Patents

Literature

44results about How to "High Effective Permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

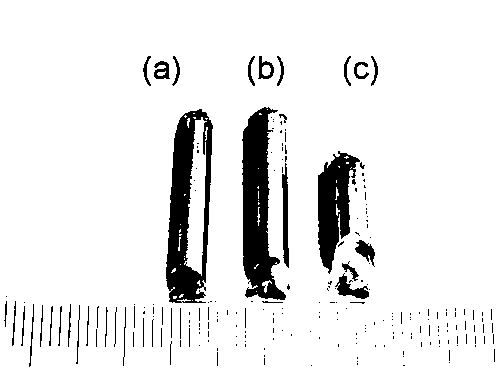

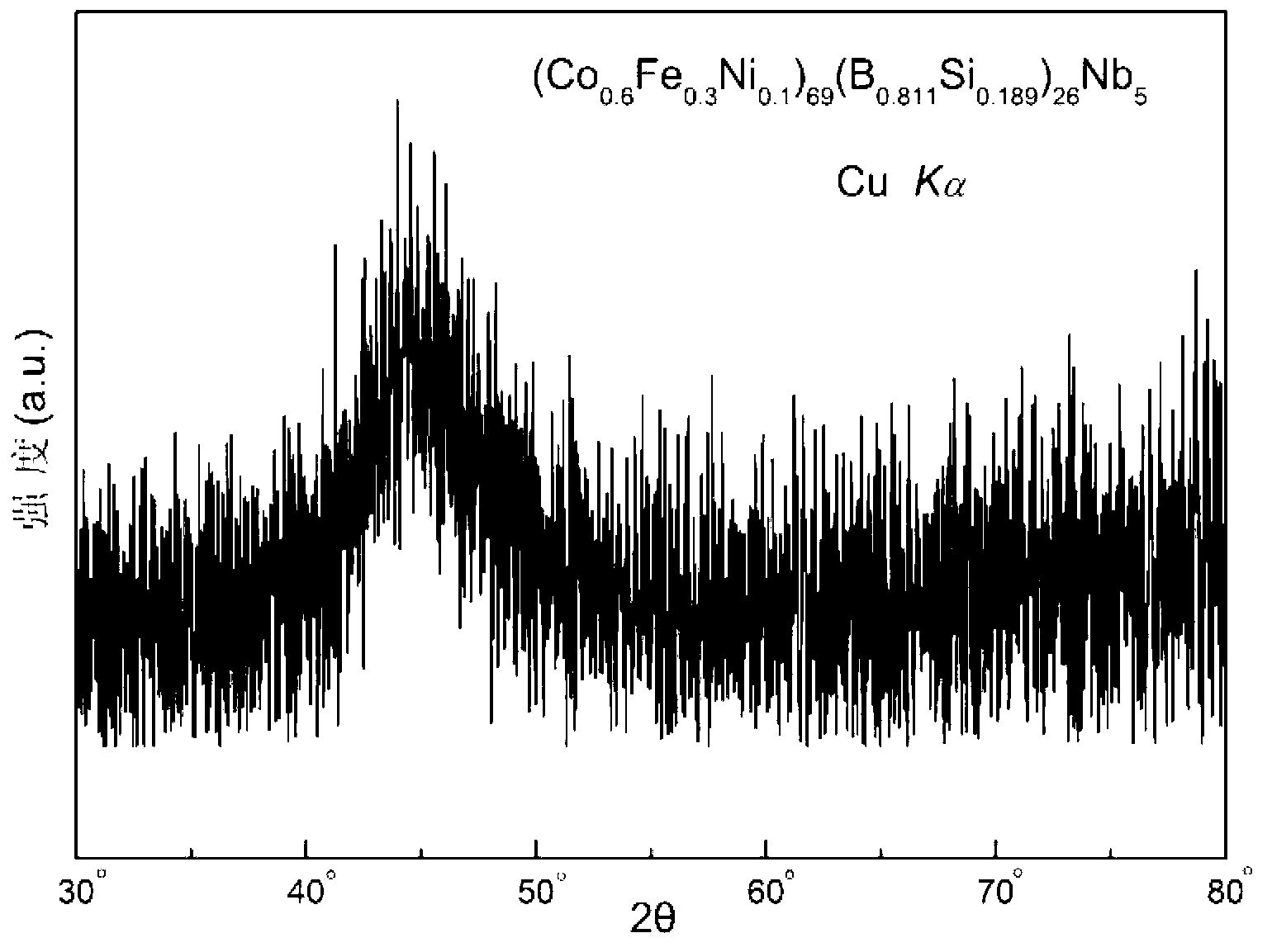

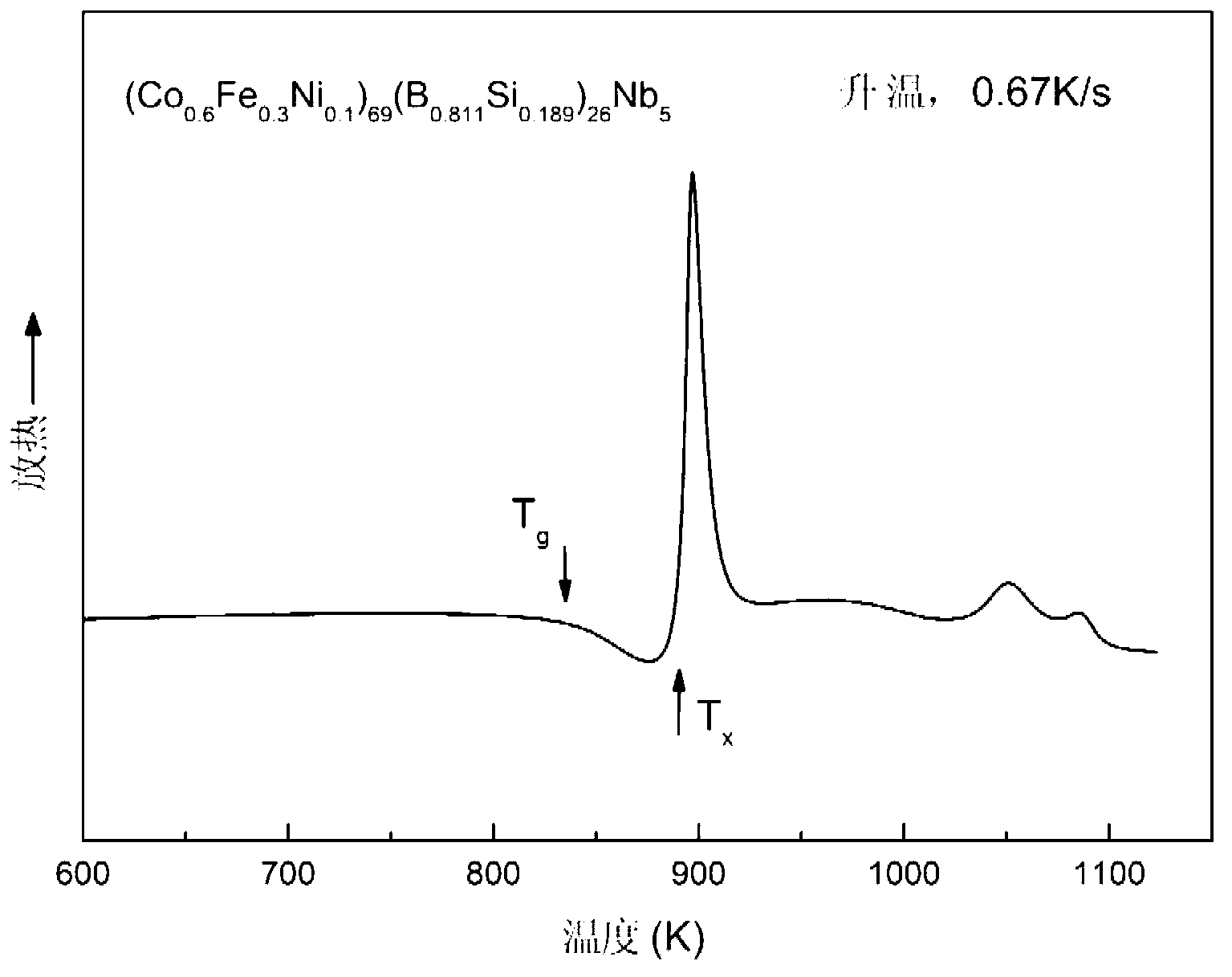

Cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and preparation method thereof

InactiveCN102915820ARaise the transition temperatureEnhanced Amorphous Formation AbilityMagnetic materialsMechanical properties of carbon nanotubesLiquid phase

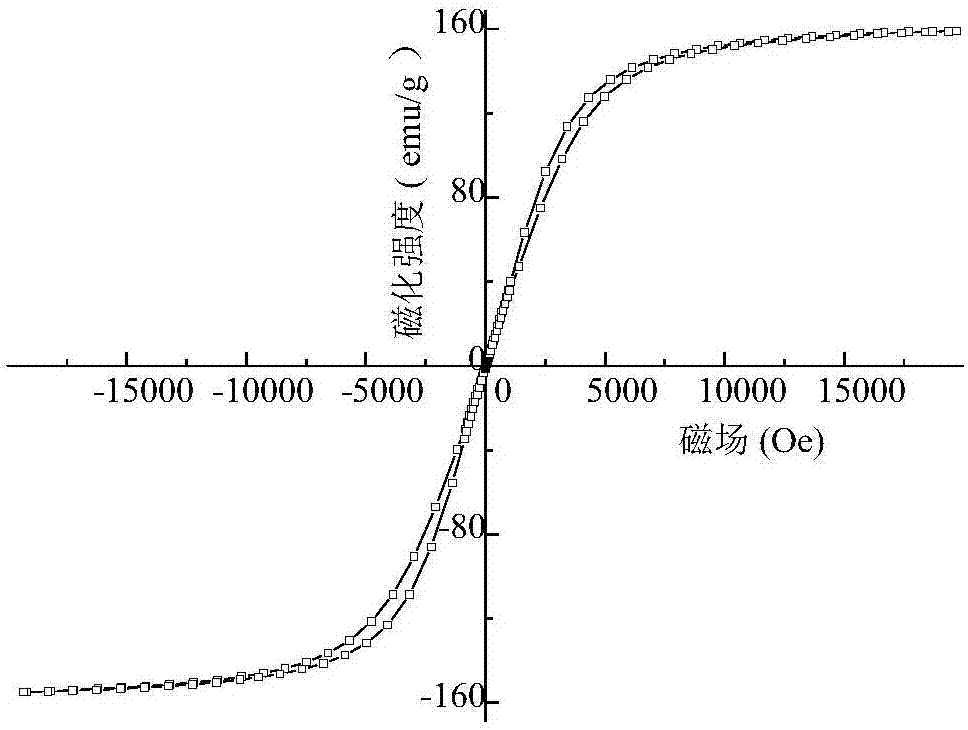

The invention provides a cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and a preparation method thereof. The molecular formula of the amorphous soft magnetic alloy is CoaFebNicBdSieNb5, in which a, b, c, d and e are atomic percents, wherein a is larger than or equal to 25 and smaller than or equal to 60, b is larger than or equal to 10 and smaller than or equal to 28, c is larger than or equal to 2 and smaller than or equal to 10, d is larger than 0, e is larger than 0, d+e is larger than or equal to 14 and smaller than or equal to 39, and a+b+c+d+e+5 is equal to 100. Compared with the prior art, the alloy material has the advantages of high amorphous forming ability, excellent soft magnetic property and mechanical property, the reduced glass transition temperature of the alloy material reaches 0.5-0.7, the coercive force of the alloy material reaches below 1.5A / m, the rupture strength of the alloy material is larger than 4200MPa, and the alloy material can be prepared into amorphous bars with the diameters of 1mm-7mm due to the high amorphous forming ability; therefore, the alloy material can be widely applied in the fields of transformers, magnetic sensors and the like, and has good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

