Strap-shaped welding wire filling-in type stirring friction treatment method

A technology of friction stir and treatment method, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency and high welding cost, and achieve the effect of improving welding efficiency, reducing welding cost and cleaning the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

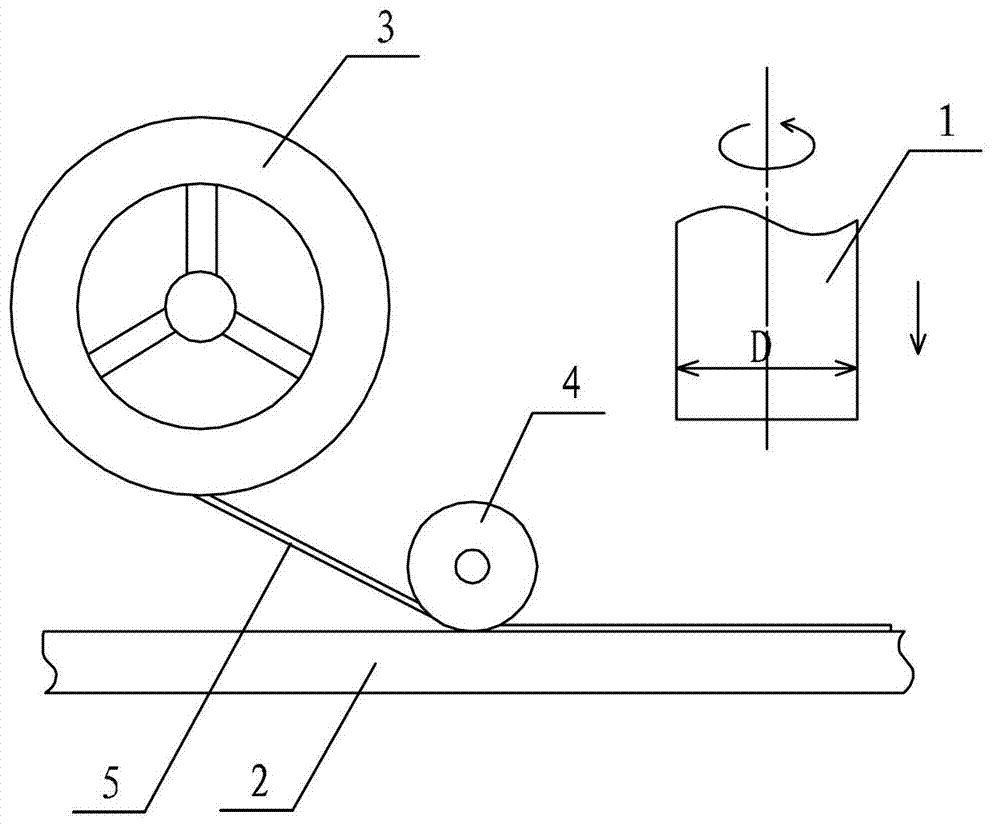

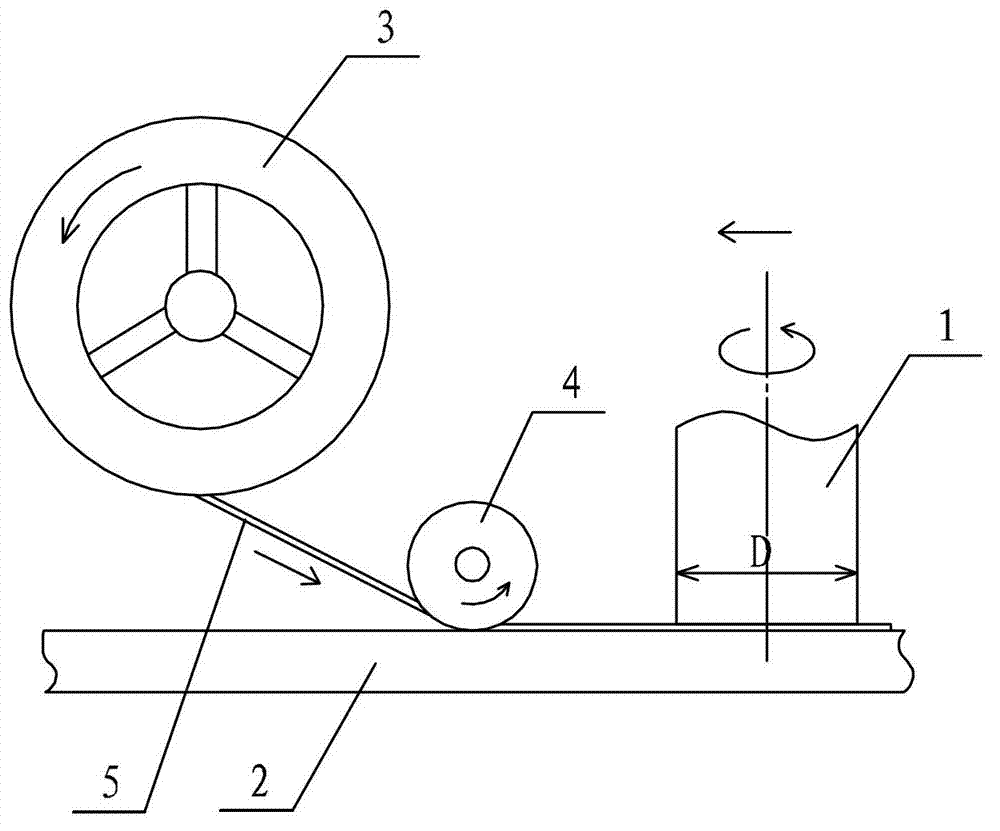

[0013] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this implementation mode, this implementation mode is realized through the following steps:

[0014] Step 1. Preparation before processing: Install and fix the wire feed roller 3 and the positioning guide wheel 4 on the main shaft of the welding machine, clamp the material 2 to be processed, place the strip welding wire 5 under the positioning guide wheel 4, and position the guide wheel 4. Wheel 4 is close to the surface of material 2 to be processed, and the strip welding wire 5 is fixed on the surface of material 2 to be processed, see figure 1 , place the end of the strip-shaped welding wire 5 directly below the needle-free welding