High-cobalt martensitic stainless steel and preparation method

A technology of martensitic stainless steel and high-cobalt martensite, which is applied in the field of alloys and can solve problems such as low tensile strength and difficulty in meeting the high-strength requirements of stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing high-cobalt martensitic stainless steel described in the above technical solution, comprising the following steps:

[0046] (1) Mix the raw materials corresponding to each chemical composition according to the above mass content, and then carry out vacuum smelting and casting of the mixed raw materials in sequence to obtain steel ingots; the temperature of the vacuum smelting is 1580-1620°C, and the time of vacuum smelting is 30-180min ; Vacuum degree of vacuum melting ≤ 5Pa;

[0047] (2) Forging the steel ingot obtained in the step (2) to obtain a forging material; the starting forging temperature of the forging is 1180-1230°C, and the final forging temperature is 800-900°C;

[0048] (3) performing normalizing treatment and tempering treatment on the forging material obtained in the step (3) successively to obtain a machined forging material;

[0049] The temperature of the normalizing treatment is 1080-1130°C...

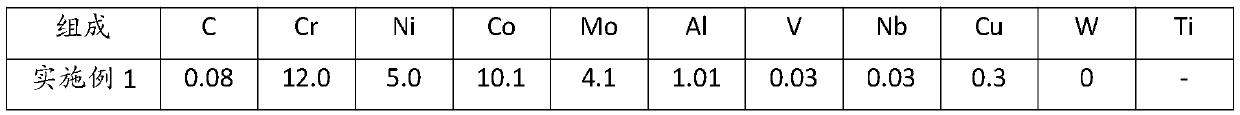

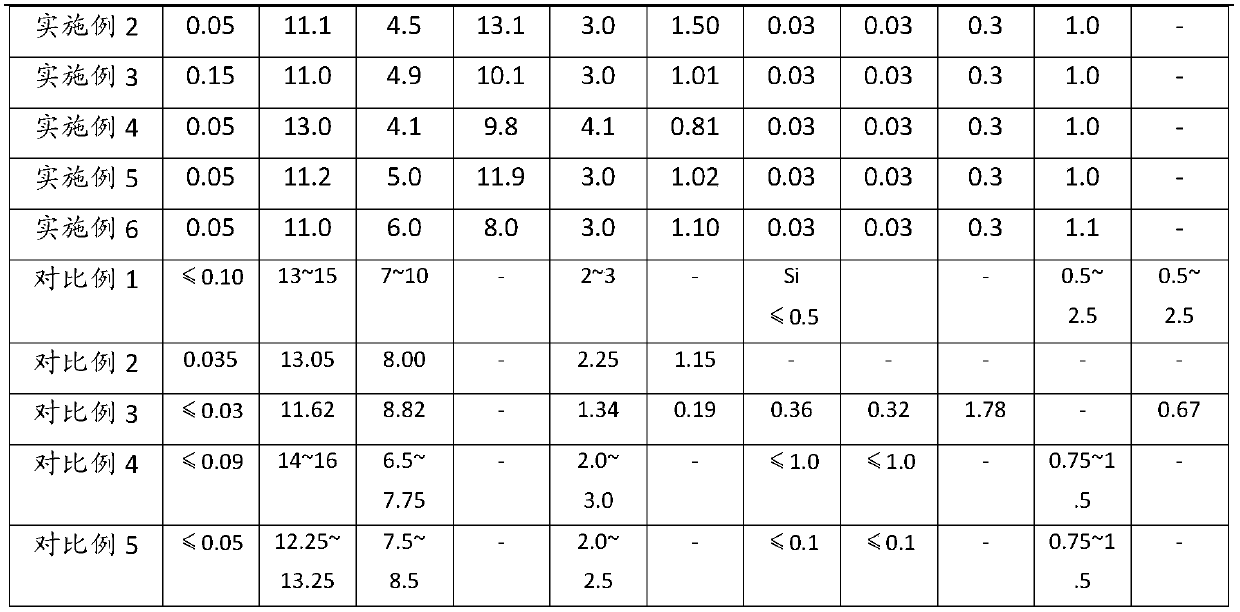

Embodiment 1~6

[0078] Based on 100% mass content, the chemical composition of Examples 1-6 is shown in Table 1, and the balance is Fe; the process parameters of the preparation method are shown in Table 2. Wherein, the smelting method of the embodiment is: two-stage smelting, and the time ratio of the first-stage smelting and the second-stage smelting is about 3:2.

