Low-frequency induction type magnetic sensor based on non-volatile detuning

A magnetic sensor and inductive technology, applied in the direction of instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of magnetic loss of soft magnetic materials, limit the wide application, increase the cost of current source, etc., to improve the effective magnetic permeability, realize Non-volatile tuning, enhanced effect of convergence capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereto.

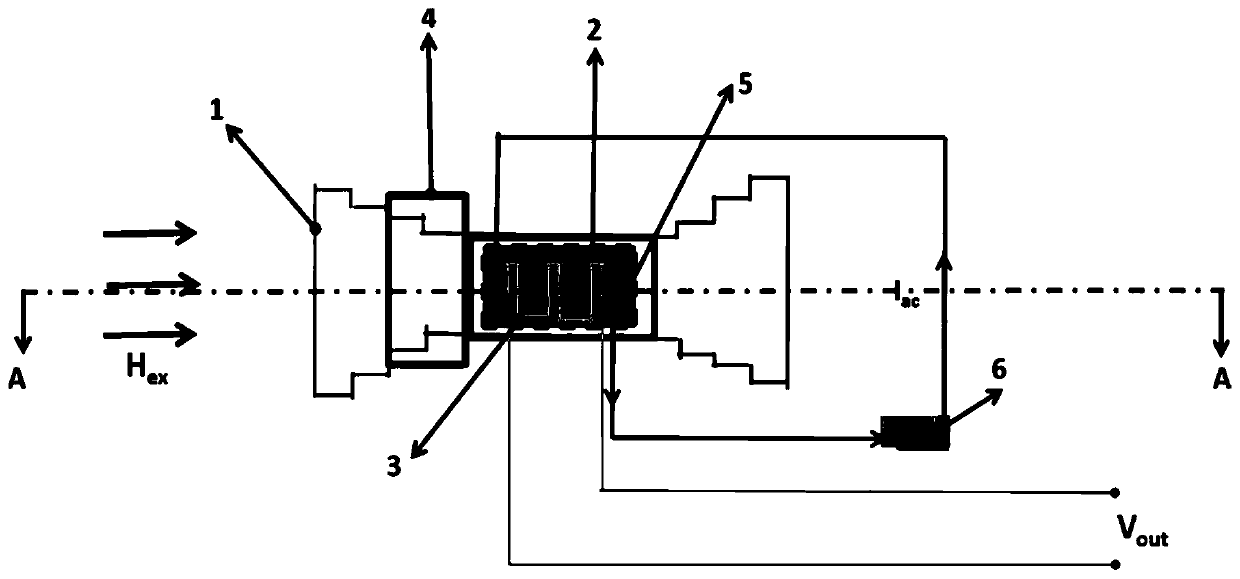

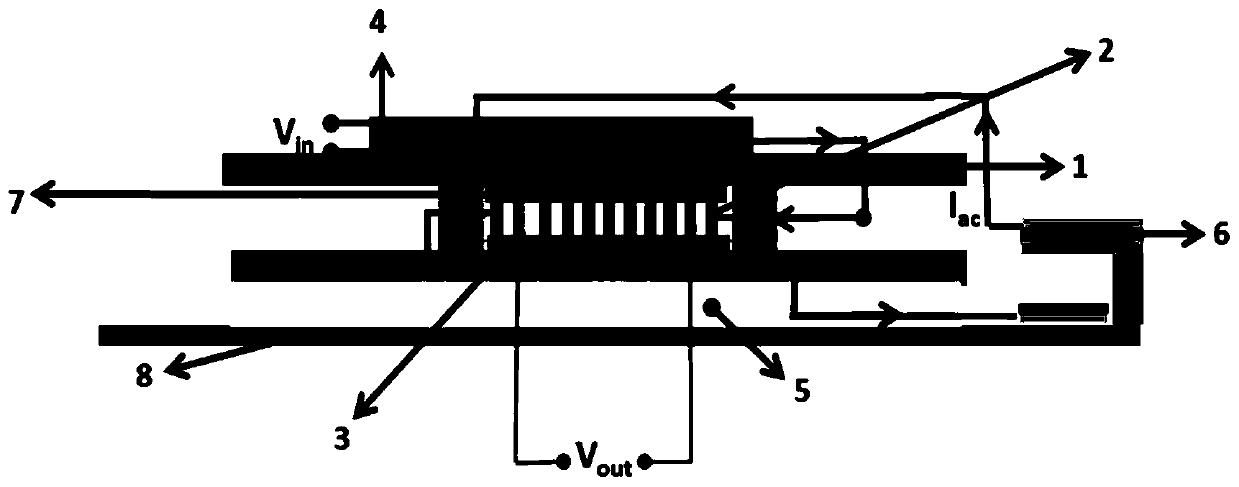

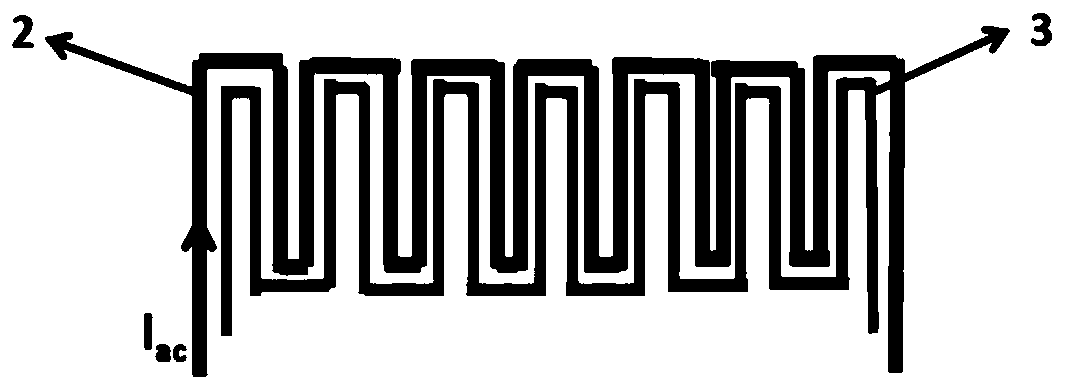

[0021] according to figure 1 and figure 2 , as can be seen from the figure, the present invention is based on a non-volatile tuned low-frequency inductive magnetic sensor, including a sensing unit structure and an adjustable capacitance 6 driven by a piezoelectric beam, and the sensing unit structure is on the substrate 8 From bottom to top, giant magnetostrictive layer 5, multi-layer stepped soft magnetic film 1, insulating layer 7, integrated planar excitation coil 2 and planar induction coil 3, insulating layer 7, multi-layer stepped soft magnetic film 1 , piezoelectric transformer layer 4; the integrated planar excitation coil 2 and planar induction coil 3, insulating layer 7, and multi-layer stepped soft magnetic film 1 form a sandwich structure, and the adjustable capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com