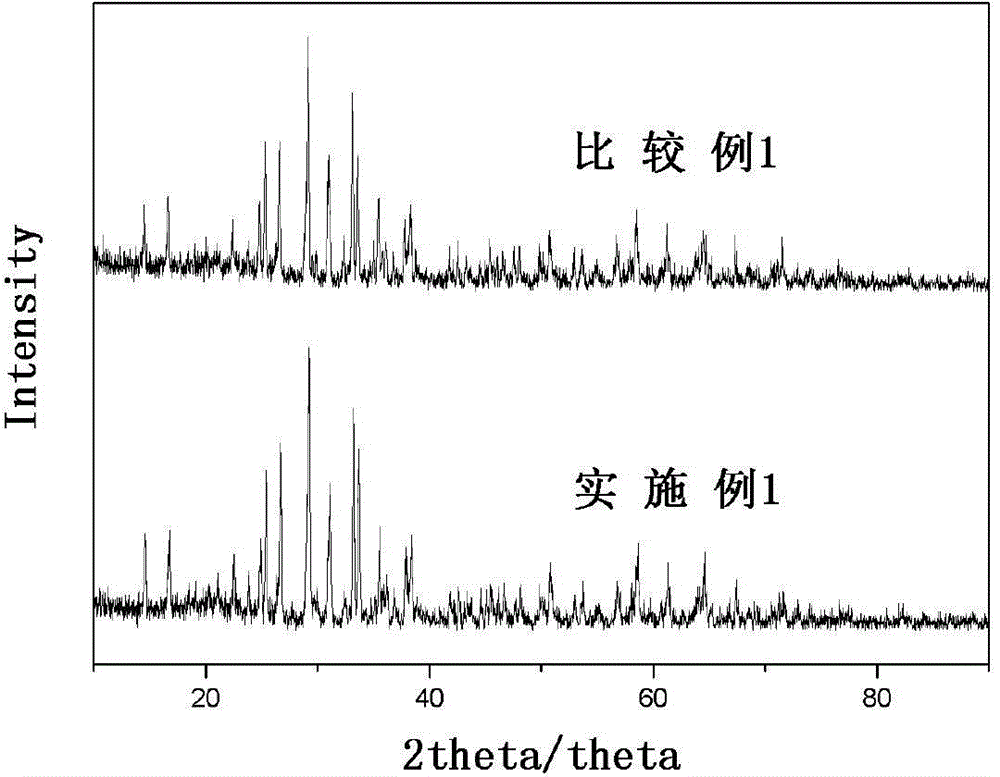

Lithium ion battery positive electrode lithium iron pyrophosphate preparation method

A technology for lithium iron pyrophosphate and lithium-ion batteries, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc. It can solve the problems that the particle size cannot be further reduced, the performance of the positive electrode material is not good, and the mixing of raw materials is uneven. Achieve the effect of good consistency, uniform molecular level and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of lithium iron phosphate lithium iron battery cathode material is characterized in that it comprises the following preparation steps:

[0027] Step 1 Preparation of small volume transparent gel

[0028] After mixing the lithium source compound, iron source compound and phosphorus source compound according to the stoichiometric ratio Li:Fe:P=2:1:2, add a solvent to form a transparent solution containing lithium, phosphorus, and iron compounds; place the transparent solution in Evaporate under reduced pressure in the evaporator at 60°C-90°C and the pressure is less than -0.098Mpa to obtain a small-volume transparent gel;

[0029] Step 2 Material heat treatment

[0030] Place the small-volume transparent gel made in step 1 in a heating device, raise the temperature to 450°C-550°C in an inert atmosphere, and perform pre-decomposition for 0.5-4 hours; continue to heat up to 820°C-875°C in an inert atmosphere, After sintering for 0.5-2 hours and natu...