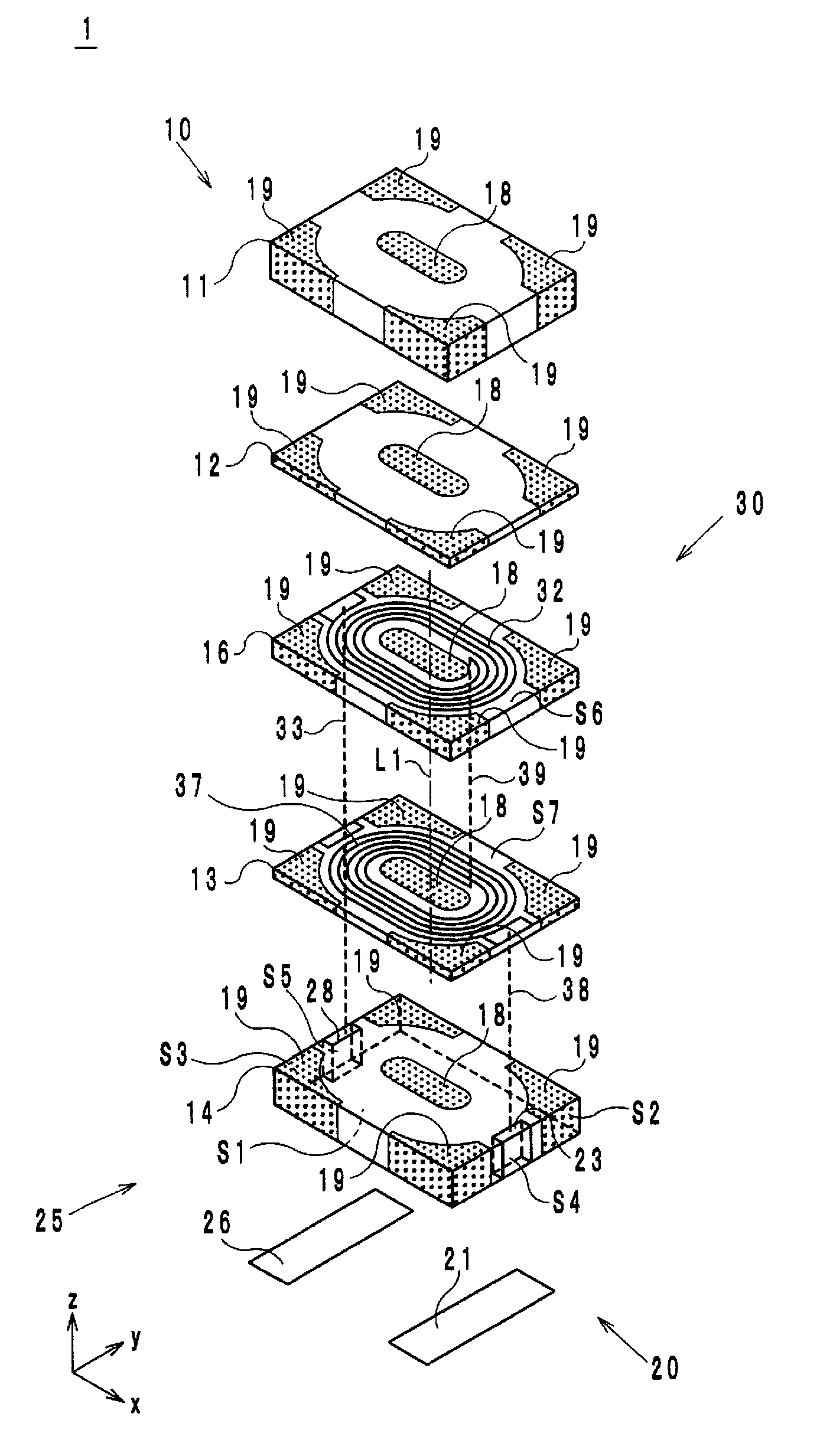

Electronic component

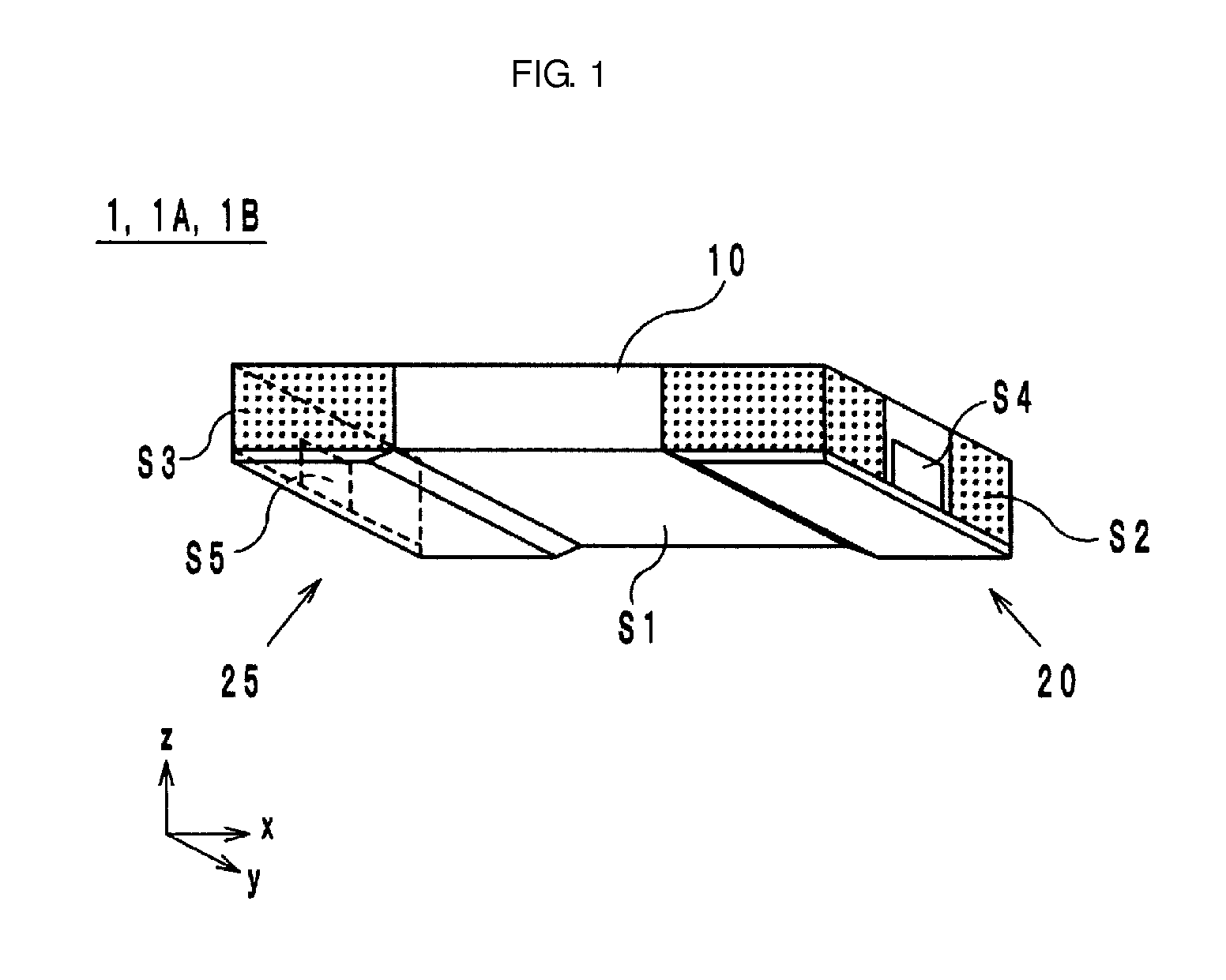

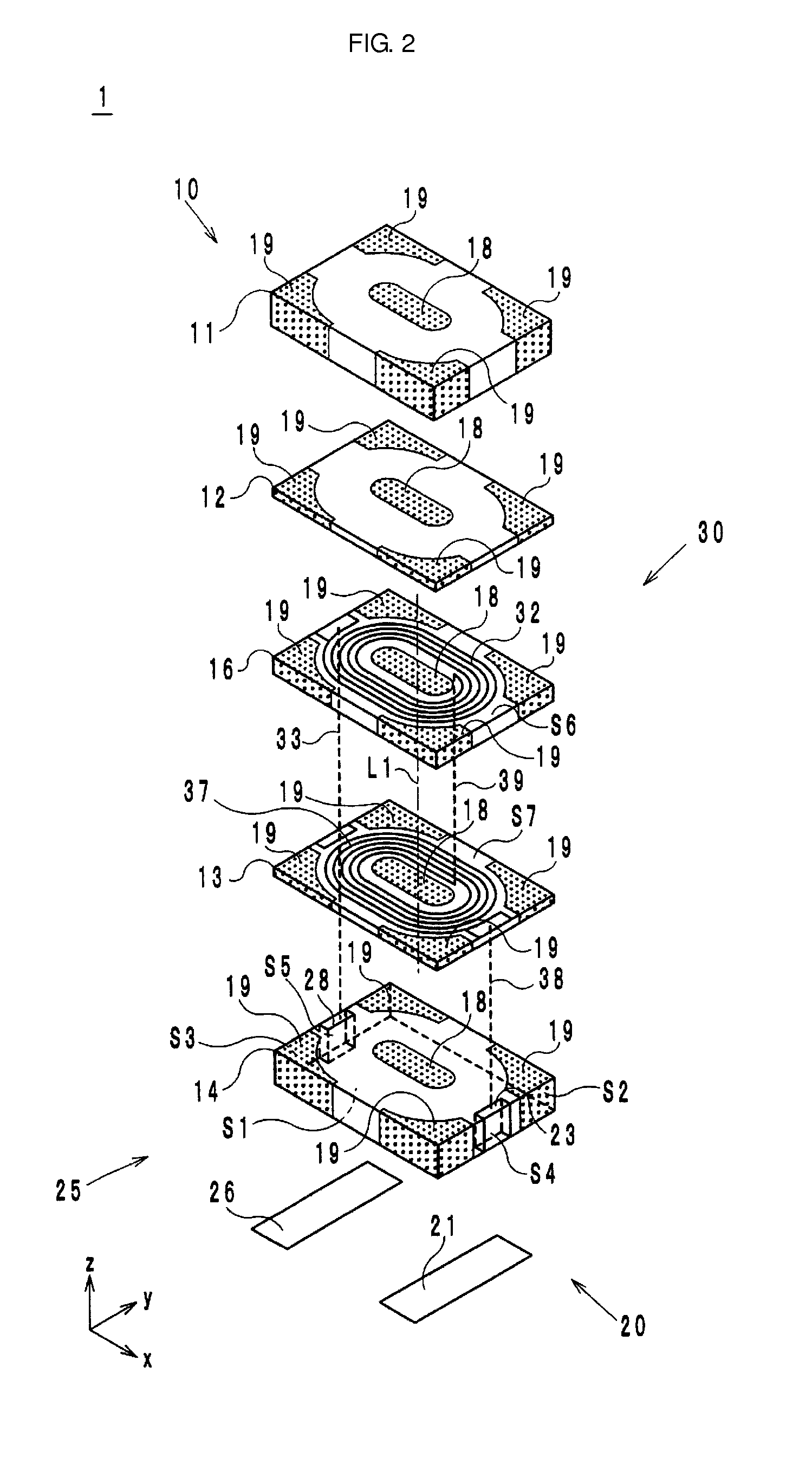

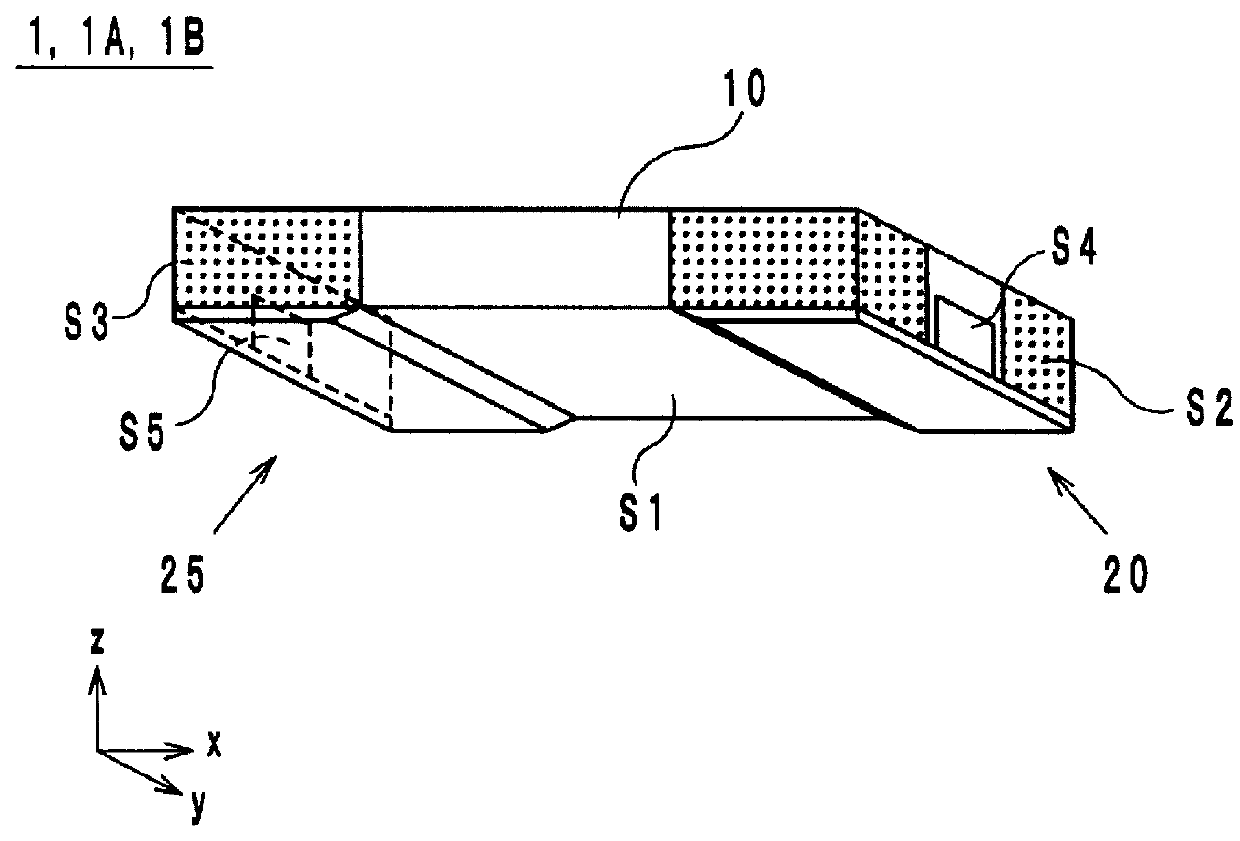

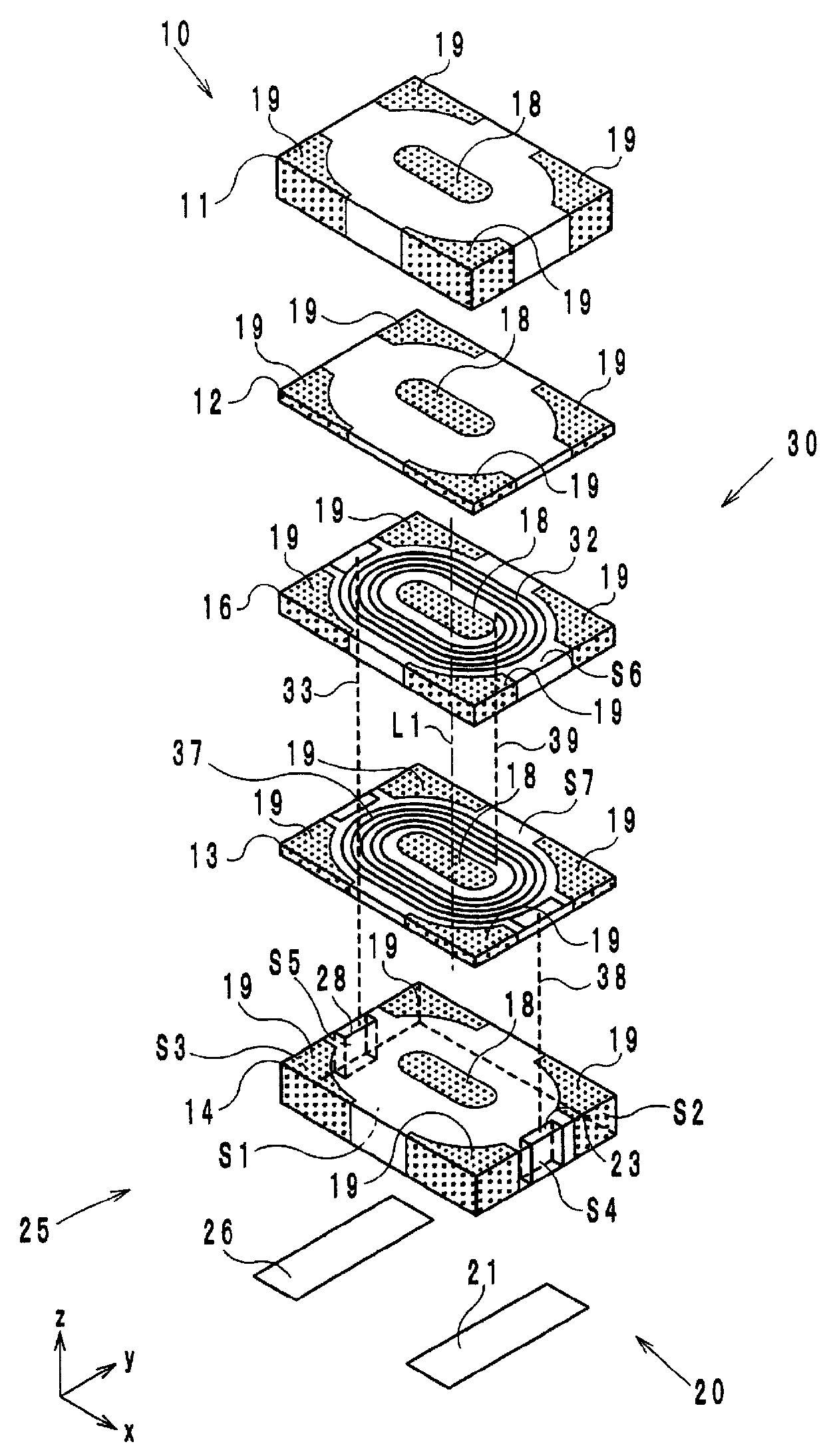

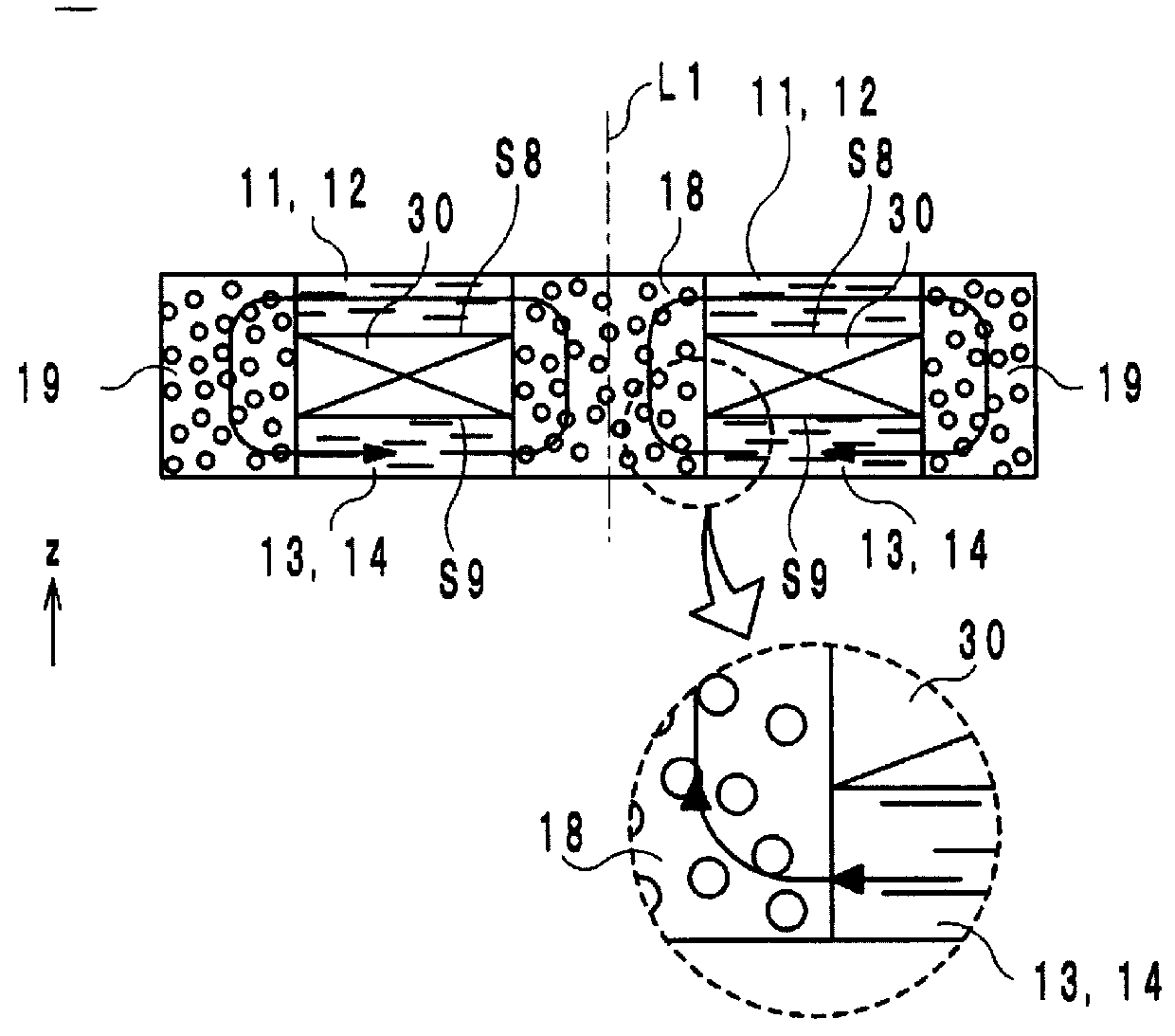

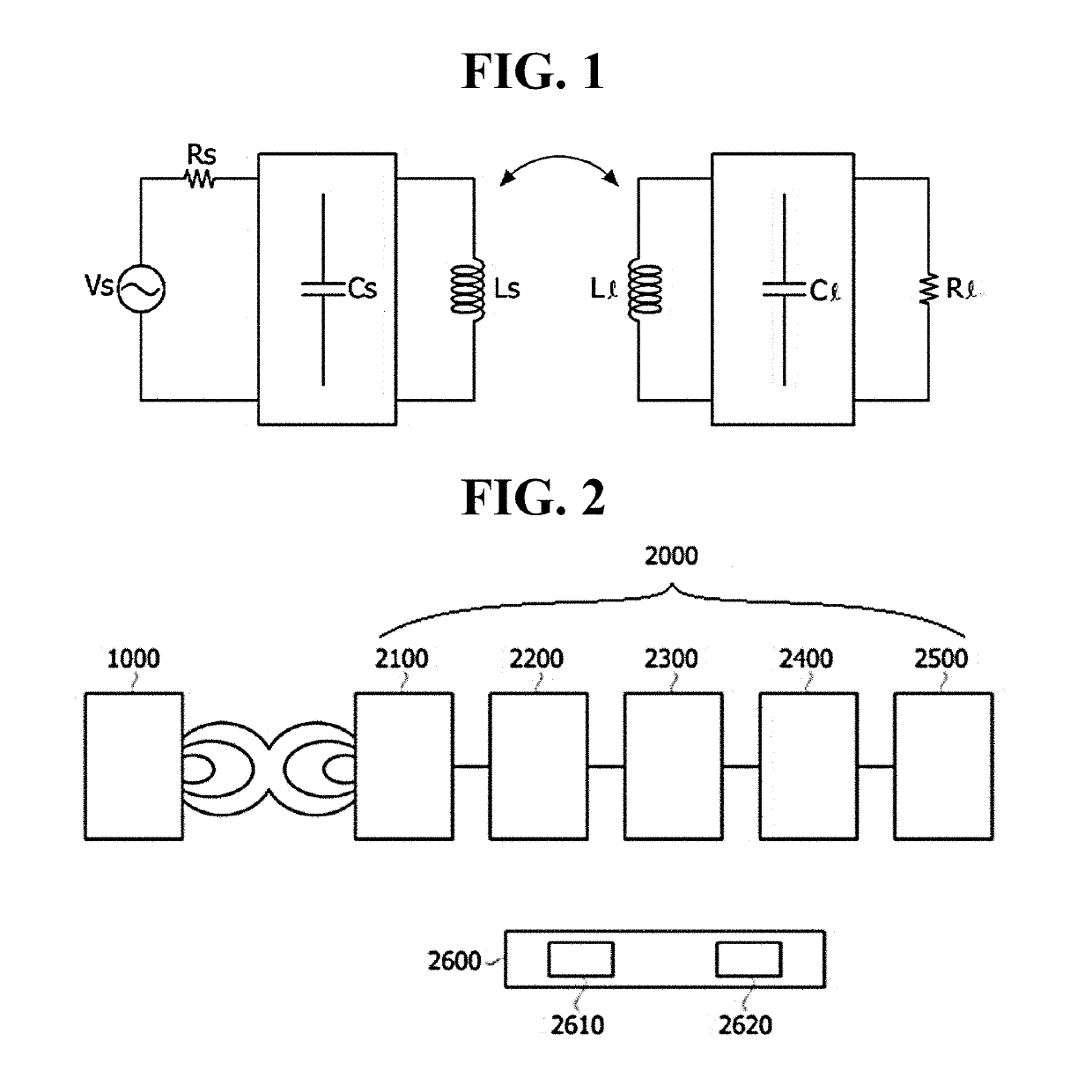

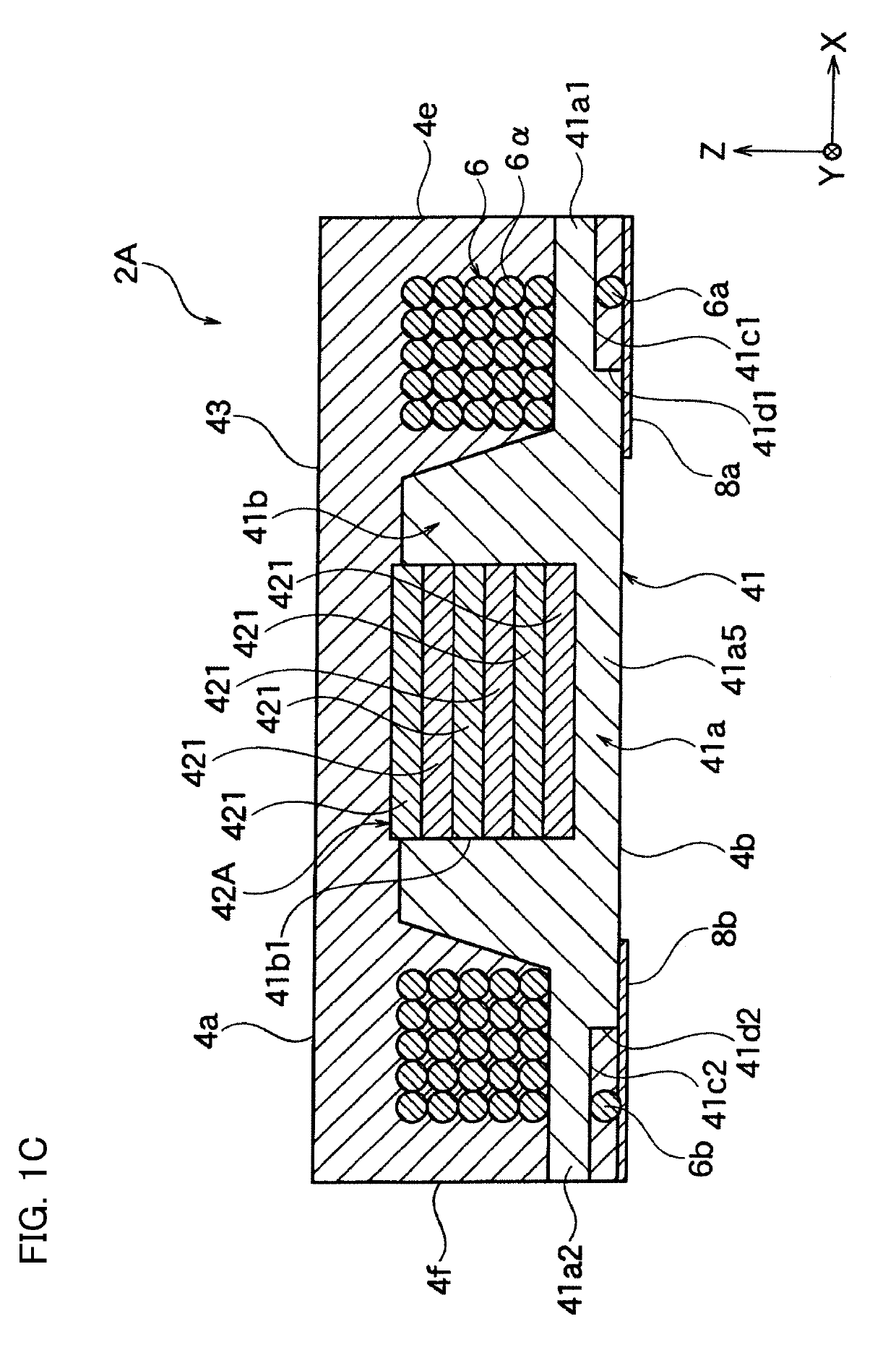

ActiveUS20160099098A1High Effective PermeabilityTransformers/inductances magnetic coresPrinted inductancesMagnetizationElectronic component

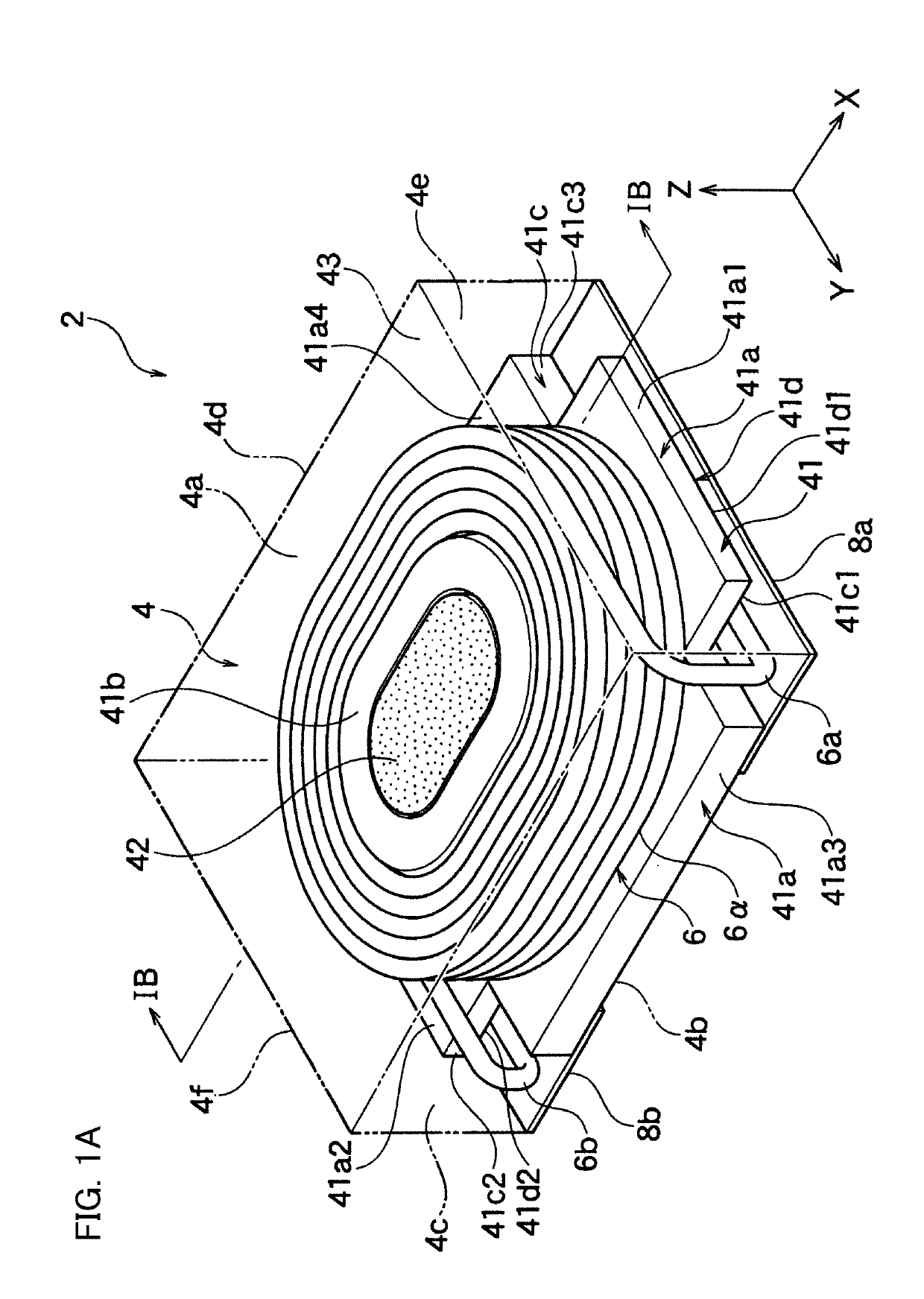

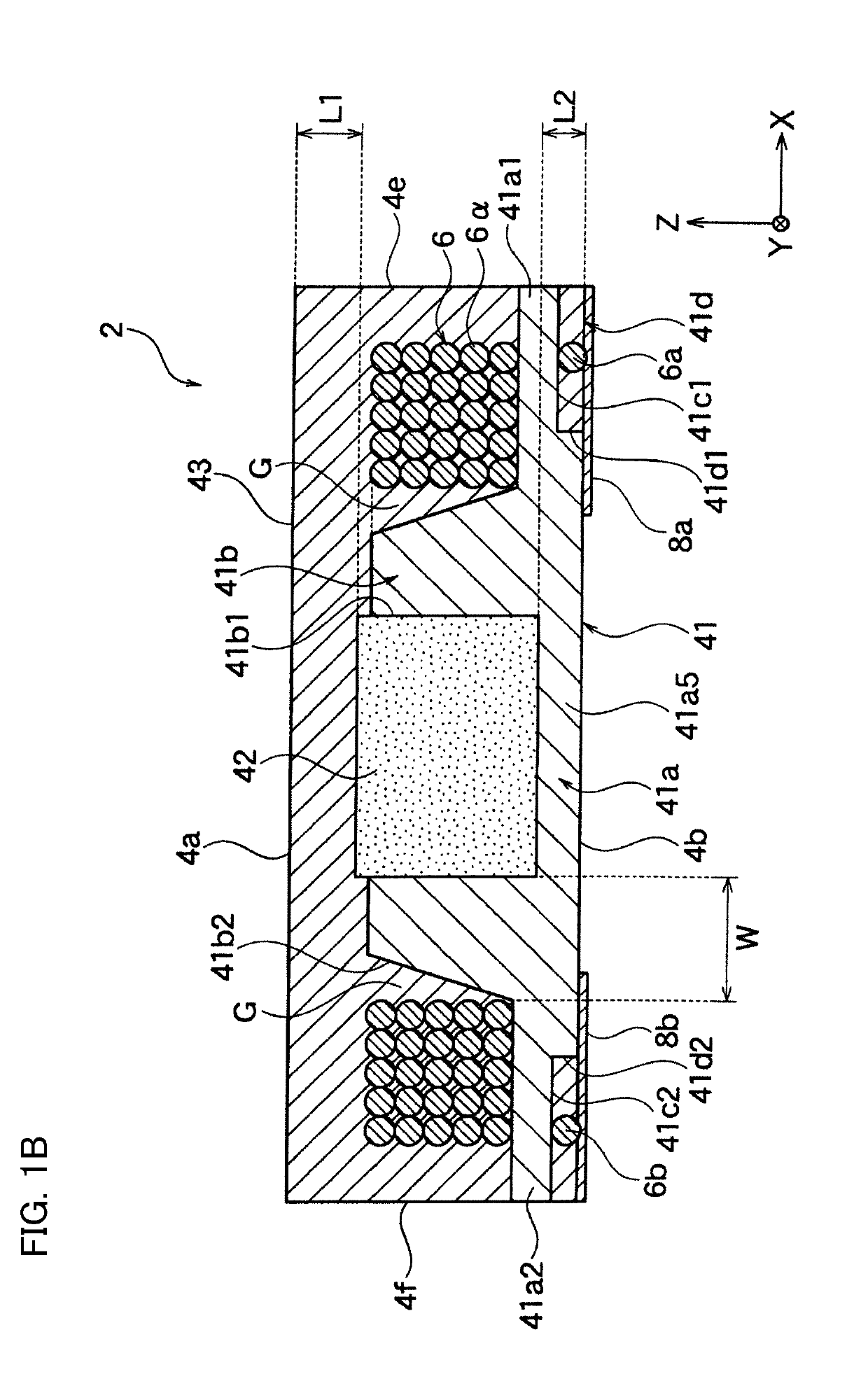

An electronic component includes a body and a coil. The body includes first to fourth insulator layers composed of an anisotropic magnetic material, an internal magnetic circuit composed of an isotropic magnetic material and an external magnetic circuit composed of an isotropic magnetic material. The second and third insulator layers cover an upper surface and a lower surface of the coil from a z-axis direction. The internal magnetic circuit and the external magnetic circuit are adjacent to each other in a direction orthogonal to the z-axis direction. In addition, a direction of easy magnetization of the anisotropic magnetic material used in the first to fourth insulator layers is orthogonal to the z-axis direction.

Owner:MURATA MFG CO LTD

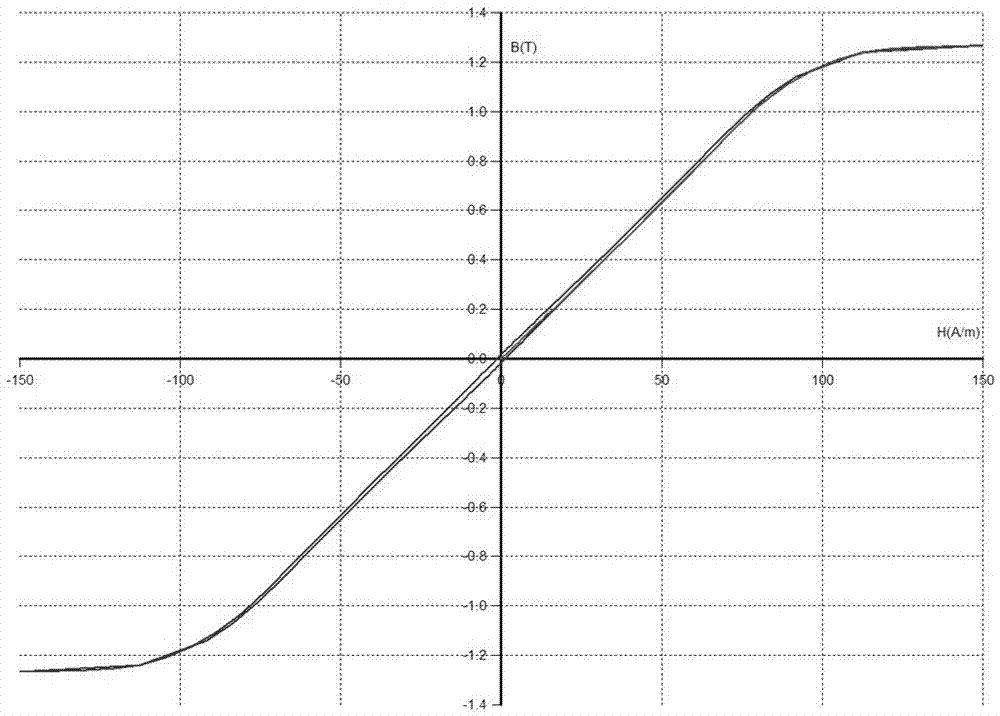

Preparation method of soft magnetic composite powder core

InactiveCN107170575AHigh mechanical strengthGive full play to the advantages of soft magnetic propertiesTransportation and packagingMetal-working apparatusMetallurgyMass ratio

The invention discloses a preparation method of a soft magnetic composite powder core, and relates to a magnet distinguished by the adopted magnetic materials. Amorphous nanocrystalline FeSiM<c>B<d>Cu<e> powder is taken as the main powder; the main powder and auxiliary powder which is formed by at least one of water atomized Fe powder, gas atomized FeNi<50> powder and gas atomized FeSi<3.5> powder are uniformly mixed based mass ratio; the mixed powder is processed by a passivation solution and an insulating agent to form a passivated and insulated thin film on the surface; and next, steps of pressing and shaping and annealing are performed to prepare the soft magnetic composite powder core with excellent comprehensive soft magnetic performance. By adoption of the preparation method, the defects of low saturation flux induction density, relatively high coercivity, high loss and reduction of effective magnetic conductivity under high frequency of the soft magnetic powder core prepared in the prior art can be overcome.

