Original fragrant perilla edible blend oil and production process thereof

A technology of edible plants and production technology, which is applied in the direction of edible oil/fat, fat oil/fat production, food science, etc., and can solve the problems that affect the qualified rate of products, the fragrance cannot be felt, and the toxicity of physiological functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

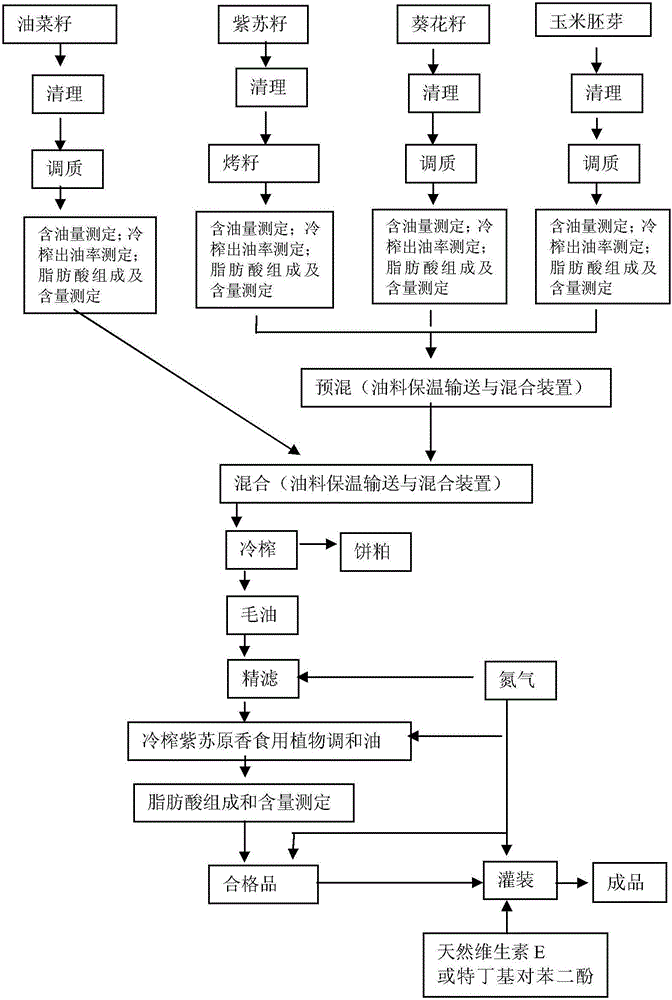

[0077] This embodiment provides a method for producing original flavor type perilla edible vegetable blend oil with fresh perilla seeds, rapeseed, sunflower seeds and corn germ, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0078] Transport perilla seeds, rapeseeds, sunflower seeds and corn germs to their respective cleaning devices (air separation, screening combined device) for dust removal and impurity removal. The residence time of oil in the device is 10 seconds, and the thickness is 5 mm;

[0079] Then, except for the perilla seeds, they are transported to their respective conditioning devices for conditioning. The conditioning temperature of rapeseed is 65°C, adjusted to a moisture content of 7%; the conditioning temperature of sunflower seeds and corn germ is 65°C, adjusted to a moisture content of 7%;

[0080] Transport the cleaned perilla seeds to the seed roasting device for roasting. The roasting temperature of ...

