Powder coating for MDF transfer printing and application method of powder coating

A technology of powder coating and application method, which is applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., can solve the problems of paper tearing difficulty, no powder coating, etc., and achieve strong three-dimensional effect, clear texture, and easy peeling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

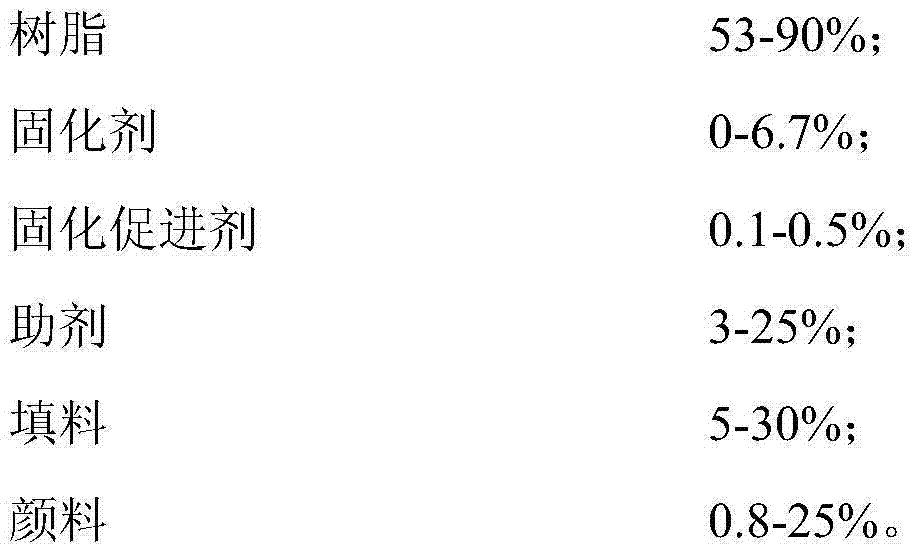

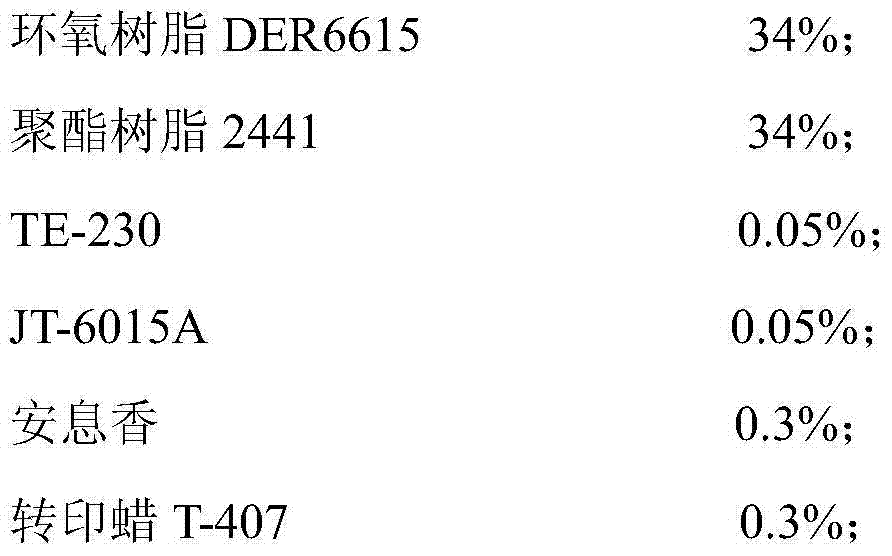

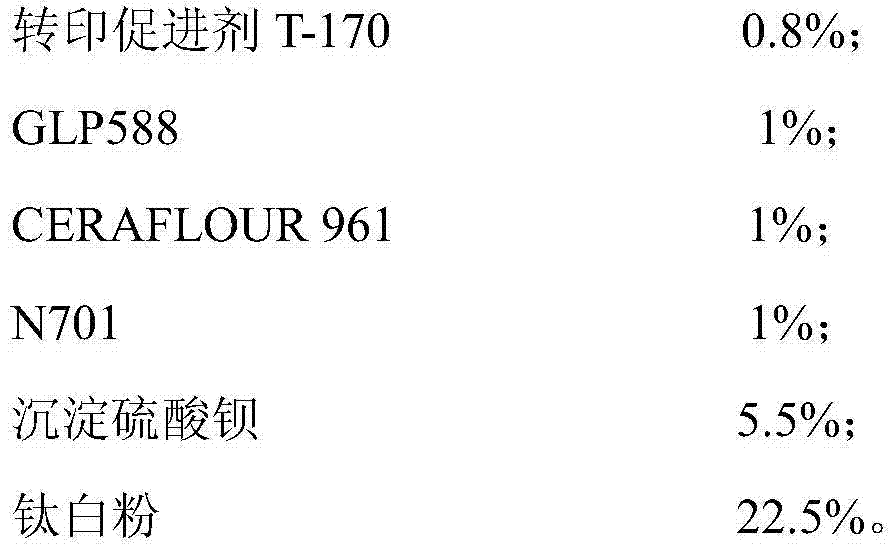

[0032] The MDF transfer printing powder coating described in the present embodiment is made of the following raw materials in percentage by weight:

[0033]

[0034]

[0035] Its application method is:

[0036] (1) Electrostatic powder spraying is carried out on the MDF after surface pretreatment, and the thermosetting coating is obtained by curing treatment; the curing method adopts mid-wave infrared pulse irradiation heating and curing, the curing temperature is 130 ° C, and the curing time is 15 minutes; the coating thickness is 70μm;

[0037] (2) Wrap the matching heat transfer paper on the surface of the above coating, and transfer on a flat heat transfer machine with a heating temperature of 190°C and a heating time of 3 minutes;

[0038] (3) Workpiece inspection and warehousing.

Embodiment 2

[0040] The MDF transfer printing powder coating described in the present embodiment is made of the following raw materials in percentage by weight:

[0041]

[0042] Its application method is:

[0043] (1) Electrostatic powder spraying is carried out on the MDF after surface pretreatment, and the thermosetting coating is obtained by curing treatment; the curing method adopts mid-wave infrared pulse irradiation heating and curing, the curing temperature is 160 ° C, and the curing time is 5 minutes; the coating thickness is 90μm;

[0044] (2) Wrap the matching heat transfer paper on the surface of the above coating, and transfer it on a flat heat transfer machine with a heating temperature of 195°C and a heating time of 2.8 minutes;

[0045] (3) Workpiece inspection and warehousing.

Embodiment 3

[0047] The MDF transfer printing powder coating described in the present embodiment is made of the following raw materials in percentage by weight:

[0048]

[0049] Its application method is:

[0050] (1) Electrostatic powder spraying is carried out on the MDF after surface pretreatment, and the thermosetting coating is obtained by curing treatment; the curing method adopts mid-wave infrared pulse radiation heating and curing, the curing temperature is 150 ° C, and the curing time is 10 minutes; the coating thickness is 80μm;

[0051] (2) Wrap the matching heat transfer paper on the surface of the above coating, and transfer on a flat heat transfer machine with a heating temperature of 200°C and a heating time of 2.5 minutes;

[0052] (3) Workpiece inspection and warehousing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com