Preparation method of soft magnetic composite powder core

A soft magnetic composite, powder core technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc. High saturation magnetic induction, low eddy current loss, and the effect of improving molding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

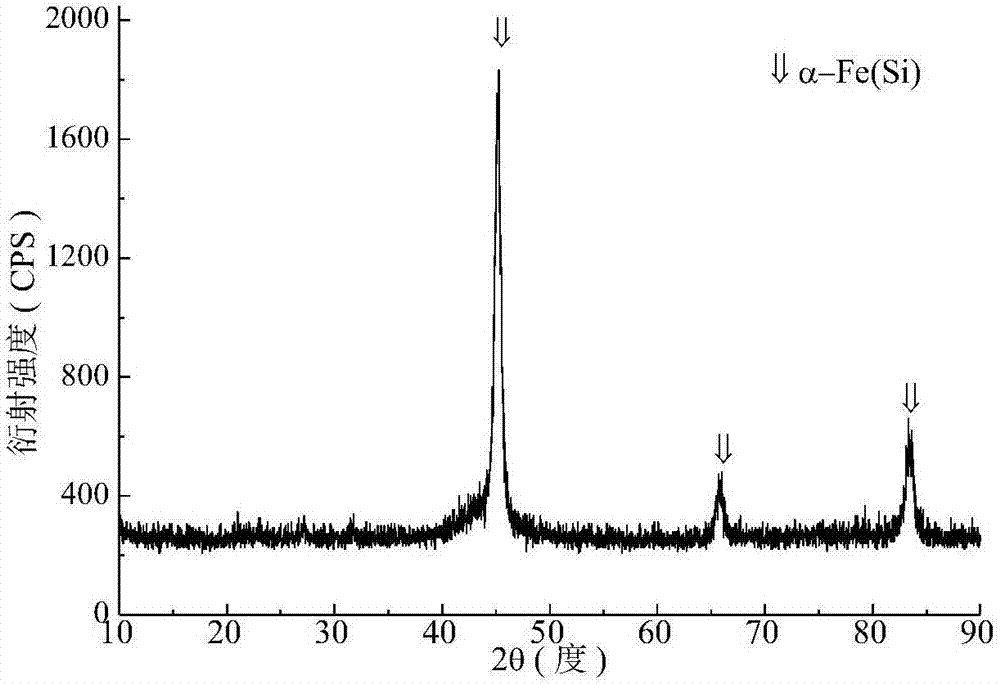

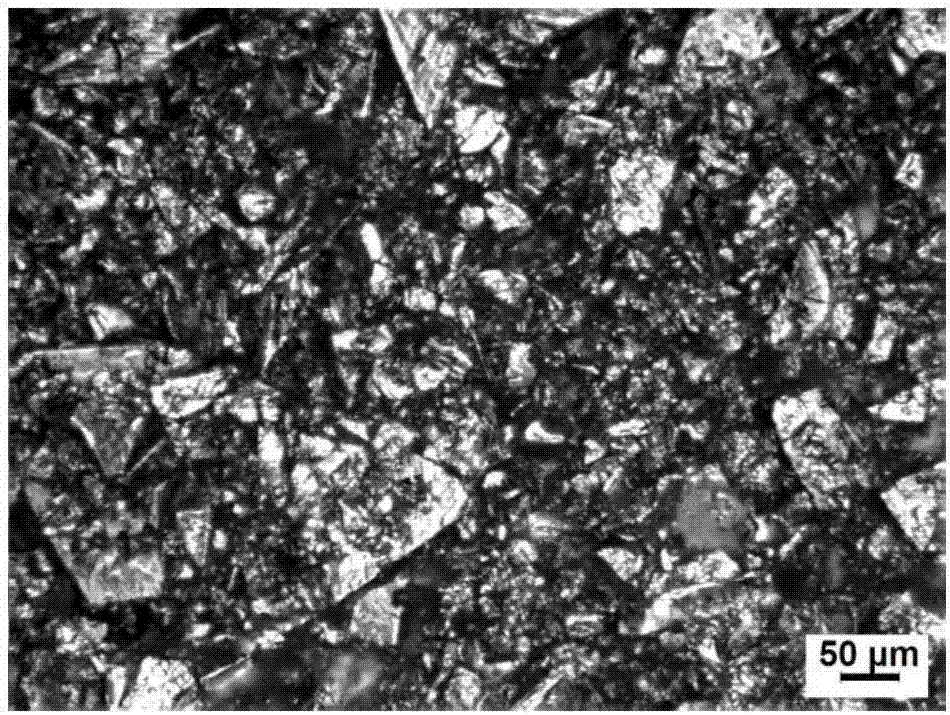

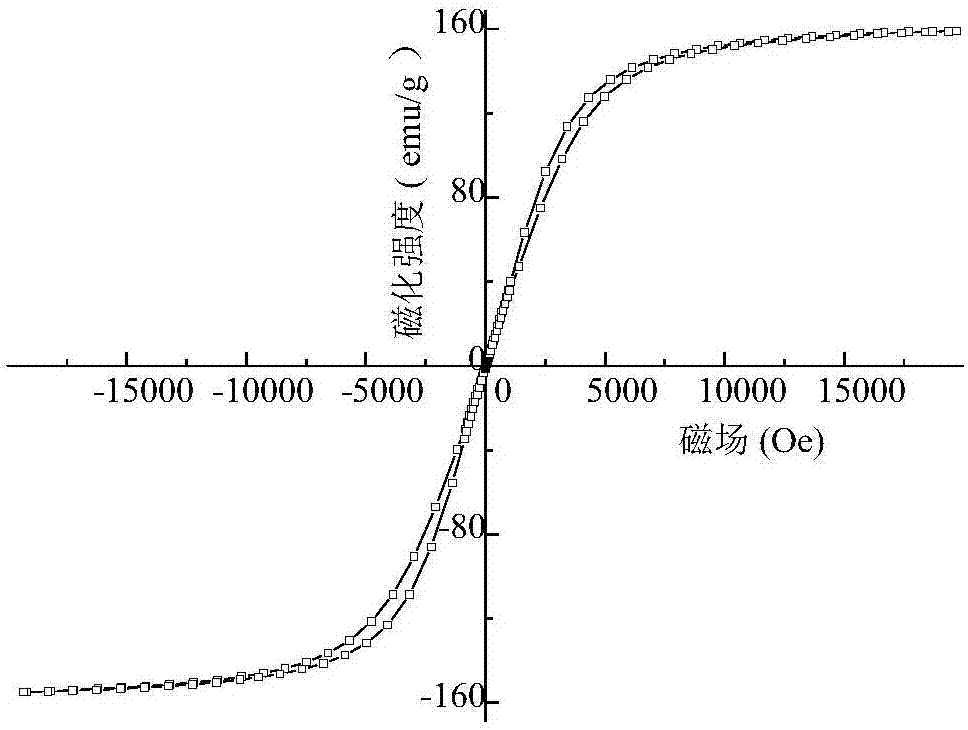

[0043] The first step is to prepare amorphous and nanocrystalline Fe 74.5 Si 13.5 Nb 2.5 B 8.5 Cu 1 Main powder:

[0044] Calculate the element composition formula Fe according to the atomic percentage 74.5 Si 13.5 Nb 2.5 B 8.5 Cu 1 The mass percent of the constituent elements in the element, weigh the required amount of component raw materials according to the calculated mass percent of the element: pure iron, pure silicon, ferro-niobium, ferro-boron and pure copper, wherein the mass fraction of niobium in ferroniobium 66.5%, and the mass fraction of boron in ferroboron is 17.4%, thus completing the preparation of raw materials, smelting the raw materials of the above components evenly and spraying out an amorphous thin strip with a thickness of 30 μm and a width of 10 mm in the atmospheric environment. Thin strip in vacuum -1 In the heat treatment furnace of Pa, the temperature is heated from room temperature to 480°C at a heating rate of 1°C / min, and then heated fr...

Embodiment 2

