Waterproof wear-resistant environment-friendly vegetable tanning method for sole leather

A technology for sole leather and vegetable tanning is applied in the field of waterproof, wear-resistant and environmentally friendly vegetable tanned sole leather, which can solve the problems of inability to meet the production requirements of leather for soles, flatness and wear resistance, and insufficient water resistance of vegetable tanned leather.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

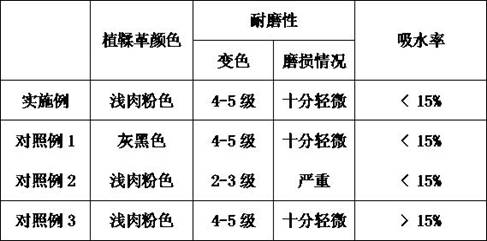

Examples

Embodiment

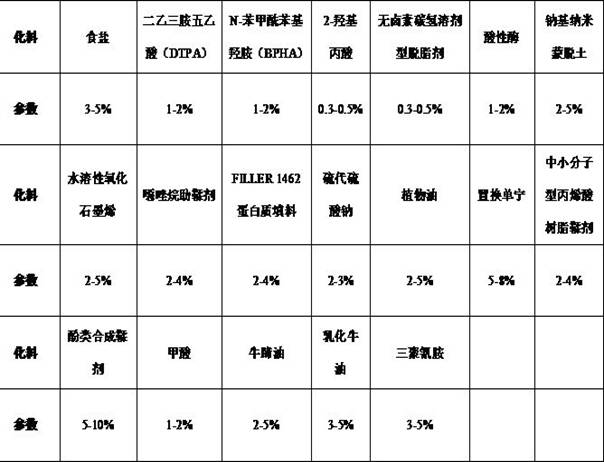

[0031] Table 1 is the main process parameters of the waterproof, wear-resistant and environmentally friendly vegetable tanned shoe sole leather method, and the main steps of the waterproof and wear-resistant environmentally friendly vegetable tanned shoe sole leather are as follows:

[0032] (1) Add 20°C water, salt, diethylenetriaminepentaacetic acid (DTPA), N-benzoylphenylhydroxylamine (BPHA), 2-hydroxypropionic acid and halogen-free carbon into the drum according to the amount of the formula Hydrogen solvent-based degreasing agent, rotate for 60 minutes, then drain and wash with water, then add water and acid enzyme at 30°C to the drum according to the formula, rotate for 90 minutes, then add sodium formate and sodium sulfate to adjust the pH to 4.

[0033] (2) Add warm water at 40°C, sodium-based nano-montmorillonite, water-soluble graphene oxide, oxazolidine cotanning agent, FILLER 1462 protein filler into the drum according to the amount of the formula, rotate for 180 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com