Co-combustion device and method capable of automatically adjusting blending combustion amount of sludge

An automatic adjustment and sludge technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of incomplete mixing, increased fuel injection and increased heat loss of exhaust smoke, etc., to speed up sludge treatment, The effect of reducing the average calorific value and increasing the feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, specific details are set forth in order to fully understand the present invention. However, the present invention can be implemented in many other ways different from the description herein, and those skilled in the art can make similar popularizations without departing from the connotation of the present invention. Therefore, the present invention is not limited by the specific embodiments disclosed below.

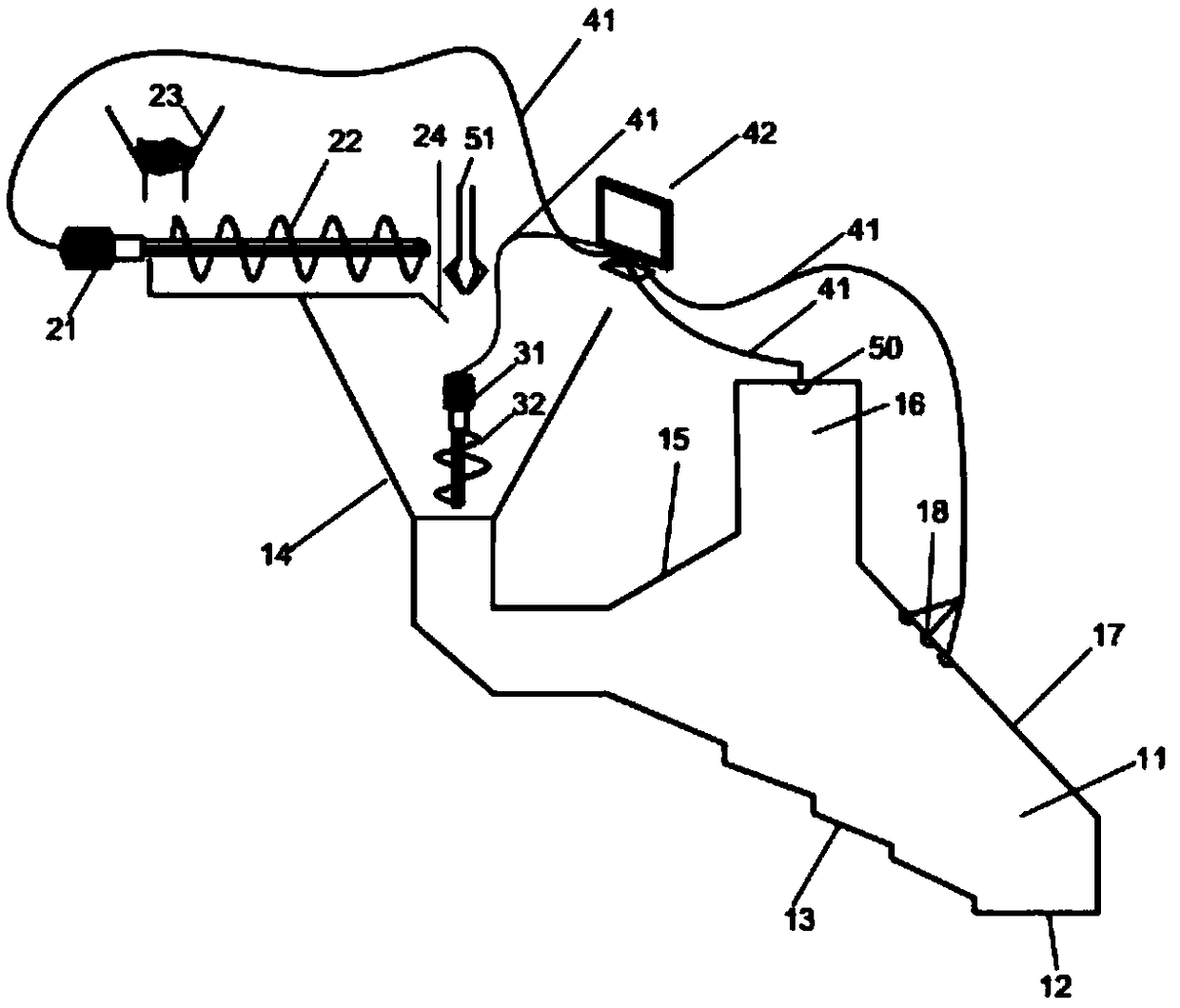

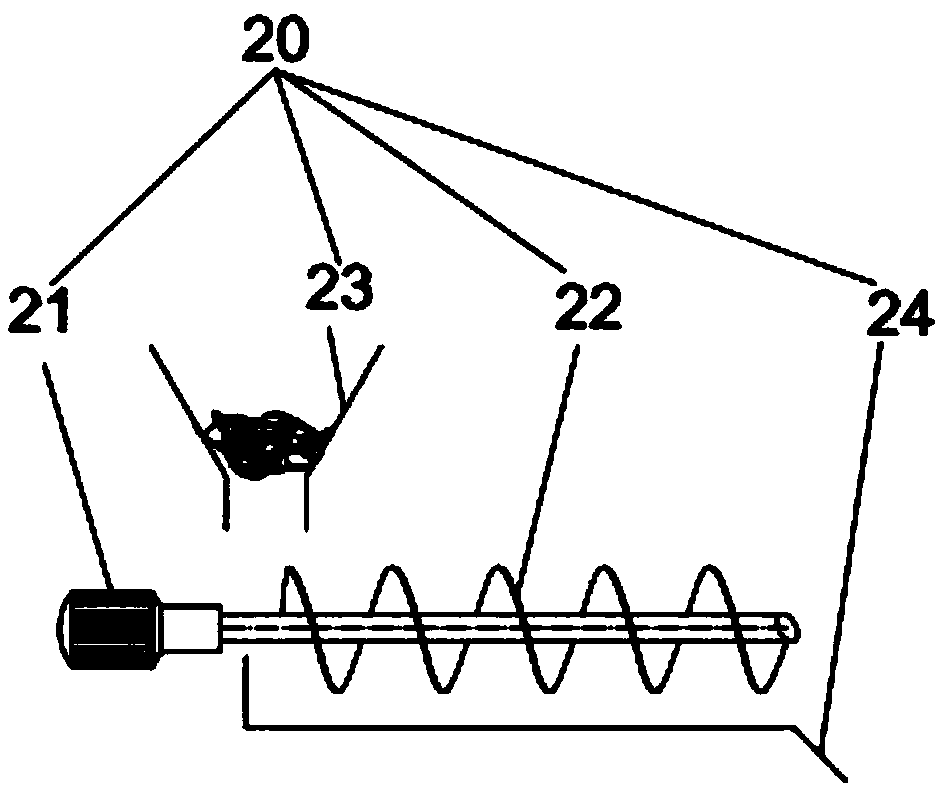

[0035] Refer to figure 1 As shown, the present invention provides a mixed burning device that automatically adjusts the amount of sludge blended burning, including a mechanical grate furnace 10, a sludge feeding device 20, a stirring device 30, a control system 40, and a steam sensor 50; The mud feeding device 20, the stirring device 30 and the water vapor sensor 50 are respectively connected to the control system 40.

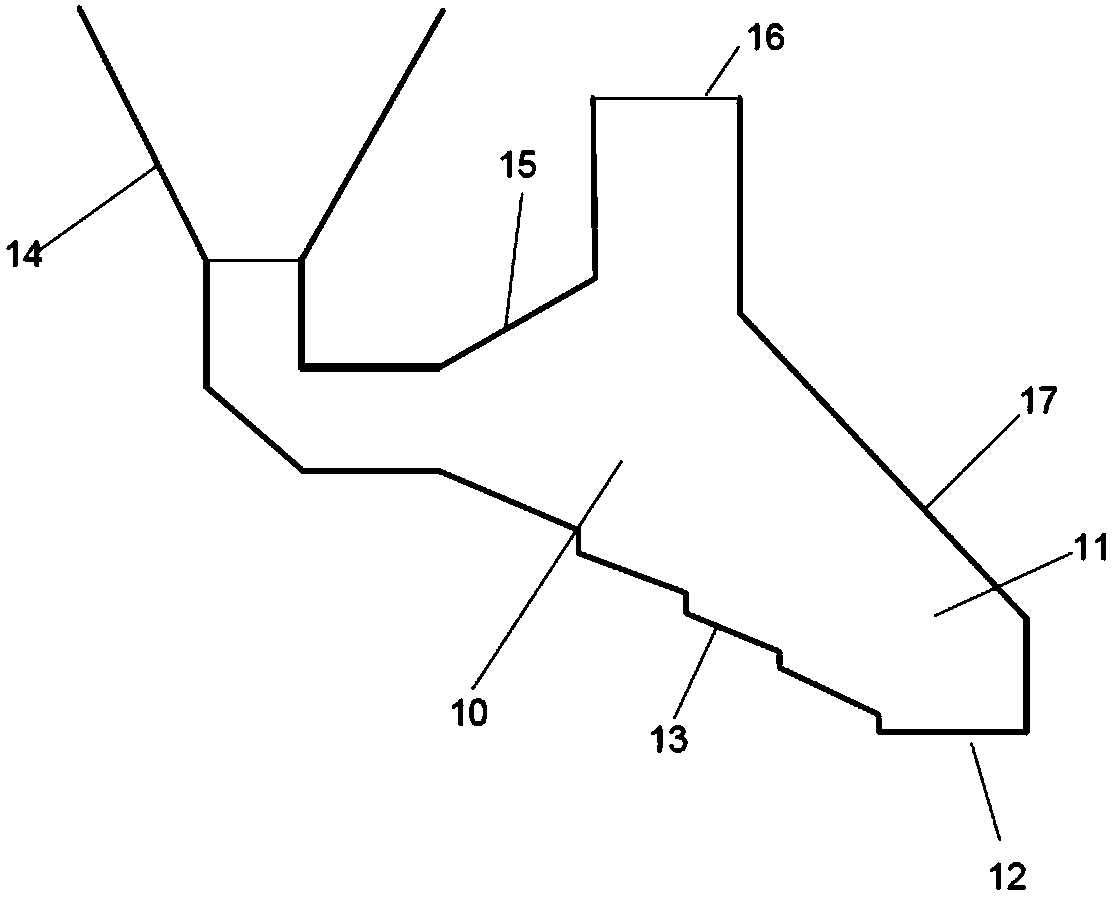

[0036] The mechanical grate furnace 10 mainly includes a hearth 11, a slag discharge port 12, a grate 13, a garbage hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com