Composite positive electrode material for sodium-ion battery and preparation method of composite positive electrode material

A technology of composite cathode material and sodium ion battery, applied in the field of sodium ion battery, can solve the problems of deteriorating material properties, many impurity phases of materials, poor doping effect, etc. Effect of Rate Cycling Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

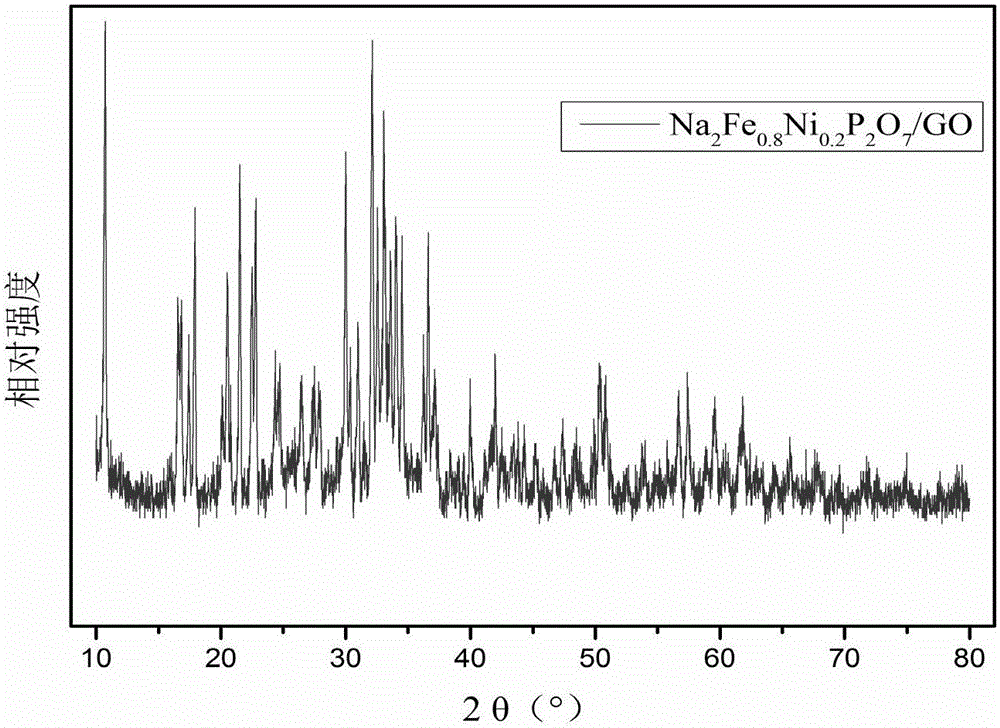

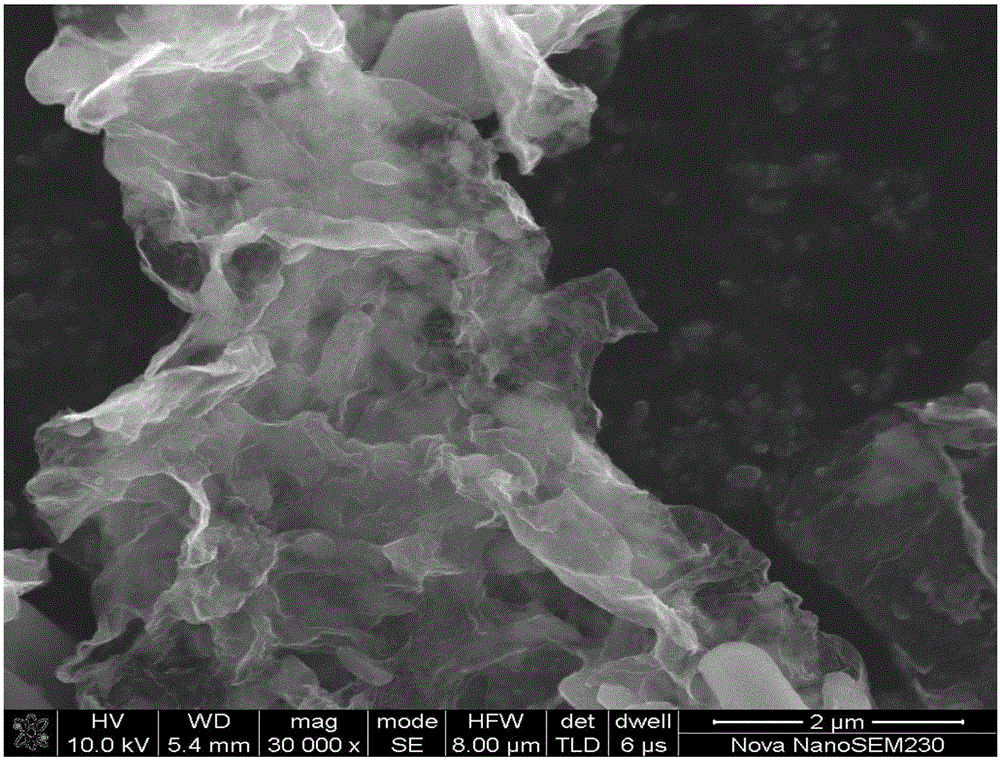

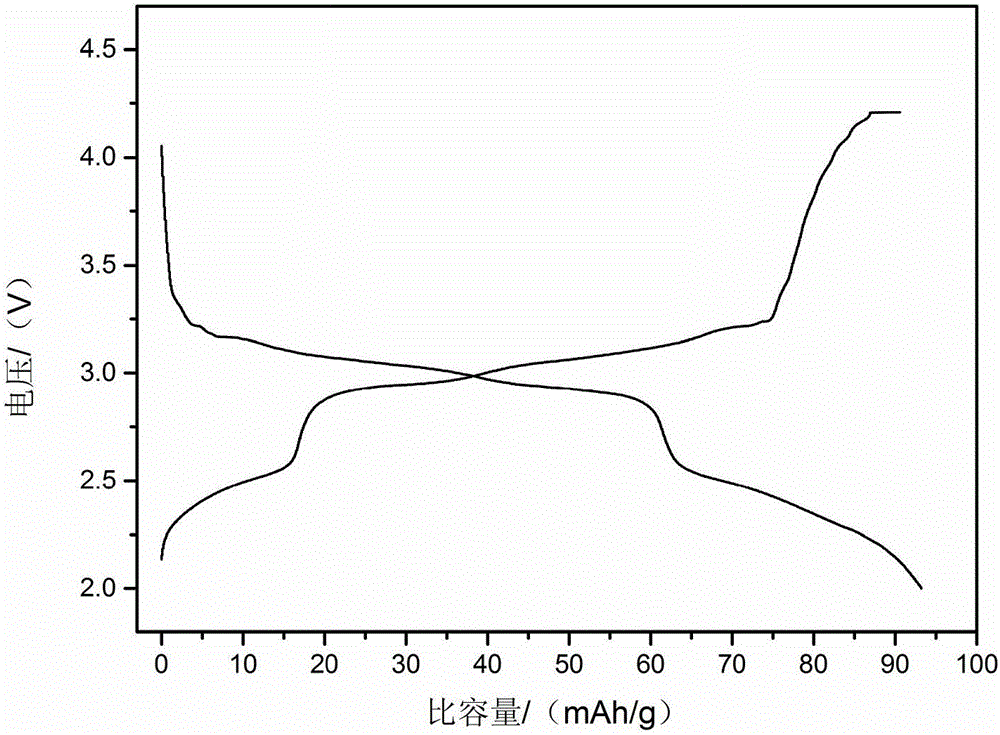

[0052] (1) present embodiment comprises the following steps: present embodiment design generates 0.03mol target product Na 2 Fe 0.8 Ni 0.2 P 2 o 7 / rGO, dissolve 0.85g graphene oxide in 80mL ethanol solution, add 1g ascorbic acid, ultrasonically disperse for 3h, add 0.024mol ferric nitrate and 0.006mol nickel acetate into the graphene oxide ethanol solution, stir well and then slowly add 0.06mol Ammonium dihydrogen phosphate, while supplemented by vigorous stirring, to obtain a mixed solution;

[0053] (2) Stir and heat the obtained mixed solution at 80° C. for 1 h, add 0.031 mol of sodium carbonate at a uniform rate, and at the same time supplement with vigorous stirring, react at 80° C. for 2 h, and then separate the solid from the liquid, wash with ethanol aqueous solution until the eluate is neutral, Drying, the resulting solid product is Na 2 Fe 0.8 Ni 0.2 P 2 o 7 Precursor of / rGO;

[0054] (3) The precursor obtained in step (2) is first sintered at 350°C under...

Embodiment 2

[0061] This embodiment includes the following steps:

