Epoxy resin composite material and preparation method thereof

An epoxy resin and composite material technology, which is applied in the field of insulating packaging materials, can solve the problems of high crack resistance requirements, complex operating conditions of high-frequency transformers, and increased viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

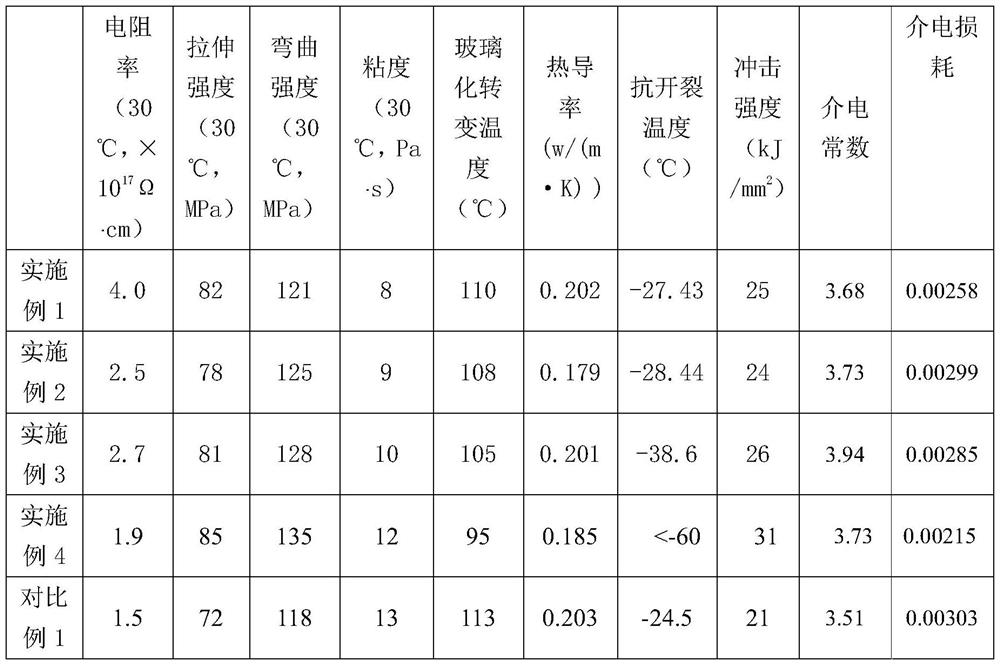

Examples

Embodiment 1

[0028] The epoxy resin composite material that present embodiment provides, its preparation method comprises:

[0029] 1) Preparation of monohydroxy polyether alcohol grafted epoxy resin

[0030] Take 10 parts by mass of toluene diisocyanate (TDI), 0.01 parts by mass of dibutyltin dilaurate and 10 parts by mass of polyethylene glycol monomethyl ether-550, and add them to 450 parts by mass of tetrahydrofuran (THF), mix well, and heat at 60°C React for 4 hours, then add 10 parts by mass of bisphenol A type epoxy resin (epoxy value 0.54), mix well, continue to react for 4 hours, remove the solvent, and obtain monohydroxy polyether alcohol grafted epoxy resin.

[0031] 2) Preparation of epoxy resin composite materials

[0032] In the preheated mold, add 2.5 mass parts of monohydroxy polyether alcohol grafted epoxy resin and 100 mass parts of bisphenol A type epoxy resin, 100 mass parts of hexahydrophthalic anhydride curing agent and 1 Accelerator benzyldimethylamine (BDMA) of ma...

Embodiment 2

[0034] The epoxy resin composite material that present embodiment provides, its preparation method comprises:

[0035] 1) Preparation of monohydroxy polyether alcohol grafted epoxy resin

[0036] Take 15 parts by mass of toluene diisocyanate (TDI), 0.02 parts by mass of dibutyltin dilaurate and 12 parts by mass of polyethylene glycol monomethyl ether-550, and add them to 460 parts by mass of tetrahydrofuran (THF), mix well, and heat at 60°C React for 4 hours, then add 15 parts by mass of bisphenol A type epoxy resin (epoxy value 0.54), mix well, continue to react for 4 hours, remove the solvent, and obtain monohydroxy polyether alcohol grafted epoxy resin.

[0037] 2) Preparation of epoxy resin composite material

[0038] In the preheated mold, add 5 mass parts of monohydroxy polyether alcohol grafted epoxy resin and 100 mass parts of bisphenol A type epoxy resin, 60 mass parts of hexahydrophthalic anhydride curing agent and 1 Accelerator benzyl dimethylamine (BDMA) of mass ...

Embodiment 3

[0040] The epoxy resin composite material that present embodiment provides, its preparation method comprises:

[0041] 1) Preparation of monohydroxy polyether alcohol grafted epoxy resin

[0042] Take 15 parts by mass of toluene diisocyanate (TDI), 0.03 parts by mass of dibutyltin dilaurate and 14 parts by mass of polyethylene glycol monomethyl ether-550 and add them to 480 parts by mass of tetrahydrofuran (THF), mix well, and put React for 4 hours, then add 25 parts by mass of bisphenol A type epoxy resin (epoxy value 0.54), mix well, continue to react for 4 hours, remove the solvent, and obtain monohydroxy polyether alcohol grafted epoxy resin.

[0043] 2) Preparation of epoxy resin composite material

[0044] Get 8 mass parts of monohydroxypolyether alcohol grafted epoxy resin and 100 mass parts of bisphenol A type epoxy resin, 80 mass parts of hexahydrophthalic anhydride curing agent and 1 mass part of accelerator benzyl Dimethylamine (BDMA) was mixed and heated to 100°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com