High-alloy steel pipe piercing plugand manufacturing method thereof

A technology of perforated plugs and alloy steel pipes, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as easy peeling off of oxide film, sticking steel, melting loss, etc., to avoid flat nose and deformation, and low alloy cost , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

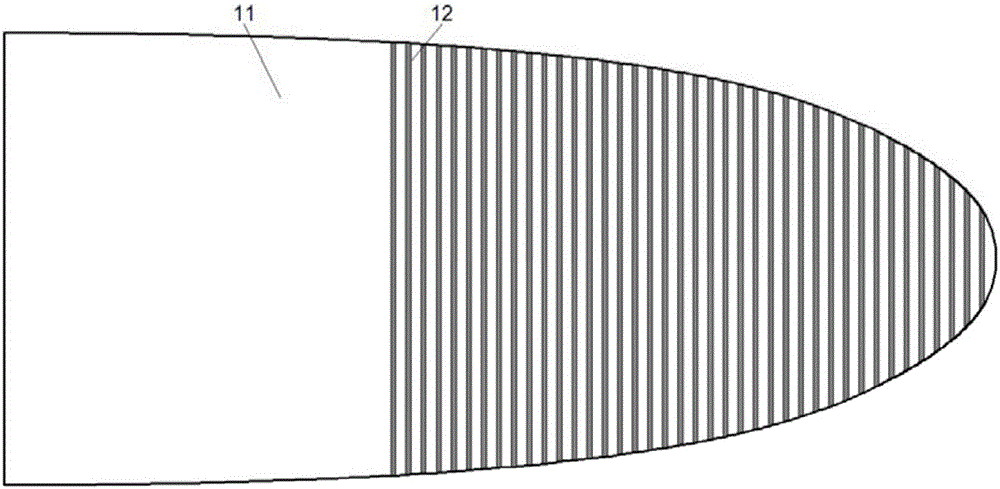

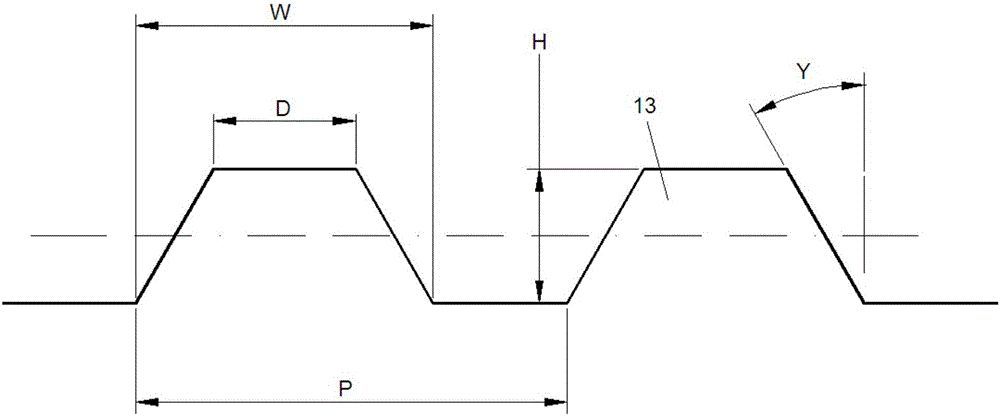

[0078] figure 2 A further magnification shows, in one embodiment, the screw channel structure of the perforated plug.

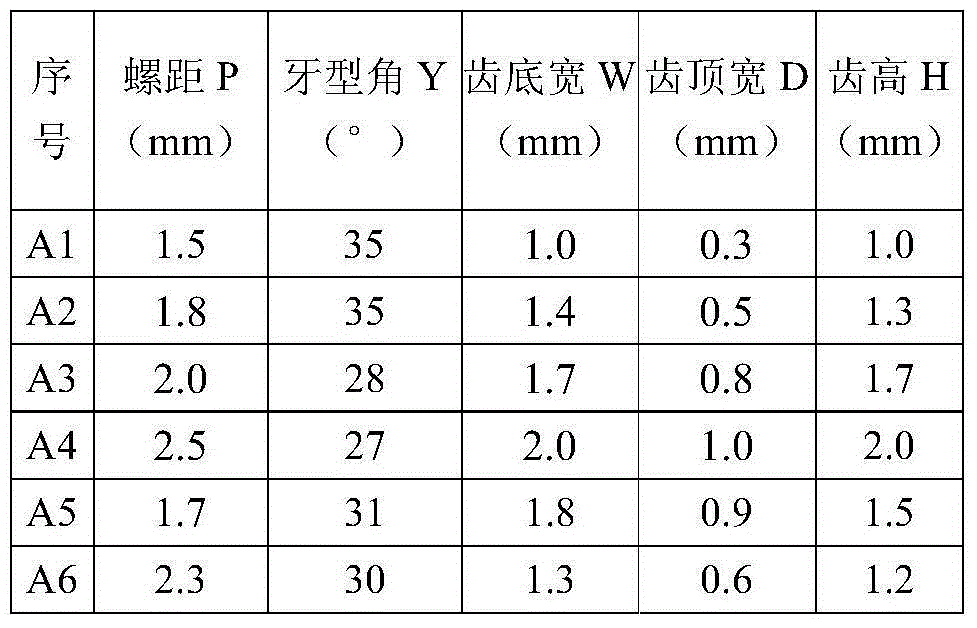

[0079] Such as figure 2 As shown, the tooth shape 13 of the screw track 12 is a trapezoidal tooth. Preferably, the pitch P of the screw track is set to 1.5-2.5 mm, the tooth profile angle Y is set to 25-35°, and the tooth bottom width W is set to 1.0-2.0 mm, the tooth top width D is set to 0.3-1.0mm, and the tooth height H is set to 1.0-2.0mm.

[0080] Please refer to Table 2 for specific process parameters in each step involved in the above-mentioned manufacturing method, and refer to Table 3 for details about the relevant parameters of the oxide film on the surface of the perforated plug.

[0081] Table 1 lists the mass percent content of each chemical element in the perforated plugs of Examples A1-A6 and Comparative Examples B1-B4.

[0082] Table 1. (wt.%, the balance is Fe and other unavoidable impurities)

[0083] serial number

C

S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com