Electric calcination furnace and application of electric calcination furnace in preparing industrial-grade phosphoric acid

A calciner, industrial-grade technology, applied in the field of industrial-grade phosphoric acid production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

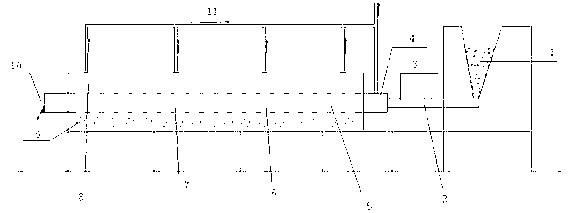

[0023] An electric calciner used in the preparation of technical-grade phosphoric acid, the calciner includes a feeding area, a preheating area, a heating area, a constant temperature area and a cooling area, the feeding area is connected to the feeding port through a spiral feeding pipe, The hearth of the electric calciner is a cylindrical structure. The hearth of the electric calciner is placed horizontally on the operating platform. Electric heating tubes are evenly arranged on the lower side of the hearth of the electric calciner. The feeding area and the entrance of the furnace Connection, the preheating zone, heating zone, constant temperature zone and cooling zone are sequentially distributed in the furnace of the electric calciner, and the outlet at the other end of the furnace is connected with the hydrolysis tank. The electric calciner also includes a hydrogen fluoride recovery device. The hydrogen fluoride collection branch pipes are respectively connected to the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com