Owner:HEBEI UNIV OF TECH

Magnetic core with linear hysteresis loop

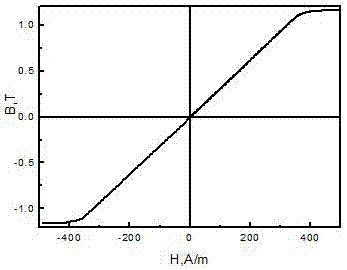

ActiveCN107464649AExcellent anti-DC component performanceThe output is stable and does not changeTransformers/inductances magnetic coresMagnetic materialsHysteresisNiobium

The invention discloses a magnetic core with a linear hysteresis loop. The magnetic core comprises a magnetic core body, wherein the magnetic core body is made of iron-based nanocrystal soft magnetic alloy, and the iron-based nanocrystal soft magnetic alloy comprises the following constituents according to atomic ratios: 72-76 parts of iron, 12-16 parts of silicon, 5.2-7.5 parts of boron, 1.5-3 parts of niobium, 1-1.8 parts of vanadium, 0.8-1.1 parts of copper and 0.2-3 parts of rare metal. The magnetic core is provided with the linear hysteresis loop, the residual magnetic flux density Br is smaller than 0.02T, the coercivity is smaller than 1.5A / m, the saturation flux density is larger than 1.1T, and the linear magnetic conductivity of different magnetic cores which are produced can be controlled between 1,500 and 35,000.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

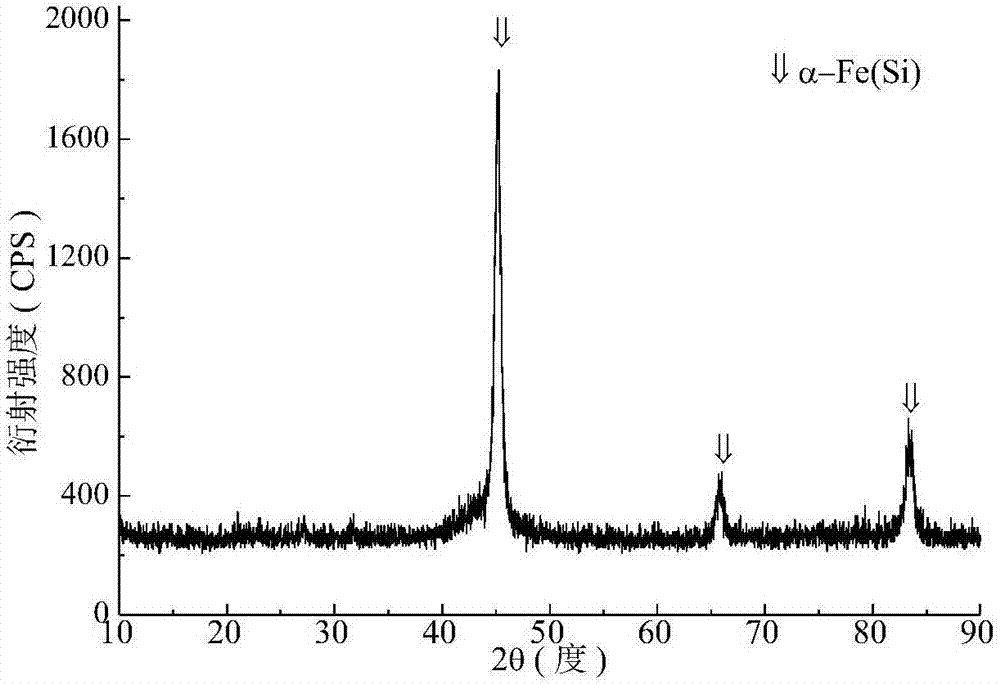

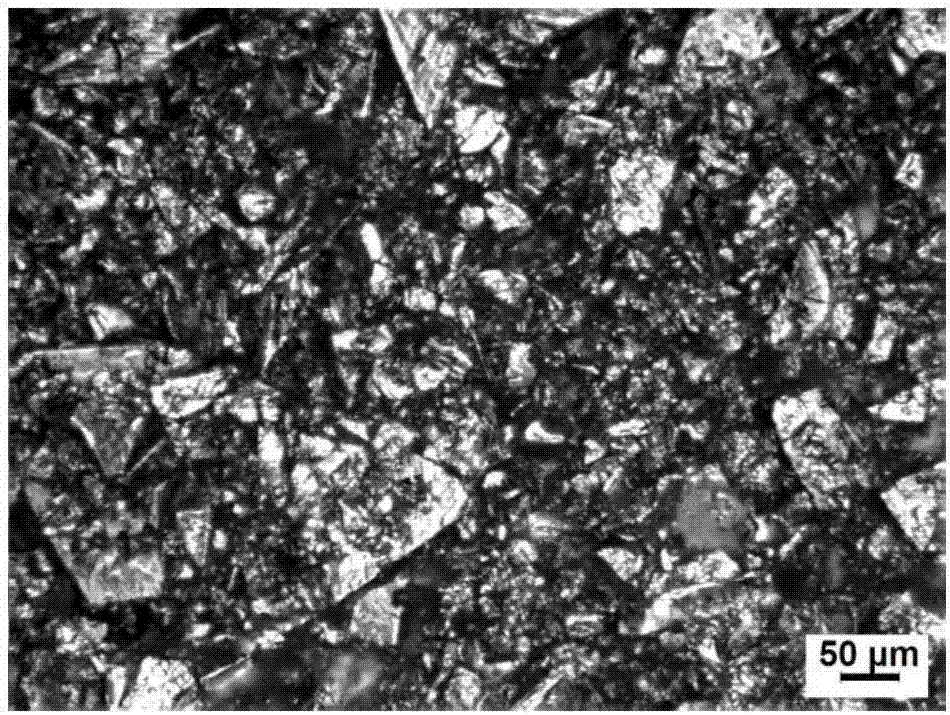

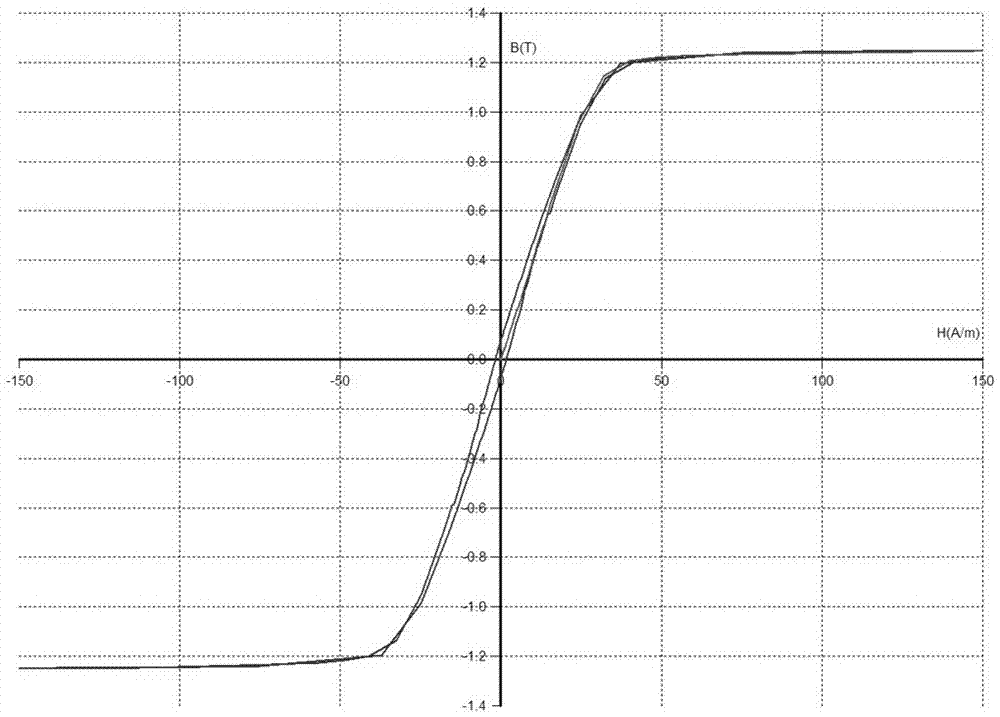

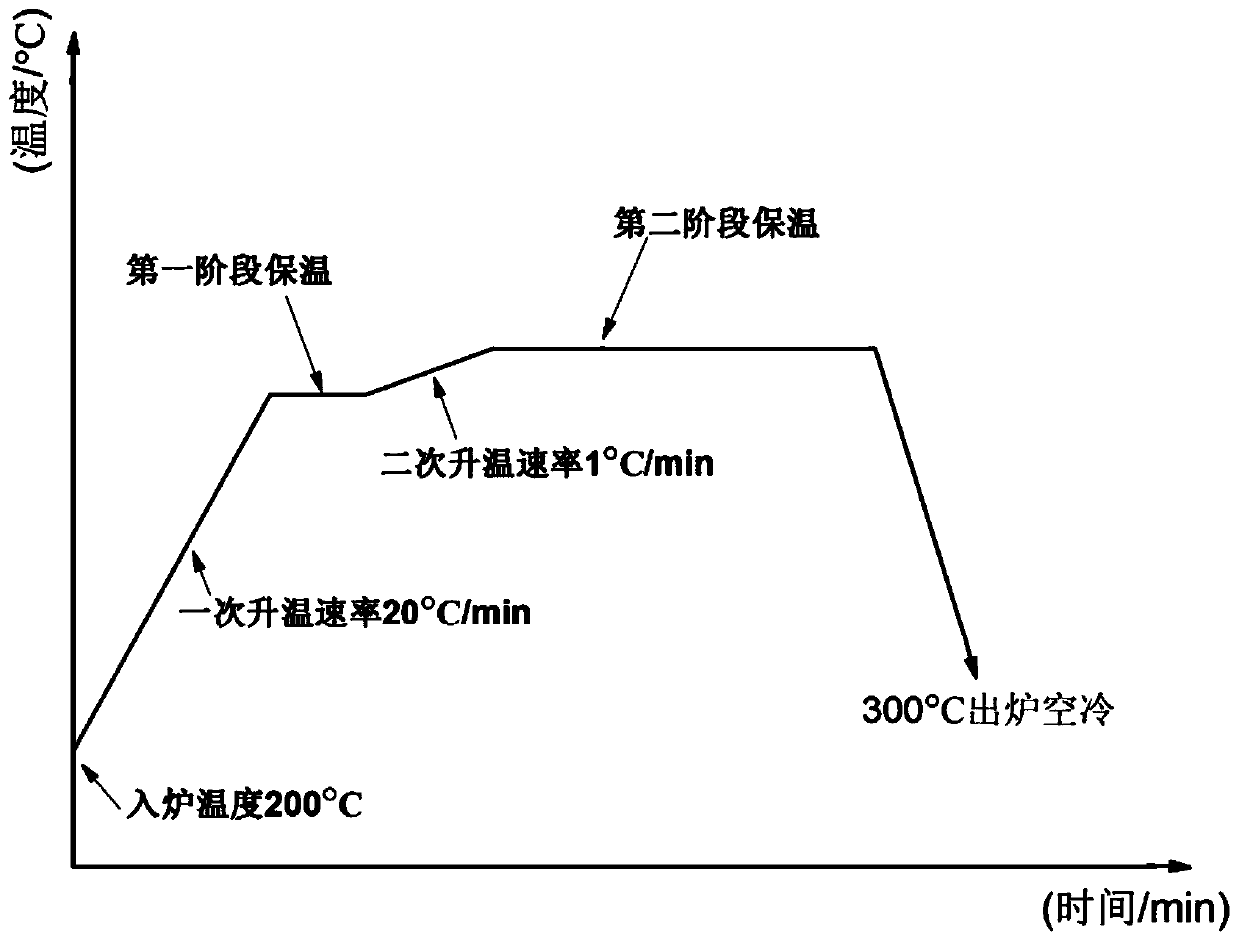

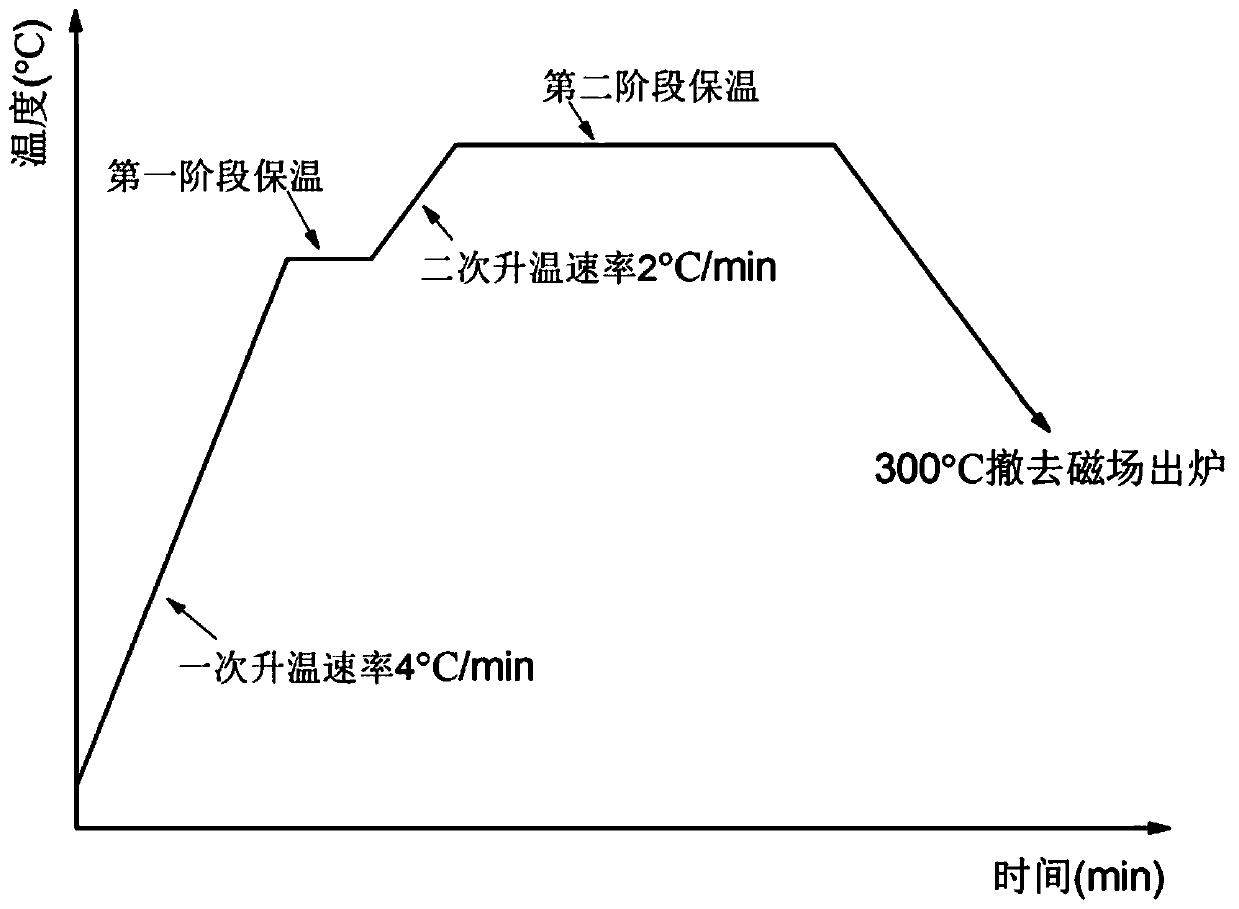

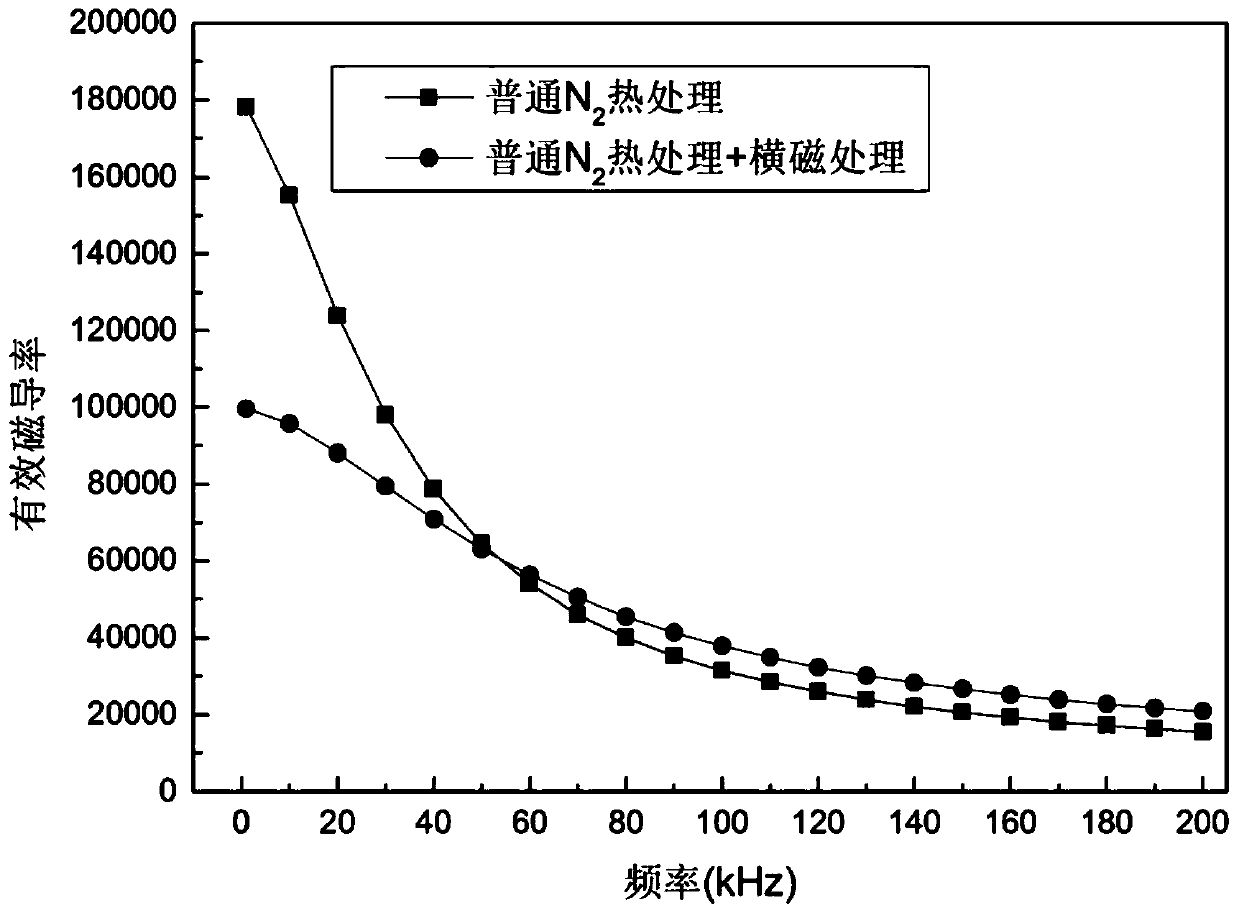

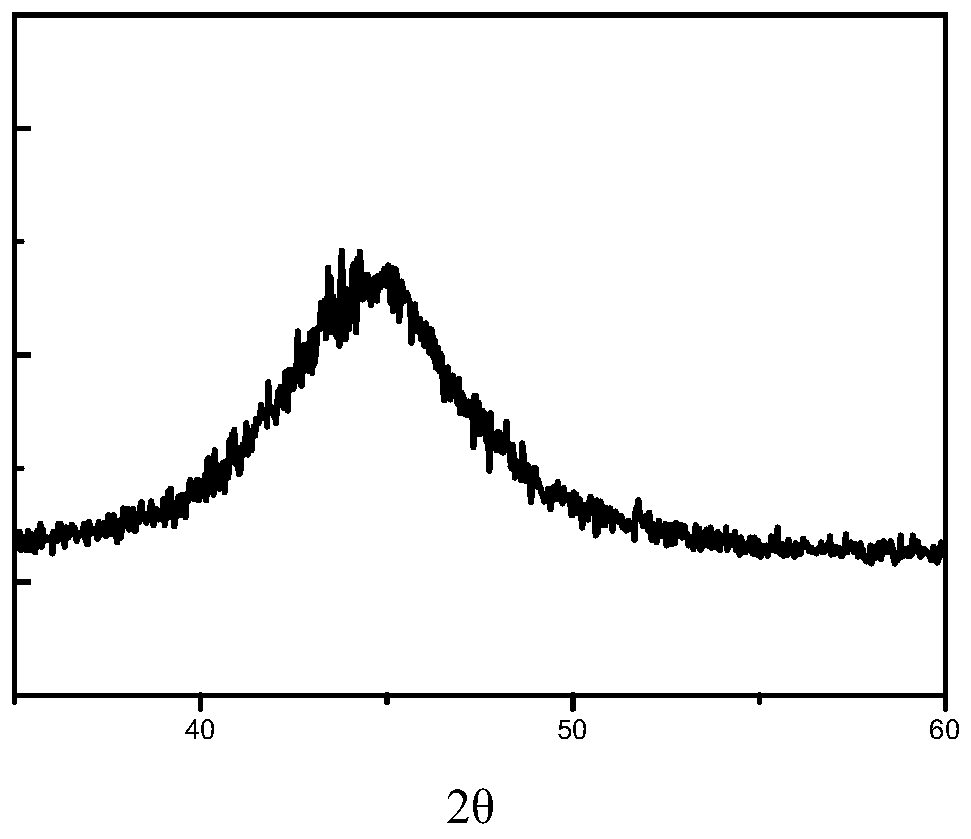

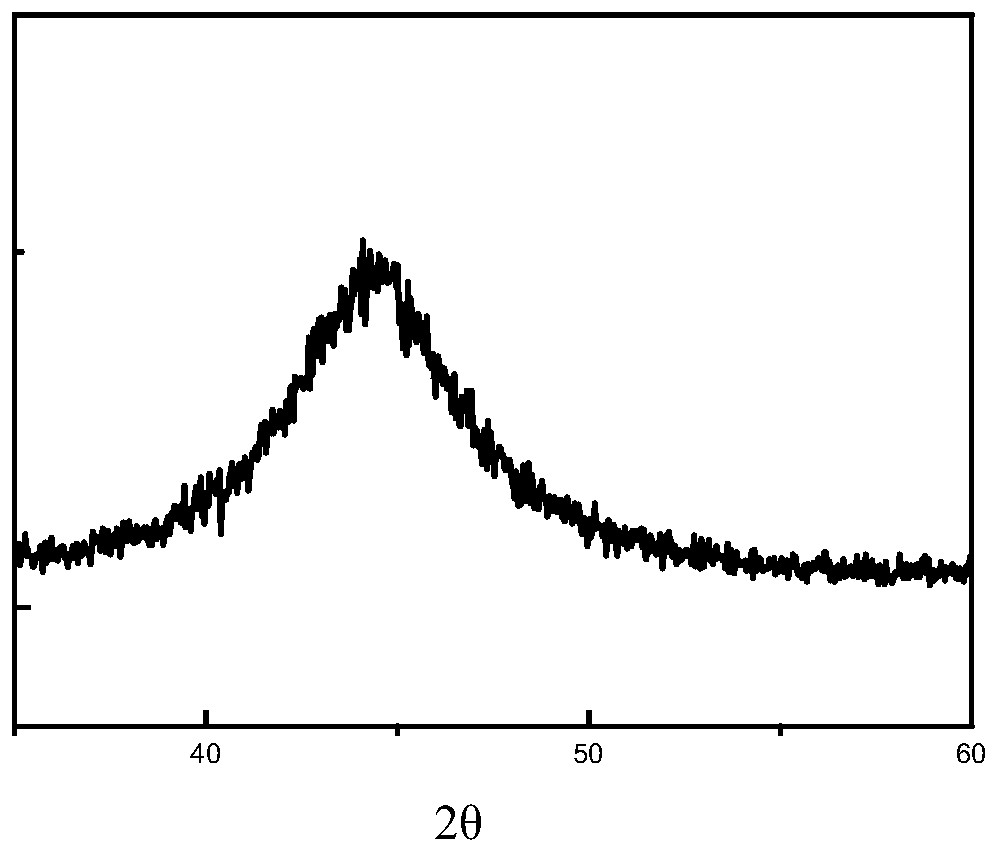

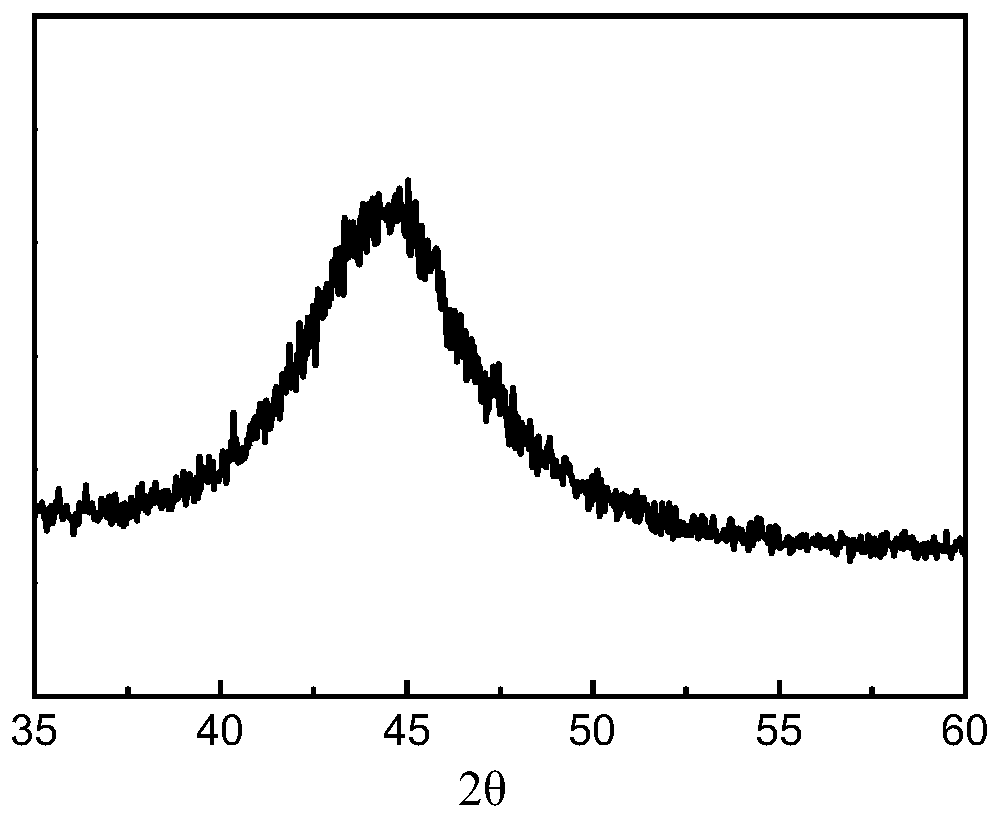

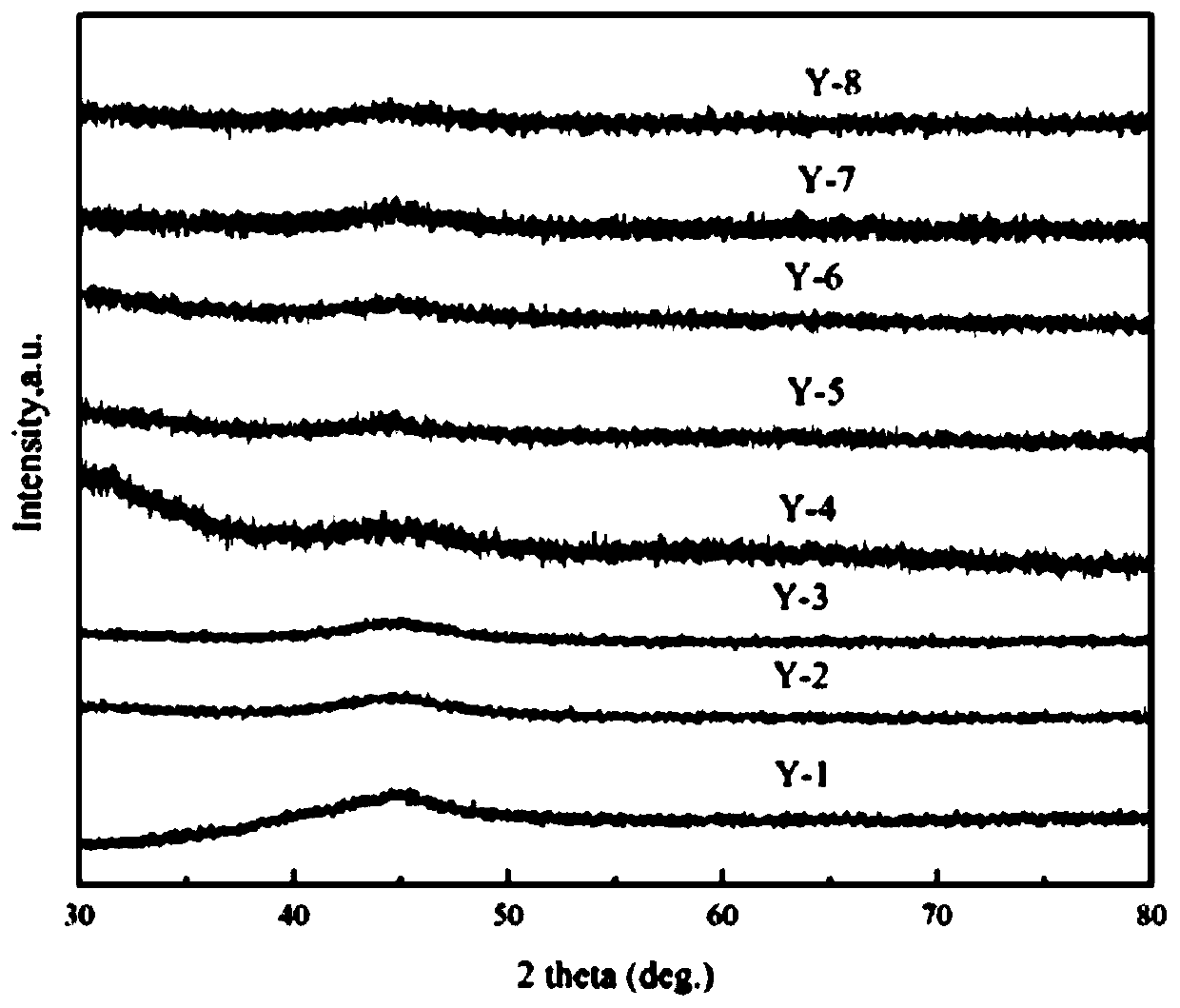

Magnetic field heat treatment method for improving high frequency magnetic property of iron based nanocrystal

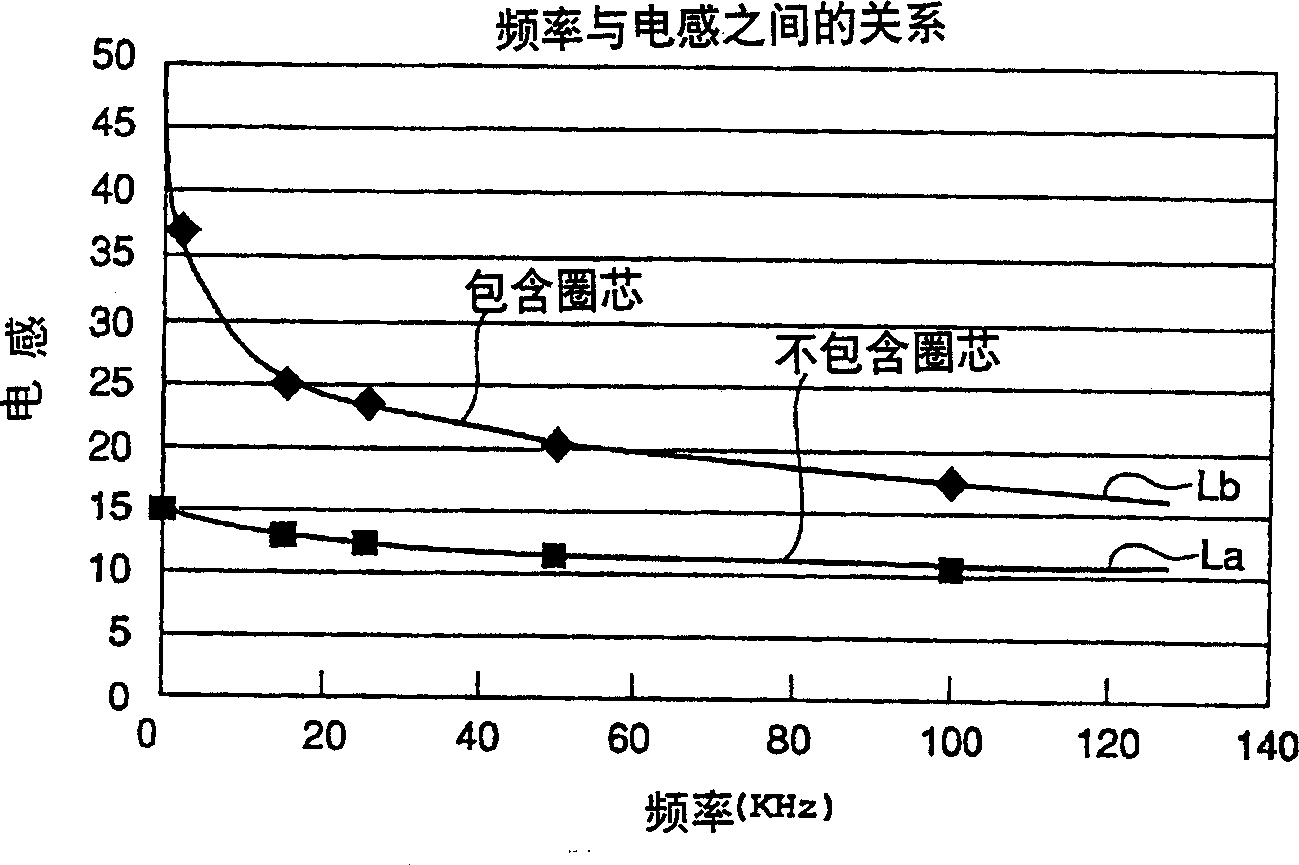

InactiveCN109735688AHigh Effective PermeabilityReduce lossFurnace typesInductances/transformers/magnets manufactureTube furnaceMagnetic core

The invention discloses a magnetic field heat treatment method for improving high frequency magnetic property of iron based nanocrystal. The magnetic field heat treatment method for improving the highfrequency magnetic property of the iron based nanocrystal comprises the following steps that a belt material is rolled into a ring shape magnetic core, heat treatment is conducted in two system devices respectively, firstly the magnetic core is placed in a heat treatment tube furnace, crystallization annealing is conducted, and alpha-Fe (Si) nanocrystal phase is separated out; then the magnetic core after crystallization is placed in a high-intensity magnetic field heat treatment furnace, crossed magnetic field heat treatment is conducted, magnetic anisotropy of the magnetic core is generatedin the magnetic field applying direction, and thus magnetic property of the magnetic core in high frequency is improved; a precision magnetic element analyzer is used for measuring the single-turn inductance value of the treated magnetic core, and effective magnetic conductivity is conversed through formulas; then loss of the magnetic core in the high frequency is measured using a soft magnetic alternating current testing device; and finally, the phase structure of a magnetic core sample is analyzed using an X-ray analyzer, and a detecting result is acquired and is compared with an existing magnetic core. The magnetic field heat treatment method for improving the high frequency magnetic property of the iron based nanocrystal further has the advantages that the logic is clear, the operation is simple, and implement is easy to conduct.

