySecondary cellsPositive electrodesElectrical batteryIron pyrophosphate

The invention relates to a preparation method of a metallic oxide coated sodium ferric pyrophosphate electrode material, a product and application thereof, and belongs to the technical field of electrode material preparation. The metallic oxide-coated sodium ferric pyrophosphate electrode material comprises sodium ferric pyrophosphate and a metallic oxide coated on the surface of the sodium ferric pyrophosphate, a simple continuous ball milling method is used as a synthesis method, the process is simple and easy to copy and amplify, and after the sodium ferric pyrophosphate is coated with the metallic oxide on the surface, the sodium ferric pyrophosphate can be used for preparing the metallic oxide-coated sodium ferric pyrophosphate electrode material. The stability of the material is further improved, the intrinsic ion diffusivity of the material is also obviously improved, the first effect reaches 88% or above, the specific capacity per gram can reach 107 mA h g <-1 >, the capacity retention rate exceeds 90% after 200 cycles, and the electrochemical performance is close to that of other polyanion materials. Therefore, the material is beneficial to large-current charging and discharging and long-time cycle application in a sodium-ion battery material.

Owner:SOUTHWEST UNIVERSITY

Nutritional sliced dried meat processing method

InactiveCN103766920AStrong fragranceFull of nutritionSugar food ingredientsInorganic compound food ingredientsBiotechnologyNutritive values

The invention provides a nutritional sliced dried meat containing trace elements of calcium, iron and zinc, and a processing method thereof. The sliced dried meat contains 80-85 parts by weight of a main material rabbit meat, auxiliary materials comprising 5-8 parts by weight of sugar and 1-2 parts by weight of salt, and trace elements comprising, by weight, 0.3 parts of calcium citrate, 0.01 parts of zinc lactate, 0.02 parts of ferric sodium pyrophosphate, 0.01 parts of magnesium sulfate and 0.01 parts of edible selenium. The reinforced addition of essential nutritional elements for human bodies into the sliced dried meat enhances the nutritional values of the sliced dried meat and eliminates the problems of malnutrition caused by the deficiency of the trace elements in the human bodies, and the like.

Owner:张欢

Lithium ion battery positive electrode lithium iron pyrophosphate preparation method

InactiveCN105655539AImprove consistencySmall particle sizeNon-aqueous electrolyte accumulator electrodesDecompositionEvaporation

The present invention relates to a lithium ion battery positive electrode lithium iron pyrophosphate preparation method, which comprises: 1, mixing a lithium source-containing compound, an iron source-containing compound and a phosphorus source-containing compound, adding a solvent to form a transparent solution containing the lithium compound, the phosphorus compound and the iron compound, placing the transparent solution into an evaporator, and carrying out pressure reducing evaporation to obtain a small volume transparent gel; and 2, carrying out pre-decomposition and high temperature sintering on the small volume transparent gel, and naturally cooling so as to complete the lithium ion battery positive electrode lithium iron pyrophosphate preparation process. According to the present invention, the material synthesized through the wet sol-gel is sequentially subjected to pressure reducing evaporation, pre-decomposition and sintering so as to achieve the uniform molecular level of the raw material mixing, the material synthesis uniformity is good, the particle size is small, the rate performance is good, and the initial charge-discharge efficiency and the discharge capacity are high; and the inexpensive lithium source, the inexpensive iron source, the inexpensive phosphorus source and the doped elements are used so as to achieve the cheap material price, and the materials are easy to store.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Low-temperature golden yellow metallic luster glaze and manufacturing method thereof

The invention discloses low-temperature golden yellow metallic luster glaze and a manufacturing method thereof. The low-temperature golden yellow metallic luster glaze comprises a ferro phosphorus material and ceramic-based glaze in a mass ratio of 0.5-1:1, wherein the ferro phosphorus material consists of sodium ferric pyrophosphate and ferric phosphate or the sodium ferric pyrophosphate and a mixture of ferric oxide and aluminum phosphate; and the ceramic-based glaze comprises albite, quartz, limestone and kaolin in a weight ratio of 20-50:5-10:2-8:3-10. The low-temperature golden yellow metallic luster glaze has the advantages of a few types of raw materials, low manufacturing cost, one-time sintering at a low temperature, contribution to energy conservation and environmental protection, bright golden yellow metallic luster of the sintered product, obvious decorative effect and wide application range; and the method is particularly suitable for manufacturing ceramic wall tiles, ceramic waist lines, ceramic mosaic and the like with golden yellow appearance.

