Imitation tatting knitted fabric with same texture and multiple patterns and production process of imitation tatting knitted fabric

A knitted fabric and multi-pattern technology, which is applied in knitting, weft knitting, and fabric surface trimming, can solve the problems of less research on the production process of woven-like knitted shirt fabrics, limited pattern changes, and long production processes. , to achieve the effects of strong production process stability, improved texture definition, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The specific production process is: raw material → design → weaving → finishing.

[0040] Raw material: Cotton: N40 single yarn; by weight, cotton: 100%.

[0041] Design: See Table 1.

[0042] Table 1

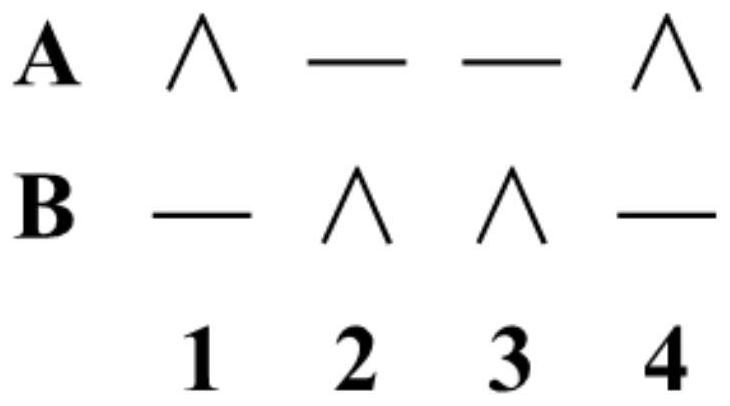

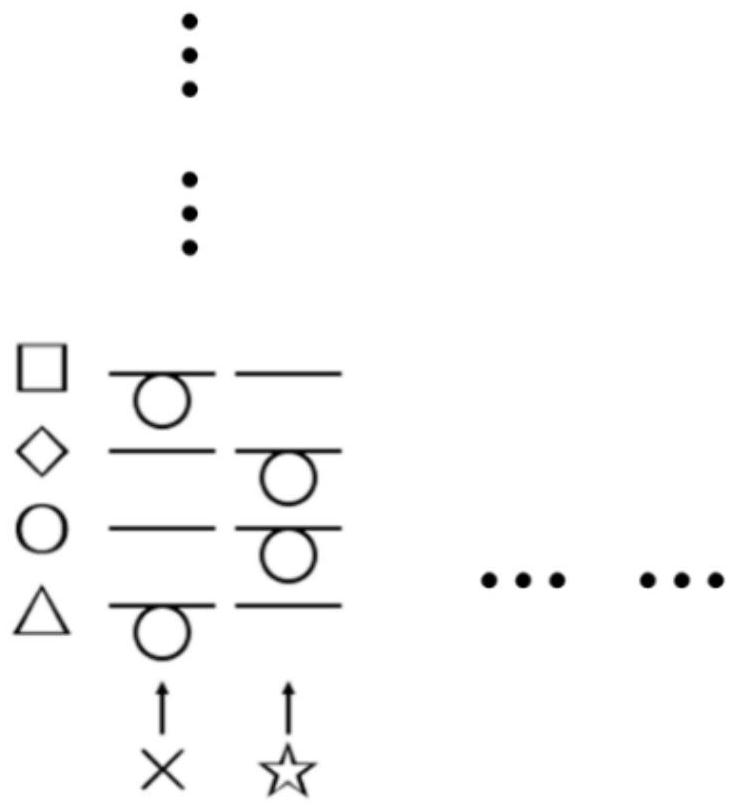

[0043] Yarn arrangement 1A1B Needle arrangement high, low, low, high, low, high, high, low yarn A: 40 British brown cotton; B: 40 British yellow cotton Triangular arrangement like figure 1 flower pattern like Figure 4

[0044] Weaving: Weaving by circular knitting machine, the specification is 34"32G, the 100-circle thread length of the grey fabric is 15.2cm, the gram weight of the blank is 140gsm, the width of the blank is 200cm, the width of the cloth support is 98cm, the rolling force is 13%, and the needle cylinder pressing is 7.5;

[0045] Finishing: singeing → mercerizing → liquid ammonia → tentering → pre-shrinking.

[0046] The singeing speed is 70m / min, the singeing method adopts cutting and burning, and the fla...

Embodiment 2

[0052] The specific production process is: raw material → design → weaving → finishing.

[0053] Material: Cotton: N.50 single yarn; by weight, cotton: 100%

[0054] Design: See Table 2.

[0055] Table 2

[0056] Yarn arrangement 1A1B Needle arrangement high, high, low, high, low, low yarn A: Count 50 blue cotton; B: Count 50 white cotton Triangular arrangement like figure 1 flower pattern like Figure 5

[0057] Weaving: Weaving by circular knitting machine, the specification is 30"36G, the 100-turn thread length of grey fabric is 14cm, the gram weight of the blank is 119gsm, the width of the blank is 192cm, the width of the cloth support is 98cm, the rolling force is 16%, and the needle cylinder pressure is 7 ;

[0058] Finishing: singeing → mercerizing → liquid ammonia → tentering → pre-shrinking.

[0059] The singeing speed is 70m / min, the singeing method adopts cutting and burning, and the flame intensity is 12mbar;

[00...

Embodiment 3

[0065] The specific production process is: raw material → design → weaving → finishing.

[0066] Material: Cotton: N. 60 single yarn; by weight, cotton: 100%

[0067] Design: See Table 3.

[0068] table 3

[0069]

[0070]

[0071] Weaving: Weaving by circular knitting machine, the specification is 36"40G, the 100-turn thread length of the grey fabric is 12.4cm, the gram weight of the blank is 109gsm, the width of the blank is 230cm, the width of the cloth support is 104cm, the rolling force is 20%, and the needle cylinder pressing is 7;

[0072] Finishing: singeing → mercerizing → liquid ammonia → tentering → pre-shrinking.

[0073] The singeing speed is 70m / min, the singeing method adopts cutting and burning, and the flame intensity is 12mbar;

[0074] The mercerizing speed is 30m / min, the mercerizing overfeed is 20%, the mercerizing alkali concentration is 26Be, the mercerizing water washing temperature is 50℃, and the mercerizing drop is 170cm;

[0075] Liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com