Biomass granulation system and device

A biomass and granulation technology, applied in the direction of biofuel, waste fuel, raw material extrusion granulation, etc., can solve the problems of uncontrollable particle humidity, unstable operation of heat energy utilization equipment, scattered distribution, etc., to solve the problem of equipment investment and Reduce power consumption, facilitate high-grade utilization, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

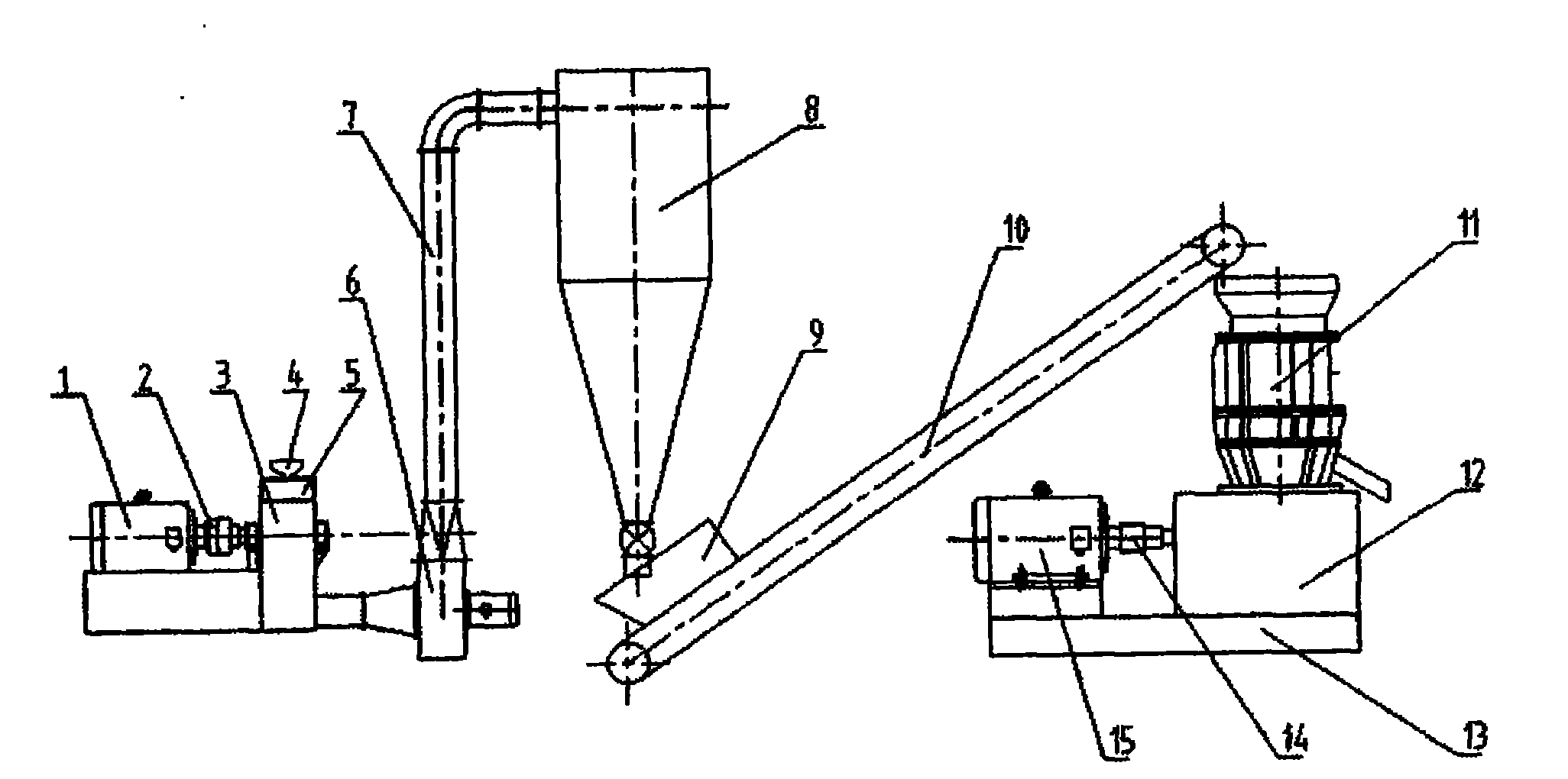

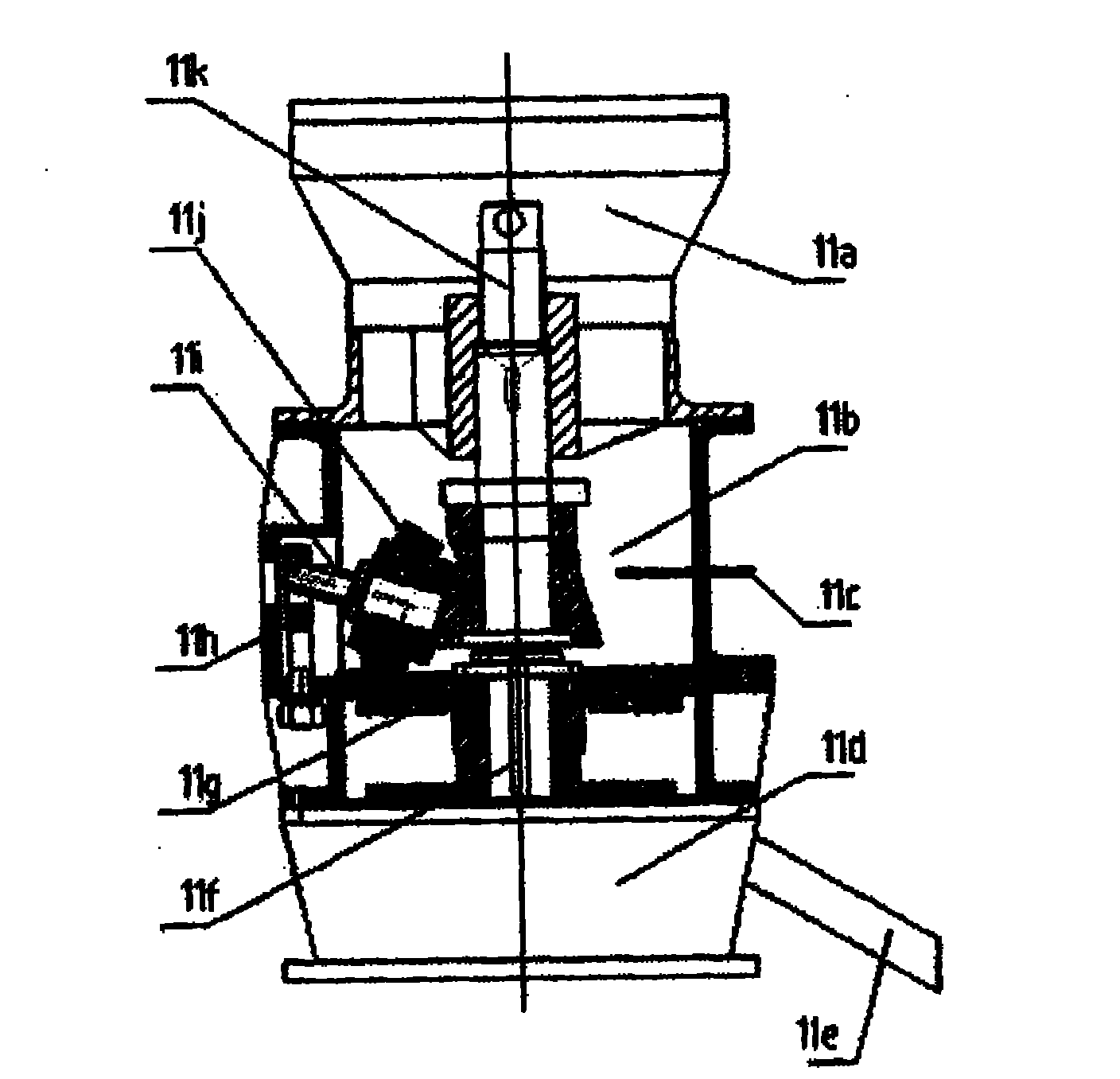