Owner:广东道氏陶瓷材料有限公司

Composite colostrum and preparation method thereof

PendingCN109674064AImprove immunityPromote functional recoveryVitamin food ingredientsNatural extract food ingredientsDiseaseVitamin C

The invention provides composite colostrum and a preparation method thereof. The composite colostrum is prepared from the following components in percentage by weight: 20-40% of soybean protein isolate; 5-10% of lactoferrin-containing whey protein, 0.05-0.5% of a transfer factor, 1-10% of bovine colostrum, 3-40% of oligomeric polysaccharide, 1-10% of polydextrose, 1-20% of a traditional Chinese medicinal extract, 0.18-10% of calcium carbonate, 0.013-0.073% of iron pyrophosphate, 0.002-0.128% of zinc oxide, 0.0003-0.022% of vitamin A, 0.000001-0.00045% of vitamin D, 0.005-1.3% of vitamin C, 0.005-0.85% of vitamin E and 0.0001-1% of B-vitamin. The composite colostrum has the advantages that the spleen can be strengthened, the intestinal microenvironment can be improved, the absorption rate of trace elements can be increased, the composite colostrum is better utilized by the human body, and accordingly, the effects of strengthening nutrition and enhancing human immunity are achieved; through the comprehensive synergistic effect of the components, the human immune system can be enhanced, rehabilitation of patients suffering from respiratory diseases such as recurrent respiratory tractinfections is promoted, and the frequency of developing a disease is reduced.

Owner:JIANGXI DETAI MEDICINE BIOTECH CO LTD

Methods of treating iron deficiency

InactiveUS20200276232A1Reduce the amount requiredReducing and eliminating dosePeptide/protein ingredientsInorganic phosphorous active ingredientsIron deficientErythropoiesis-stimulating agent

Owner:CHARAK LLC

Pregnant woman nutrition bag special dietary protein powder and preparation method thereof

InactiveCN109527094AHigh nutritional valueSolve the disadvantages of single ingredientsMilk preparationDocosahexaenoic acidWhey protein

The invention discloses pregnant woman nutrition bag special dietary protein powder and a preparation method thereof, and the pregnant woman nutrition bag special dietary protein powder comprises thefollowing components in part by weight: 630-650 parts of whole milk powder, 130 to 150 parts of concentrated whey protein, 230 to 260 parts of edible glucose, 5 to 6 parts of iron pyrophosphate, 0.6 to 0.8 parts of vitamin A, 0.2 to 0.3 parts of vitamin D, 0.02 to 0.03 parts of folic acid, 0.002 to 0.003 parts of vitamin B12, and 0.01-0.02 parts of docosahexaenoic acid. The pregnant woman nutrition bag special dietary protein powder is easy for pregnant women to absorb, has a high degree of absorption, provides pregnant women with sufficient nutrition during pregnancy, and promotes the development of the fetus.

Owner:安徽康博特保健食品有限公司

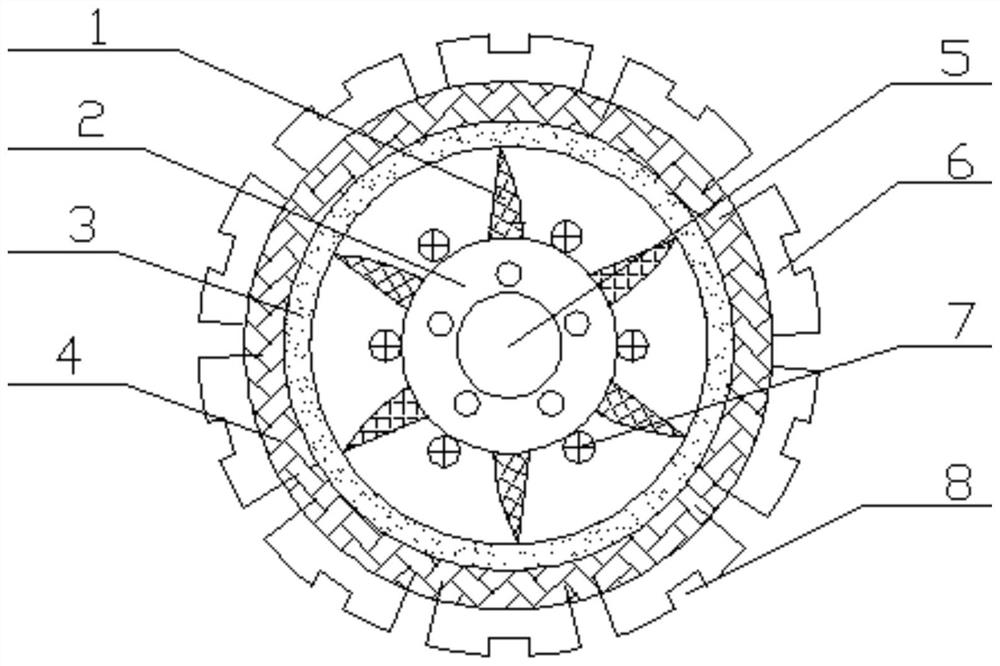

Grinding abrasive wheel

InactiveCN112059932AImprove grinding performanceImprove grinding qualityBonded abrasive wheelsMolecular sieveNano silicon

The invention discloses a grinding abrasive wheel. The grinding abrasive wheel is composed of an abrasive wheel body, a grinding layer at the outermost end and a through hole which is formed in the center of the abrasive wheel body, the grinding layer is composed of a plurality of grinding blocks arranged at intervals, each grinding block comprises the the following raw material components of, inparts by weight, 20-35 parts of titanium steel, 1-10 parts of zinc borate, 1-10 parts of dimethyl silicone oil, 5-15 parts of nano silicon nitride, 5-15 parts of polypropylene, 5-15 parts of a nano mesoporous molecular sieve, 1-10 parts of magnesium oxide, 5-10 parts of ferric pyrophosphate and 1-5 parts of cobalt, and a plurality of chip removal grooves are formed in the end faces of the grindingblocks. According to the grinding abrasive wheel, the grinding performance of the abrasive wheel is greatly improved, the hardness is high, the abrasion resistance and the buffering effect are good,the better cooling and chip removal effects are achieved, and the grinding quality of the abrasive wheel is further improved.

