Preparation method of sodium ferric pyrophosphate electrode material coated with metal oxide, product and application of sodium ferric pyrophosphate electrode material

A technology of sodium iron pyrophosphate and electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of toxicity, incompatibility with sodium-ion battery system, expensive vanadium resources, etc., and achieves low pyrolysis treatment temperature and intrinsic Increased ion diffusivity, effect of green process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

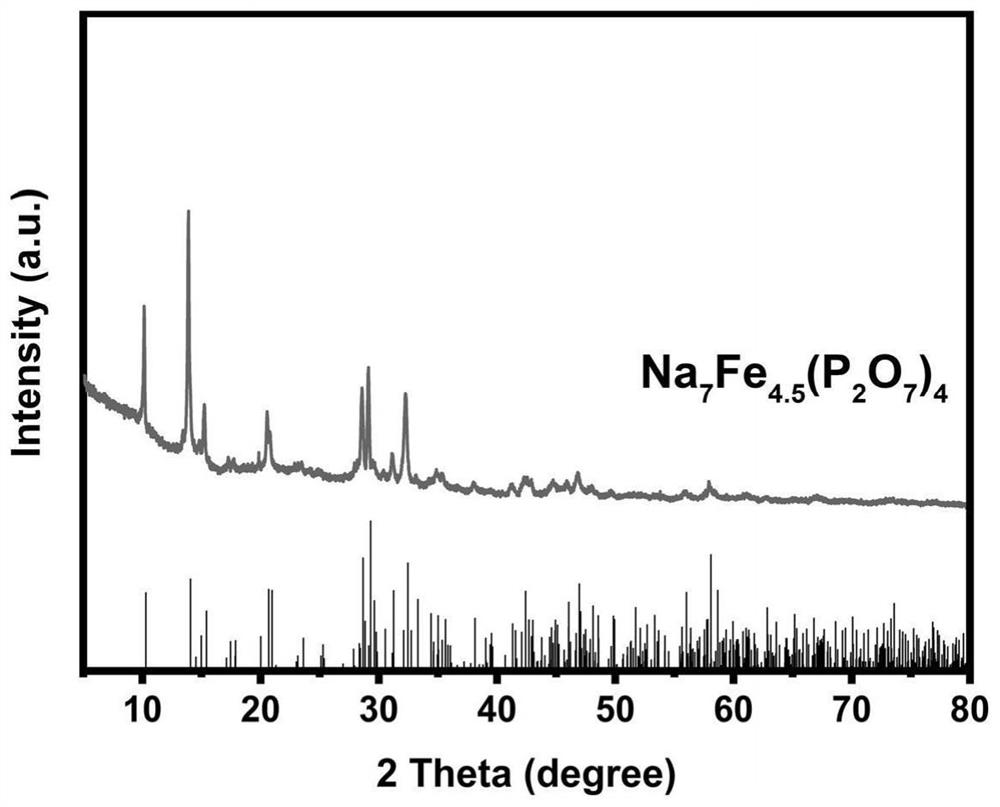

[0043] A manganese dioxide-coated sodium iron pyrophosphate (Na 7 Fe 4.5 (P 2 O 7 ) 4 @MnO 2 ) electrode material, and the specific method specifically includes the following steps:

[0044] (1) Sodium acetate, ferrous oxalate dihydrate, concentration is 1moL -1 Phosphoric acid is mixed to obtain mixture (wherein the mol ratio of the sodium in sodium acetate, the iron in ferrous oxalate dihydrate and the phosphate radical in phosphoric acid is 7:4.5:8) after adding the ball mill tank, and adding alcohol (the alcohol quality added is 200% of the mass of the mixture) as a dispersing solvent, add agate beads (the mass of the agate beads added is 300% of the mass of the mixture) as a grinding medium, carry out ball milling, and the product obtained after the ball milling is a pale yellow homogenate, and the homogenate and the agate beads are mixed together. Separation is carried out through a screen, and then the separated homogenate is dried to obtain a sodium ferric pyroph...