Owner:GUANGDONG UNIV OF TECH

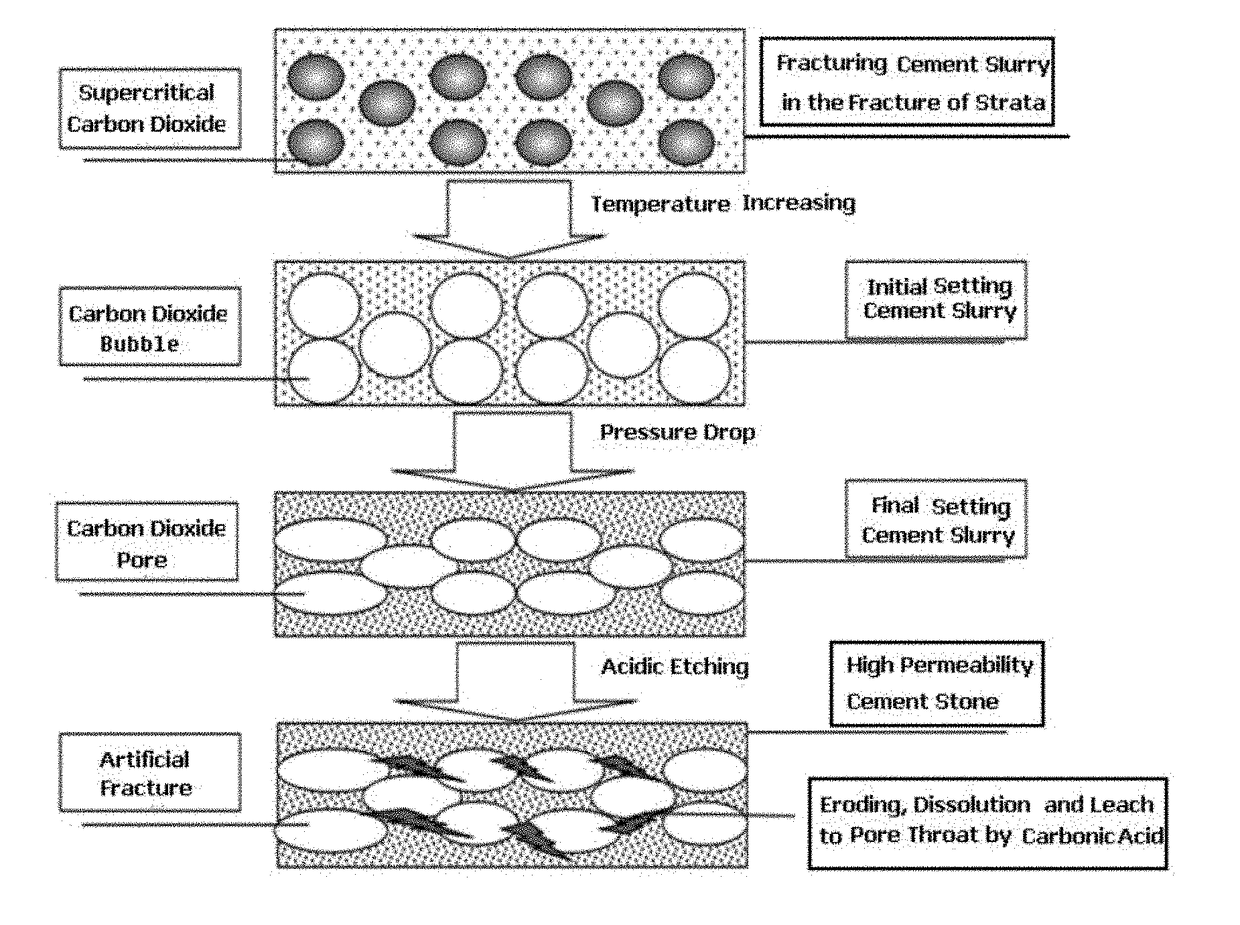

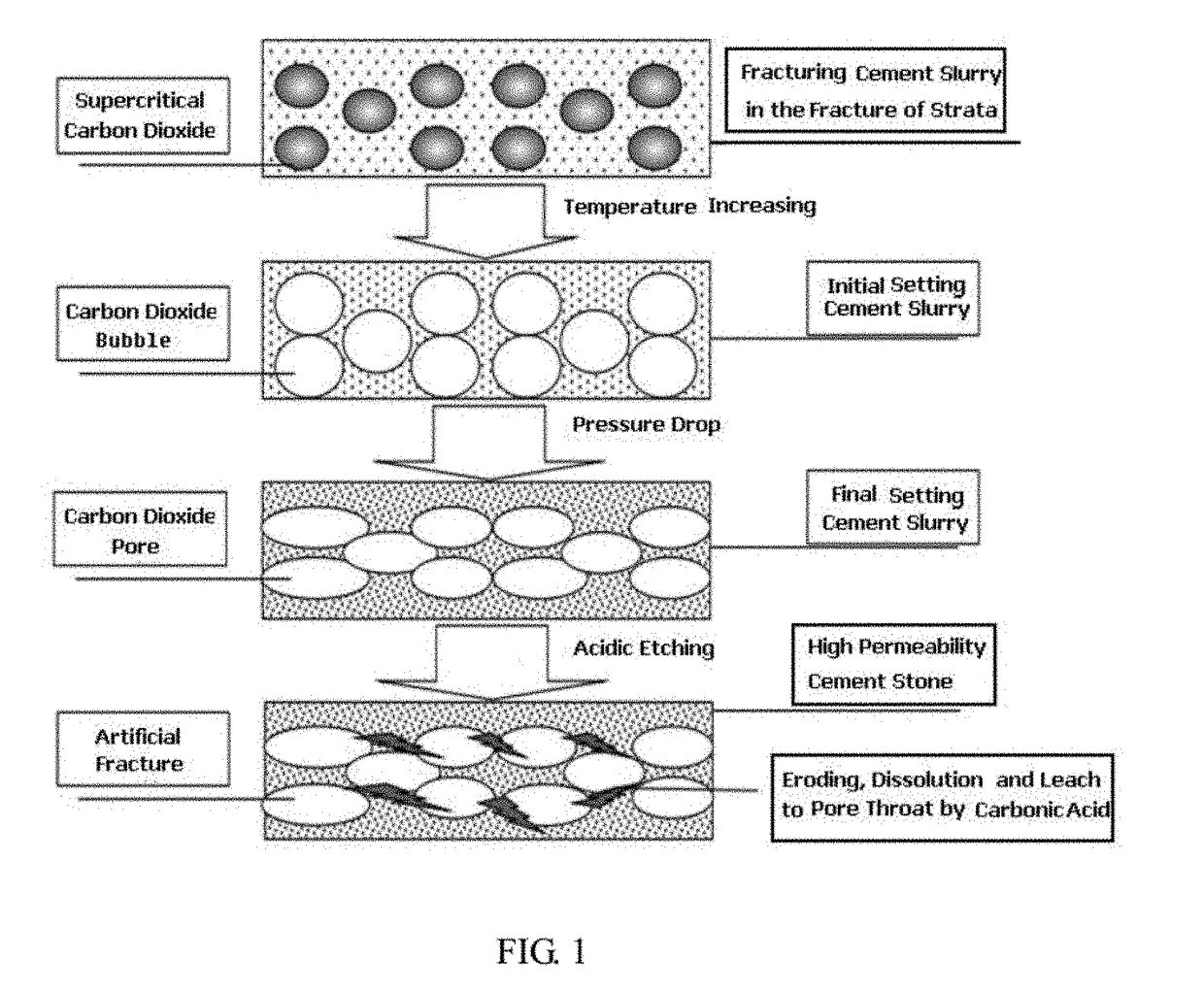

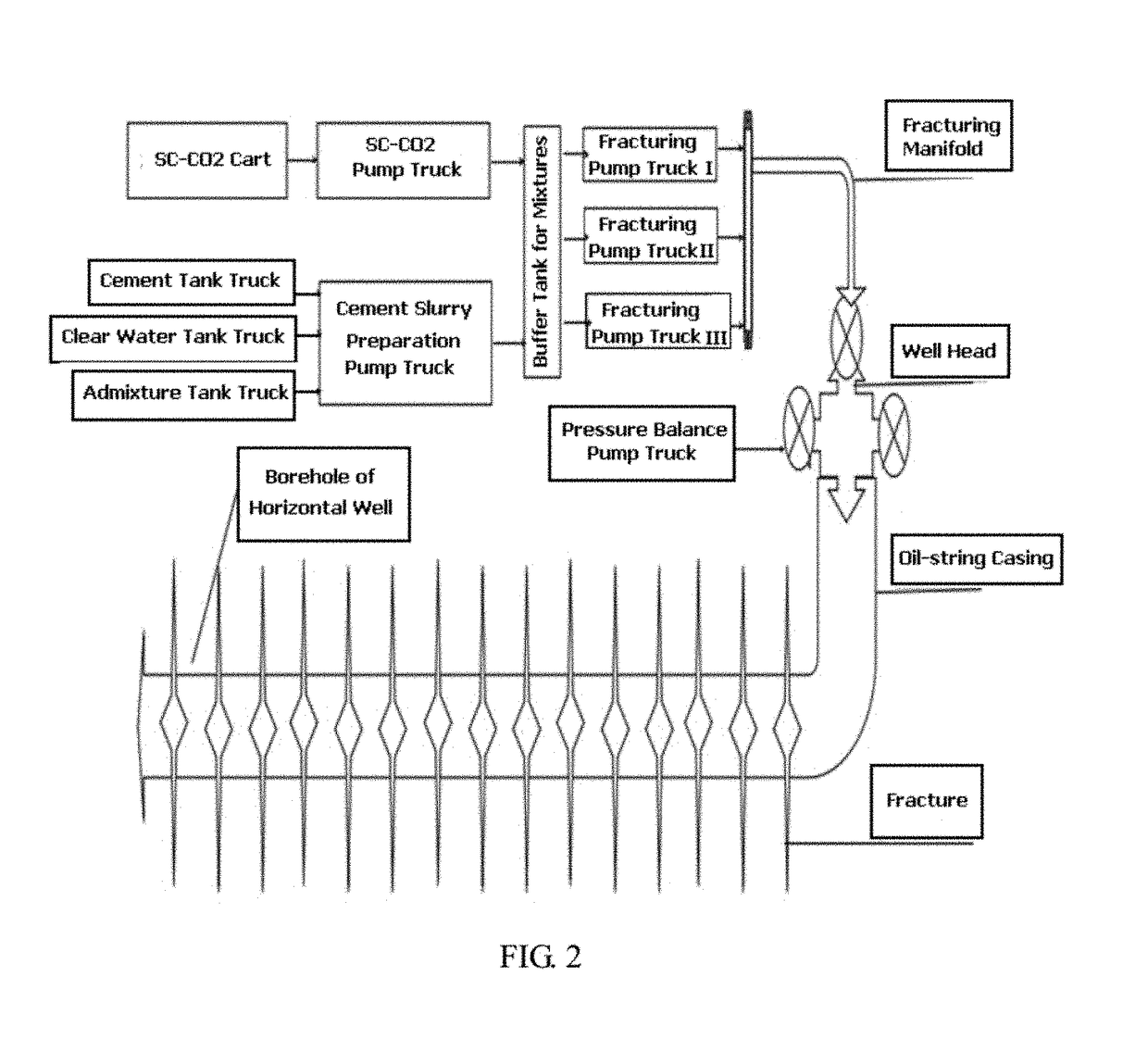

Permeable cement stone fracturing exploitation method for non-conventional oil and gas layer

ActiveUS20180238157A1High Effective PermeabilityStimulated is largeConstructionsOther gas emission reduction technologiesTight oilFracturing fluid

Disclosed is a permeable cement stone fracturing exploitation method for non-conventional oil and gas layer such as tight oil and gas, shale gas, coal-bed gas, combustible ice and so on. The method comprises the following complementary processes and embodiments: transporting, storing and pumping process for supercritical carbon dioxide; transporting, storing, preparing and pumping process for fracturing cement slurry; process for mixing the supercritical carbon dioxide and the cement slurry; process of fracturing the supercritical carbon dioxide and the cement slurry on ground; process of forming a permeable cement stone under the ground; and so on. The present invention provides a method for non-conventional oil and gas layer fracturing exploitation without using conventional fracturing proppant and fracturing fluid, having advantages of no flow-back fluid, less water, less material, less equipment, smaller area of well site, lower cost, better stimulation effect, environmental protection, and wide application.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD +1

Magnetic core and magnetic field shielding component and coil, transformer, electronic apparatus and camera device

InactiveCN1490829AEasy to manufactureAvoid it happening againInduction heatingTransformers/inductances coils/windings/connectionsTransformerInductance

A magnetic core as a magnetic material that acts on an electromagnetic characteristic of the generated magnetic field and a magnetic field shield member that shields the magnetic field generated by magnetic field generation unit are structured such that magnetic particles are arranged in a base material under a dispersed state. As a result, a magnetic core in which an inductance can be set and a magnetic field shield member in which magnetic field leakage can be suppressed effectively, as well as an excitation coil, a transformer, electric equipment and an electrophotographic apparatus using them are easily provided at low costs.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Electronic component

ActiveUS9997288B2High Effective PermeabilityTransformers/inductances coils/windings/connectionsPrinted inductancesMagnetizationElectronic component

An electronic component includes a body and a coil. The body includes first to fourth insulator layers composed of an anisotropic magnetic material, an internal magnetic circuit composed of an isotropic magnetic material and an external magnetic circuit composed of an isotropic magnetic material. The second and third insulator layers cover an upper surface and a lower surface of the coil from a z-axis direction. The internal magnetic circuit and the external magnetic circuit are adjacent to each other in a direction orthogonal to the z-axis direction. In addition, a direction of easy magnetization of the anisotropic magnetic material used in the first to fourth insulator layers is orthogonal to the z-axis direction.

Owner:MURATA MFG CO LTD

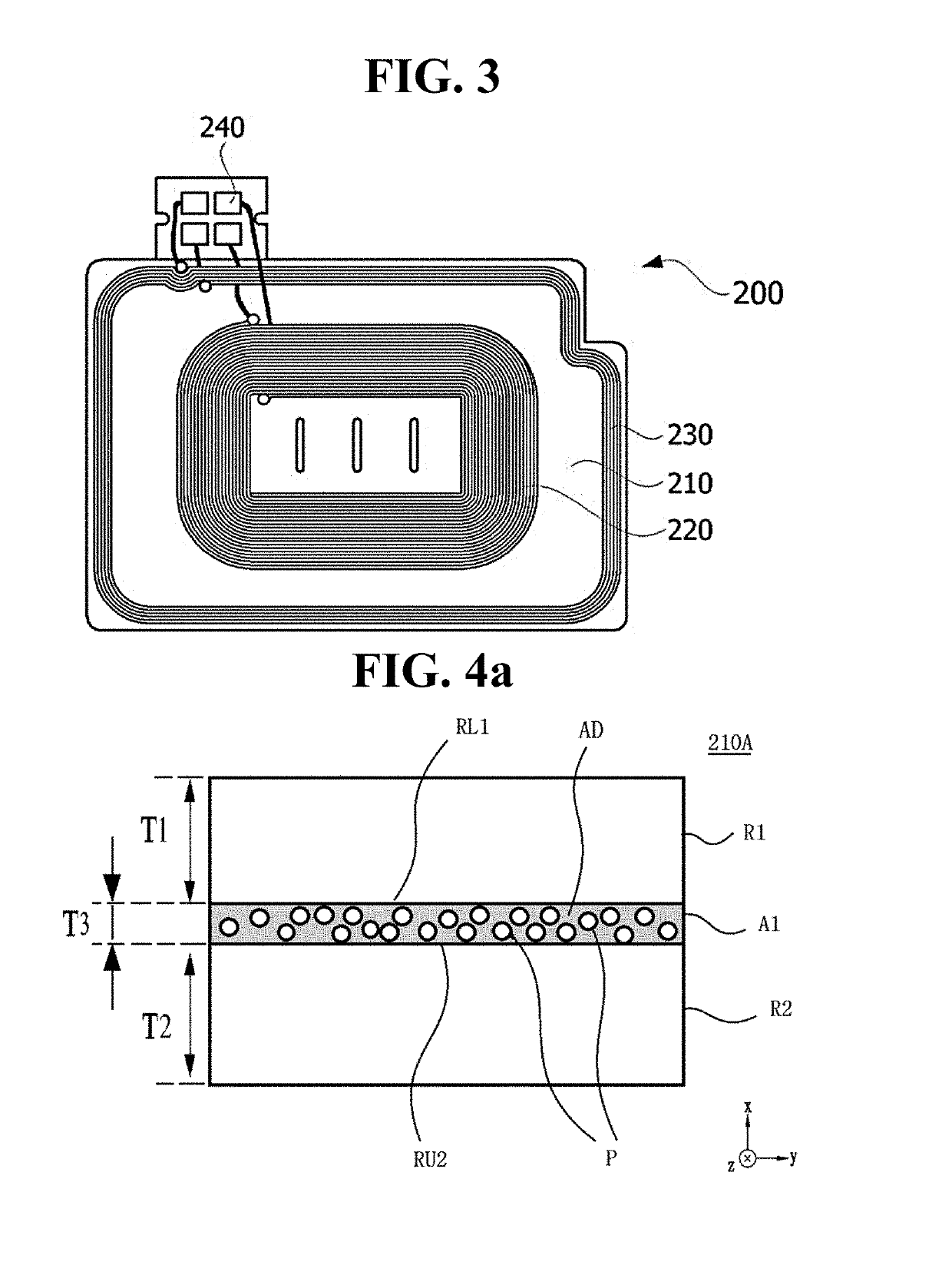

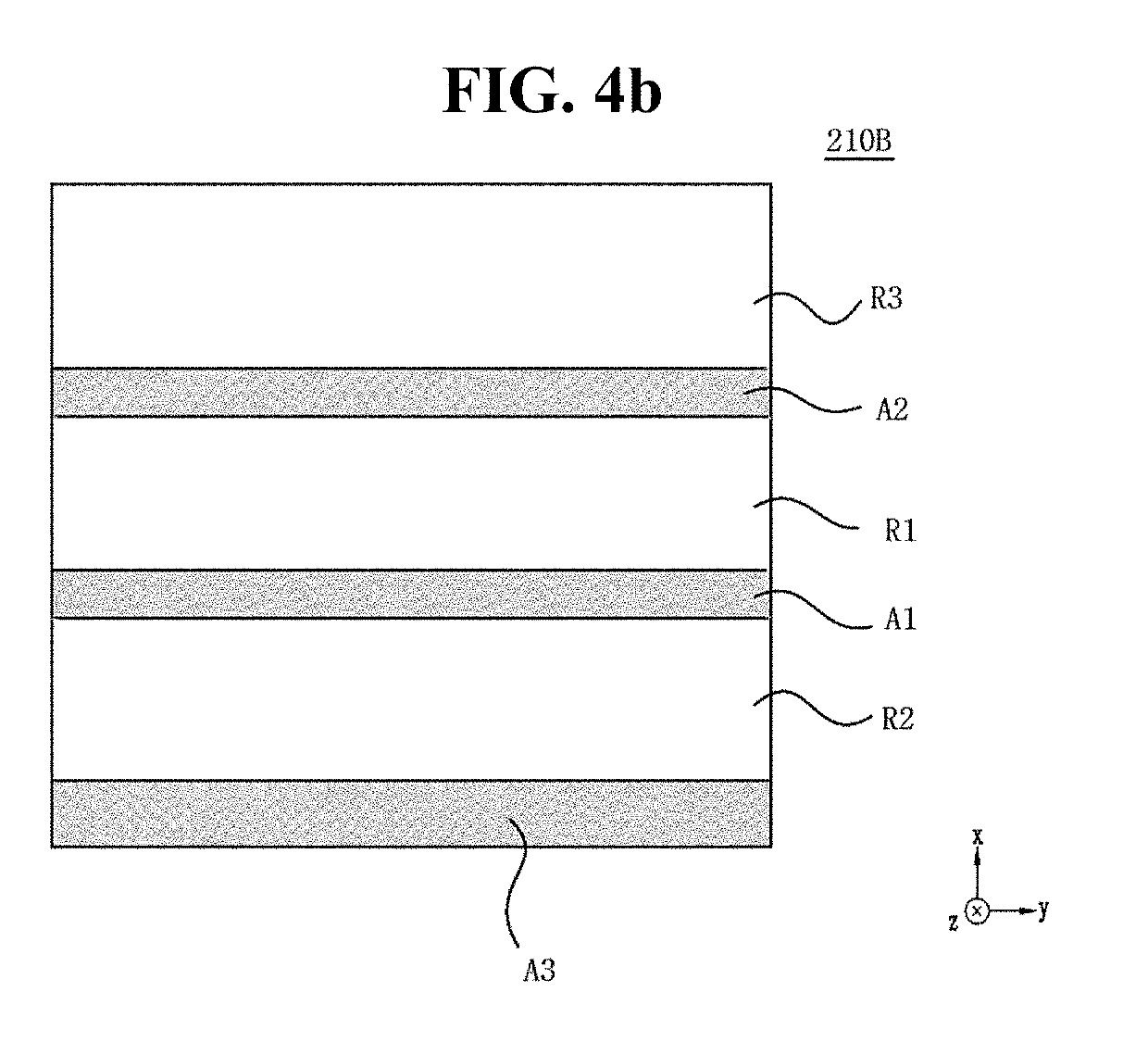

Magnetic sheet and wireless power receiving device comprising same

InactiveUS20190214180A1Strong adhesionImprove transmission efficiencyBatteries circuit arrangementsTransformersEngineeringElectric power

A magnetic sheet according to an embodiment comprises: a first magnetic sheet portion comprising a first surface; a second magnetic sheet portion comprising a second surface that faces the first surface; and an attachment portion arranged between the first surface and the second surface, wherein the attachment portion may comprise a plurality of magnetic particles and a coating layer that is coated with the plurality of magnetic particles and comprises an organic material.

