Anti-graffiti and scrubbing-resistant coating composition and preparation method thereof

A technology of scrub resistance and composition, applied in the field of coatings, can solve the problems of poor graffiti resistance of coatings, fast attenuation of hydrophobic effect of coatings, affecting market application prospects, etc., and achieve low VOC and excellent hydrophobic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

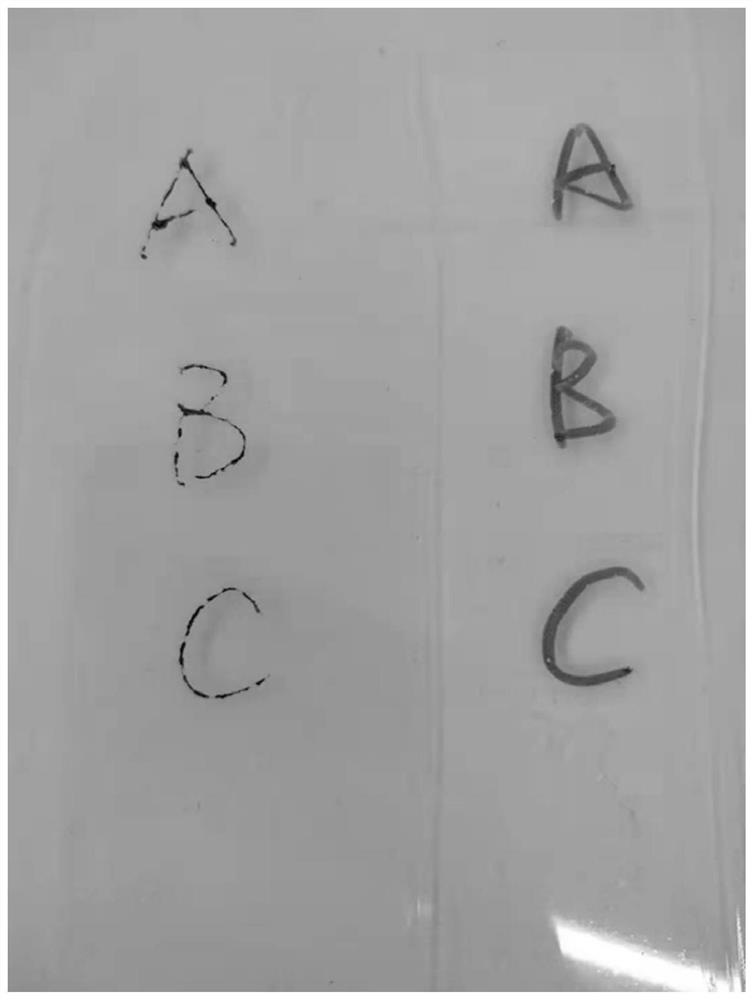

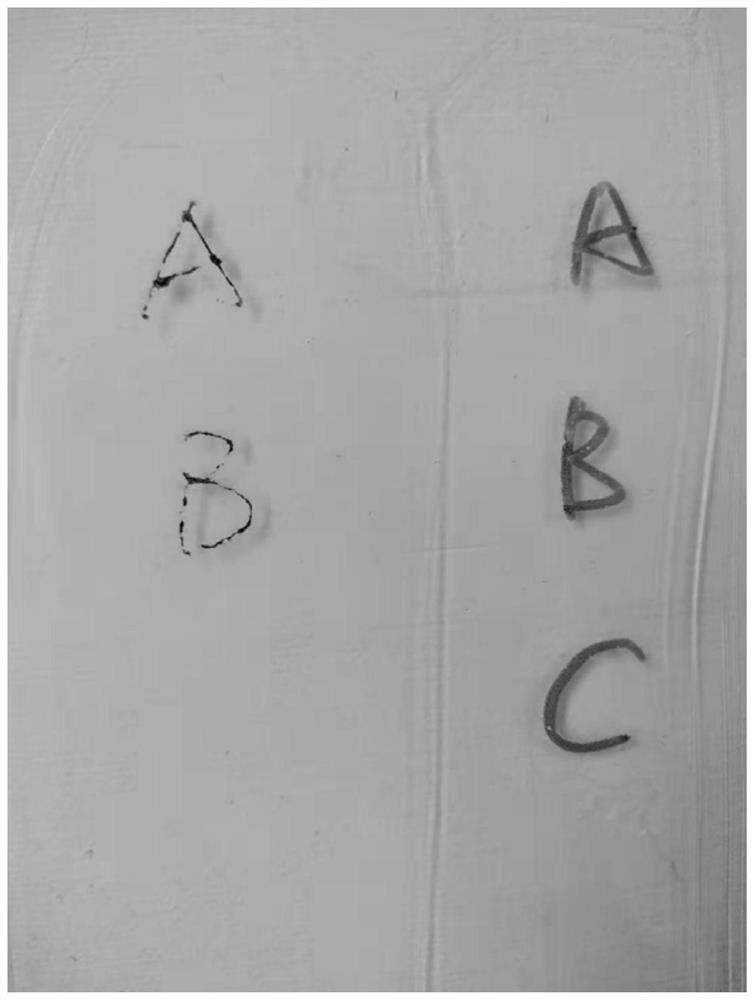

Image

Examples

Embodiment 1

[0045] An anti-graffiti and scrubbing-resistant coating composition, its raw materials include component A and component B, and the mass ratio of component A and component B is 100:20.

[0046] The ingredients and parts by mass that respectively constitute component A and component B are shown in the table below.

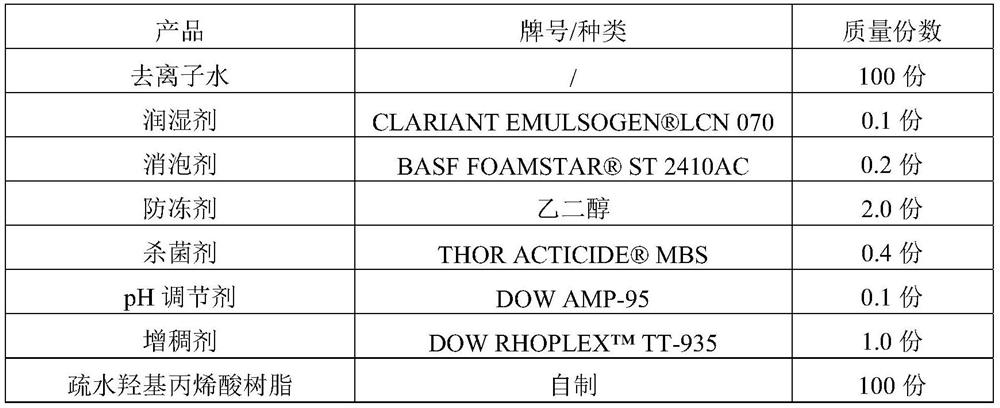

[0047] Component A:

[0048]

[0049] Component B:

[0050]

[0051] in,

[0052] The preparation method of component A is, according to the above mass parts, in the reaction kettle, put deionized water in the disc disperser, start the disperser and control the speed at 500r / min, and then add the remaining ingredients to the disperser in turn medium, disperse for 15 minutes, mix evenly;

[0053] The preparation method of component B is as follows: according to the above-mentioned parts by mass, in the reaction kettle, polyisocyanate and propylene glycol methyl ether acetate are placed in a disc disperser, start the disperser and control the speed at 500r / mi...

Embodiment 2

[0064] An anti-graffiti and scrubbing-resistant coating composition, its raw materials include component A and component B, and the mass ratio of component A and component B is 100:40.