[0063] In this embodiment, the amorphous nanocrystalline Fe 74.5 Si 13.5 Nb 2.5 B 8.5 Cu 1 The mass fraction of the main powder is changed to 60%, the mass fraction of the gas-atomized FeNi50 powder is changed to 40%, and other processes are the same as in Example 1.

[0064] The soft magnetic properties and mechanical properties of the soft magnetic composite powder core prepared in this example are shown in Table 1.

Embodiment 3

[0066] The first step is to prepare amorphous and nanocrystalline Fe 70 Si 15.5 Nb 2 Mo 1.5 B 10 Cu 1 Main powder:

[0067] Calculate the element composition formula Fe according to the atomic percentage 70 Si 15.5 Nb 2 Mo 1.5 B 10 Cu 1 The mass percentage of the constituent elements in the element, weigh the required amount of component raw materials according to the calculated mass percentage of the element: pure iron, pure silicon, ferro-niobium, ferro-molybdenum, ferro-boron and pure copper, wherein niobium in ferroniobium The mass fraction of boron in ferro-boron is 66.5%, the mass fraction of boron in ferro-molybdenum is 17.4%, and the mass fraction of molybdenum in ferro-molybdenum is 50%, thus completing the preparation of raw materials, smelting the raw materials of the above components evenly and spraying them out in the atmosphere An amorphous thin strip with a thickness of 40 μm and a width of 5 mm, the thin strip is vacuumed -1 In the heat treatment fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com