Owner:SCRAMOGE TECH LTD

High-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and preparation method thereof

InactiveCN102832006ALow coercivityHigh saturation magnetic inductionMagnetic materialsCobaltNickel based

The invention provides a high-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and a preparation method thereof. The material reduces the cobalt content under the condition of guaranteeing better soft magnetic properties. The preparation method is simple in process, low in production cost and suitable for industrial production. The material comprises the following components in percentage by weight: 18-22% of Fe, 30-35% of Ni, 4-7% of Gd, 0.01-0.05% of Ho, 0.1-0.5% of V, 0.01-0.05% of Ru, 6-9% of Al, 1-3% of P1, and the balance of Co.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

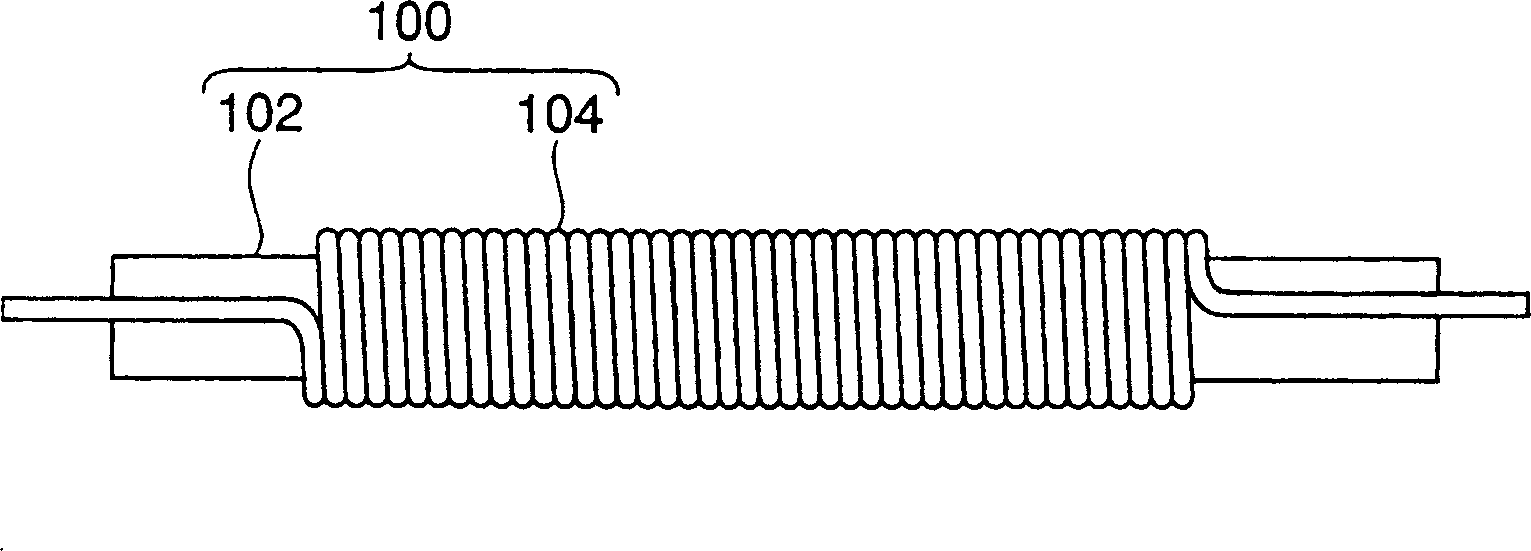

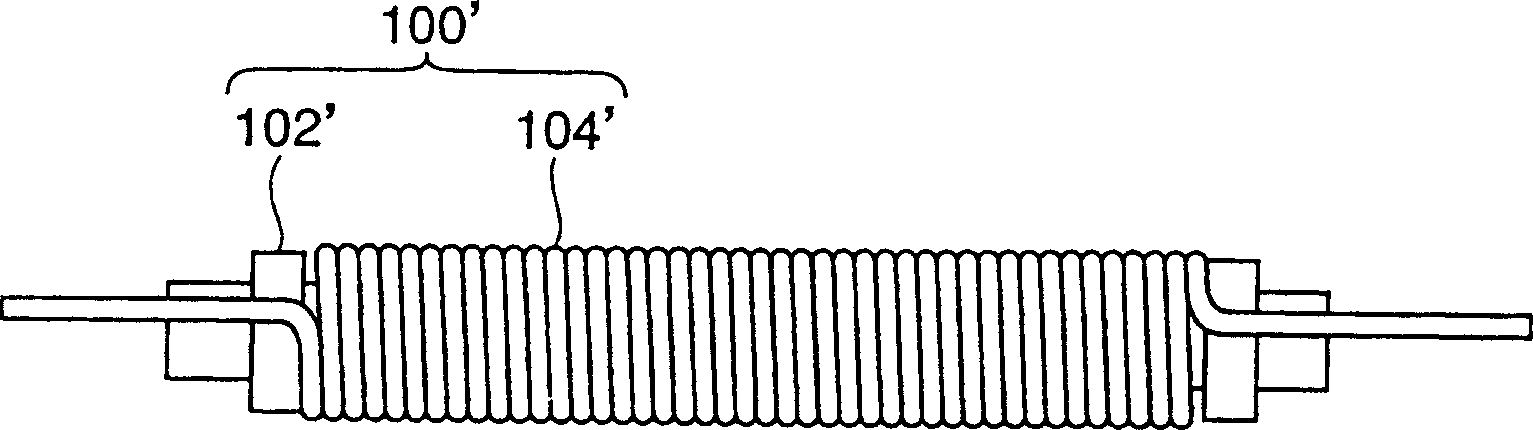

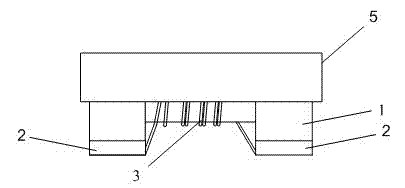

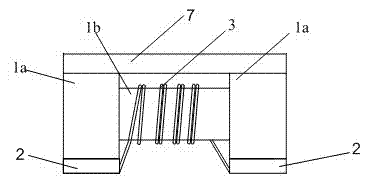

Wire-wound coil

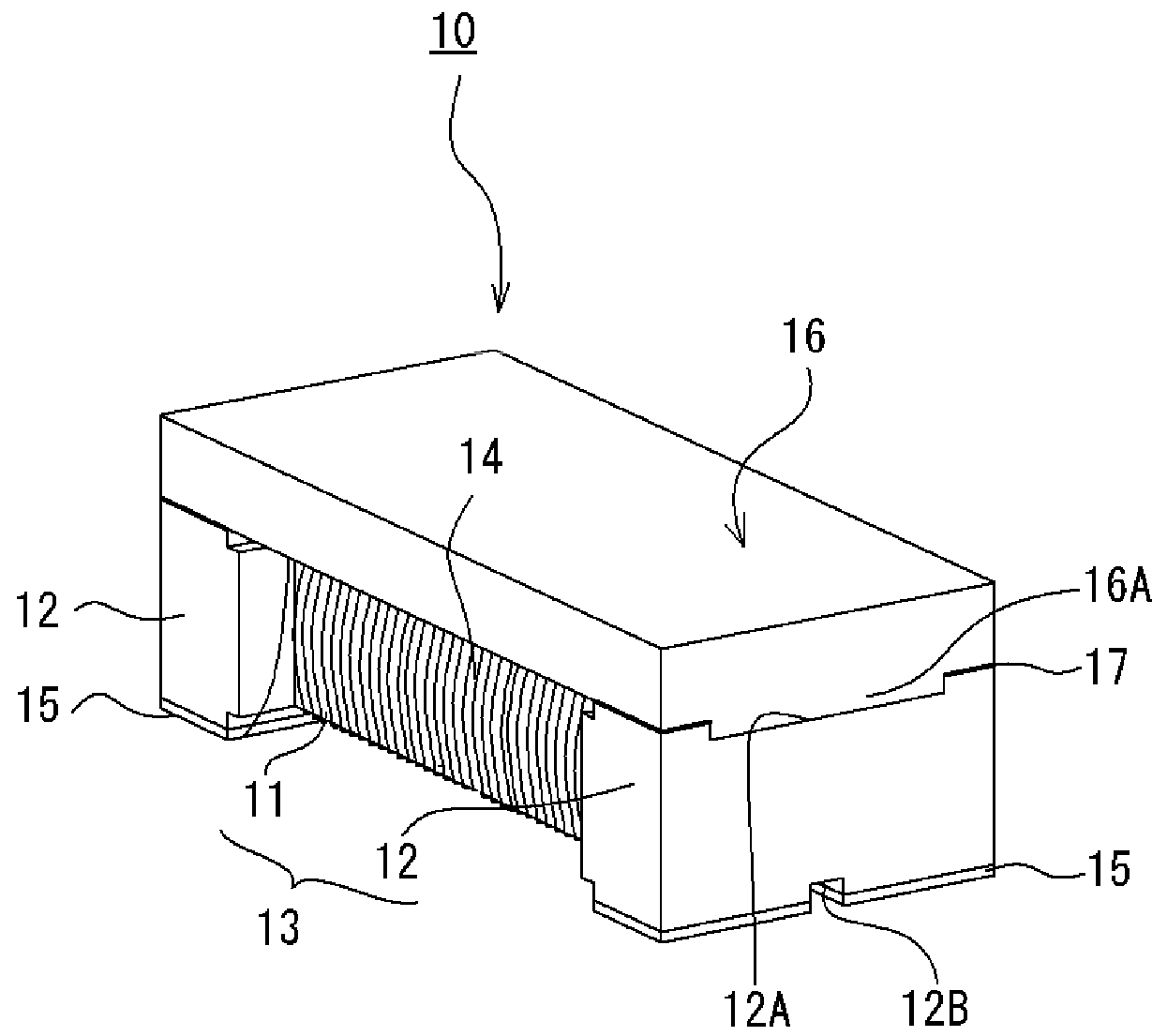

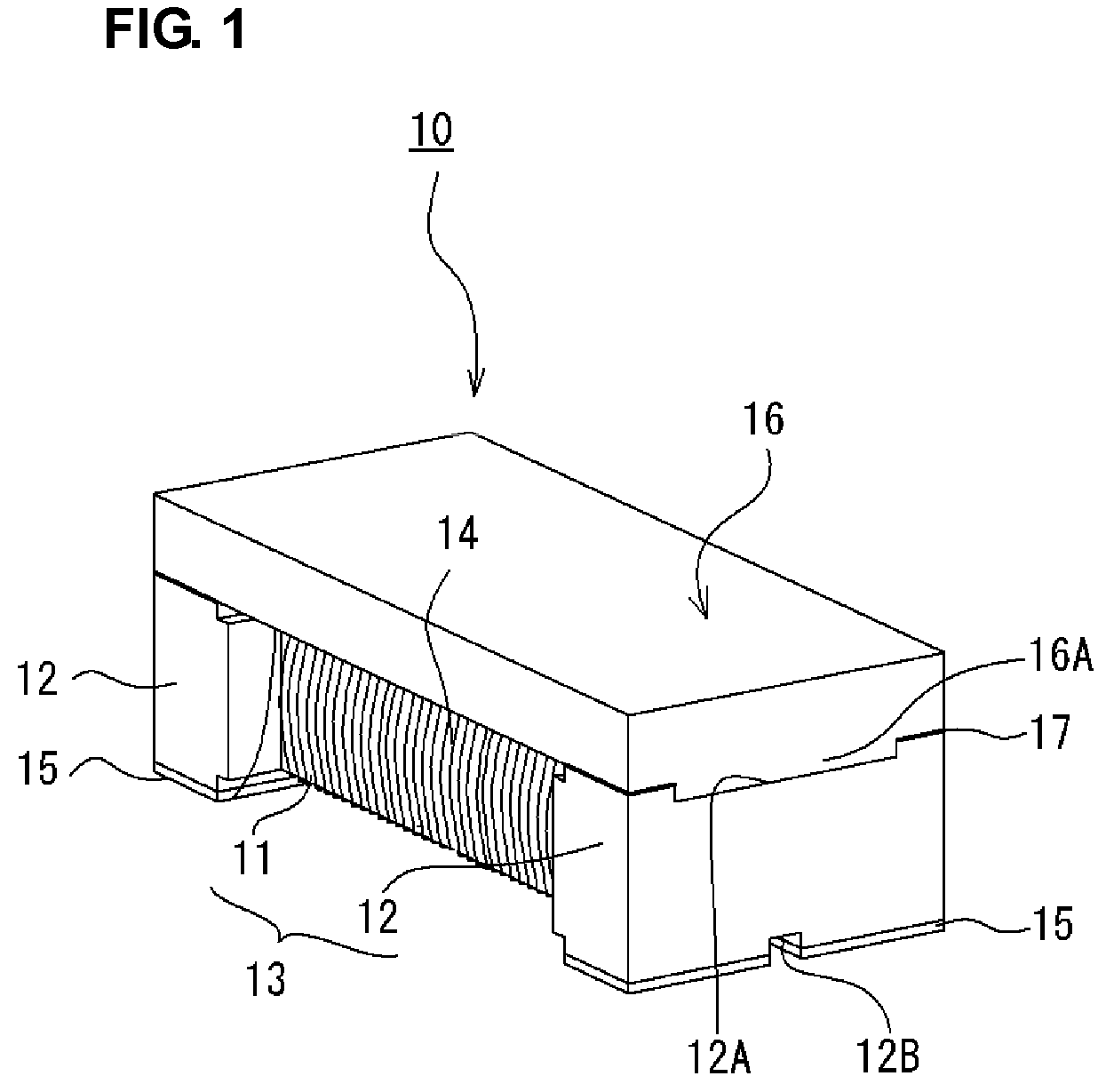

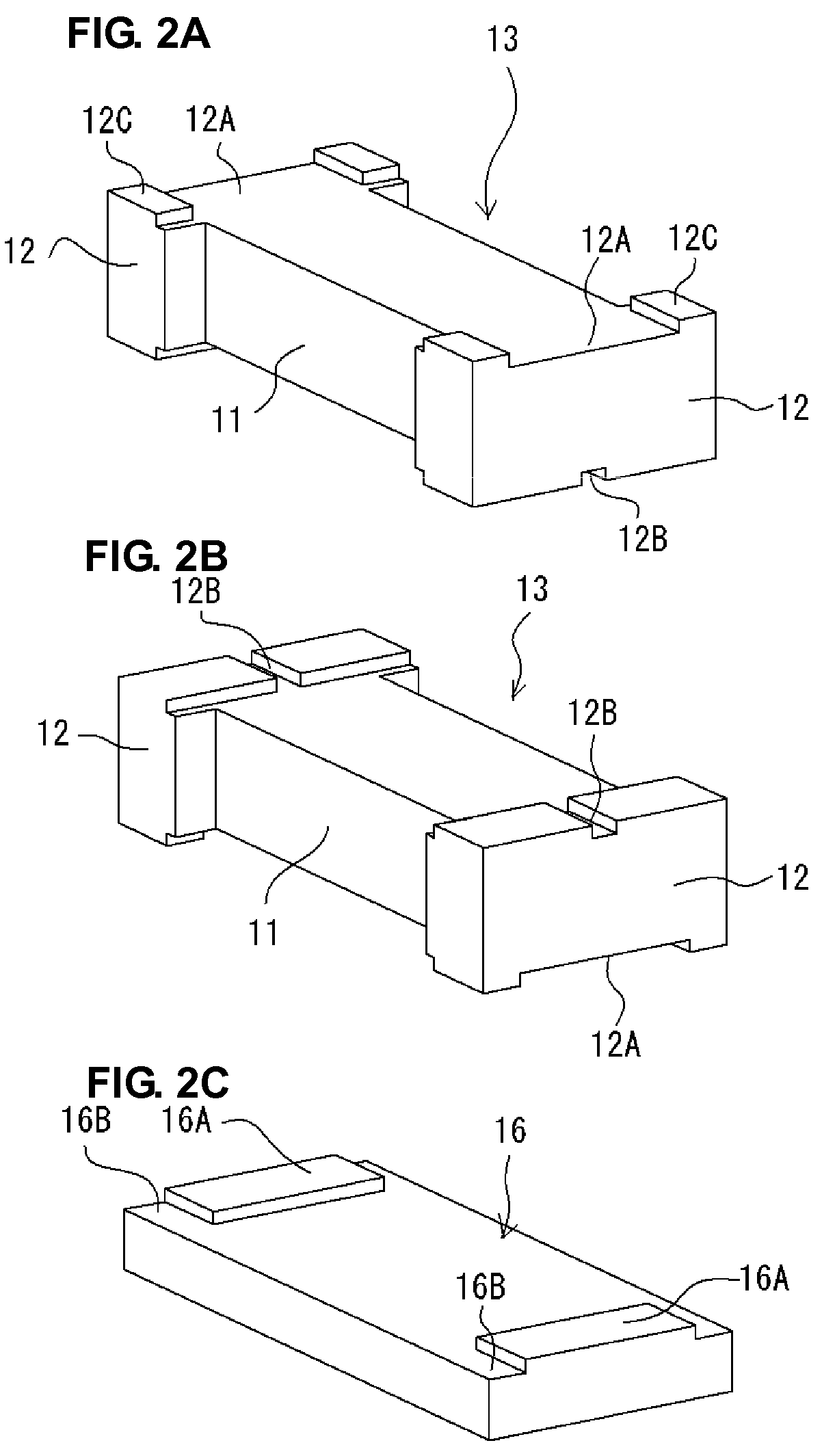

ActiveUS7633366B2Reduce Flux LeakageImprove efficiencyTransformers/inductances casingsCores/yokesAdhesiveConductor Coil

A wire-wound coil includes a ferrite core having a winding core portion and flange portions, a wire wound around the winding core portion, electrodes connected to the wire on lower surfaces of the flange portions, and a ferrite plate attached to upper surfaces of both of the end flange portions so as to extend over the winding core portion. The flange portions and the ferrite plate are provided with corresponding recessed and projecting portions and, and the flange portions and the ferrite plate are integrated through the recessed and projecting portions. Joint sections between the flange portions and the ferrite plate include contact sections that are in direct contact with each other, and adhesion sections arranged to receive an adhesive.

Owner:MURATA MFG CO LTD

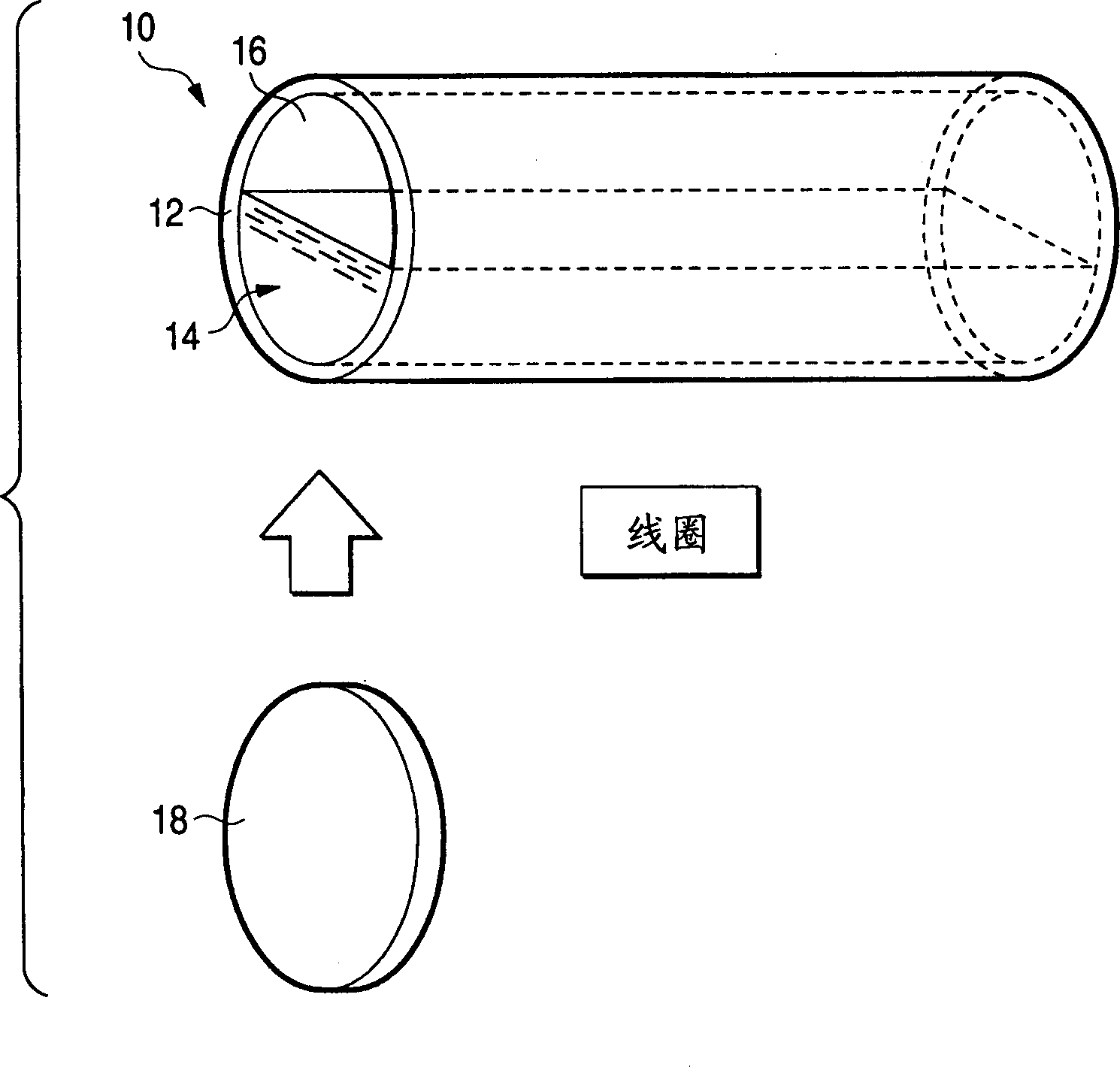

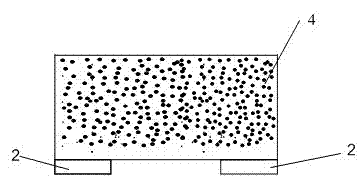

Magnetic core, magnetic field shielding part and electronic photographic equipment with them

InactiveCN1400509AEasy to manufactureEliminate generationInorganic material magnetismElectrographic process apparatusElectronMagnetic core

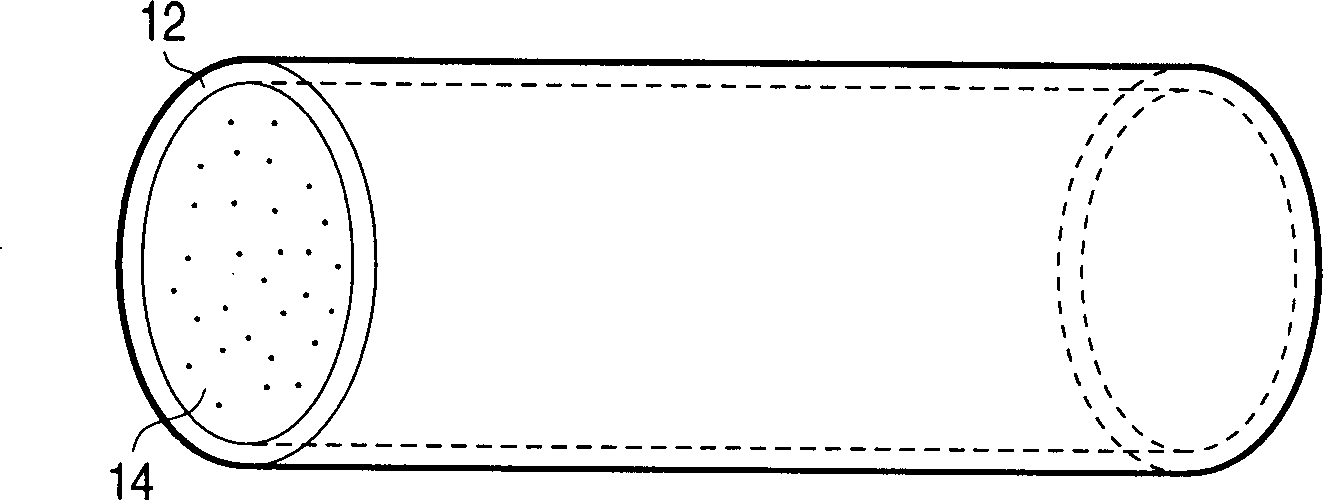

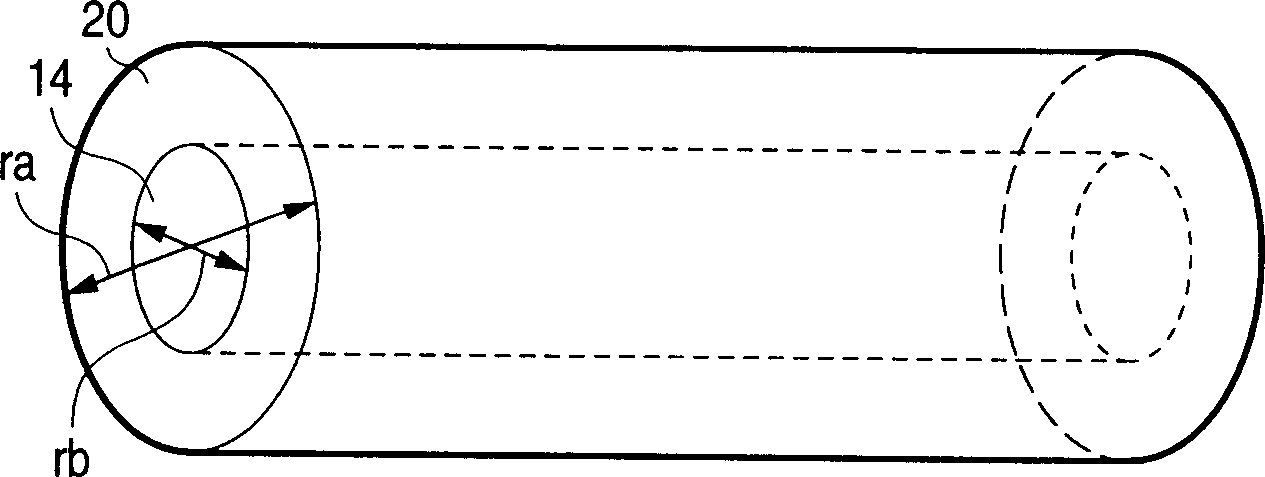

The present invention provides: (1) a magnetic coil in which magnetic particles 14 form an aggregate and the aggregate of the magnetic particles is disposed in a vessel 12 while the magnetic particles are keeping a particle state, (2) a magnetic field shield member for shielding magnetic field generated from a magnetic field generation member, the magnetic field shield member in which magnetic particles form an aggregate and the aggregate of the magnetic particles is disposed in a vessel 12 while the magnetic particles are keeping a particle state, and an electrophotographic apparatus using them.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Coil device

ActiveUS20190304659A1Well formedHigh Effective PermeabilityTransformers/inductances coils/windings/connectionsInorganic material magnetismInductorMechanical engineering

An inductor has a coil portion made of a wire wound in a coil shape and an element body in which the coil portion is provided. The element body has a first core member, a second core member, and a third core member. The first core member has a winding core portion configured to be positioned inside the coil portion. The second core member is accommodated in the winding core portion. The third core member covers the coil portion and the first core member in which the second core member is accommodated in the winding core portion.

Owner:TDK CORPARATION

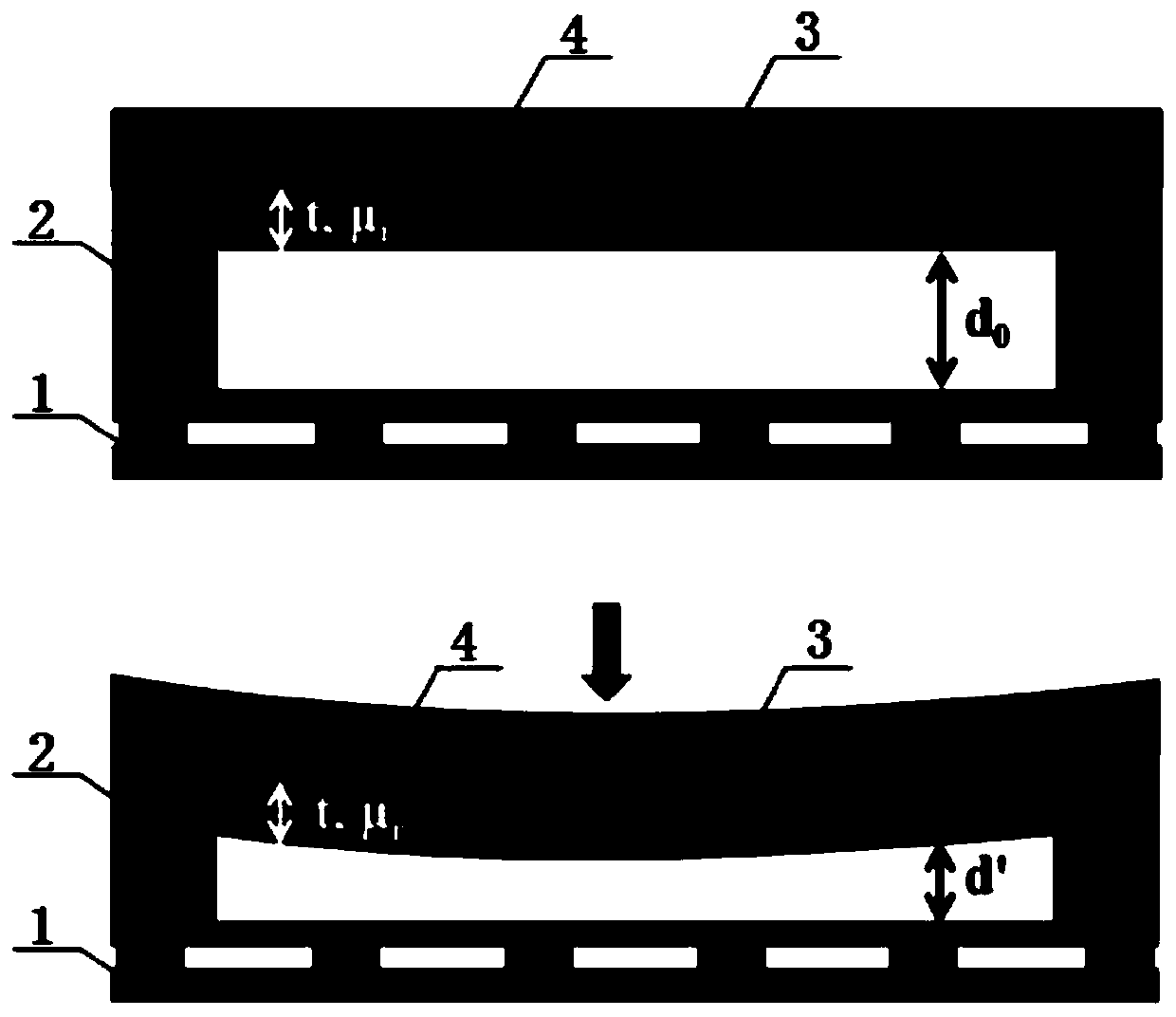

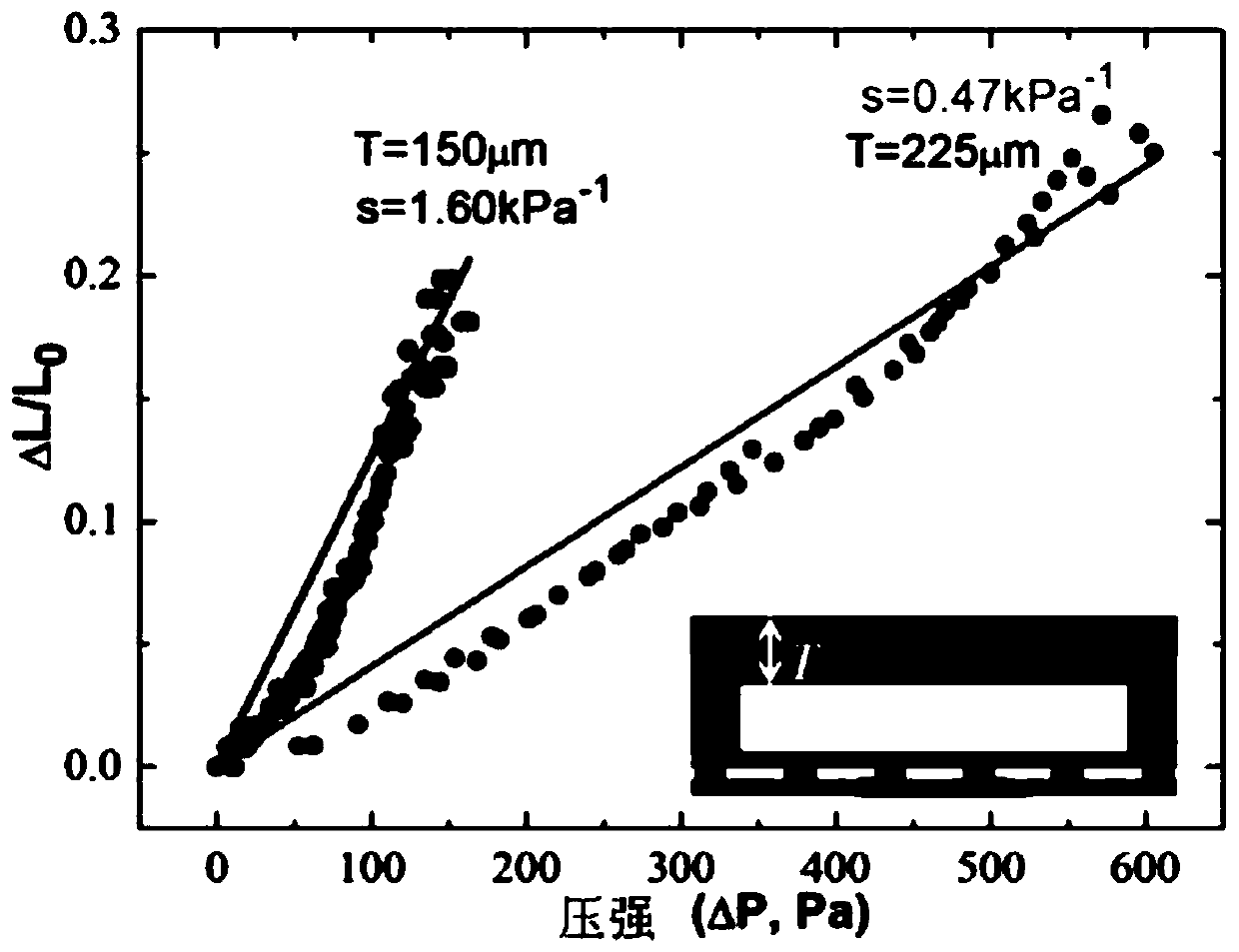

Inductance type pressure sensor, manufacturing method and application thereof

InactiveCN110243502AIncrease self-inductancePlay a shielding roleForce measurementEngineeringInductor

The invention discloses an inductance type pressure sensor, a manufacturing method and application thereof. The inductance type pressure sensor comprises a plane inductor, a ferrite film, an elastic support pillar and a flexible cover film, wherein the ferrite film is adhered into the flexible cover film, and is positioned between the plane inductor and the flexible cover film; and the elastic support pillar is supported between the plane inductor and the flexible cover film, so that an air gap exists between the ferrite film and the plane inductor. The inductance type pressure sensor has the characteristics of high sensitivity, short response time, high stability and high repeatability.

