Method for manufacturing composite surface section bar and composite surface plastic section bar

A technology of plastic profiles and composite surfaces, which is applied in the field of plastic materials, can solve the problems of unsightly appearance, impermanent coloring, and easy abrasion, etc., and achieve the effects of good anti-slip performance, simple construction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

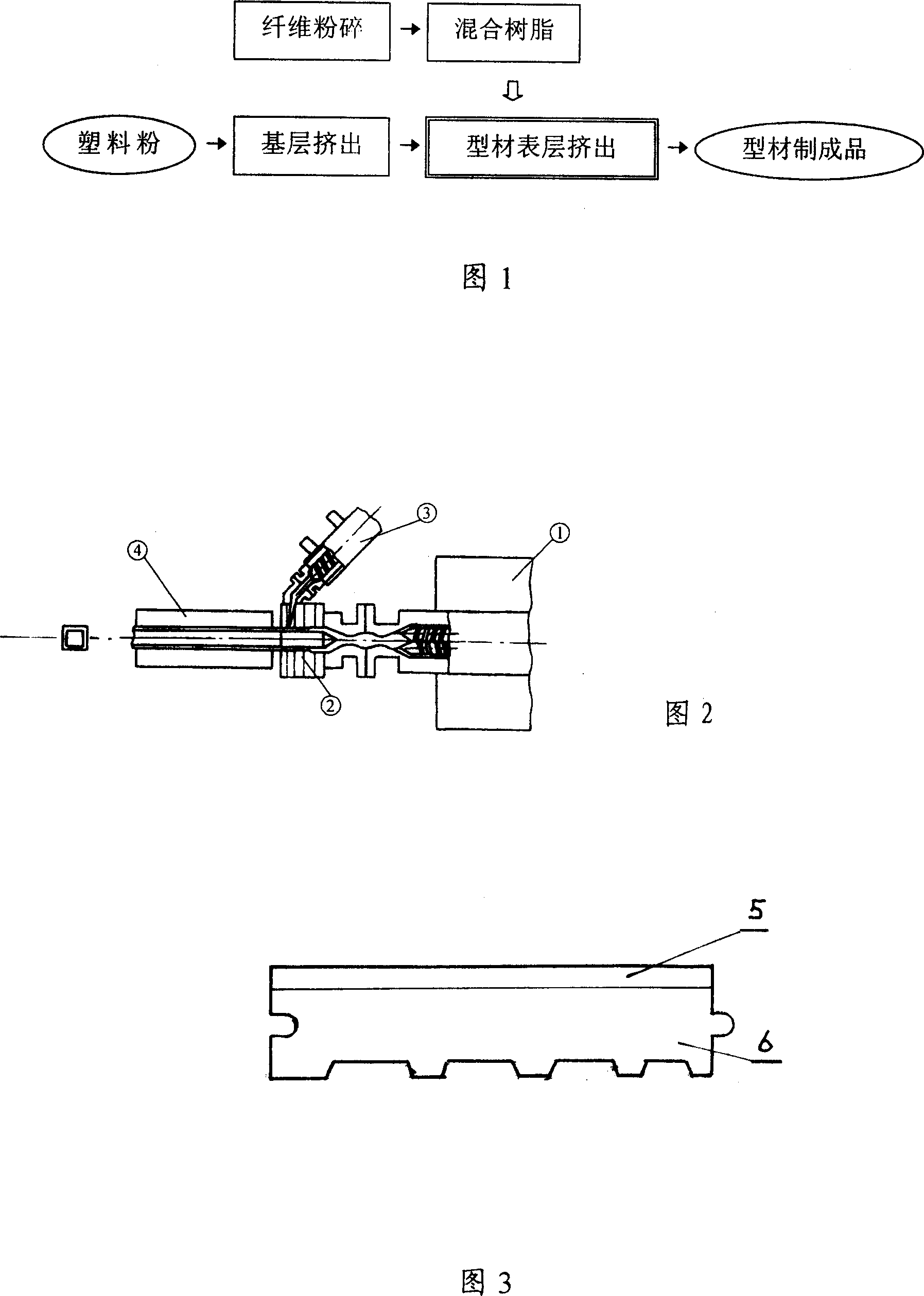

[0010] A method for manufacturing composite surface profiles, which is characterized in that vegetable fibers such as rice husk powder and wood powder, or textile waste fibers are used as fillers and mixed with synthetic resin powder to form plastics with natural plant characteristics. The plastic with natural plant characteristics is used as the surface material of the plastic profile, and the traditional plastic is used as the base layer of the profile, and the composite surface plastic profile is made by a co-extrusion process of the plastic profile.

[0011] A composite surface plastic profile, consisting of a surface layer and a base layer, characterized in that the surface layer is made of plant fibers such as rice husk powder, wood powder, or textile waste fibers as fillers, mixed with synthetic resin powder to make it have natural plant characteristics Composed of plastic, the base layer is traditionally made of calcium carbonate, light calcium carbonate, kaolin, gypsum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com