tool 1, so that the end can be completely covered by the shoulder at the beginning of welding, and the width d of the strip-shaped welding wire 5 should be equal to or less than that of the needle-free welding The shaft shoulder diameter D of the tool 1 makes the edge...

specific Embodiment approach 2

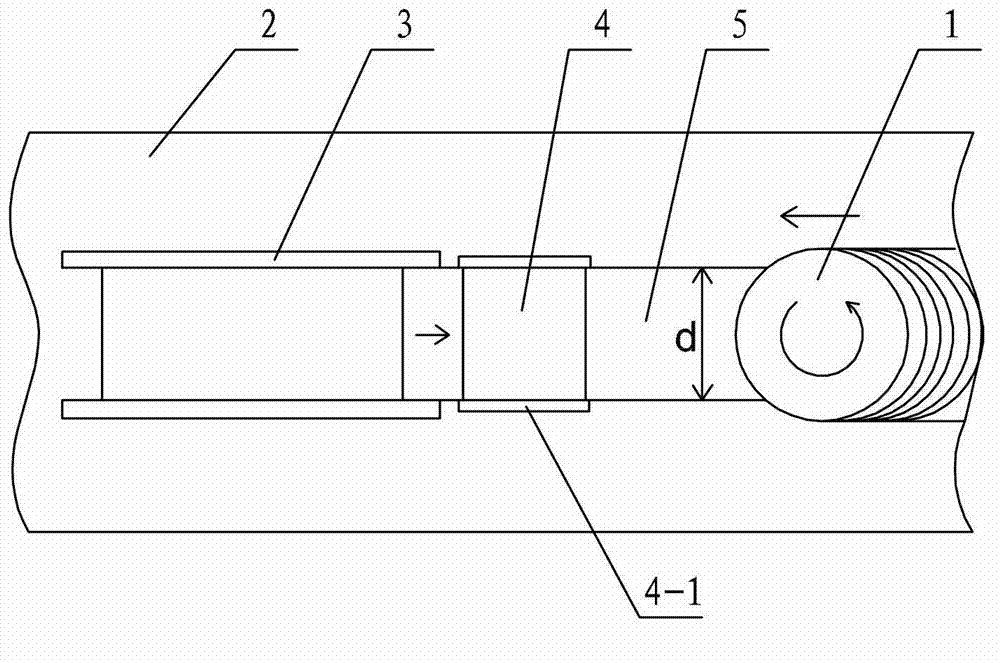

[0017] Specific implementation mode two: combination image 3 Describe this embodiment, this embodiment is that the stirring head 1, the positioning guide wheel 4, the strip welding wire 5, and the wire feeding wheel 3 are located on the same straight line. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: combine 2 and image 3 Describe this embodiment. In this embodiment, flanges 4-1 are designed on both sides of the positioning guide wheel 4 in step 1, and the height of the flanges 4-1 should be greater than or equal to the thickness of the strip welding wire 5. The flange 4-1 can prevent the strip welding wire 5 from moving laterally, and the flange 4-1 guides the strip welding wire 5 to lay along the welding direction. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com