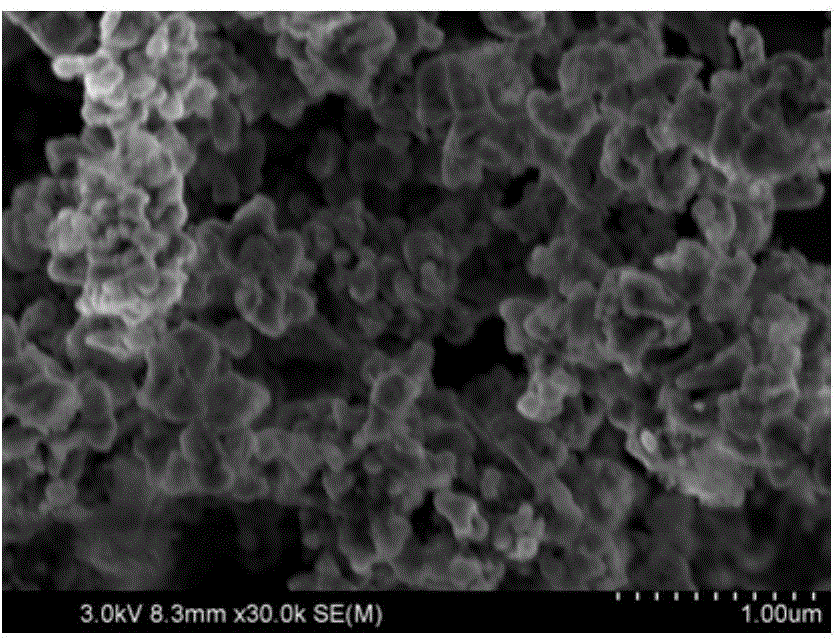

Embodiment 1

[0036] Step 1: After mixing lithium nitrate, iron nitrate and phosphoric acid according to the stoichiometric ratio Li:Fe:P=2:1:2, add isopropanol to form a transparent solution containing lithium, phosphorus and iron compounds; place the transparent solution in Evaporate under reduced pressure in an evaporator at 80°C and a pressure of -0.1Mpa to obtain a small-volume transparent gel;

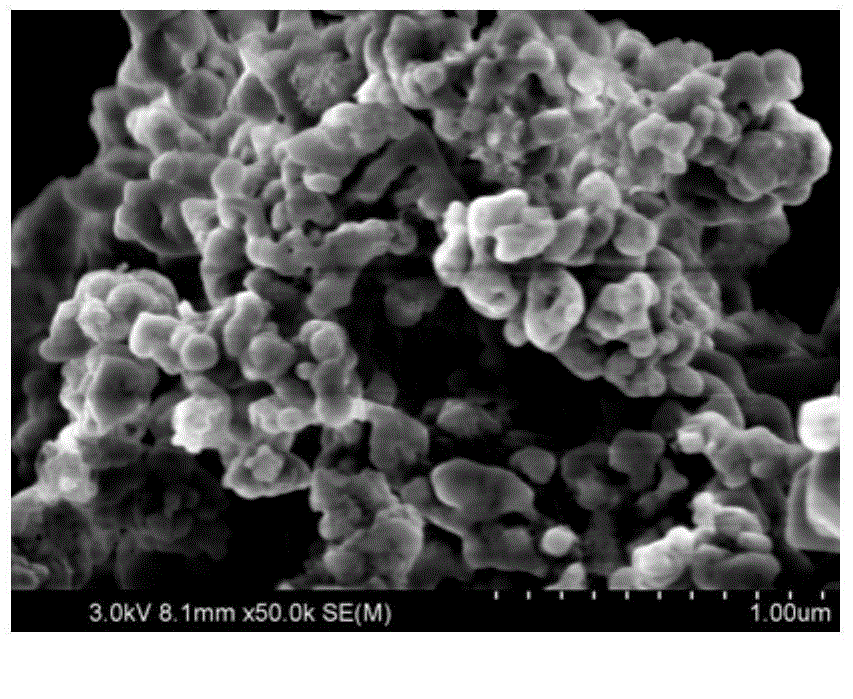

Embodiment 2

[0038] Step 1: After mixing lithium sulfate, ferrous sulfate and phosphoric acid according to the stoichiometric ratio Li:Fe:P=2:1:2, add glycolic acid to form a transparent solution containing lithium, phosphorus and iron compounds; place the transparent solution in Evaporate under reduced pressure in an evaporator at 65°C and a pressure of -0.098Mpa to obtain a small-volume transparent gel;

[0039] Step 2: Material heat treatment

[0040] Place the small-volume transparent gel made in step 1 in a preheater, raise the temperature to 500°C in a nitrogen atmosphere, and perform low-temperature pre-decomposition for 1 hour; raise the temperature to 850°C in a high-temperature sintering furnace in a nitrogen atmosphere, and perform 1 Hours of high-temperature sintering and natural cooling complete the manufacturing process of lithium iron phosphate lithium ion battery cathode material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com