Owner:SUZHOU UNIV

Multicomponent iron-based amorphous soft magnetic alloy

InactiveCN108597715AEnhanced Amorphous Formation AbilityHigh saturation magnetic inductionMagnetic materialsIron basedHigh frequency

The invention relates to a multicomponent iron-based amorphous soft magnetic alloy. An expression of the alloy is FeaSibBcPdNieCf, wherein a, b, c, d, e and f are atomic percentage contents of corresponding components respectively and meet the conditions that a is 77-82, b is 3-14, c is 8-14, d is 0-0.3, e is 0-2.2, f is 0-2, and the sum of a, b, c, d, e and f is equal to 100. The multicomponent iron-based amorphous soft magnetic alloy has high saturation magnetic induction density Bs, high effective magnetic permeability [mu]e, high frequency stability, low coercivity Hc and low core loss andis good in moldability, loose in preparation technological conditions and low in production cost.

Owner:ZHENGZHOU UNIV

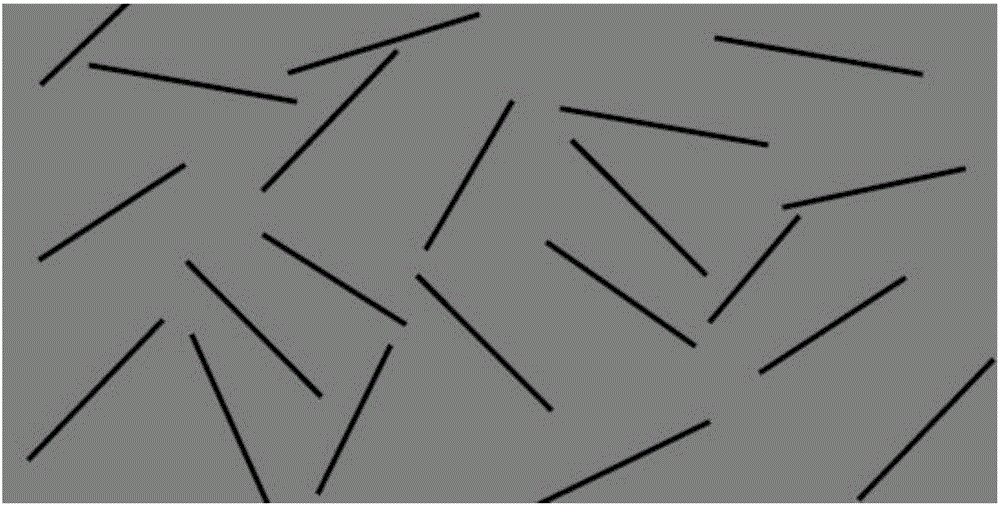

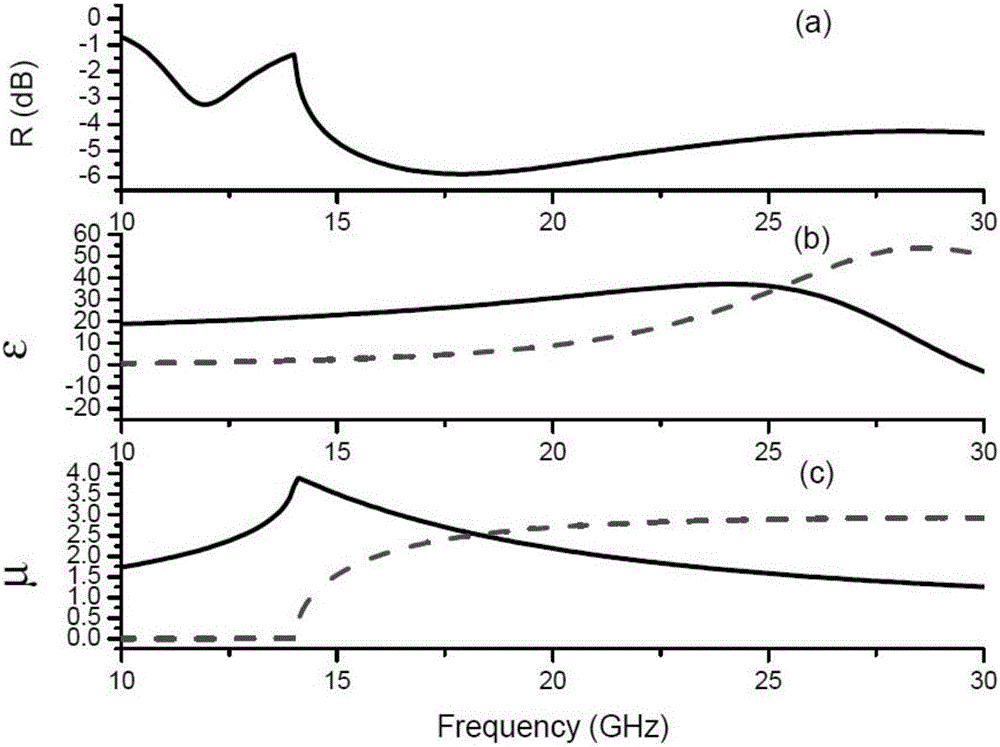

High-temperature-resistant microwave absorbing material based on linear copper particle composite

InactiveCN105860927AHigh Effective PermeabilityAppropriate effective dielectric constantOther chemical processesMicrowaveThin layer

The invention discloses a high-temperature-resistant microwave absorbing material based on a linear copper particle composite. The material is composed of a linear copper particle with a concentration lower than the percolation threshold and a porous material mainly composed of polytetrafluoroethylene. Among them, the wire-shaped copper particles have a diameter of about 80 microns and a length of about 4 mm; the porous material mainly composed of polytetrafluoroethylene has low dielectric constant (about 1.6) and high temperature resistance. The invention aims to apply a thin layer with a thickness of 1 mm on the surface of a metal block, realize a microwave energy reflectivity lower than -5dB in the frequency range of 15-20GHz, and have the characteristics of high temperature resistance.

Owner:NANJING UNIV OF POSTS & TELECOMM

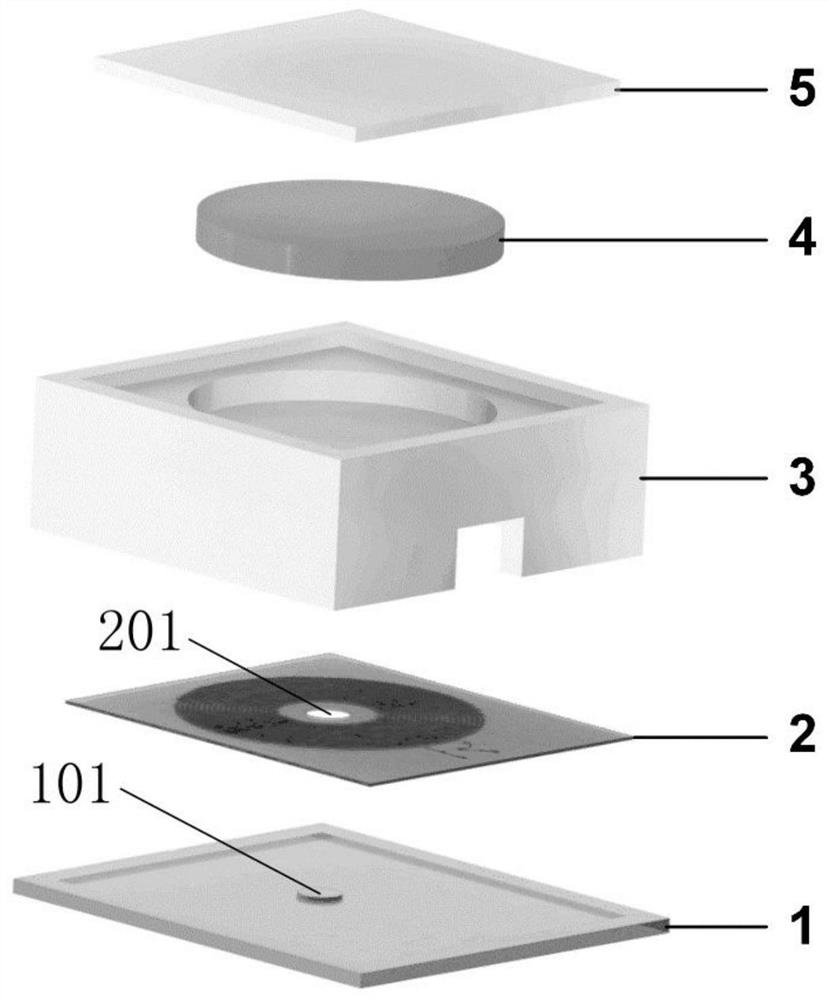

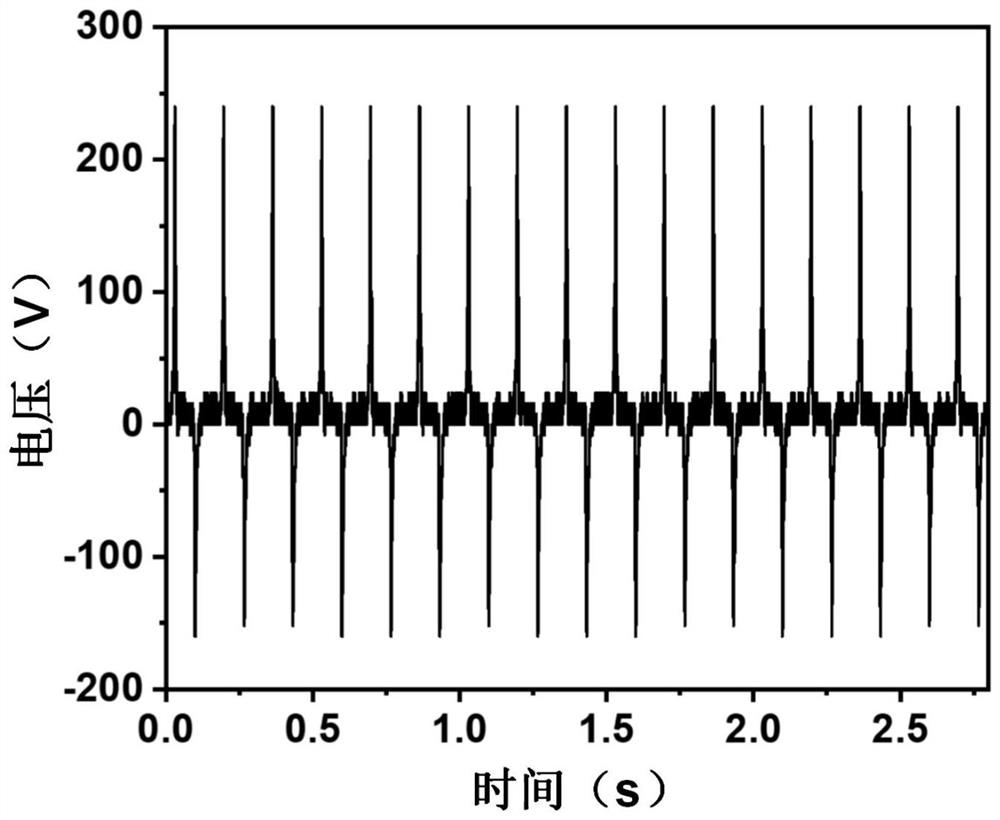

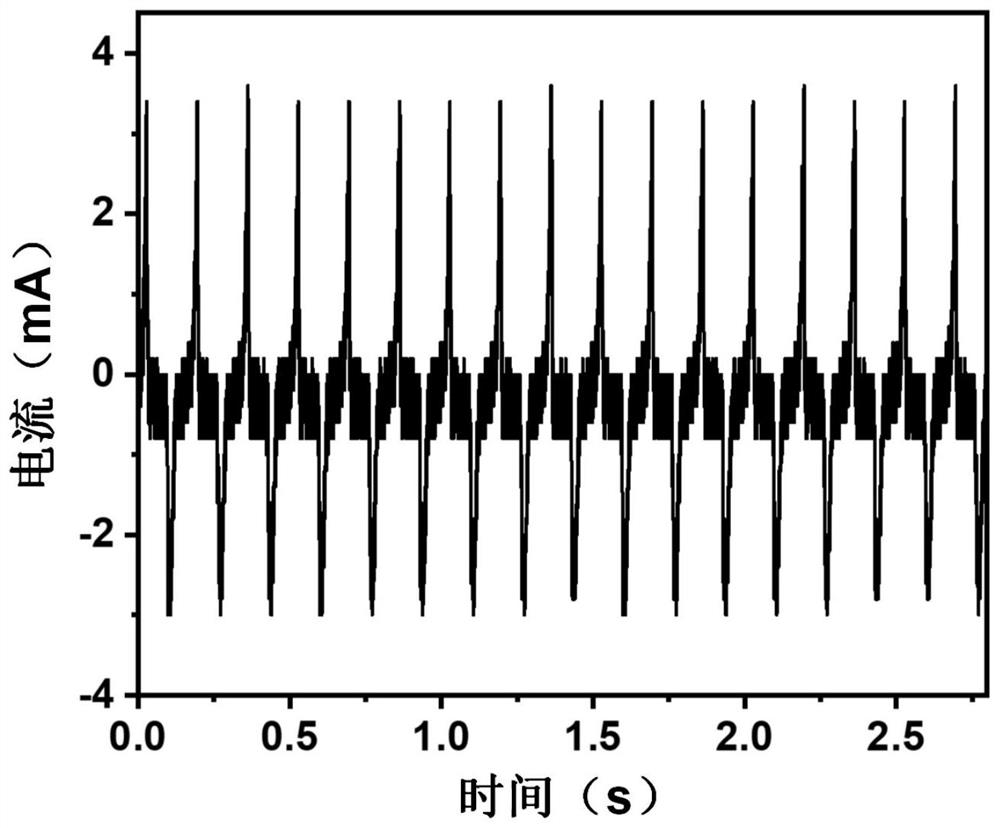

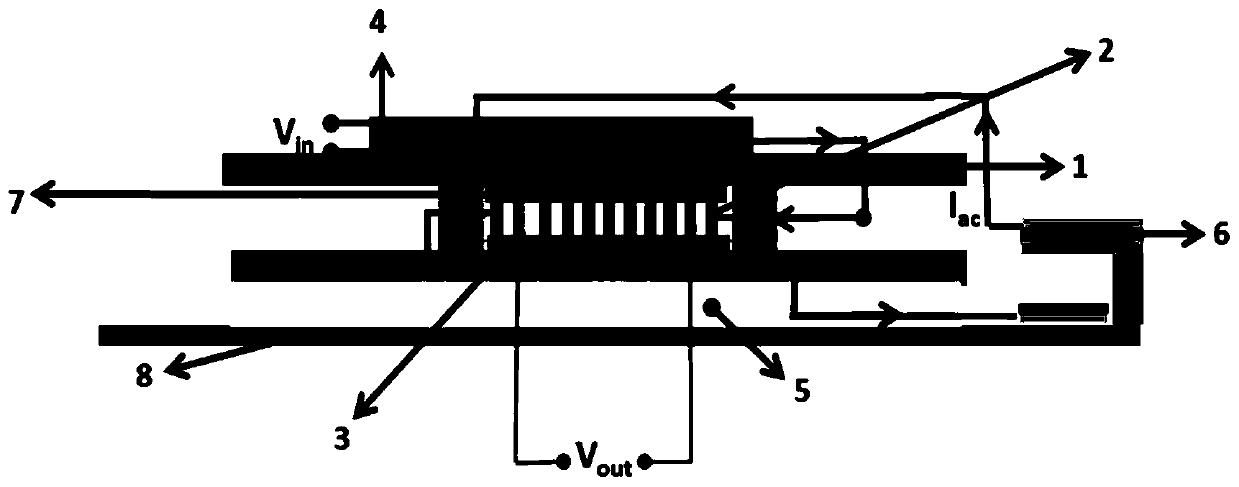

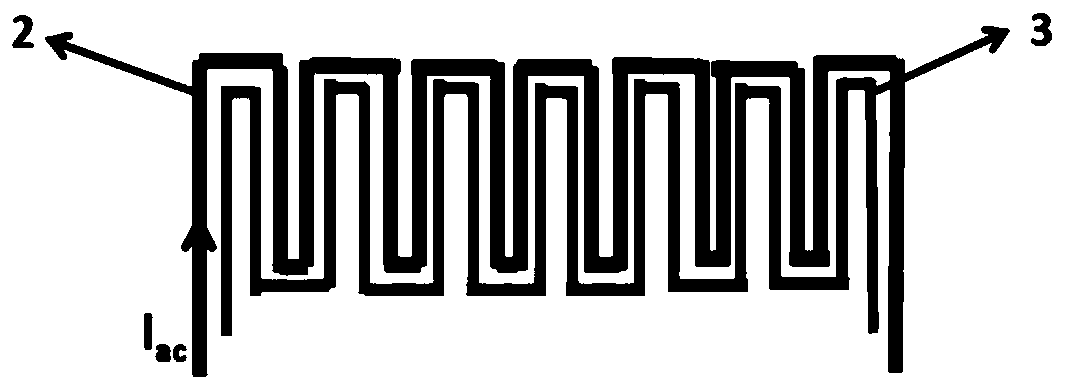

Superelastic micro-nano energy acquisition and sensing integrated microsystem, manufacturing method and use method

ActiveCN114301328ARealize the function of electromagnetic motion sensingGood electrical performance outputDynamo-electric machinesFriction generatorsElastic substrateFlexible circuits

The invention discloses a hyperelastic micro-nano energy acquisition and sensing integrated microsystem, a manufacturing method and a use method. The microsystem comprises an elastic substrate, a flexible circuit board coil, a deformation body, a conductive permanent magnet and a packaging layer, the elastic substrate is located at the bottom of the deformation body, the packaging layer is located at the top of the deformation body, a first space for placing a flexible circuit board coil is formed between the elastic substrate and the deformation body, and a second space for placing a conductive permanent magnet is formed between the packaging layer and the deformation body; the flexible circuit board coil and the conductive permanent magnet are externally connected with power supply equipment, and / or the flexible circuit board coil is externally connected with excitation alternating current. According to the super-elastic micro-system integrating micro-nano energy acquisition and sensing, the friction part and the electromagnetic part both have good electrical property output; and meanwhile, an active electromagnetic motion sensing function based on an electromagnetic induction law and / or a passive inductive pressure sensing function based on an eddy current effect (an expression form of an electromagnetic induction effect) are / is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Magnetoconductive polyamide hot melt adhesive and preparation method thereof

InactiveCN106893547AGood magnetic conductivityHigh Effective PermeabilityNon-macromolecular adhesive additivesPolymer scienceAntioxidant

The invention discloses a magnetoconductive polyamide hot melt adhesive and a preparation method thereof. The magnetoconductive polyamide hot melt adhesive is prepared from the following raw materials in percentage by mole: 35-45% of dimer fatty acid, 5-20% of dicarboxylic fatty acid, 40-55% of aliphatic diamine, 0.1-2% of an antioxidant, 0.01-0.1% of an acid catalyst and 1.5-15% of a nano magnetic ferrite. The magnetoconductive polyamide hot melt adhesive disclosed by the invention not only has a good magnetoconductive property, but also has good compatibility, and has the characteristics of being high in bonding strength, high in surface hardness, good in heat resistance, high in practicality and the like.

Owner:SHANDONG HIGHDEV NEW MATERIAL TECH CO LTD

Ferrites soft magnetic powder core and preparation method thereof

ActiveCN109599240AHigh resistivityLow priceInorganic material magnetismPower addedCompression molding

The invention discloses a magnetic powder core based on ferrites soft magnetic material. The magnetic powder core is formed by coating metal powder with strong power adding reducibility in an insulating manner, performing compression molding, and then performing thermal treatment; the ingredients of the magnetic powder core at least comprise the ferrite soft magnetic material, iron, metal with strong reducibility, and oxide of the metal with strong reducibility, and can comprise organic or inorganic insulating adhesive and organic or inorganic dispersion agent. The ferrites soft magnetic powder core prepared through the method provided by the invention can improve the effective magnetic conductivity and the quality factor of the magnetic powder core and improve the resistivity of the magnetic powder core, and can effectively reduce the eddy current loss under high frequency, and the magnetic powder core has good high-frequency characteristic and temperature stability.

Owner:陕西汇锋电子科技有限责任公司

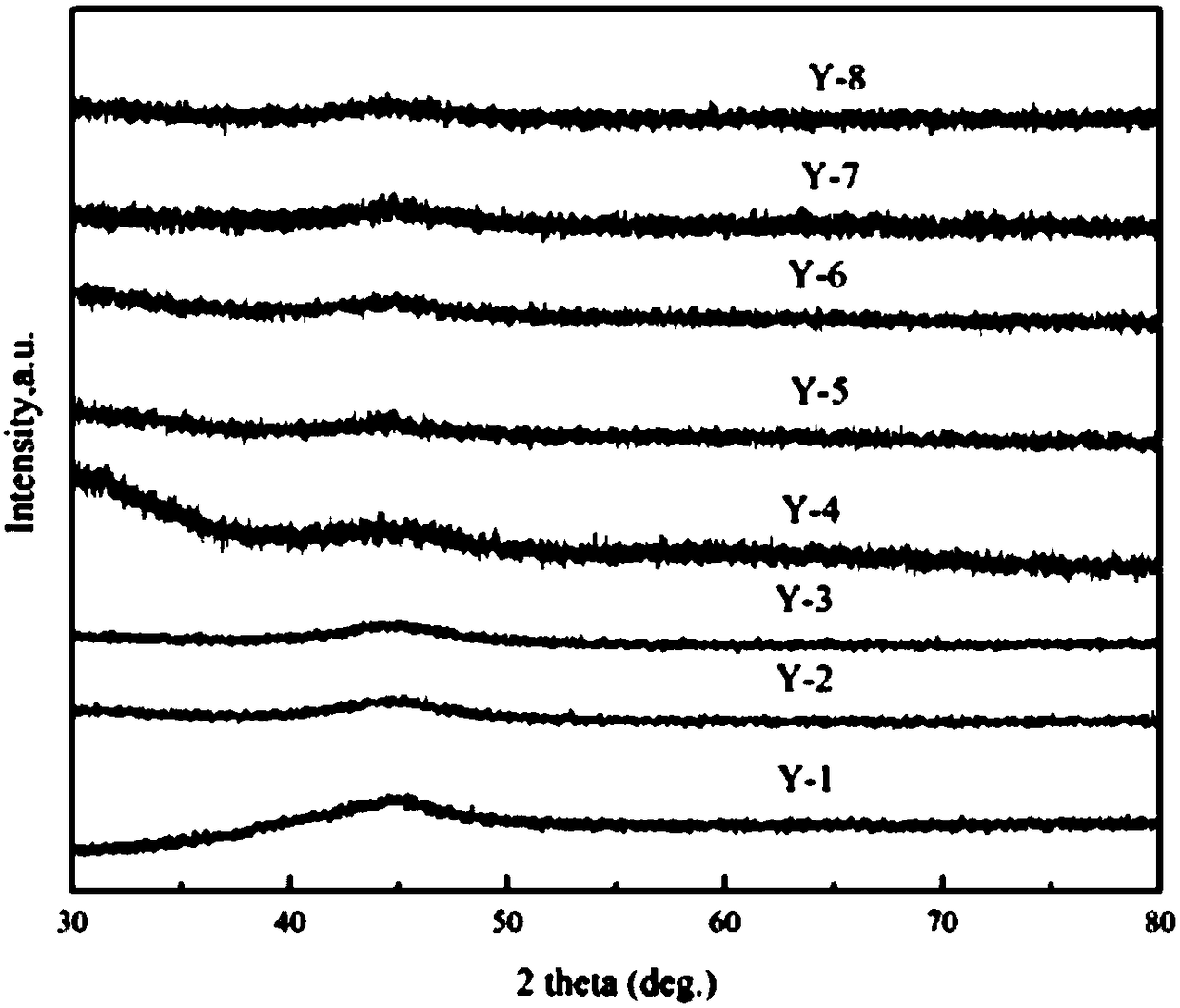

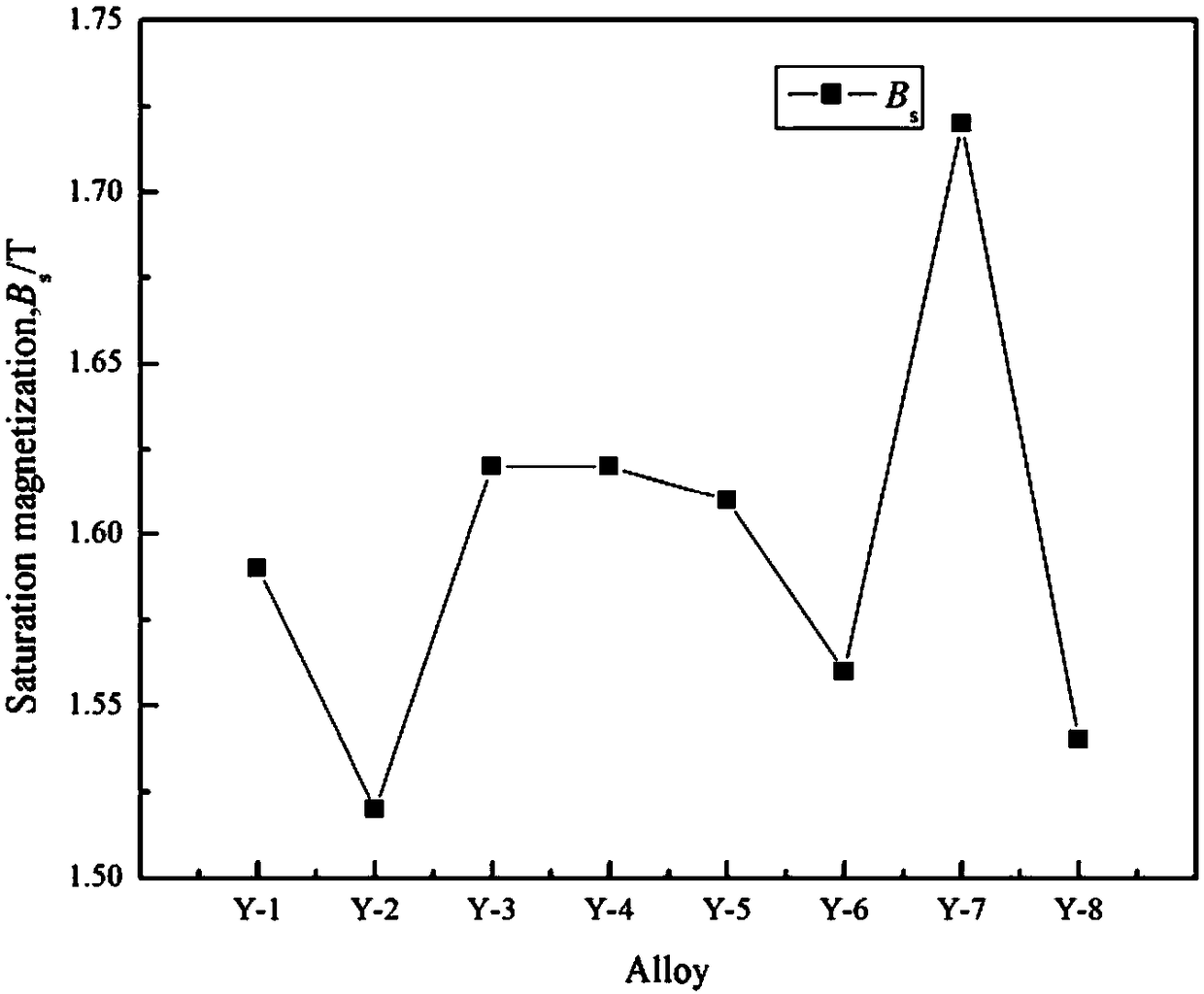

A kind of iron-based amorphous strip material and its preparation method and the preparation method of high-frequency high-permeability nanocrystalline alloy

