Nano-copper soldering paste, preparing method thereof and copper-copper bonding method

A nano-copper and solder paste technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of easy oxidation of nano-copper solder paste sintering, and achieve the effects of easy acquisition, cost reduction, and oxidation avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In some embodiments of the present invention, a method for preparing nano copper solder paste is also provided, comprising the steps of: cleaning the nano copper particles, ultrasonically treating them with an ethanol solution containing an organic acid, and then mixing with alcohol amine and a viscosity modifier Mix and grind to obtain the nano copper solder paste.

[0027] In some specific embodiments of the invention, the organic acid described in the above preparation method is selected from formic acid, acetic acid, glycolic acid, oxalic acid or lactic acid; the cleaning step can use dilute acid solution for stirring or ultrasonic cleaning.

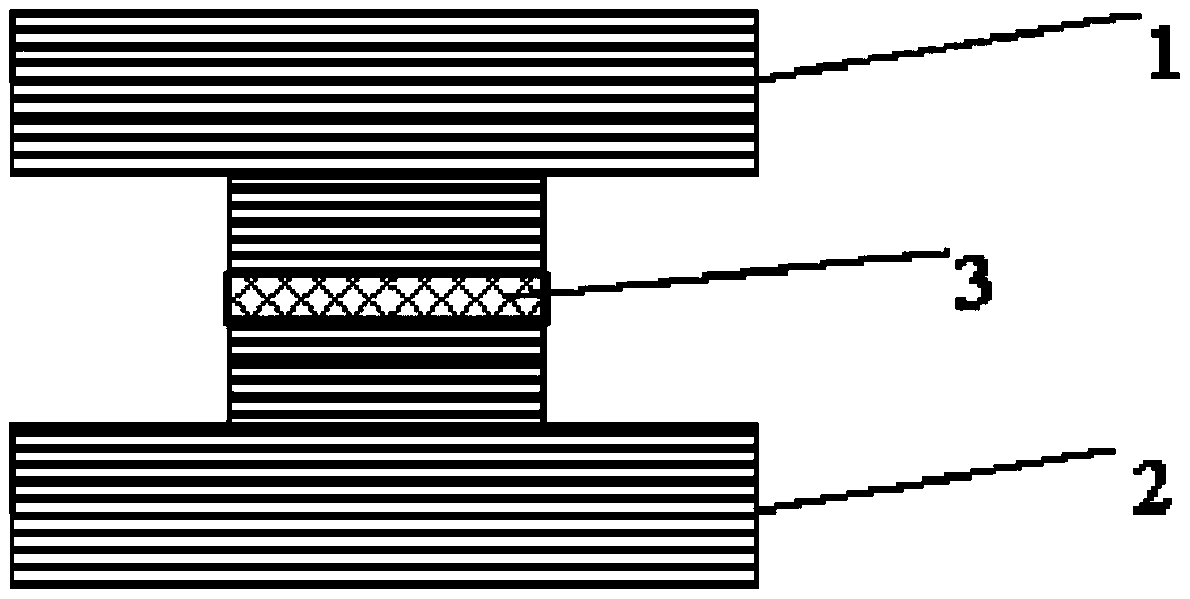

[0028]In some embodiments of the present invention, there is also provided a method for copper-copper bonding using the above-mentioned nano-copper solder paste, including the following steps: (1) preparing a sample to be bonded: applying the nano-copper solder paste to The surface to be bonded of at least one copper sample, a...