Embodiment 2

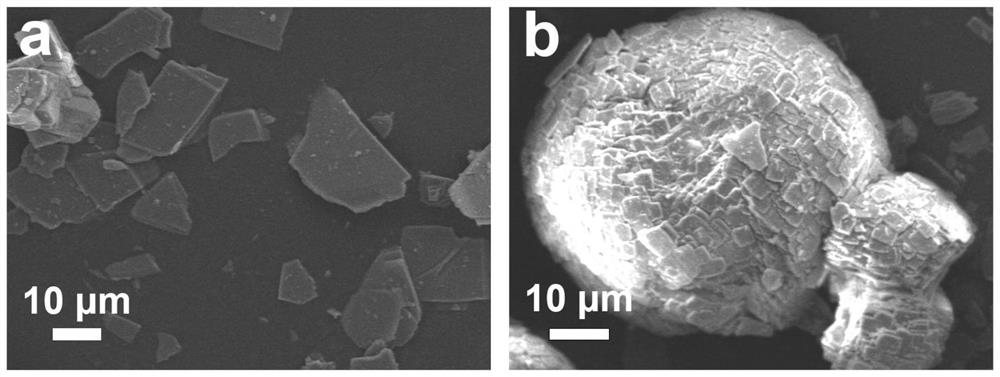

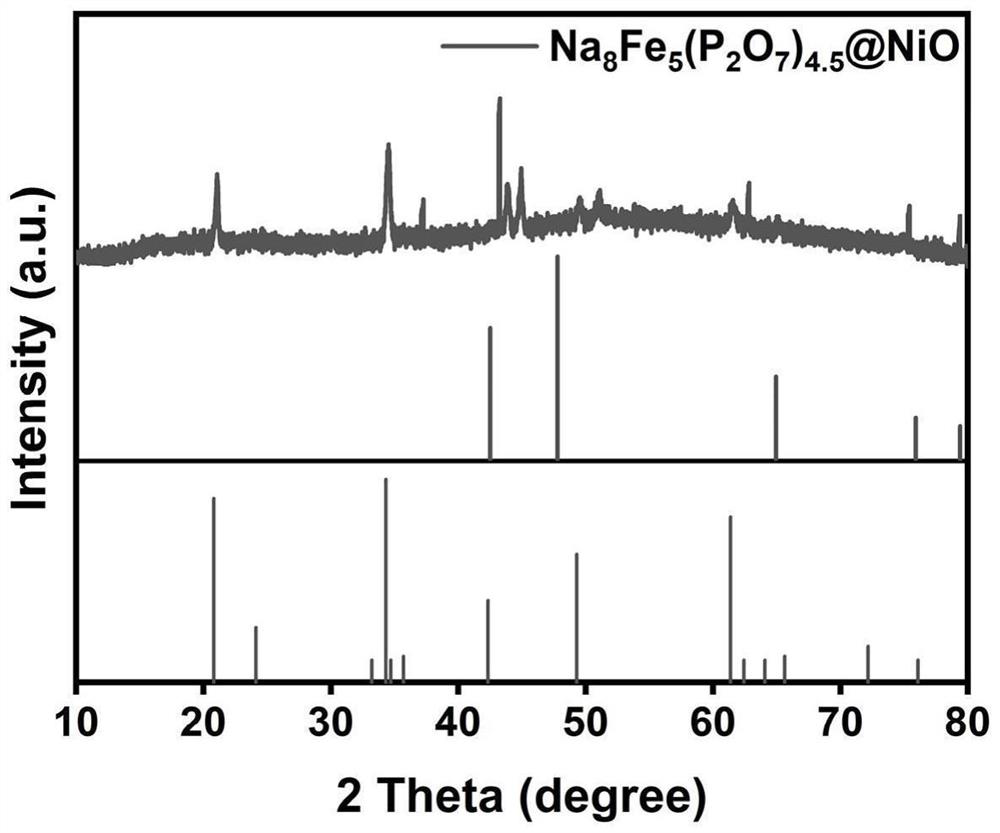

[0051] A nickel oxide-coated sodium ferric pyrophosphate (Na 8 Fe 5 (P 2 O 7 ) 4.5 @NiO electrode material, the specific method includes the following steps:

[0052] (1) mix sodium carbonate, ferrous chloride and ammonium dihydrogen phosphate to form a mixture (wherein the molar ratio of sodium in sodium carbonate, iron in ferrous chloride and phosphate in ammonium dihydrogen phosphate is 8:5 : 9) After adding the ball mill tank, and adding alcohol (the added alcohol mass is 200% of the mixture mass) as a dispersing solvent, adding zirconia beads (the added zirconia bead mass is 300% of the mixture mass) as a grinding medium, carry out Ball milling, the product obtained after the ball milling is a pale yellow homogenate, the homogenate and the agate beads are separated together through a screen, and then the separated homogenate is dried to obtain a sodium ferric pyrophosphate precursor (p-(Na). 8 Fe 5 (P 2 O 7 ) 4.5 );

[0053] (2) the above-prepared sodium iron py...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com