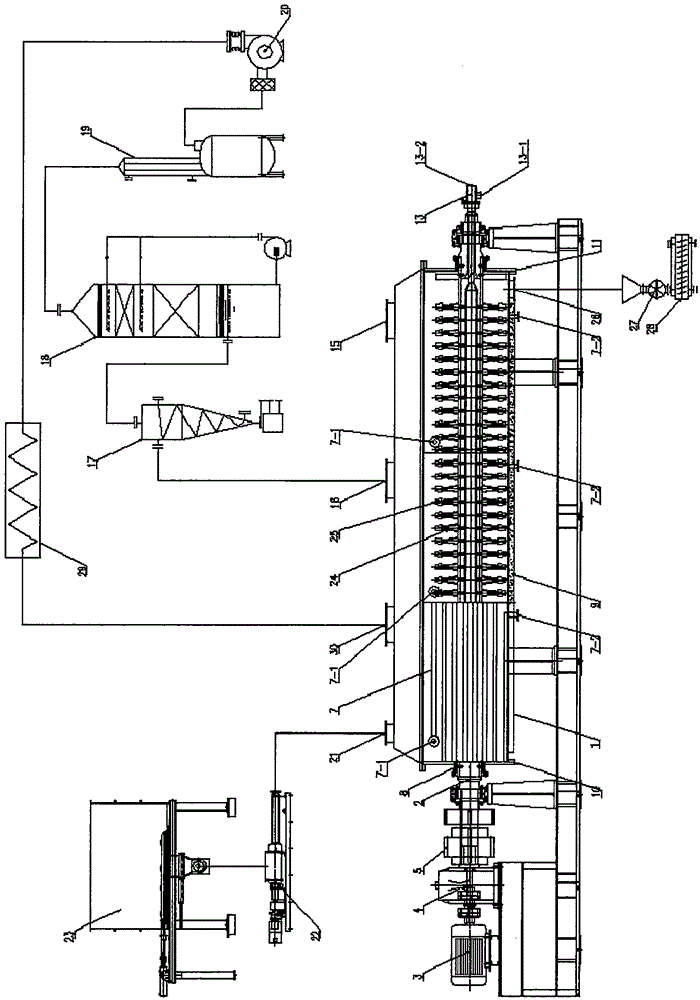

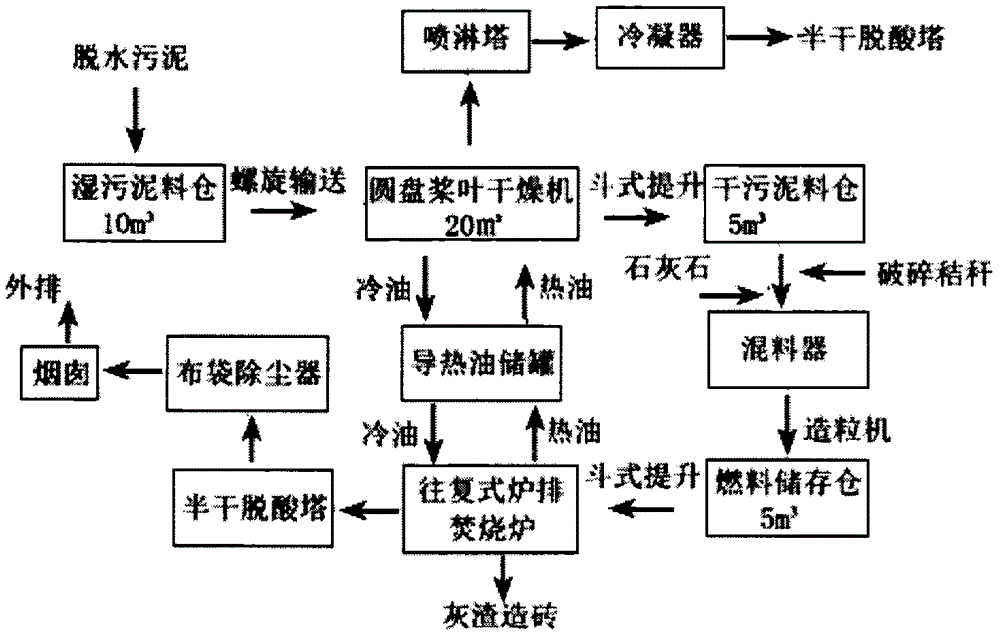

System for cooperative harmless treatment of sludge and straw

A harmless treatment and straw pretreatment technology, applied in the field of environmental protection, can solve the problems of easy sintering, low calorific value of sludge and straw combustion, etc., achieve low cost, realize efficient recycling, and realize the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

