Multiphase oxide particles enhanced copper-base composite material and preparing method thereof

A technology of copper-based composite materials and oxide particles, which is applied in the field of new copper-based electrical alloys, can solve the problems of difficult formation of oxide particle reinforcement phase, inability to form large-scale production, unstable high-temperature performance of materials, etc., and achieve rapid solidification structure Features, excellent strength and processability, and the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

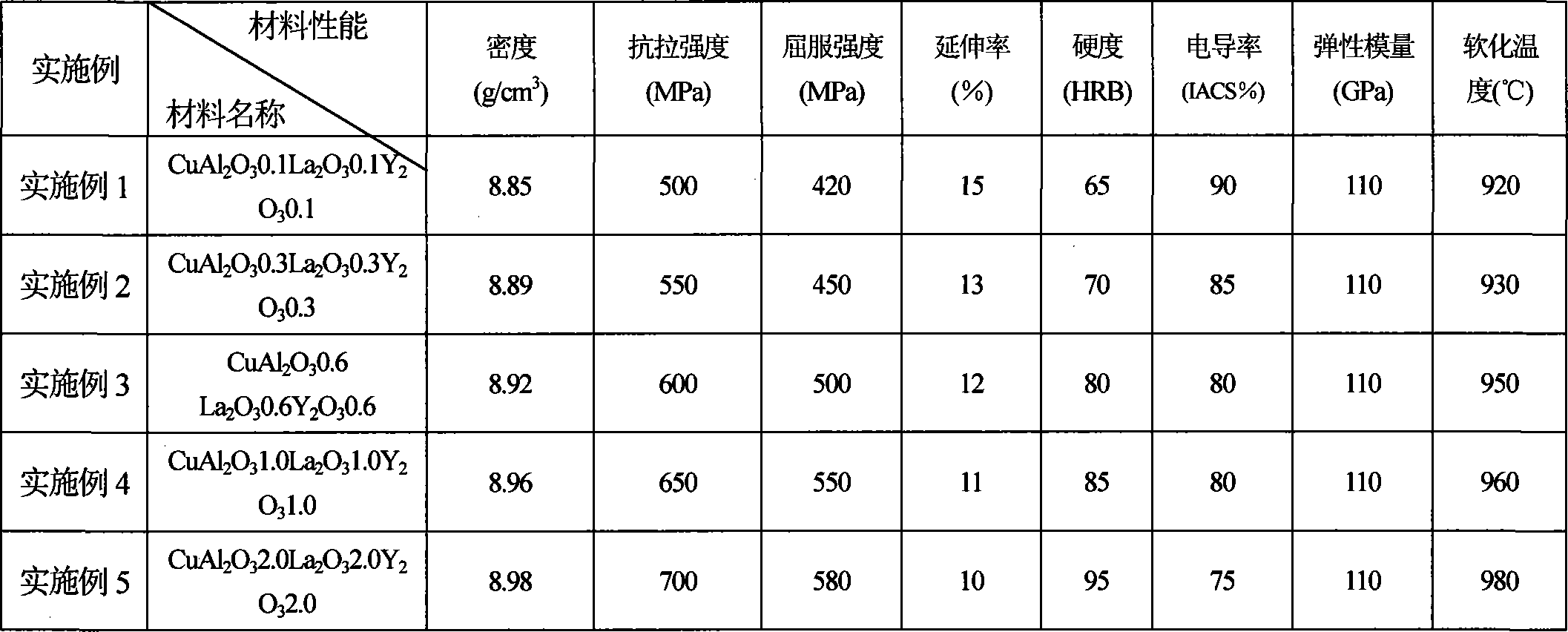

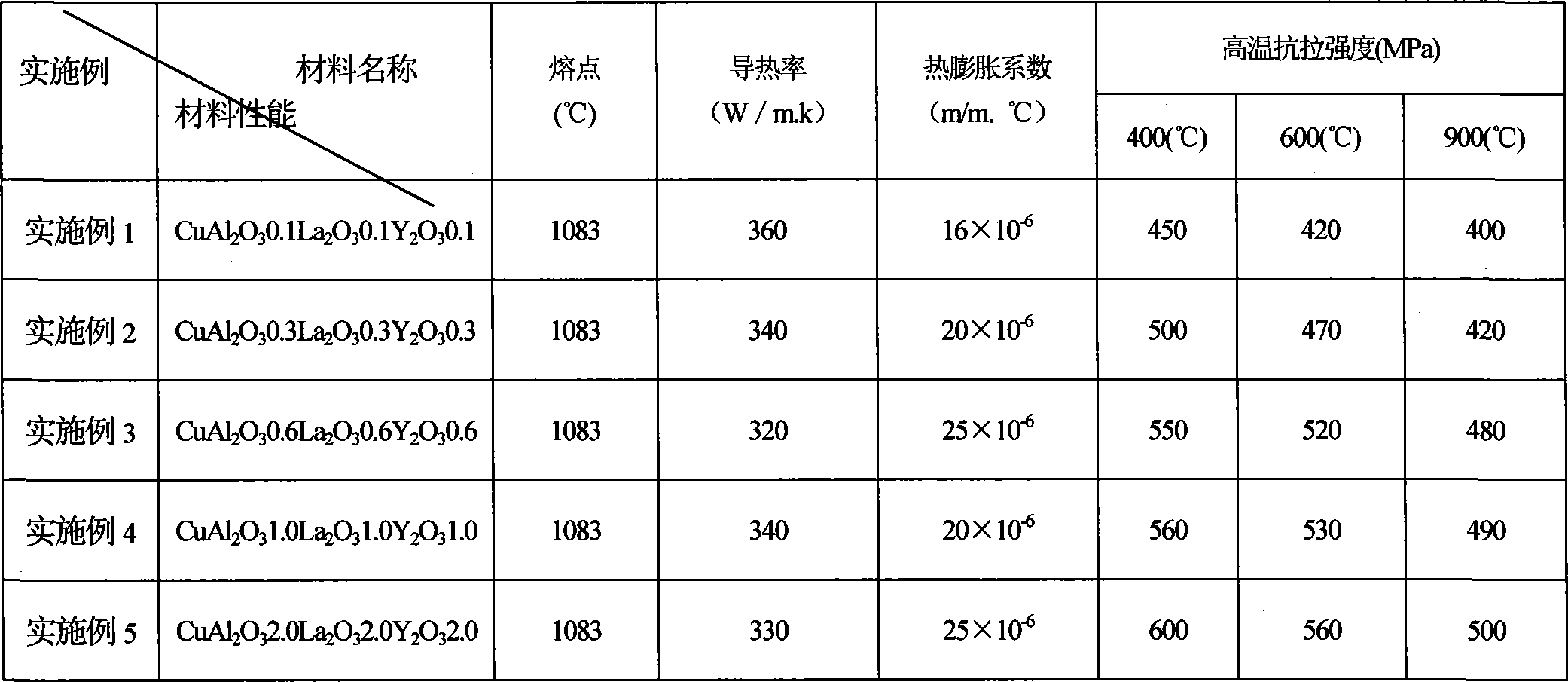

[0013] The chemical composition weight percent (wt%) of copper-based composite material of the present invention is: Al 2 o 3 : 0.1~2.0, La 2 o 3 : 0.1~2.0, Y 2 o 3 : 0.1 to 2.0, the balance being Cu.

[0014] The preparation method of copper-based composite material of the present invention, its specific process step process is:

[0015] (1) Al, La, Y, and Cu elements with a purity >99.9% are prepared according to the alloy design composition ratio, and vacuum spray deposition equipment is used to prepare near-formed components such as ingots, plates, and wheels of CuAlLaY alloys.

[0016] (2) Control the partial pressure of oxygen and perform in-situ chemical reaction treatment on CuAlLaY alloy to prepare CuAl 2 o 3 La 2 o 3 Y 2 o 3 It is a composite material, and the in-situ reaction temperature is: 800℃~1000℃.

[0017] (3) CuAl 2 o 3 La 2 o 3 Y 2 o 3 Composite materials are processed by forging, extrusion, rolling, drawing, etc., and finally processed int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com