[0065]The ingredients and parts by mass that respectively constitute component A and component B are shown in the table below.

[0066] Component A:

[0067]

[0068] Component B:

[0069]

[0070] in,

[0071] The preparation method of component A is, according to the above-mentioned mass parts, in the reaction kettle, put the deionized water in the disc disperser, start the disperser and control the rotation speed at 500r / min, and then add the remaining ingredients to the In the disperser, disperse for 15 minutes, and mix evenly;

[0072] The preparation method of component B is as follows: according to the above-mentioned parts by mass, in the reaction kettle, polyisocyanate and propylene glycol methyl ether acetate are placed in a disc disperser, start the disperser and control th...

Embodiment 3

[0083] An anti-graffiti and scrubbing-resistant coating composition, its raw materials include component A and component B, and the mass ratio of component A and component B is 100:30.

[0084] The ingredients and parts by mass that respectively constitute component A and component B are shown in the table below.

[0085] Component A:

[0086]

[0087] Component B:

[0088]

[0089] in,

[0090] The preparation method of component A is, according to the above-mentioned mass parts, in the reaction kettle, put the deionized water in the disc disperser, start the disperser and control the rotation speed at 500r / min, and then add the remaining ingredients to the In the disperser, disperse for 15 minutes, and mix evenly;

[0091] The preparation method of component B is as follows: according to the above-mentioned parts by mass, in the reaction kettle, polyisocyanate and propylene glycol methyl ether acetate are placed in a disc disperser, start the disperser and control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com