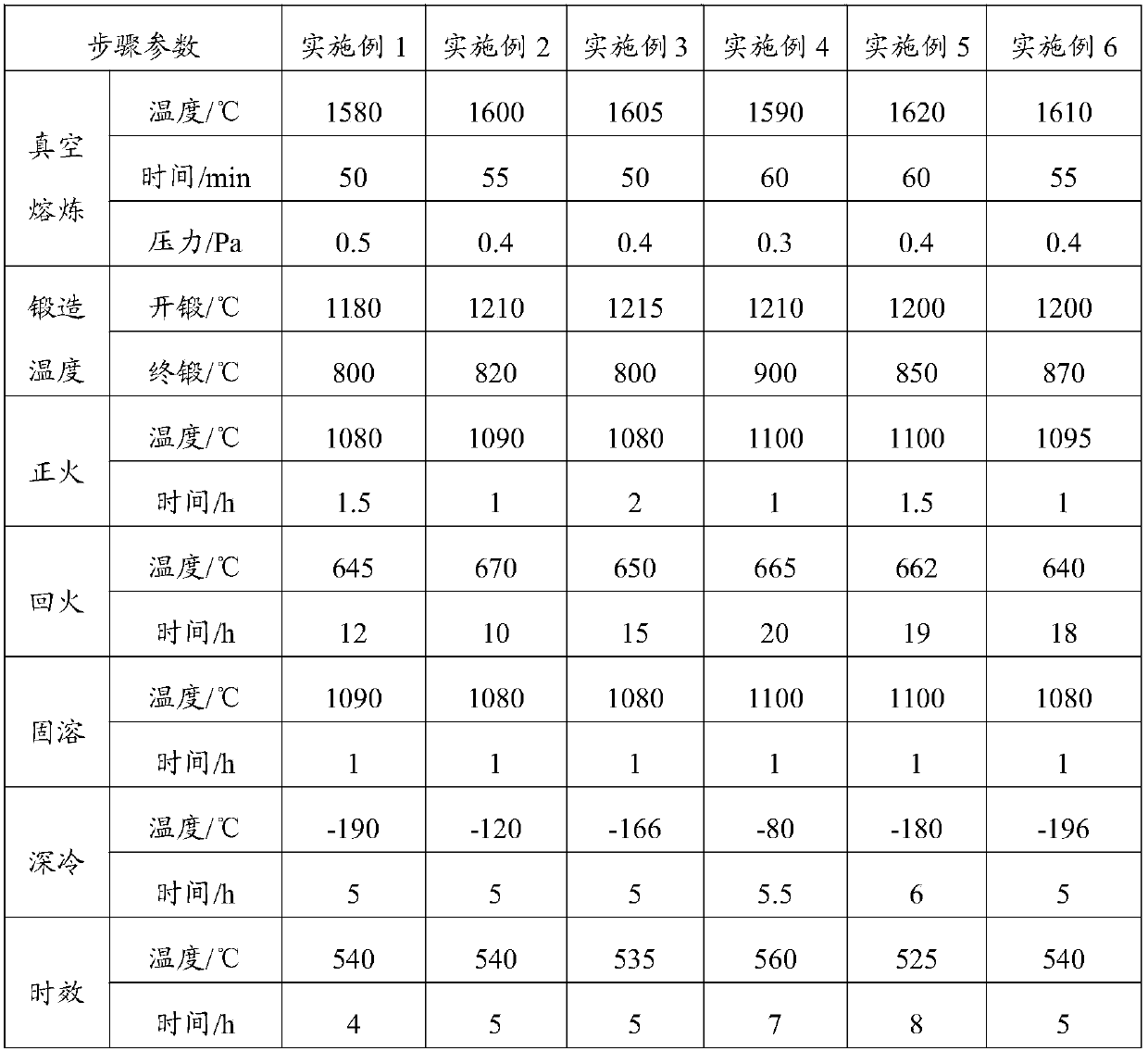

[0079] According to GB / T228.1-2010 standard to test the room temperature tensile properties of stainless steel samples; GB / T229-2007 standard to test the room temperature impact properties of stainless steel samples; GB / T4338-2006 standard to test the high temperature tensile properties of stainless steel samples, The test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com