Multifunctional plastic jetting-molding machine

An injection molding machine and multi-functional technology, applied in the field of multi-functional injection molding machines, can solve the problems of increased processing costs, low production efficiency, generally at least tens of seconds, or even one or two minutes, so as to improve productivity and reduce production costs. The Effect of Injection Molding Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

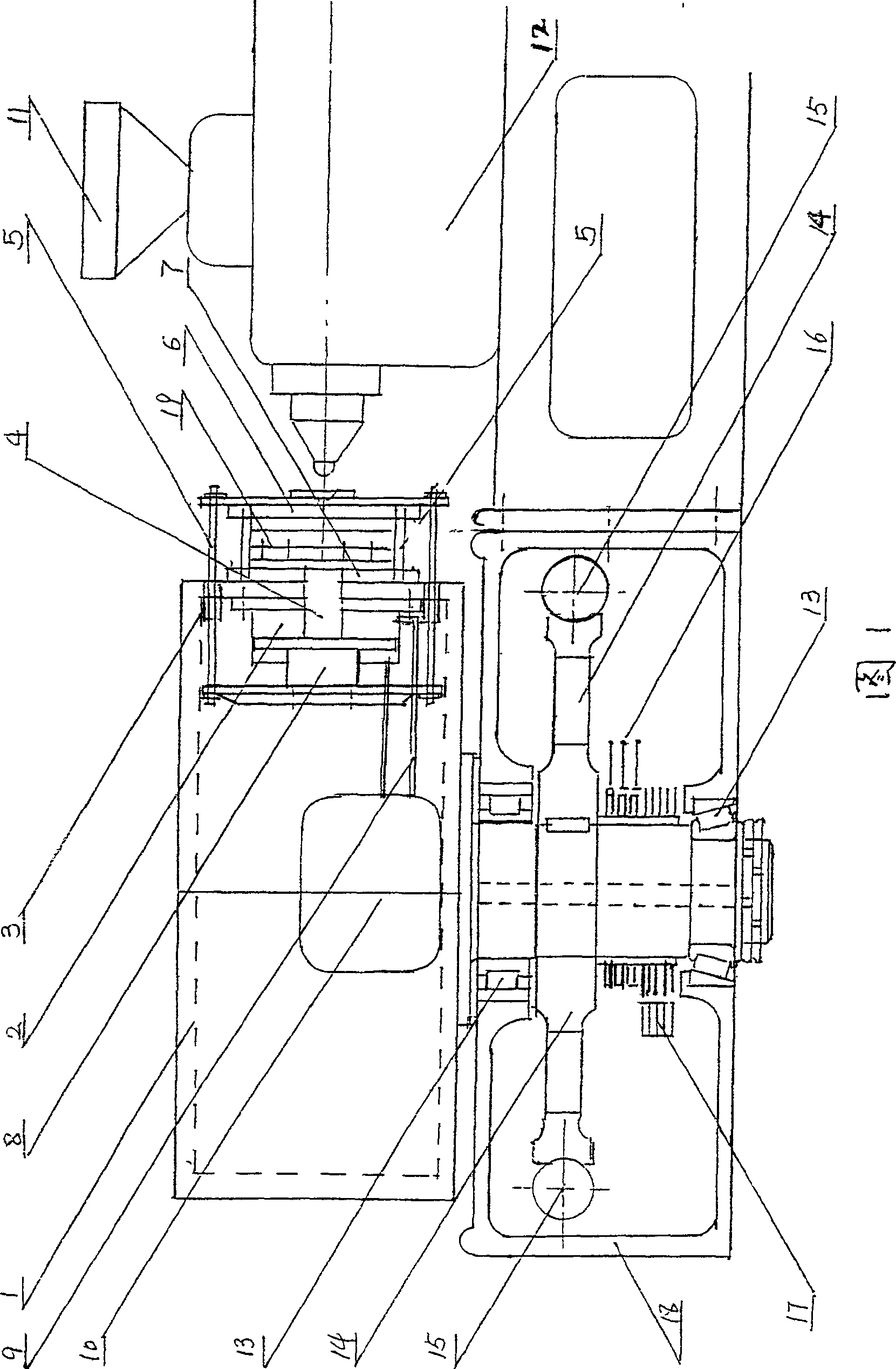

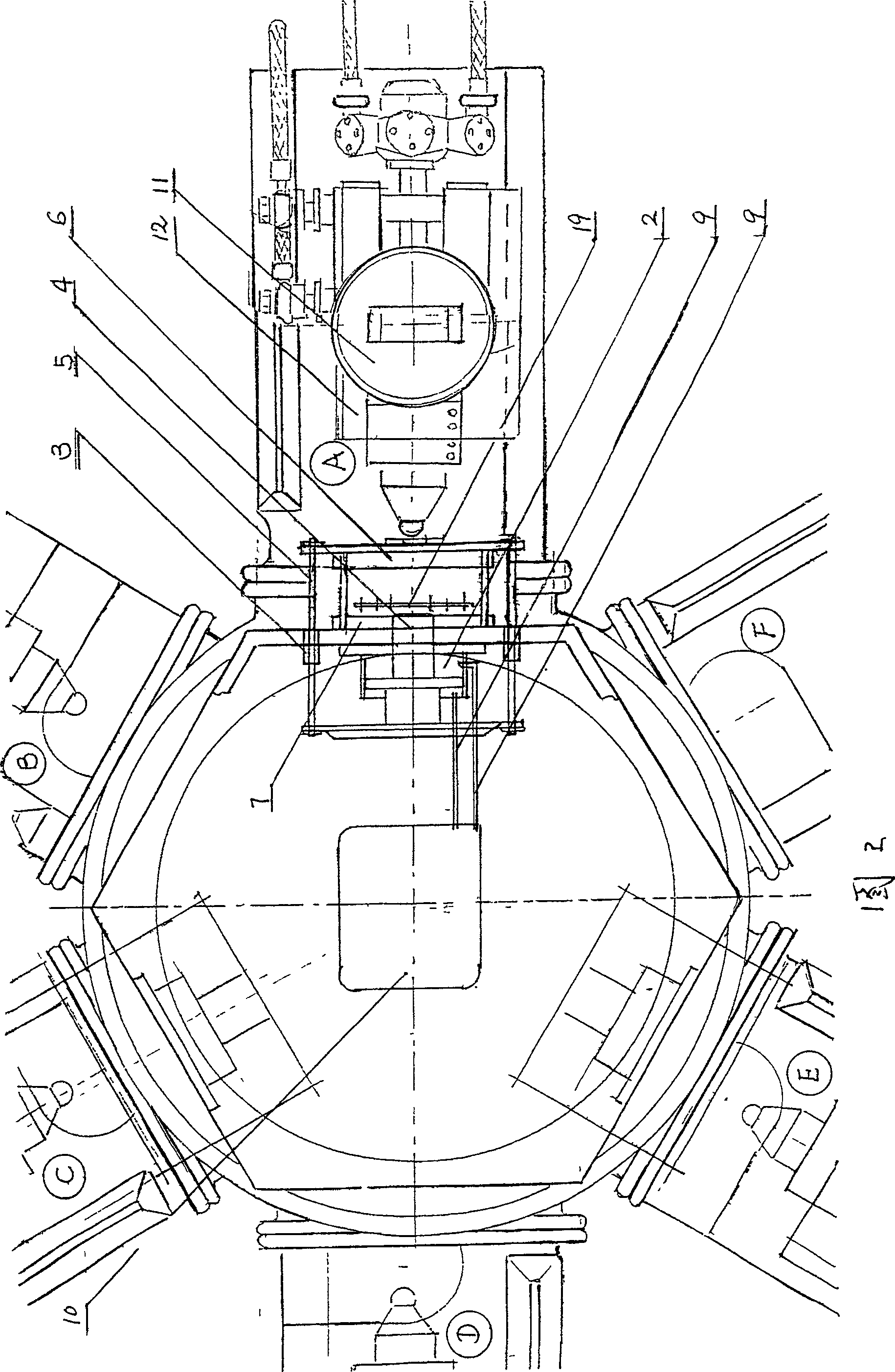

[0012] As shown in Figures 1 and 2, it includes workbench, injection molding part, mold clamping device and hydraulic system. Workbench 1 is rotary and has a multi-mold station structure, and is controlled by a motor through a transmission mechanism; the mold clamping device is The self-preserving high-pressure mold clamping structure is composed of a guide sleeve 3, a knockout rod 4 (also known as a ejector plug rod), a guide rod 5, an upper template 6, and a lower template 7, and the upper template 6 is installed together with the injection molding plate; The guide rods 5 are upper and lower layers, arranged in parallel, two in each layer, one end of each guide rod 5 is installed together with the injection molding plate in front of the injection molding head 12 of the injection molding part, and the other end passes through and is installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com