Owner:徐先祥

A kind of production method of suspended ferric pyrophosphate

ActiveCN107518235BGood suspensionEvenly distributedFood dryingFood ingredient as emulsifierStearic acidSoya bean

The invention discloses a method for producing suspended ferric pyrophosphate, and relates to the technical field of ferric pyrophosphate production. The method is to emulsify and modify ordinary ferric pyrophosphate through microencapsulation technology, and specifically includes the following steps: (1) Pulverized ordinary ferric pyrophosphate or undried ordinary ferric pyrophosphate wet material is mixed with sodium alginate, glycerol monostearate and enzymatic soybean lecithin to make a suspension above 80°C, which is subjected to high-speed shearing and homogenization Emulsifying to obtain a mixed emulsion; (2) spray drying the emulsion, the air inlet temperature is 160-190°C, the air outlet temperature is 80-95°C, and the spray-dried powder is sieved to obtain the target product. The present invention emulsifies and modifies ordinary ferric pyrophosphate through the microencapsulation method of emulsifying and homogeneous spraying, so that ferric pyrophosphate is used to strengthen the iron element of beverages without precipitation, and at the same time it is convenient for storage and transportation, so it is used in the production of beverages and foods In the process, the processing performance is greatly improved.

Owner:郑州瑞普生物工程有限公司

A method for preparing iron phosphate and iron pyrophosphate by using leaching tailings as iron source

InactiveCN104555972BRealize resource utilizationWide variety of sourcesPhosphorus compoundsPhosphateFiltration

The invention discloses a method for preparing ferric phosphate and ferric pyrophosphate by using an ore leaching tail liquid as an iron source. The method comprises the following steps: 1) while stirring, spraying a 5-10 wt% phosphate or pyrophosphate solution into the ore leaching tail liquid until the pH value is equal to 3.5-4.5 and a precipitate is formed; 2) standing for 0.5-2 hours, and spraying a 0.1-0.3% organic flocculant solution into the suspension, wherein the flocculant solution accounts for 0.5-5 wt% of the ore leaching tail liquid; and 3) standing for 4-12 hours to precipitate the suspension, dewatering the precipitate by vacuum filtration or pressure filtration, eluting with cold water, and baking the solid phase at 80-90 DEG C to obtain the ferric phosphate or ferric pyrophosphate. On the premise of implementing harmless treatment on the ore leaching tail liquid, the method recovers the dissolved-state iron in the ore leaching tail liquid, and the obtained ferric phosphate or ferric pyrophosphate is a raw material for preparing lithium ion batteries.

Owner:ZHEJIANG UNIV

Milk powder beneficial to improving immunity, and preparation method of milk powder

PendingCN111758782ANutritional diversityImprove immunityMilk preparationLactobacillusBiotechnologyEthylic acid

The invention discloses a milk powder beneficial to improve immunity, and a preparation method of the milk powder, and relates to the technical field of milk powder production. The milk powder comprises the following raw material components in parts by weight: 280-320 parts of whole milk powder, 40-60 parts of skimmed milk powder, 4-6 parts of lactose, 8-12 parts of whey protein, 4-6 parts of fructo-oligosaccharide, 1.8-2.2 parts of sodium citrate phospholipid, 0.8-1.2 parts of docosahexaenoic acid oil, 0.7-0.9 part of L-sodium ascorbate, 0.4-0.6 part of milk calcium, 0.7-0.9 part of arachidonic acid oil, 0.4-0.6 part of D-calcium pantothenate, 0.5-0.7 part of iron pyrophosphate, 0.5-0.7 part of zinc sulfate, 0.001-0.003 part of d-alpha-tocopherol acetate, 0.04-0.06 part of manganese gluconate, 0.07-0.09 part of nicotinic acid, 0.07-0.09 part of lutein, 0.5-0.7 part of retinyl acetate, 0.4-0.6 part of cholecalciferol, 3-5 parts of Lactobacillus acidophilus, 3-5 parts of Bifidobacteriumlactis HN019, 4-6 parts of Lactobacillus casei, 0.05-0.07 part of phytomenadione, 0.06-0.08 part of thiamine hydrochloride, 0.07-0.09 part of pyridoxine hydrochloride, 0.08-0.12 part of folic acid, 0.8-1.2 parts of lactoferrin, 0.8-1.2 parts of bovine colostrum, and 3-5 parts of a food flavor.

Owner:安徽贝尔宝母婴用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com