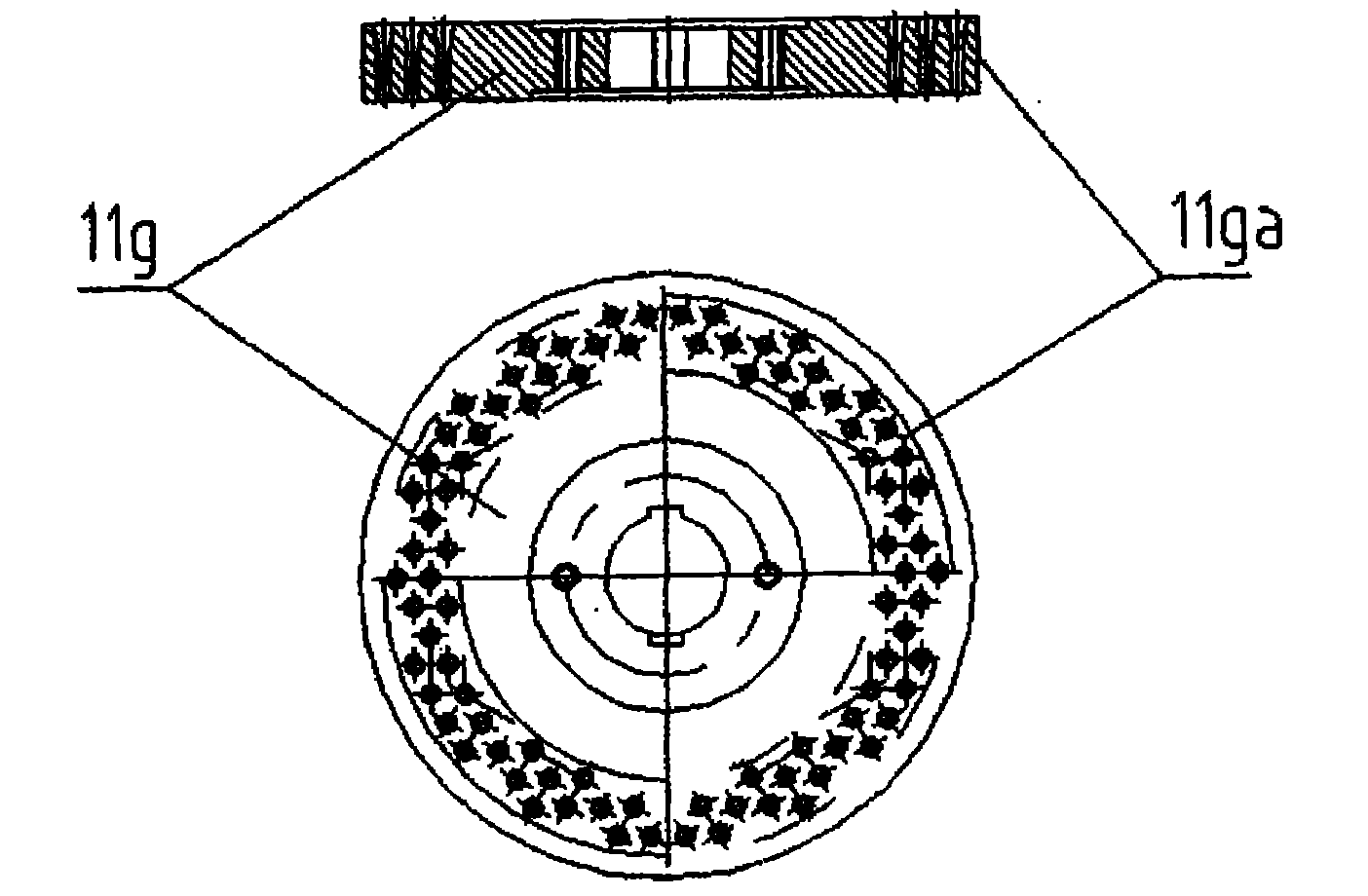

[0023] Such as figure 1 As shown, the biomass granulation system consists of a pulverizing motor 1, a coupling I 2, a pulverizer 3, an additive hopper 4, a feeding port 5, a blower 6, a feeding duct 7, a cyclone dust collector 8, and a feeding hopper 9 , Conveyor belt 10, granulator 11, gearbox 12, base 13, coupling II 14, frequency conversion motor 15 and so on.

[0024] The biomass is first sent to the pulverizer 3 for crushing, and the pulverized biomass is pumped out by the blower 6 and entered into the cyclone dust collector 8 for gas-solid separation, and the separated material is then passed through the biomass granulator 11 to make granules; the main equipment Including pulverizer 3, blower 6, cyclone dust collector 8, biomass granulator 11 and so on.

[0025] An additive hopper 4 is set at the upper end of the pulverizer 3, and pulverized coal or diatomaceous earth can be added through the additive hopper 4, which can realize mixing while pulverizing, which improves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com