Grinding abrasive wheel

A grinding wheel and grinding technology, which is applied in the field of grinding processing, can solve problems such as large frictional resistance, high temperature in the grinding area, and affecting grinding quality, so as to achieve good cooling and chip removal, improve grinding performance, and improve grinding quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

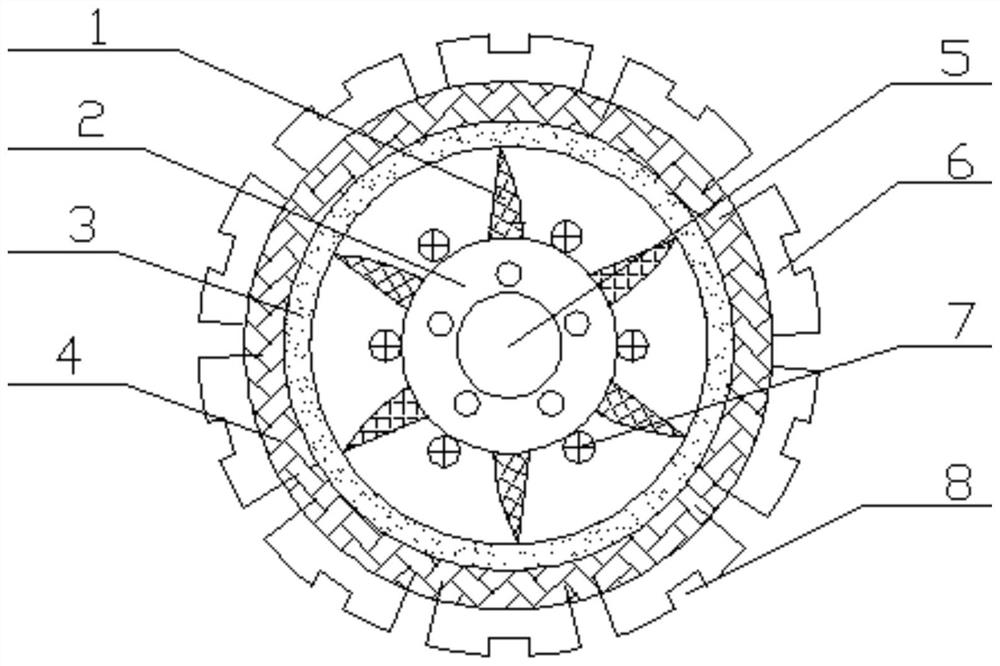

[0013] Such as figure 1 As shown, the present invention is realized by taking the following technical solutions: a grinding wheel, which is composed of a grinding wheel body, an outermost grinding layer 6 and a through hole 5 arranged at the center of the grinding wheel body, the grinding Layer 6 is composed of several grinding blocks arranged at intervals. The raw material components of the grinding blocks are: 20-35 parts by weight of titanium steel, 1-10 parts of zinc borate, 1-10 parts of dimethyl silicone oil 10 parts by weight, 5-15 parts by weight of nano-silicon nitride, 5-15 parts by weight of polypropylene, 5-15 parts by weight of nano-mesoporous molecular sieve, 1-10 parts by weight of magnesium oxide, 5-10 parts by weight of iron pyrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com