Inductance type pressure sensor, manufacturing method and application thereof

A technology of a pressure sensor and a manufacturing method, applied in the sensor field, can solve the problems of complex data acquisition system, limited application range, difficult wearable devices, etc., and achieve the effects of improving sensitivity, increasing magnetic permeability, and improving self-inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

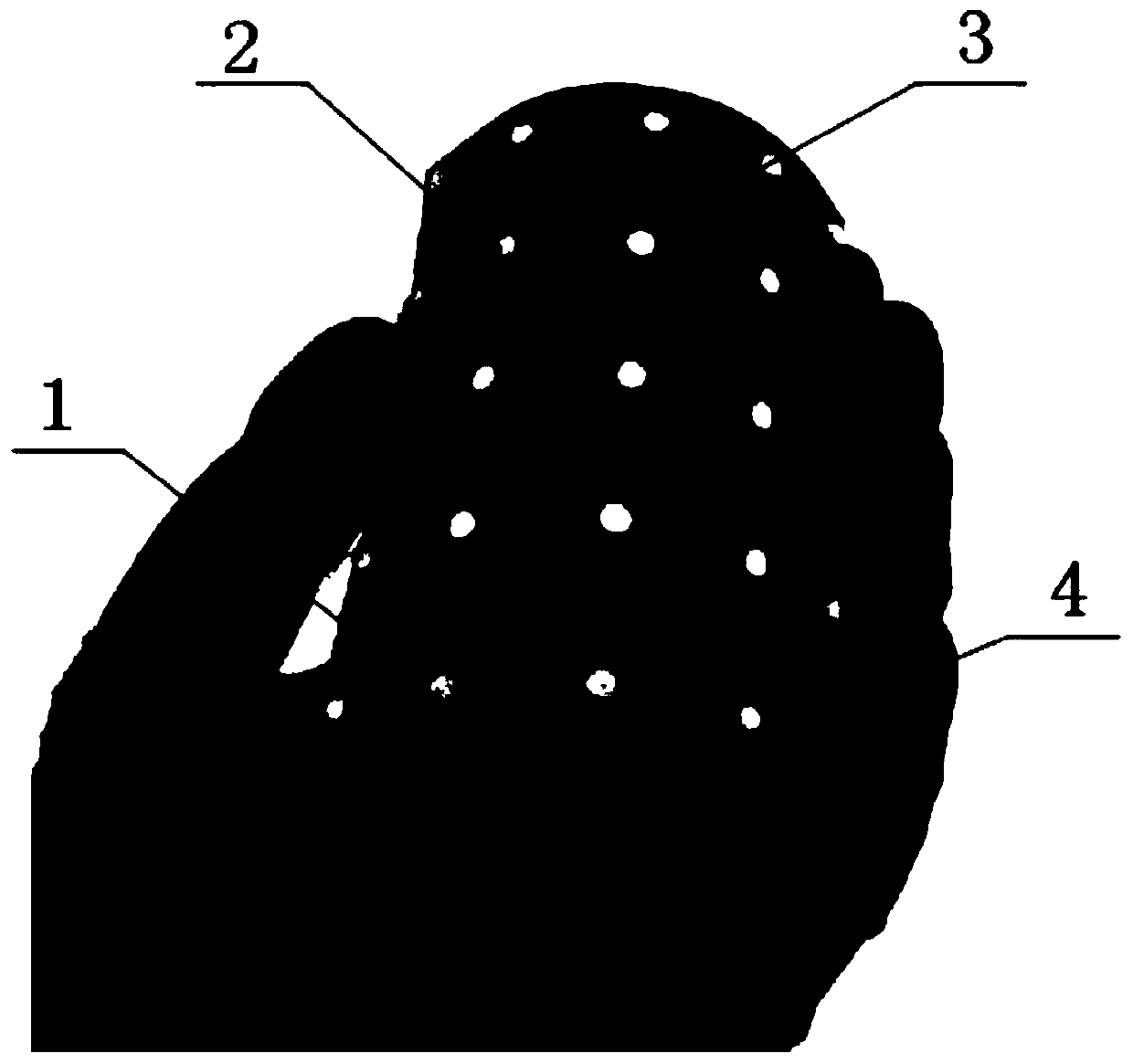

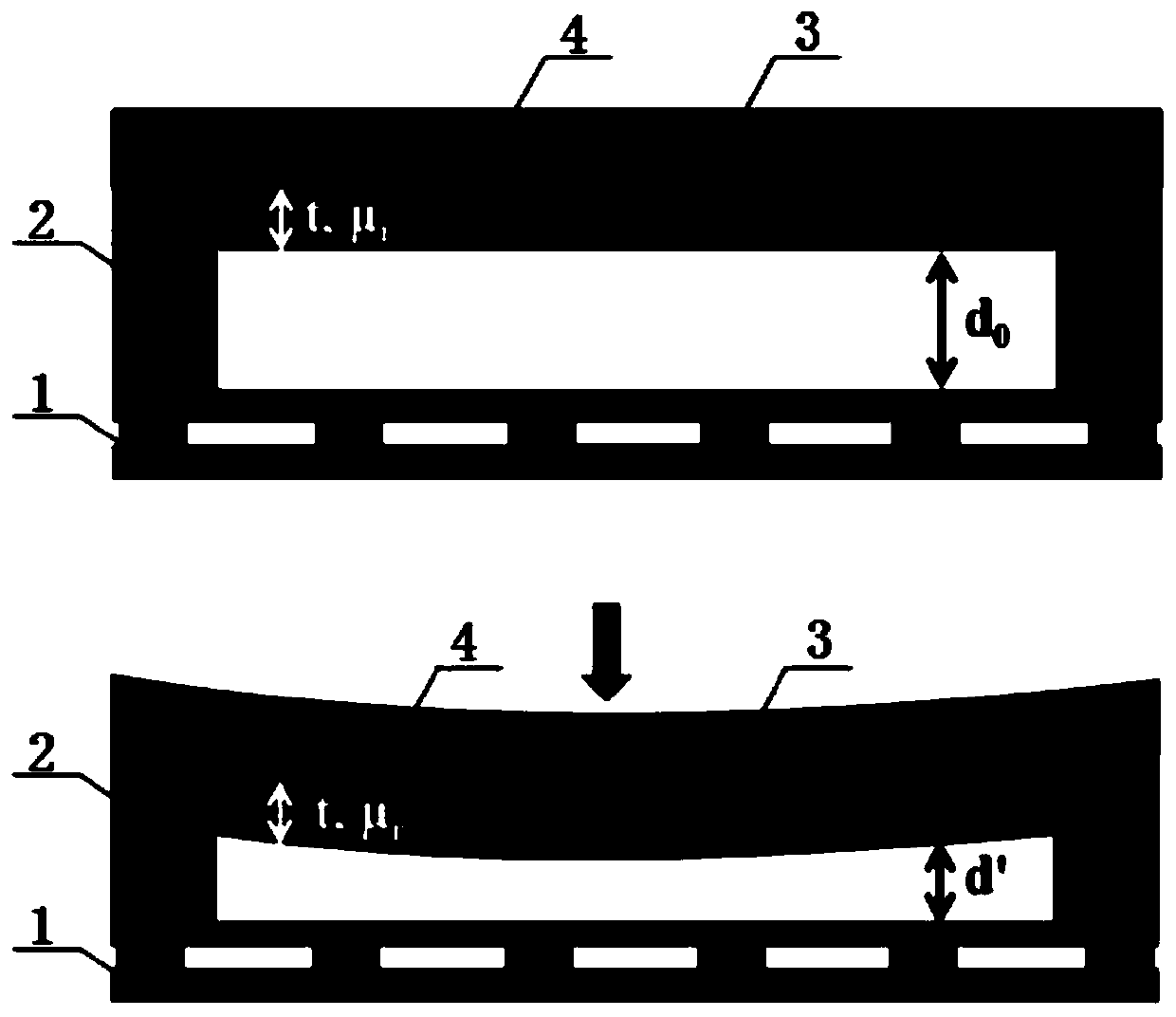

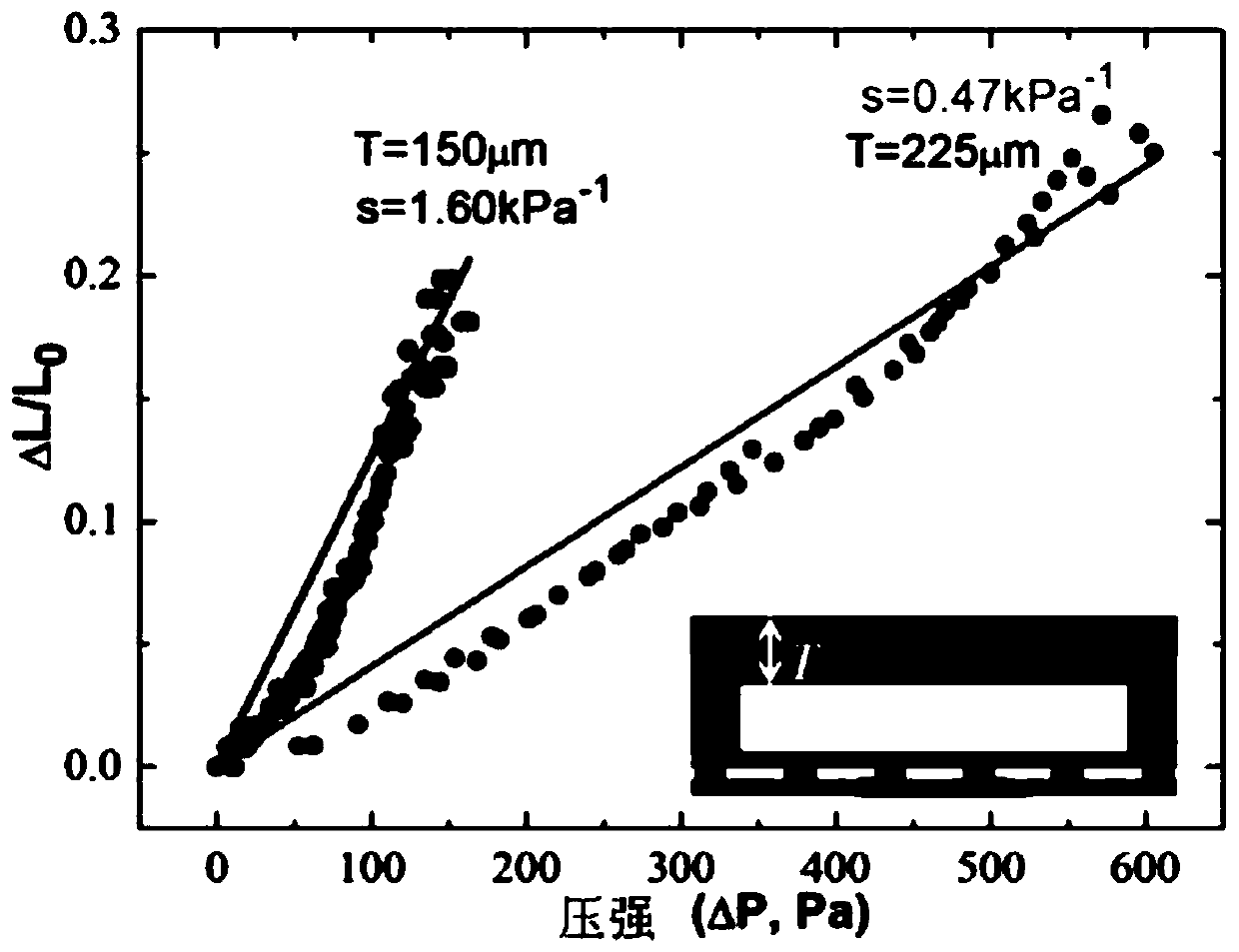

[0036] figure 1 The actual photo of the 4×4 sensor array is shown. The sensor array can be bent freely, which demonstrates the high flexibility of the array. figure 2 Shows a schematic cross-sectional view of one unit sensor in the array. The sensor is composed of a planar spiral inductor on the bottom layer, a flexible wave-absorbing material on the top layer, and an elastic pillar in the middle.

[0037] (1) Working principle

[0038] When an AC signal is input to the coil, a magnetic field will be generated inside the coil. Since the magnetic permeability of the top ferrite film is much greater than the vacuum magnetic permeability (μ 0 ), it will shield the magnetic field generated by the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com