Embodiment 2

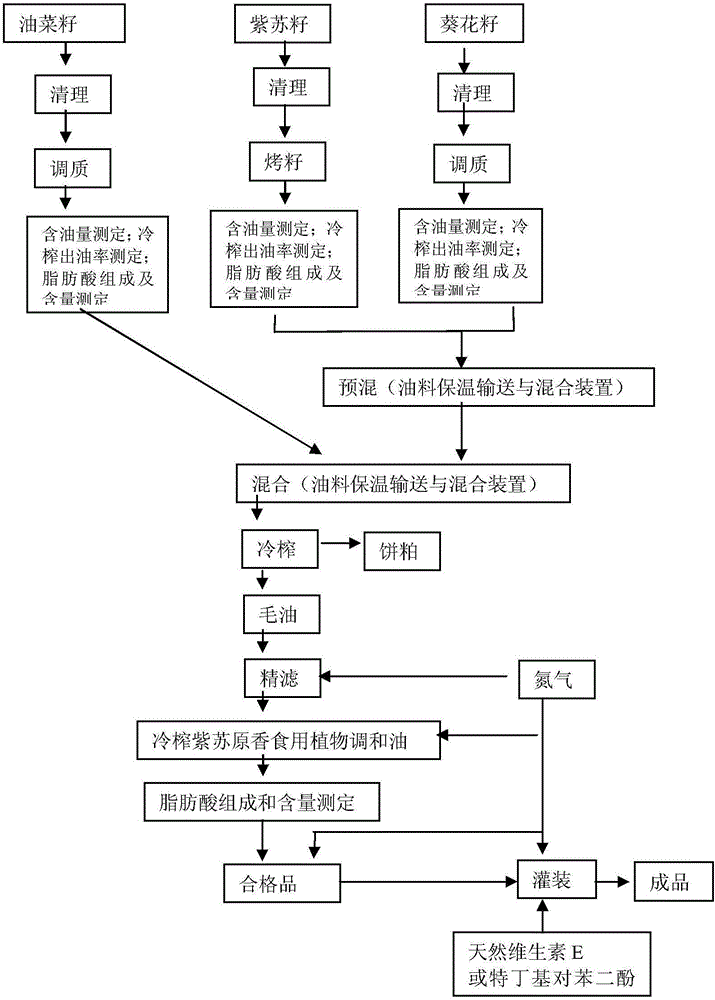

[0095] This embodiment provides a method for preparing original flavor type perilla edible vegetable blend oil with fresh rapeseed, perilla seed and sunflower seed as raw materials. The process flow is as follows: figure 2 As shown, it specifically includes the following steps:

[0096] The rapeseed, perilla seed and sunflower seed are transported to their respective cleaning devices (wind separation and screening combined device) for dust removal and impurity removal. The residence time of the oil in the device is 10 seconds and the thickness is 5 mm;

[0097] Then, except for the perilla seeds, they are transported to their respective conditioning devices for conditioning. The conditioning temperature of rapeseed is 65°C, adjusted to a moisture content of 7%; the conditioning temperature of sunflower seeds is 65°C, Adjust the moisture content to 7%; transport the cleaned perilla seeds to a seed roasting device for roasting, the roasting temperature of the perilla seeds is 1...

Embodiment 3

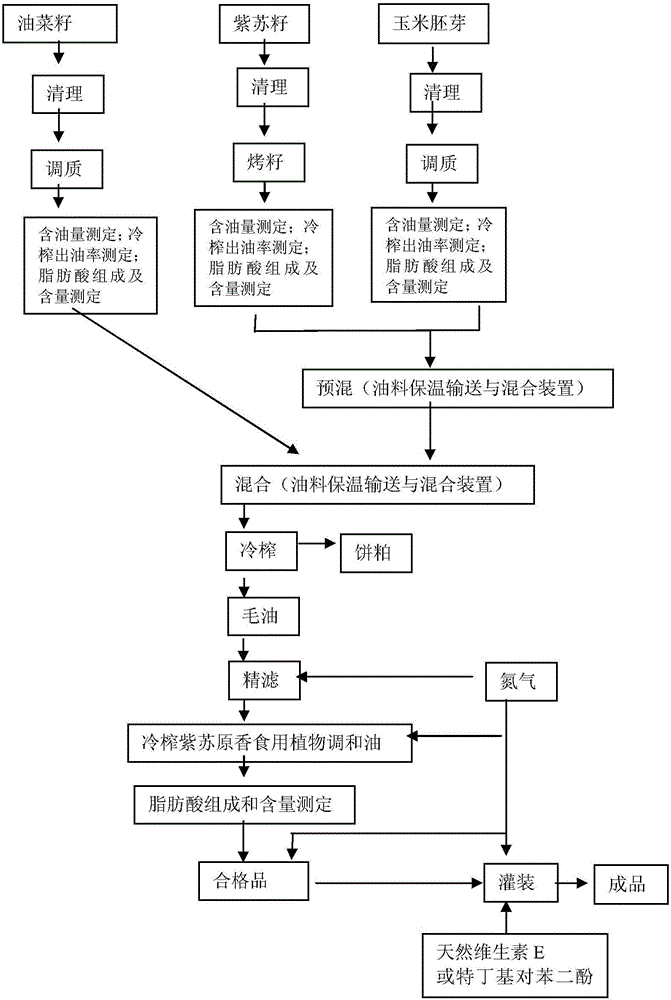

[0108] This example provides a method for preparing original-flavor perilla edible plant blend oil with fresh rapeseed, perilla seed and corn germ as raw materials. The process flow is as follows: image 3 As shown, it specifically includes the following steps:

[0109] The rapeseed, perilla seed, and corn germ are transported to their respective cleaning devices (air separation, screening combination device) for dust removal and impurity removal. The residence time of the oil in the device is 10 seconds, and the thickness is 5 mm;

[0110] Then, except for the perilla seeds, they are transported to respective conditioning devices for conditioning. The conditioning temperature of rapeseed and corn germ is 65°C, and the moisture content is adjusted to 7%; the cleaned perilla seeds Transport to the seed roasting device for roasting seeds, the roasting temperature of perilla seeds is 160°C, and the time is 10 minutes;

[0111] Take samples separately, measure fatty acid composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com