Shape-followed runner radiator based on sheet laminated connection and preparing method of shape-followed runner radiator

A radiator and runner technology, which is applied in the field of conformal runner radiators based on thin lamination connection and their preparation, can solve the problems of inability to manufacture spiral runners, general heat dissipation performance of radiators, shortened service life of molds, etc. , to achieve the effect of improved resistance to deformation, better connection performance, and improved molding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

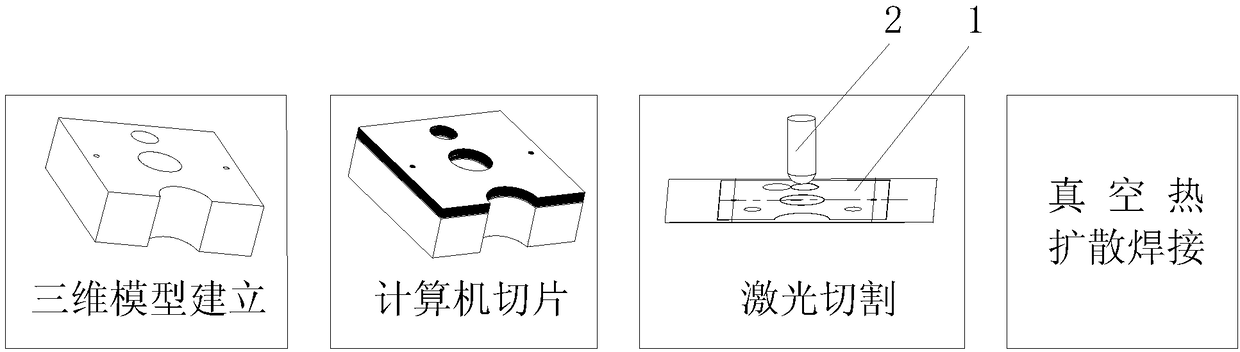

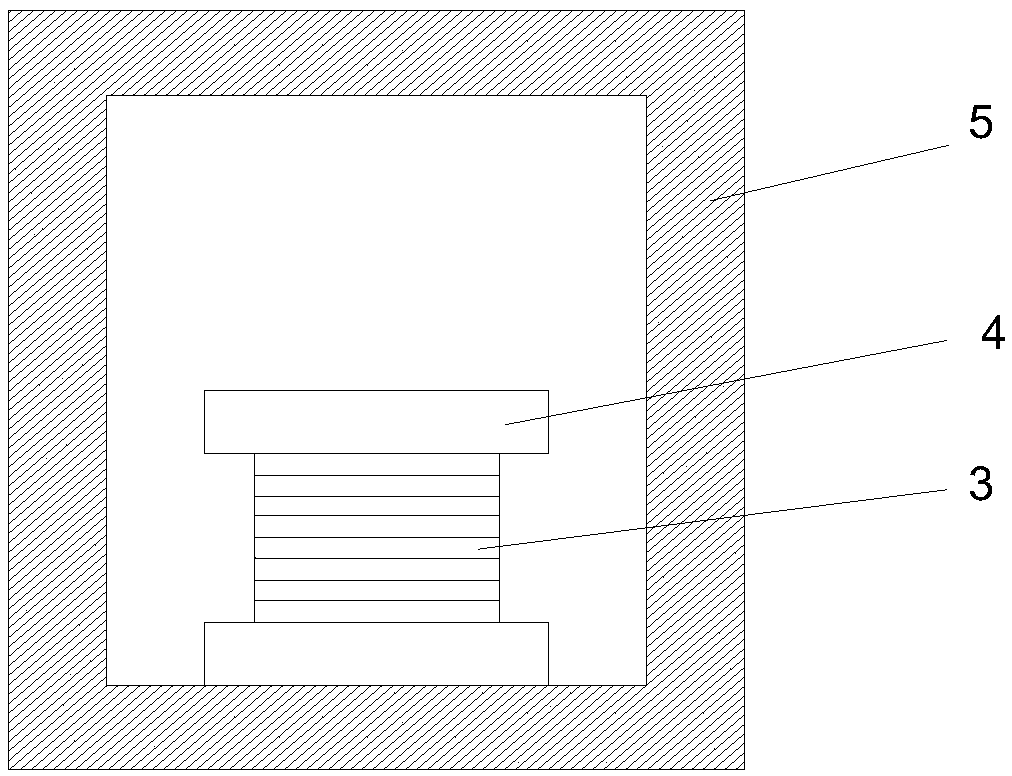

[0036] The preparation method of the conformal flow channel radiator based on laminar lamination connection of the present invention can be realized through the following steps:

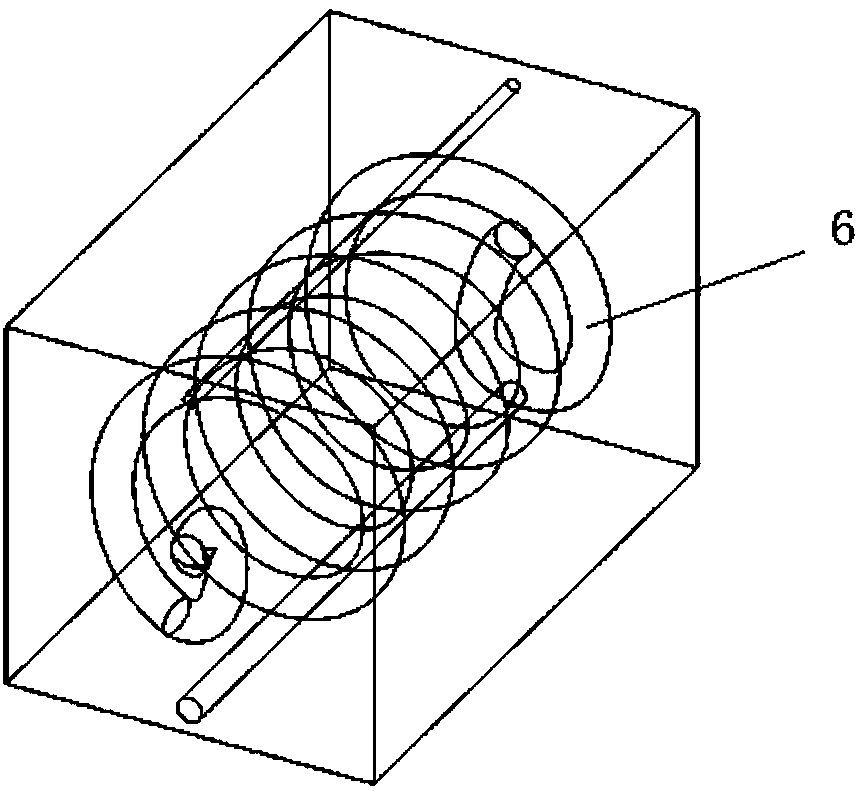

[0037] (1) Through the application analysis and effect prediction of complex flow channel radiators, the complex flow channel radiator model is established with computer 3D modeling software. The 3D axial view of the model and the schematic diagram of the middle interface section are as follows image 3 and Figure 4 As shown, save the model as a (*STL) format file.

[0038] (2) Import the STL file into the slicing software in the computer, cut and layer the radiator model with a thickness of 50-100 μm, form a multi-layer CAD model with different cross-sectional shapes, and use the computer to extract the contour information of each layer, Generate the code files needed to laser cut the sheet;

[0039] (3) Import the contour information of each layer into the laser processing system in order to gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com