The invention provides an iron-based amorphous strip. The iron-based amorphous strip comprises the following components of, by molar parts, 67-74.2 parts of Fe, 16-19.2 parts of Si, 6.5-8.5 parts of B, 2.0-3.0 parts of Nb, 0.2-1 part of V, 1.0-1.3 parts of Cu and 0.1-2.2 parts of Co. The iron-based amorphous strip contains the relatively high silicon, and therefore, alloy can conveniently obtain high magnetic conductivity; furthermore, the iron-based amorphous strip contains the relatively low boron, and the V and the Co in the defined components are combined, and therefore, the residual magnetic induction intensity Br of the alloy after double-stage crystallization annealing can be reduced, and then the effective magnetic conductivity of the alloy at a high frequency of 100 KHz is furtherimproved; and the iron-based amorphous strip does not need to be combined with a transverse magnetic field condition, a nanocrystalline structure can be obtained only by adopting double-stage crystallization annealing, and therefore, the obtained alloy has high frequency and the high magnetic conductivity.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

Wire wound inductor and manufacturing method thereof

ActiveCN102122563BSimple processLow costTransformers/inductances magnetic coresInductances/transformers/magnets manufactureInductorEngineering

Owner:贵阳顺络迅达电子有限公司

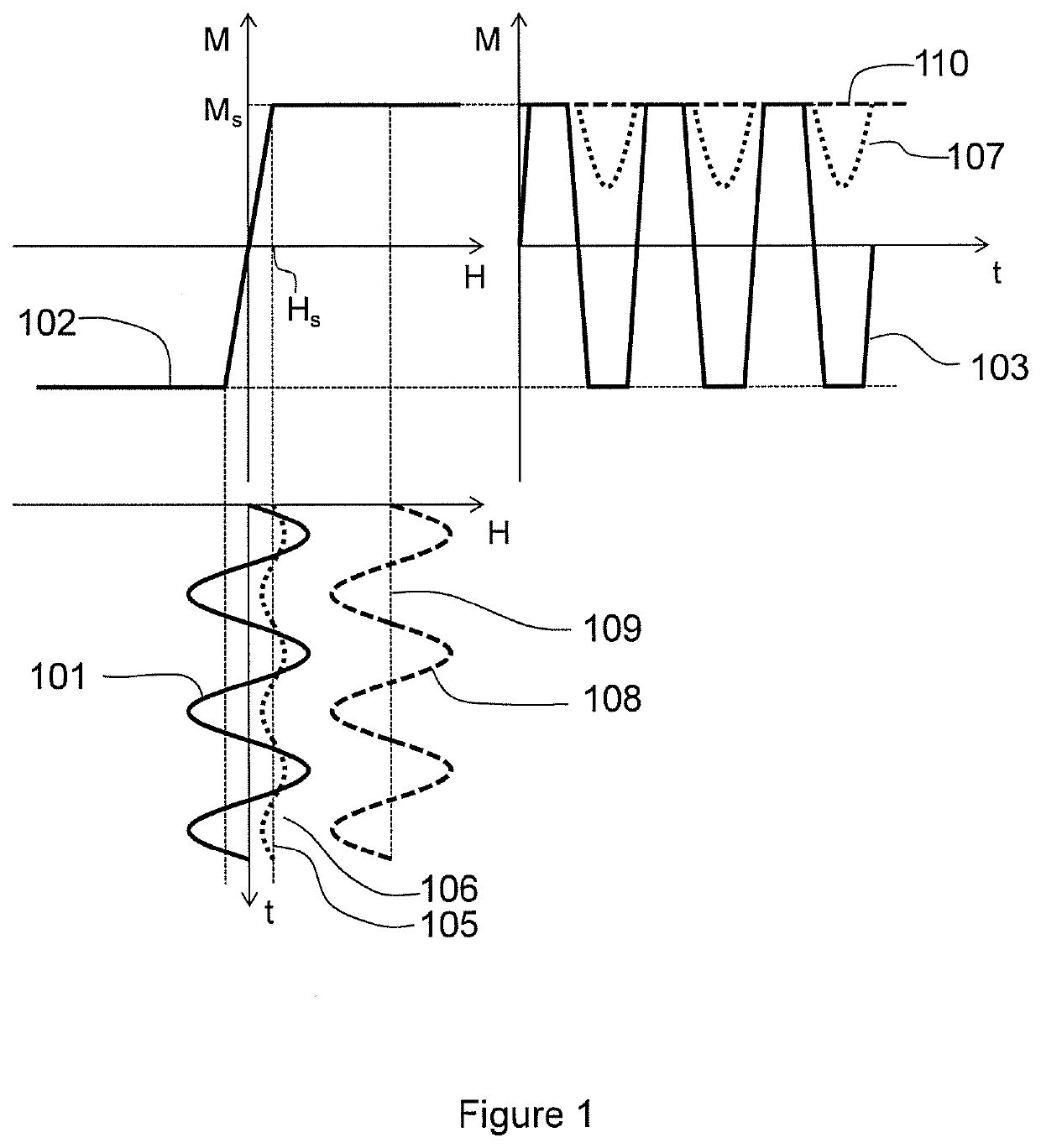

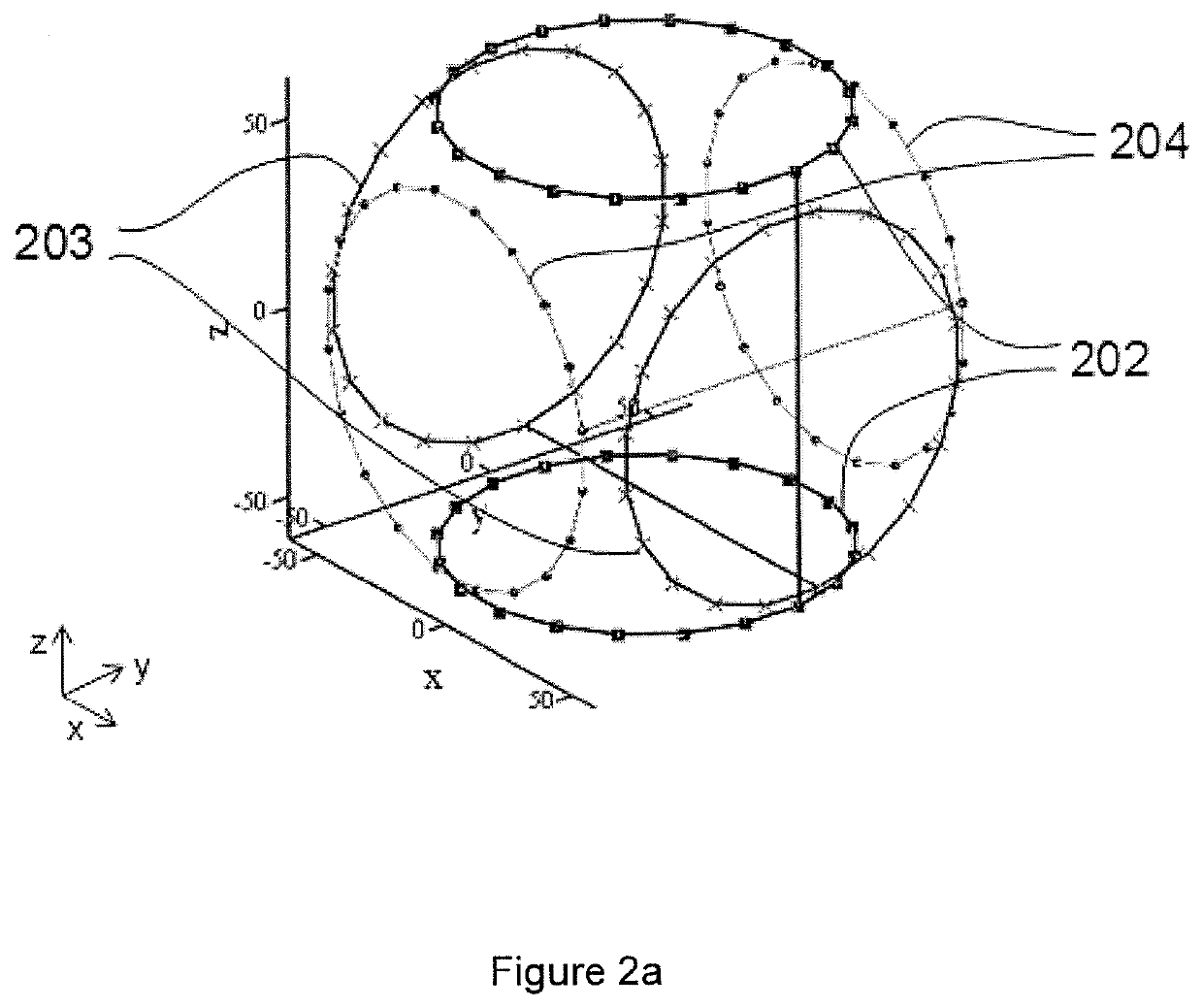

Sensing system and method

PendingUS20200060578A1Easy to measureLose weightEndoscopesDiagnostic recording/measuringEngineeringHarmonics

A sensing system for determining the location and orientation of an object which comprises a magnetic tag. The sensing system comprises selection coils and interrogation coils. The selection coils are arranged to generate a spatially-varying DC magnetic field from which the location of the tag can be determined in use. At least some of the interrogation coils are arranged to generate one or more AC magnetic fields and at least some of the interrogation coils are arranged to receive harmonics, intermodulation products or time dependent variations of the AC magnetic fields, from which the orientation of the tag is determined in use.

Owner:TTP PLC

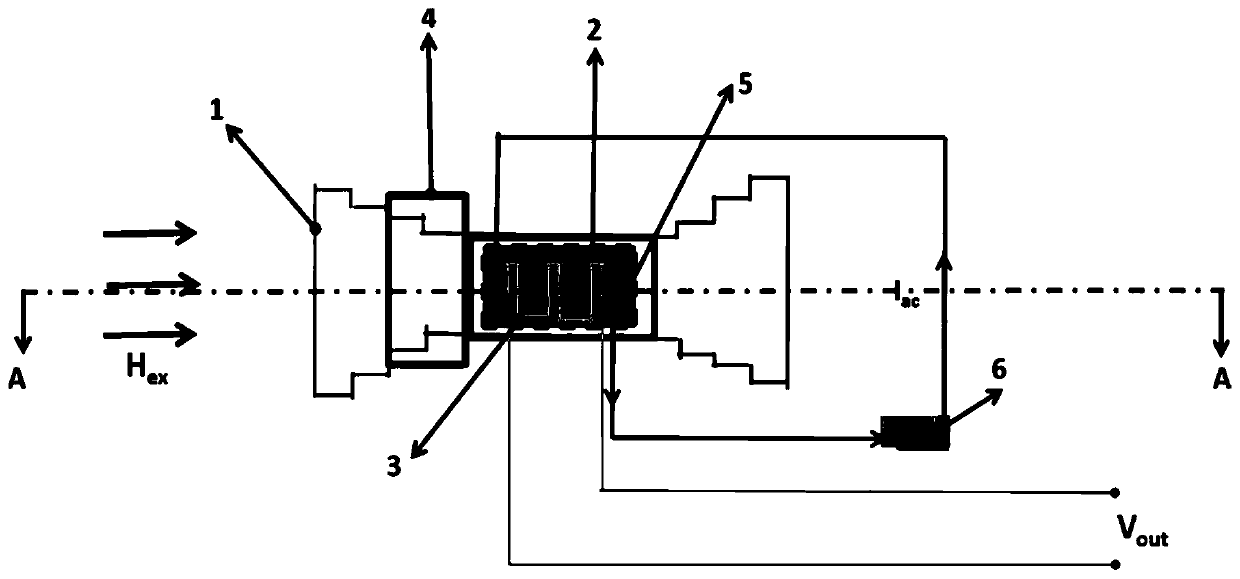

Low Frequency Inductive Magnetic Sensor Based on Nonvolatile Tuning

ActiveCN111337865BHigh Effective PermeabilityHigh magnetic field sensitivityMagnetic measurementsCapacitanceEngineering

Owner:SHANGHAI JIAO TONG UNIV

A multicomponent iron-based amorphous soft magnetic alloy

InactiveCN108597715BImprove performanceConducive to the formation of amorphousMagnetic materialsVolumetric Mass DensityProcess conditions

Owner:ZHENGZHOU UNIV

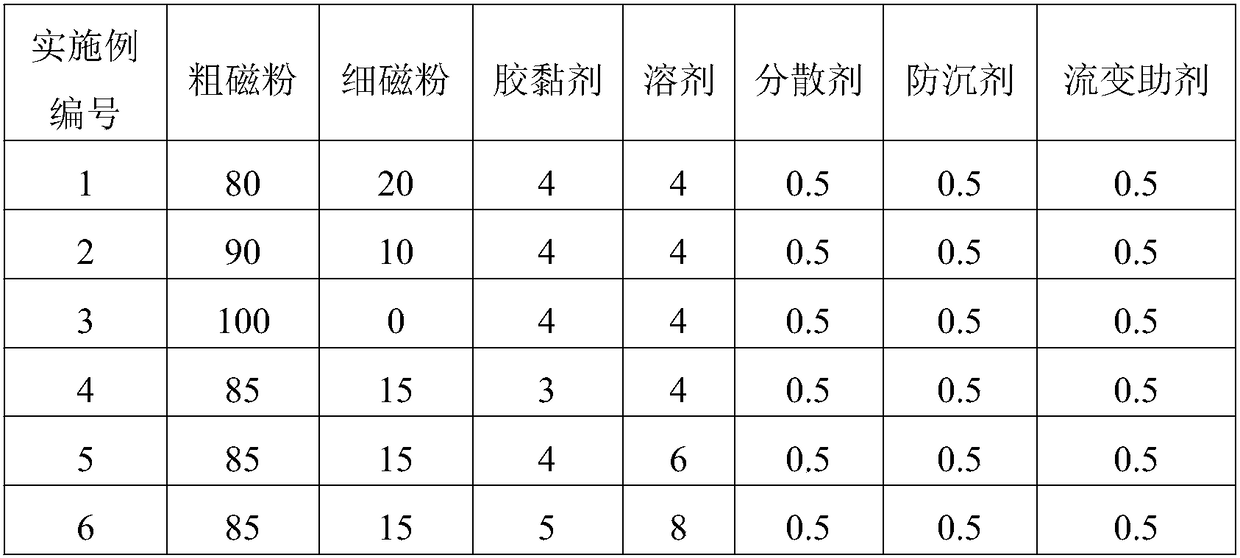

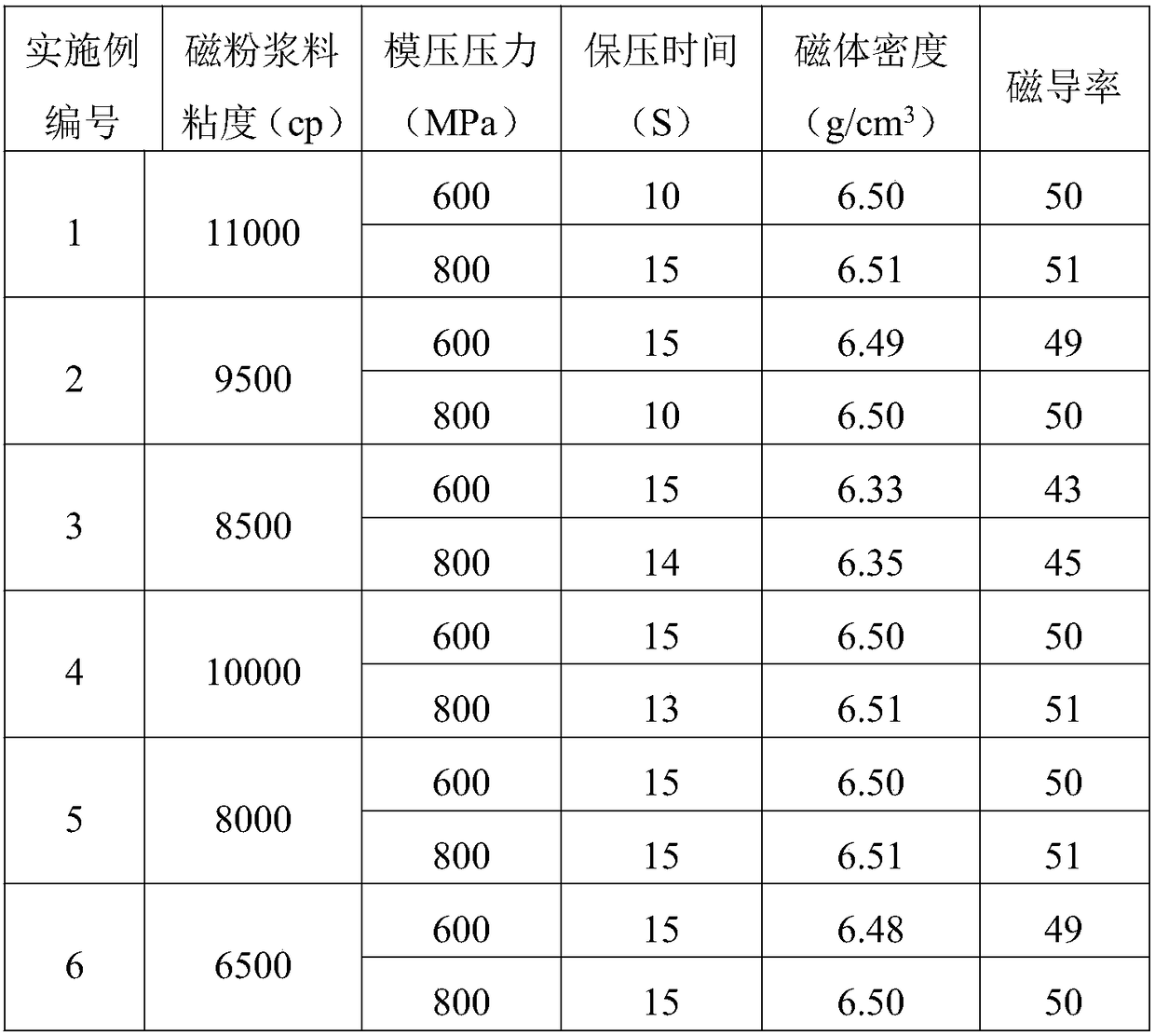

A method of manufacturing a molded inductor

ActiveCN106024359BHigh Effective PermeabilityAvoid short circuit problemsCoils manufactureInductance with magnetic coreAdhesiveInductor

The invention discloses a method for making a mold-pressed inductor. The method includes the following steps of S1, magnetic-powder slurry making, wherein magnetic powder, adhesives and solvents are mixed in the preset proportion, and magnetic-powder slurry is formed; S2, pressing, wherein the magnetic-powder slurry obtained in the step S1 is injected into a mold, the magnetic-powder slurry, a coil and a magnetic core are jointly pressed to allow at least a part of the solvents and at least a part of the adhesives in the magnetic-powder slurry to overflow out of the mold, the coil and the magnetic core are preplaced into the mold, and a mold-pressed blank in a preset shape is formed; S3, heating solidifying, wherein the mold-pressed blank obtained in the S2 is heated and solidified, and a molded blank is obtained; S4, terminal electrode making, wherein the molded blank obtained in the step S3 is subjected to appearance shaping so that an electrode can be led and exposed out of the molded blank, a terminal electrode is prepared, and the mold-pressed inductor is obtained.

Owner:SHENZHEN SUNLORD ELECTRONICS

A kind of ferrite soft magnetic powder core and preparation method thereof

Owner:陕西汇锋电子科技有限责任公司

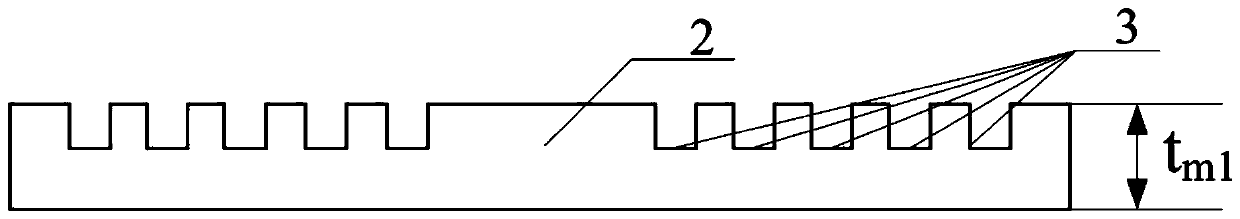

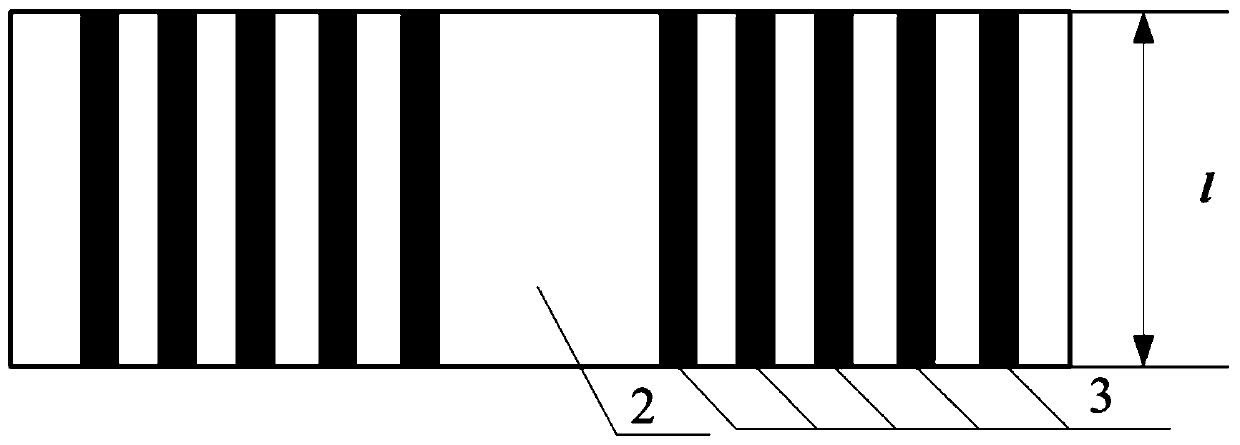

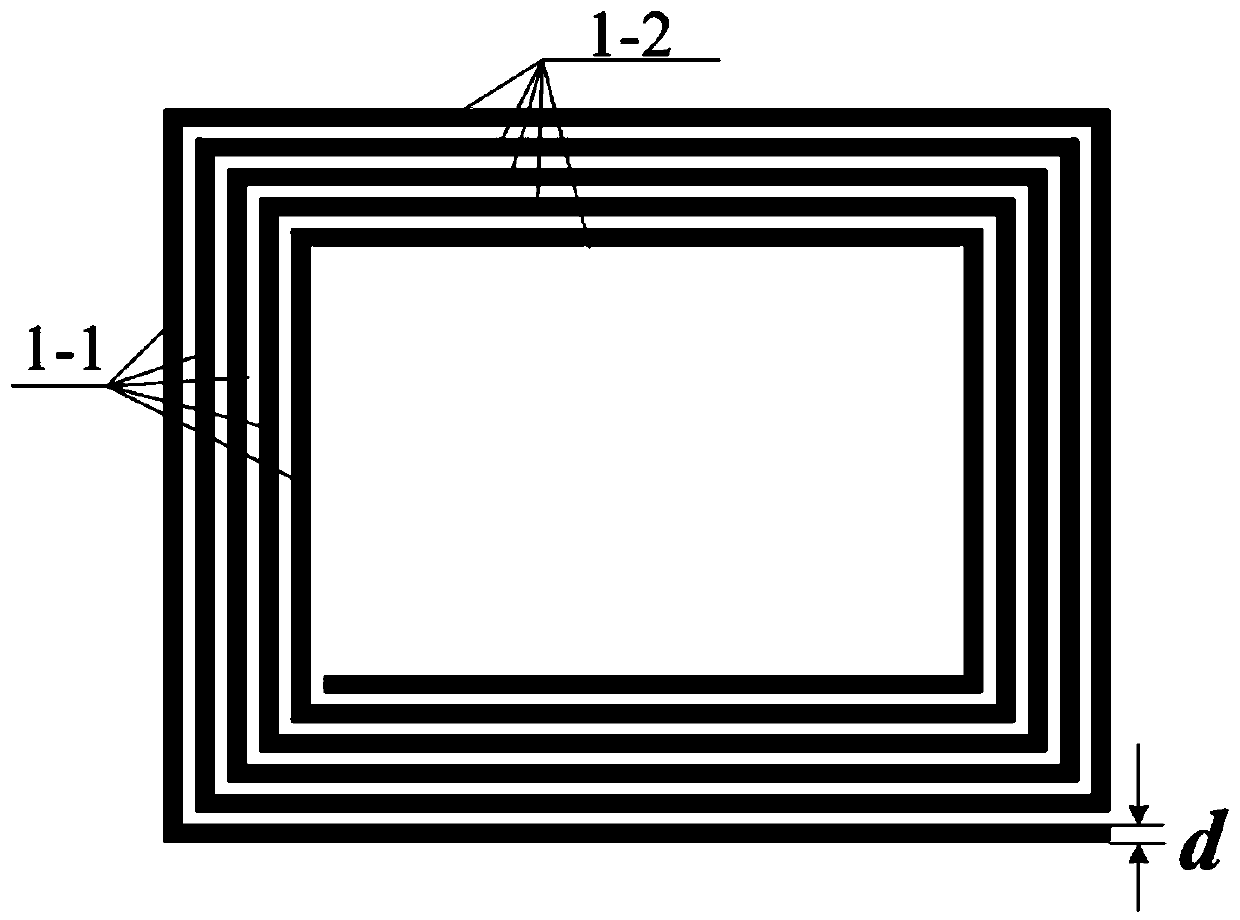

Thin-film magnetic sensor with groove structures

InactiveCN111443314AImproved Sensing RelationshipHigh sensitivityMagnetic measurementsElectrical conductorThin membrane

A thin-film magnetic sensor with groove structures is characterized by comprising two rectangular magnetic films and a rectangular spiral coil arranged between the two rectangular magnetic films, wherein the rectangular spiral coil adopts an overall planar spiral structure, and is spirally wound out from a certain position of the rectangular interior in the clockwise or anticlockwise direction; aplurality of rectangular grooves are formed on the inner surface of each rectangular magnetic film and are perpendicular to the sensing direction of the rectangular magnetic film (namely the directionof a magnetic field to be tested, which is usually the length direction of the thin film), and the number of the rectangular grooves is the same as the number of the turns of the rectangular spiral coil; and the rectangular grooves of one rectangular magnetic film are opposite to the rectangular grooves of the other rectangular magnetic film, so that conductors in the rectangular spiral coil, which are perpendicular to the sensing direction, are embedded in the rectangular magnetic films. The thin-film magnetic sensor with the groove structures provided by the invention has the advantage thatthe thin-film magnetic sensor is more sensitive to an external magnetic field.

