High-temperature alloy mold material as well as preparation method and application thereof

A mold material and high-temperature alloy technology, applied in the field of high-temperature alloy mold materials and their preparation, can solve problems such as insufficient mechanical properties, insufficient depth of nitriding layer, excess thermal strength, etc., to improve high-temperature mechanical properties, reduce material costs, Effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

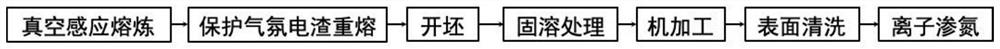

[0039] The alloy composition in this example is shown in Table 1. like figure 1 As shown, the preparation steps are as follows:

[0040] (1) The total weight of the superalloy mold material is 50kg, after vacuum induction melting and protective atmosphere electroslag remelting, the composition is shown in Table 1;

[0041] (2) During the batching process before alloy smelting, the burning loss rate of Al, Ti, and B elements must be considered as 0.3, 0.2 and 0.5 respectively. After batching, it is added to the vacuum induction furnace for melting. The melting process includes melting, refining, alloying and Pouring; first put nickel, chromium, molybdenum, iron, and carbon into the crucible, and refine for 35 minutes after refining. After refining, stir the alloy liquid melt, and then power off and cool down to make the alloy liquid film; then power on, add aluminum and titanium, and smelt After 10 minutes, stir the alloy liquid melt, fill with argon, add boron and smelt for ...

Embodiment 2

[0053] The difference between this example and Example 1 is that the flow ratio of nitrogen and hydrogen in step (7) is 1:4.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the air pressure in the furnace is maintained at 400Pa in step (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com