Embodiment 1

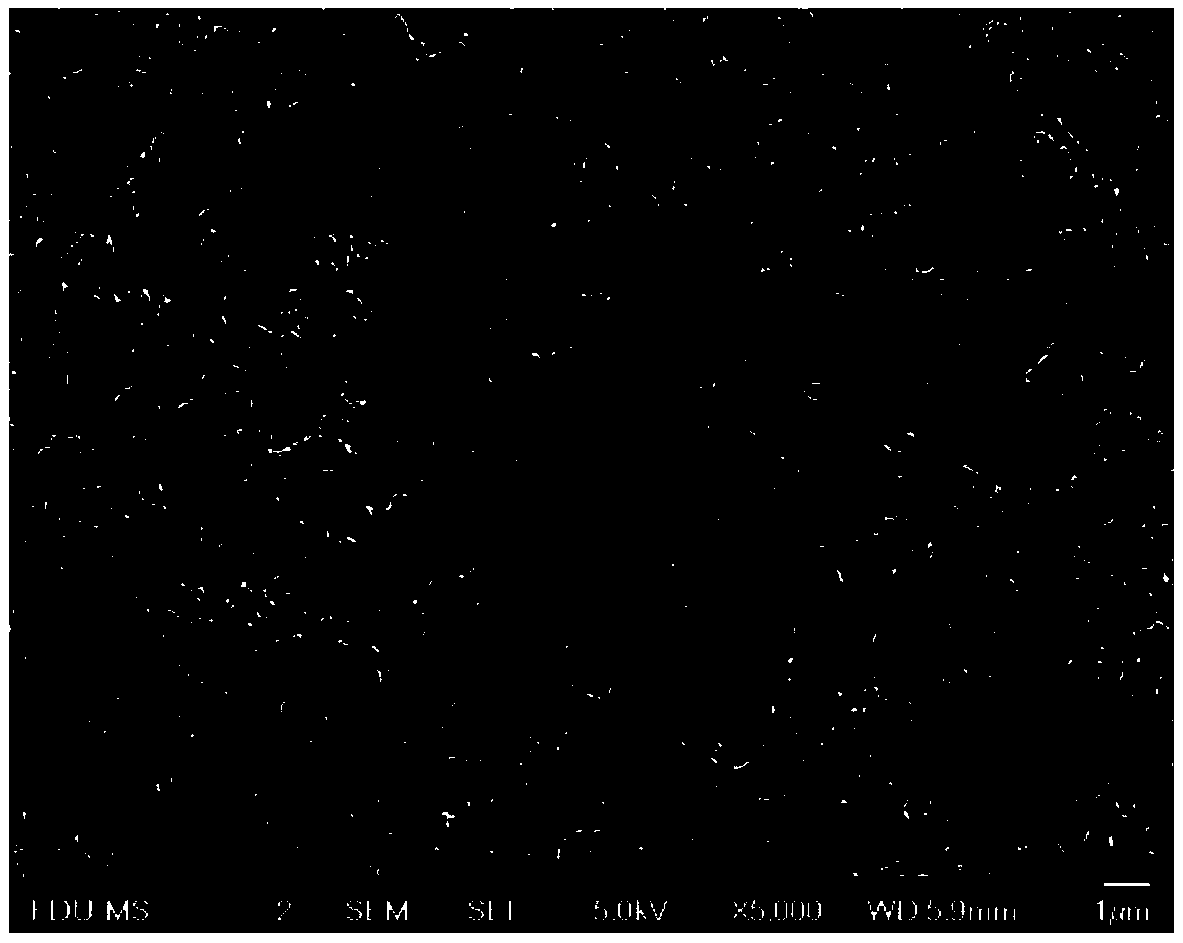

[0034] The nano-copper soldering paste of this embodiment comprises: nano-copper particles: 80%, 3-dimethylamino-1,2-propanediol: 15%, and viscosity modifier ethylene glycol: 5%.

[0035] Nano-copper particles with a particle size of 90nm are used, and the surface oxide is removed by ultrasonic cleaning with 10% volume ratio of dilute sulfuric acid. After cleaning and centrifugation, 10% mass ratio of lactic acid alcohol solution is used for ultrasonic treatment. Amino-1,2-propanediol is mixed, fully ground in a mortar, and ethylene glycol is added in proportion as a viscosity regulator to obtain a nano-copper solder paste with a moderate viscosity. The mass percentage of nano-copper particles in the solder paste is 80% %, the rest are alcohol amines and viscosity modifiers.

[0036] The copper sample is a red copper column with a diameter of 5mm. After the surface is polished, treated with dilute sulfuric acid, and cleaned, a 150-micron nano-copper solder paste is applied to ...

Embodiment 2

[0039] The nano-copper solder paste of this embodiment comprises: nano-copper particles: 90%, 3-dimethylamino-1,2-propanediol: 10% in terms of mass percentage.

[0040] Using nano-copper particles with a particle size of 90nm, use 10% volume ratio of dilute sulfuric acid to ultrasonically clean to remove surface oxides. Amino-1,2-propanediol is mixed and thoroughly ground in a mortar to form a solder paste, the proportion of copper in the solder paste is 90%, and the rest is alcoholamine.

[0041] The copper sample is a copper column with a diameter of 5mm. After the surface is polished, treated with dilute sulfuric acid, and cleaned, a 150-micron-thick solder paste is applied to the surface to be bonded of at least one copper sample by scraping, and the two copper samples are paired. After sticking, a copper-solder paste-copper "sandwich" sample to be bonded is obtained. Preheat at 100°C for 3 minutes, then carry out thermocompression welding, the pressure is 4MPa, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com