[0062] (1) The design of this embodiment generates 0.03mol target product Na 2 Fe 0.8 Ni 0.2 P 2 o 7 / rGO, dissolve 0.85g graphene oxide in 80mL ethylene glycol solution, add 1g ascorbic acid, ultrasonically disperse for 3h, add 0.024mol iron nitrate and 0.006mol nickel acetate into the graphene oxide ethanol solution, stir well and then slowly add 0.06mol ammonium dihydrogen phosphate, supplemented by vigorous stirring simultaneously, to obtain a mixed solution;

[0063] (2) Stir and heat the resulting mixed solution at 80° C. for 1 h, add 0.03 mol of sodium carbonate at a uniform rate, and at the same time supplement with vigorous stirring, react at 80° C. for 2 h, and then separate the solid from the liquid, wash with ethanol aqueous solution until the eluate is neutral, Drying, the resulting solid product is Na 2 Fe 0.8 Ni 0.2 P 2 o 7 Precursor of / rGO;

[0064] (3) The precursor obtained in step (2) is first...

Embodiment 3

[0067] This embodiment includes the following steps:

[0068] (1) The design of this embodiment generates 0.03mol target product Na 2 Fe 0.5 Ni 0.5 P 2 o 7 / rGO, dissolve 0.85g graphene oxide in 80mL ethanol solution, add 1g ascorbic acid for ultrasonic dispersion for 3h, add 0.015mol ferric nitrate and 0.015mol nickel acetate into the graphene oxide ethanol solution, stir well and then slowly add 0.06mol phosphoric acid Ammonium dihydrogen, supplemented by vigorous stirring simultaneously, obtains mixed solution;

[0069] (2) Stir and heat the resulting mixed solution at 80° C. for 1 h, add 0.032 mol of sodium carbonate at a uniform rate, and at the same time supplement with vigorous stirring, react at 80° C. for 2 h, then separate the solid from the liquid, wash with ethanol aqueous solution until the eluate is neutral, Drying, the resulting solid product is Na 2 Fe 0.5 Ni 0.5 P 2 o 7 Precursor of / rGO;

[0070] (3) The precursor obtained in step (2) is first sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com