Owner:SHANGHAI JIAO TONG UNIV

High-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and preparation method thereof

The invention provides a high-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and a preparation method thereof. The material reduces the cobalt content under the condition of guaranteeing better soft magnetic properties. The preparation method is simple in process, low in production cost and suitable for industrial production. The material comprises the following components in percentage by weight: 18-22% of Fe, 30-35% of Ni, 4-7% of Gd, 0.01-0.05% of Ho, 0.1-0.5% of V, 0.01-0.05% of Ru, 6-9% of Al, 1-3% of P1, and the balance of Co.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

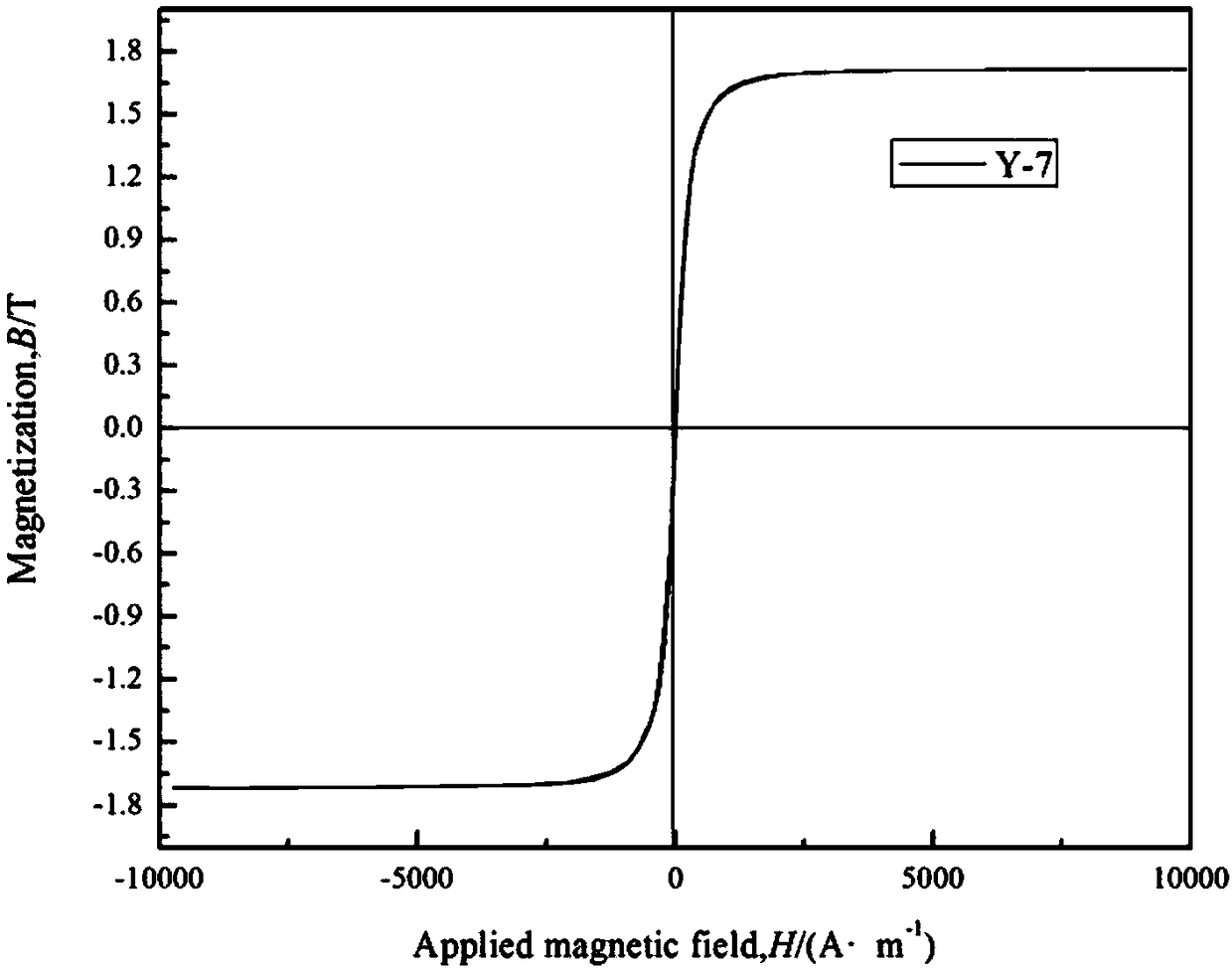

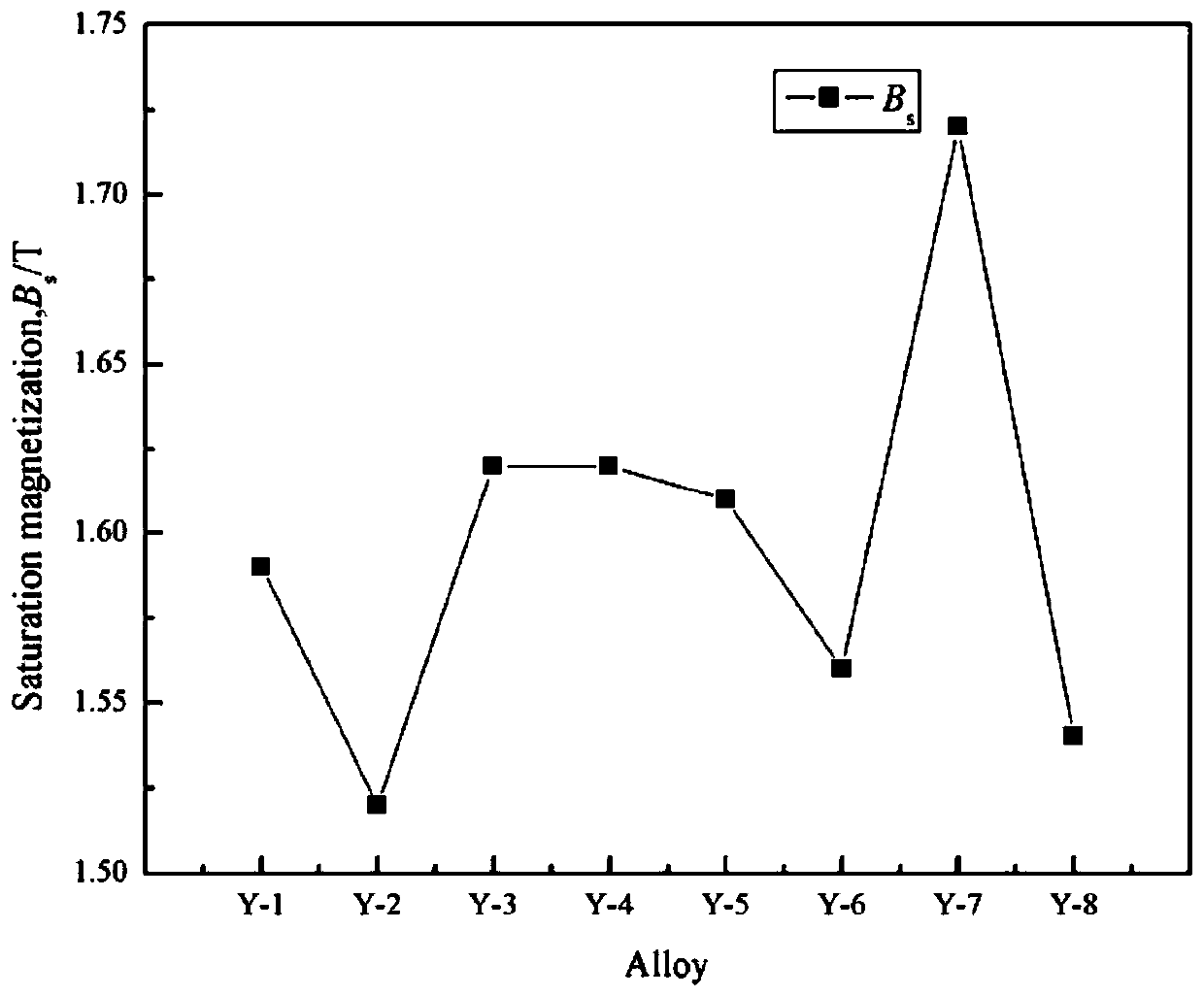

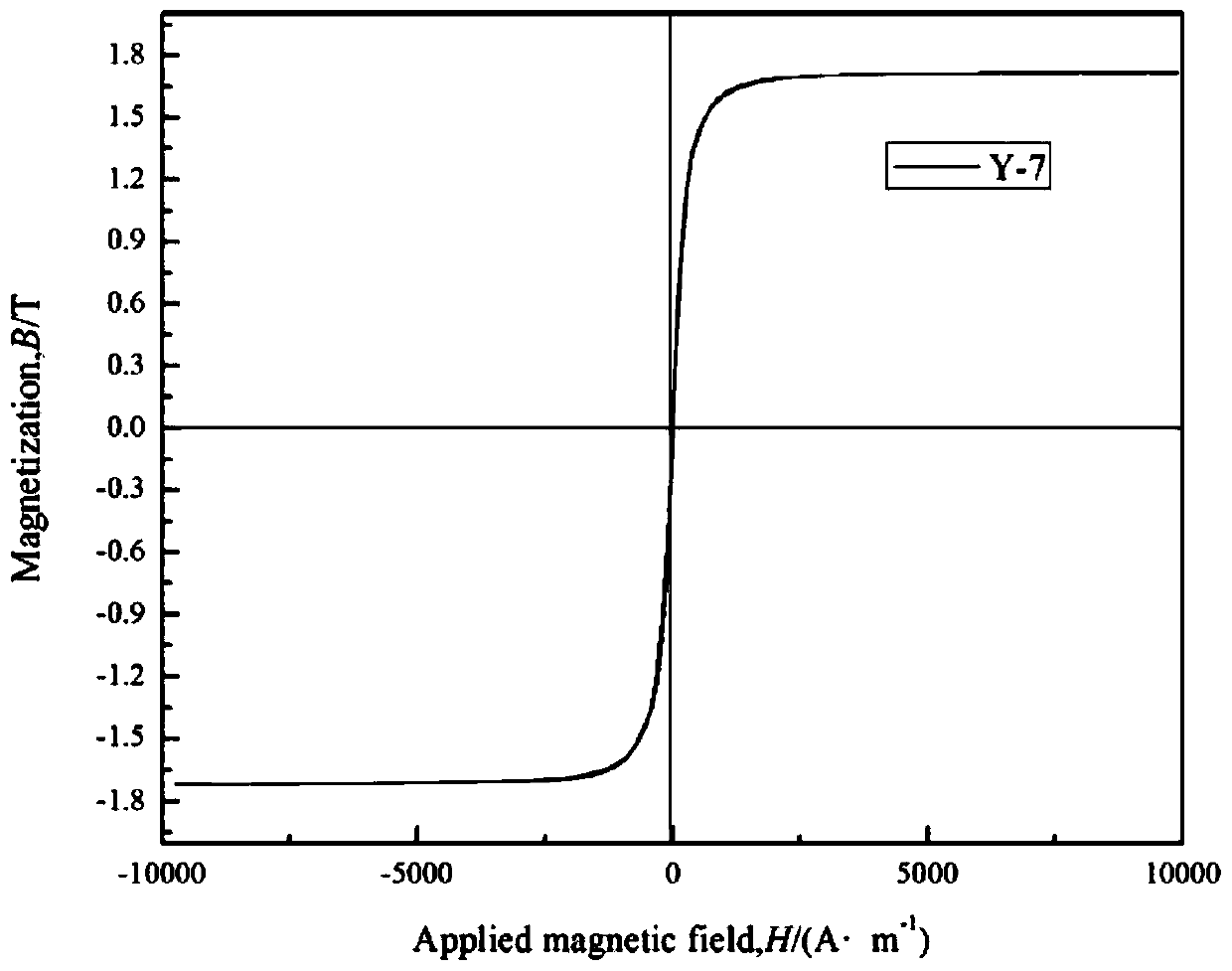

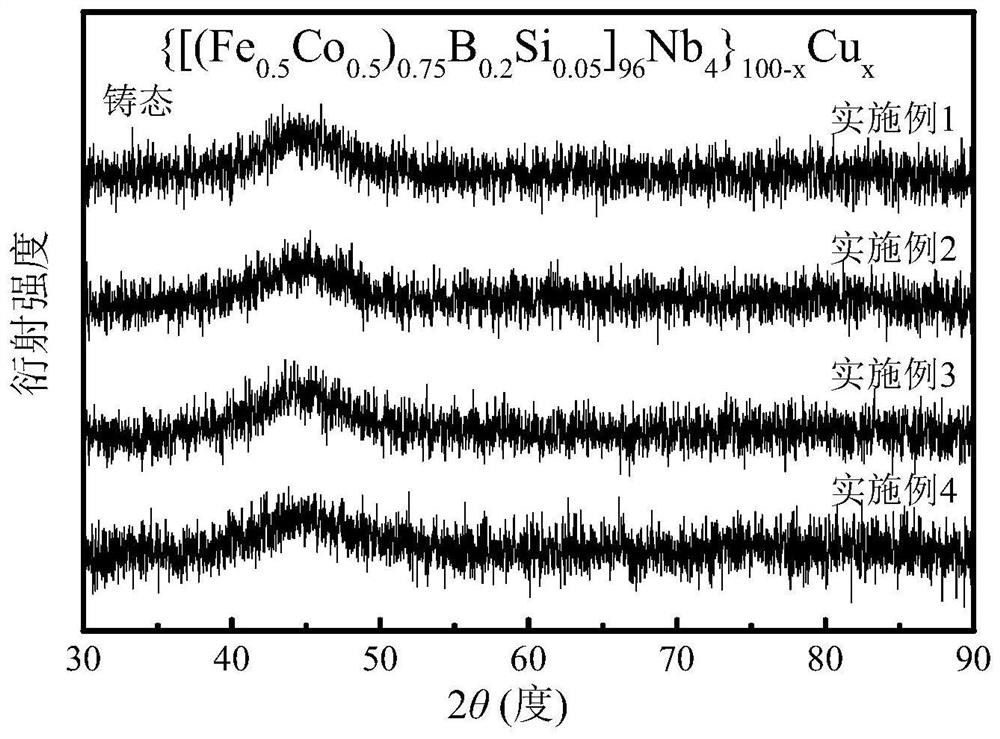

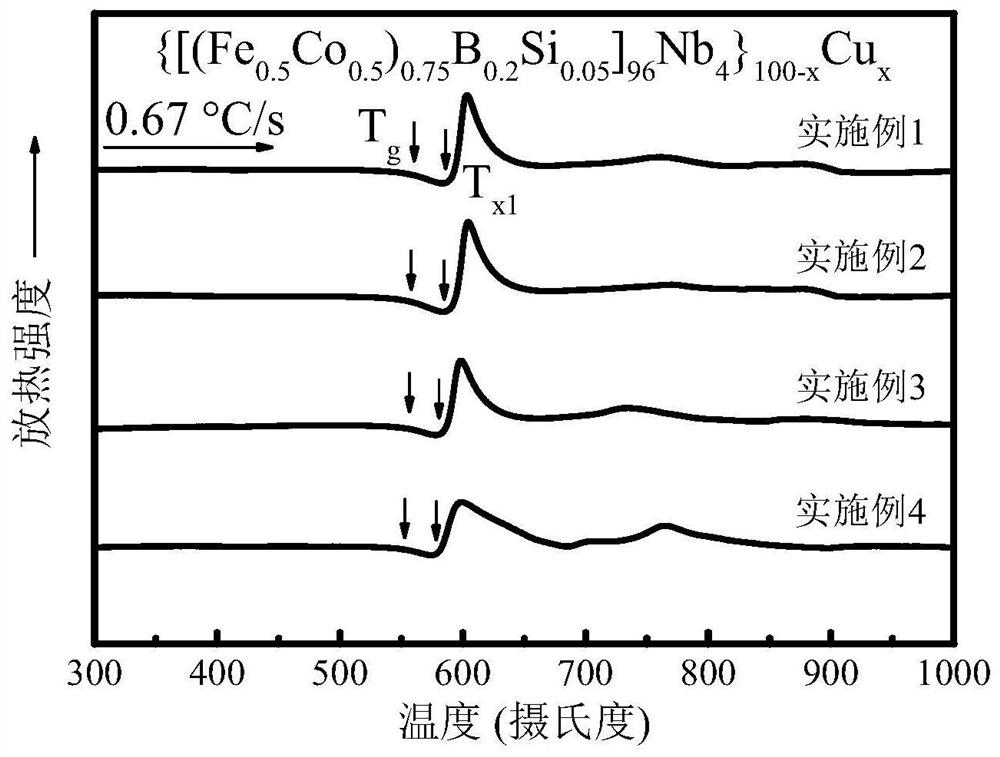

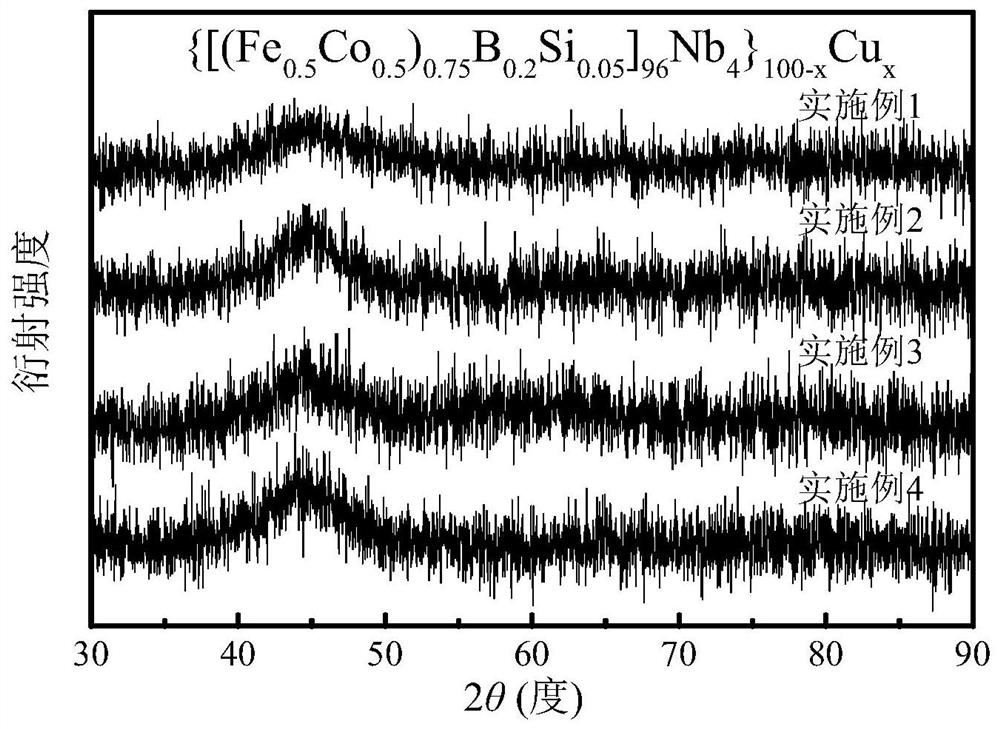

A kind of iron-cobalt based amorphous soft magnetic alloy and preparation method thereof

ActiveCN112941425BGood soft magneticExcellent effective permeabilityMagnetic materialsChemical compositionCobalt

The invention discloses an iron-cobalt-based amorphous soft magnetic alloy and a preparation method thereof. The chemical composition of the iron-cobalt-based amorphous soft magnetic alloy is Fe a co b B c Si d Nb e Cu f , a, b, c, d, e, f respectively represent the atomic percentage of the corresponding component; among them, 35≤a≤58, 14≤b≤36, 19≤c≤20, 4≤d≤5, 3 ≤e≤4, 0.1≤f≤0.4, a+b+c+d+e+f=100. The preparation method comprises: weighing the raw material according to the content of the atomic percentage to make an amorphous alloy strip; performing step-by-step heat treatment on the amorphous alloy under vacuum conditions or in an inert atmosphere to obtain an iron-cobalt-based amorphous soft magnetic alloy, wherein , the step-by-step heat treatment method is as follows: first heat the amorphous alloy strip from room temperature to 460-520°C and keep it for 20min, then water quench to room temperature; then heat the amorphous alloy strip from room temperature to 340-360°C and keep it for 40min, A longitudinal magnetic field was applied simultaneously, followed by water quenching to room temperature. Through step-by-step heat treatment, the magnetic properties of the obtained iron-cobalt-based amorphous soft magnetic alloy are greatly improved, and the optimization of magnetic properties is realized.

Owner:SOUTHEAST UNIV

Low-frequency induction type magnetic sensor based on non-volatile detuning

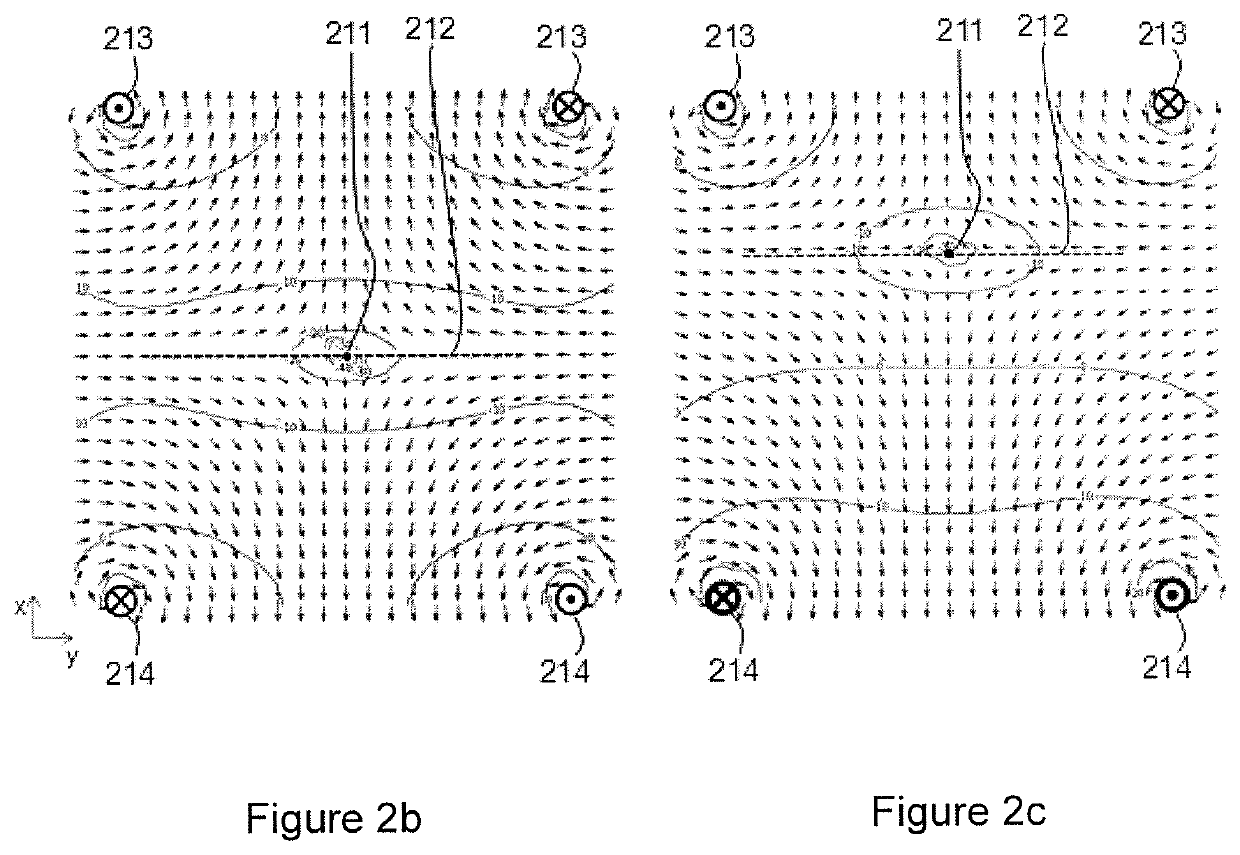

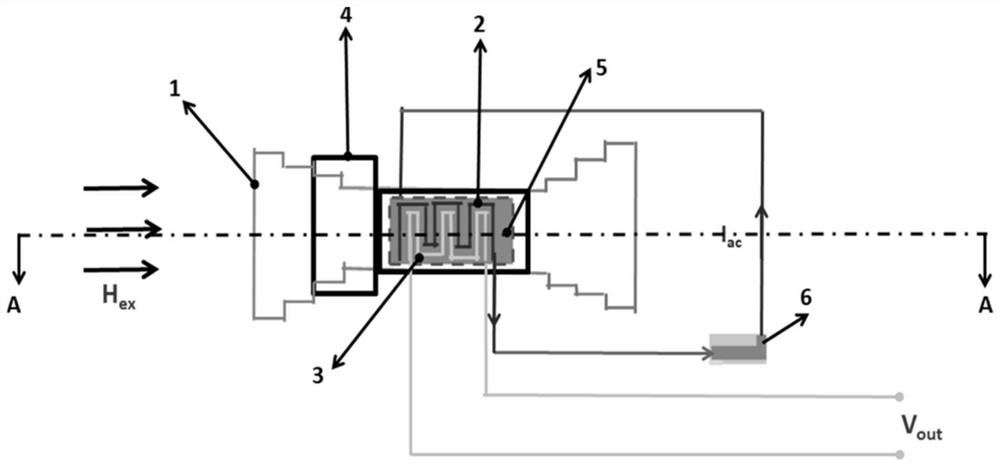

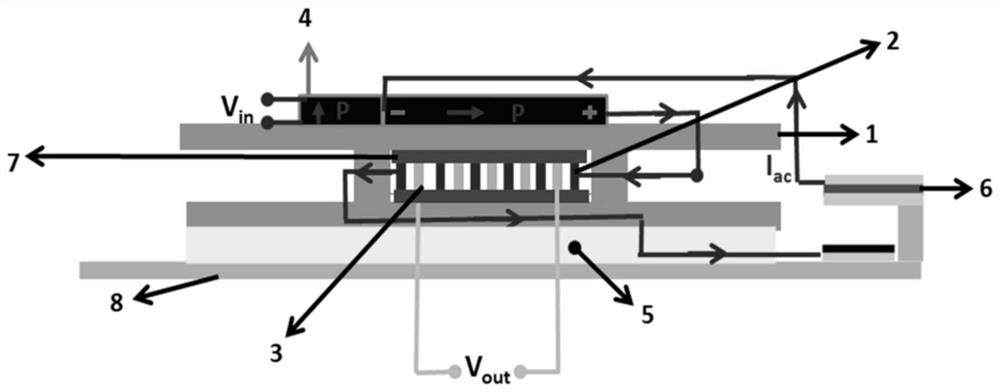

ActiveCN111337865AHigh effective permeabilityAvoid magnetizationMagnetic measurementsCapacitanceEngineering

The invention discloses a low-frequency induction type magnetic sensor based on non-volatile detuning. The sensor comprises a sensing unit structure and an adjustable capacitor driven by a piezoelectric beam, and the sensing unit structure comprises a giant magnetostrictive layer, a multi-layer stepped soft magnetic film, an insulating layer, an integrated planar excitation coil, a planar induction coil, an insulating layer, a multi-layer stepped soft magnetic film and a piezoelectric transformer layer which are sequentially arranged on a substrate from bottom to top; the effective magnetic conductivity of the soft magnetic thin film is improved. Meanwhile, the excitation current frequency is reduced, the AC driving capacity of the soft magnetic thin film is enhanced through boosting voltage and synchronous electrostriction stress obtained through the piezoelectric transformer layer, and the power consumption of a device is reduced. Meanwhile, magnetic domain movement is accelerated through magnetic force generated by the giant magnetostrictive material, so that the bottleneck of the maximum magnetic conductivity of the material is broken through, and the sensitivity is further improved. Finally, a new thought and a new method are provided for realizing a passive wireless ultrahigh-resolution and low-power-consumption magnetic sensing system in combination with an electromechanical resonance mechanism of non-volatile detuning.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com