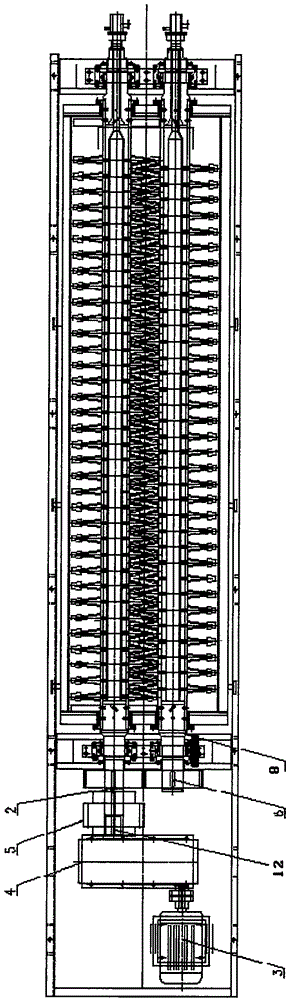

Method used

Image

Examples

Embodiment 1

[0082] A sludge and straw synergistic harmless treatment process according to the present invention comprises the following steps:

[0083] (1) Get 8kg of sludge (moisture content 80%) and carry out drying and dehydration treatment in a vacuum disc dryer until the moisture content is lower than 30%, for subsequent use;

[0084] Take 2kg of straw and pulverize it until the particle size is 20-30mm, set aside;

[0085] (2) mix the above-mentioned treated sludge and stalks, and add 2 kg of kaolin inert additives to mix;

[0086] (3) Pressing and dehydrating the mixture obtained in step (2) according to conventional methods, and then compressing to make fuel blocks of a certain size;

[0087] (4) Take the fuel block prepared in step (3) and place it in a heat-conducting oil heating device for incineration, collect ash and process tail gas, and recover the heat obtained by burning the fuel block into the vacuum disc dryer at the same time It is used for sludge drying and dehydrat...

Embodiment 2

[0089] A sludge and straw synergistic harmless treatment process according to the present invention comprises the following steps:

[0090] (1) Get 9kg of sludge (moisture content 80%) and carry out drying and dehydration treatment in a vacuum disc dryer until the moisture content is lower than 30%, for subsequent use;

[0091] Take 1kg of straw and crush it until the particle size is 20-30mm, set aside;

[0092] (2) mix the above-mentioned treated sludge and stalks, and add 1 kg of dolomite inert additive to mix;

[0093] (3) Pressing and dehydrating the mixture obtained in step (2) according to conventional methods, and then compressing to make fuel blocks of a certain size;

[0094] (4) Take the fuel block prepared in step (3) and place it in a heat-conducting oil heating device for incineration, collect ash and process tail gas, and recover the heat obtained by burning the fuel block into the vacuum disc dryer at the same time It is used for sludge drying and dehydration...

Embodiment 3

[0096] A sludge and straw synergistic harmless treatment process according to the present invention comprises the following steps:

[0097] (1) Get 8.5kg of sludge (moisture content 80%) and carry out drying and dehydration treatment in a vacuum disc dryer until the moisture content is lower than 30%, for subsequent use;

[0098] Take 1.5kg of straw and pulverize it until the particle size is 20-30mm, set aside;

[0099] (2) mix the above-mentioned treated sludge and straw, and add limestone and ammonium sulfate (mass ratio is 1: 1) inert additive 100g and mix;

[0100] (3) Pressing and dehydrating the mixture obtained in step (2) according to conventional methods, and then compressing to make fuel blocks of a certain size;

[0101] (4) Take the fuel block prepared in step (3) and place it in a heat-conducting oil heating device for incineration, collect ash and process tail gas, and recover the heat obtained by burning the fuel block into the vacuum disc dryer at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com