Explosive molding powder atomizing granulating spheroidizing apparatus

A technology for spray granulation and molding powder, which is applied in explosives, explosives processing equipment, chemical industry and other directions, and can solve the problems such as the inability to meet the charging requirements, the bulk density, the low fluidity and the large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the explosive molding powder for granulation and spheroidization is JHOL-1 explosive, which is composed of black sogen, octogen, aluminum powder and binder system, wherein the aluminum powder is composed of 75% spherical aluminum Composed of powder FLQT-4 and 25% flake aluminum powder FLQ355A, the theoretical density is 1.965g cm -3 .

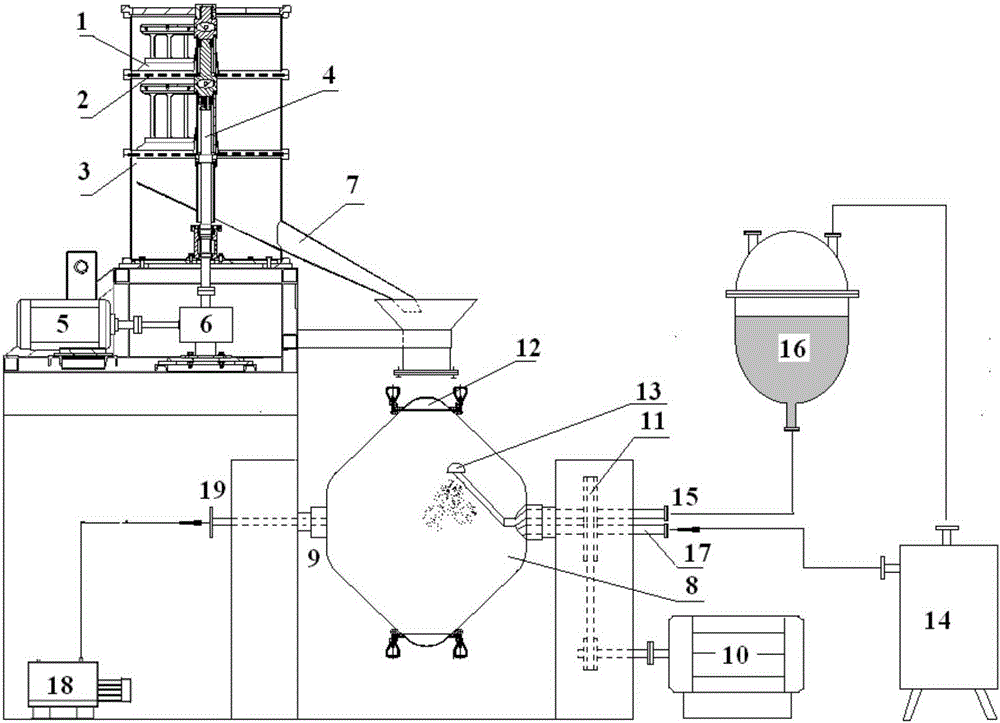

[0025] The explosive molding powder spray granulation spheroidization device includes a primary screening part and a spray spheroidization part, and the primary sieving granulation part includes a double-layer scraper (1), a primary granulation net (2), a secondary granulation Net (3), spline main shaft (4), explosion-proof frequency conversion motor (5), reducer (6), discharge chute (7). The primary granulation net (2) is located on the upper part of the secondary granulation net (3), installed in parallel, and the spline spindle (4) is located at the center of the primary granulation net (2) and the secondary granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com