Patents

Literature

105results about How to "Reduce mutual inductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

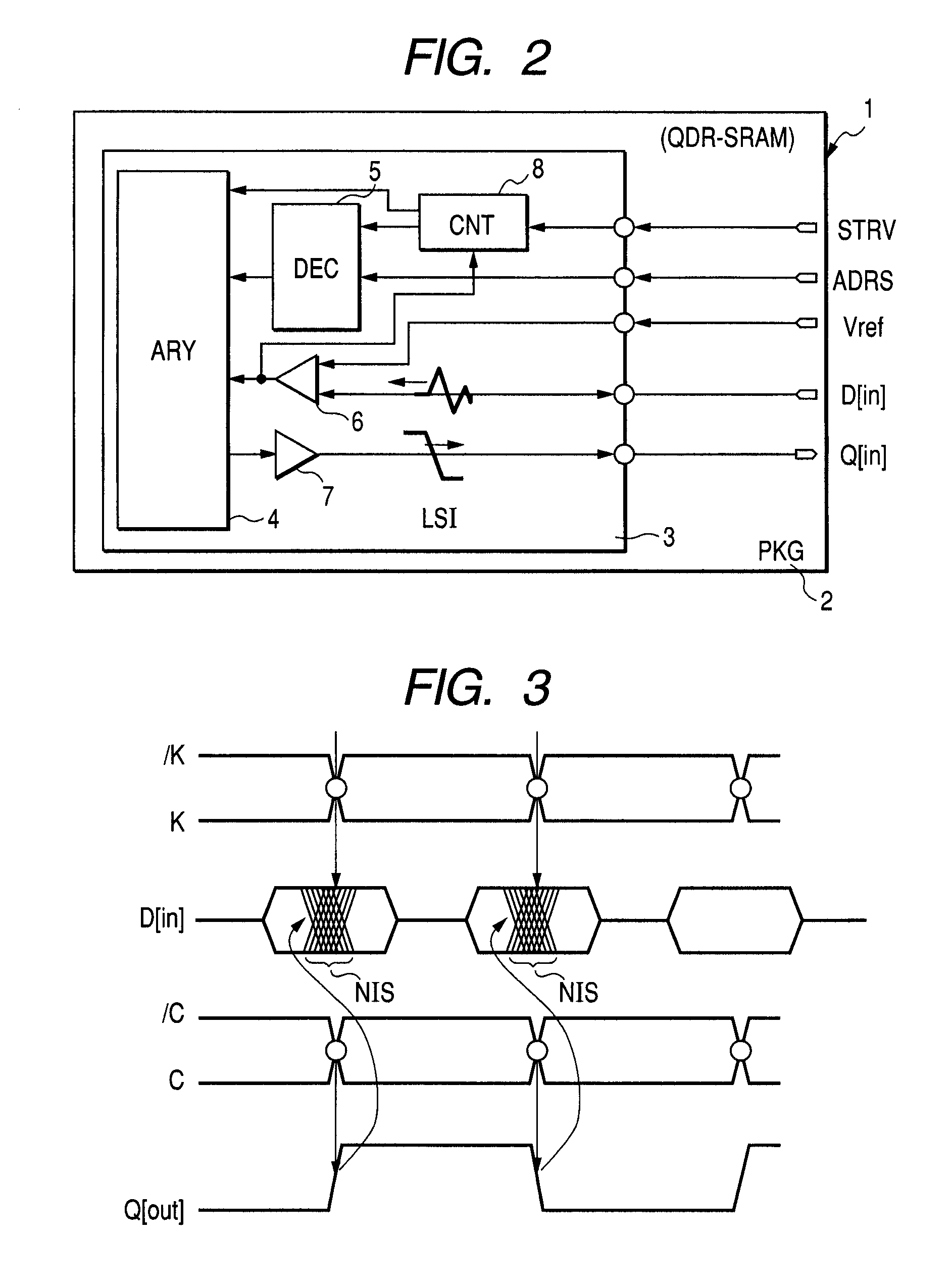

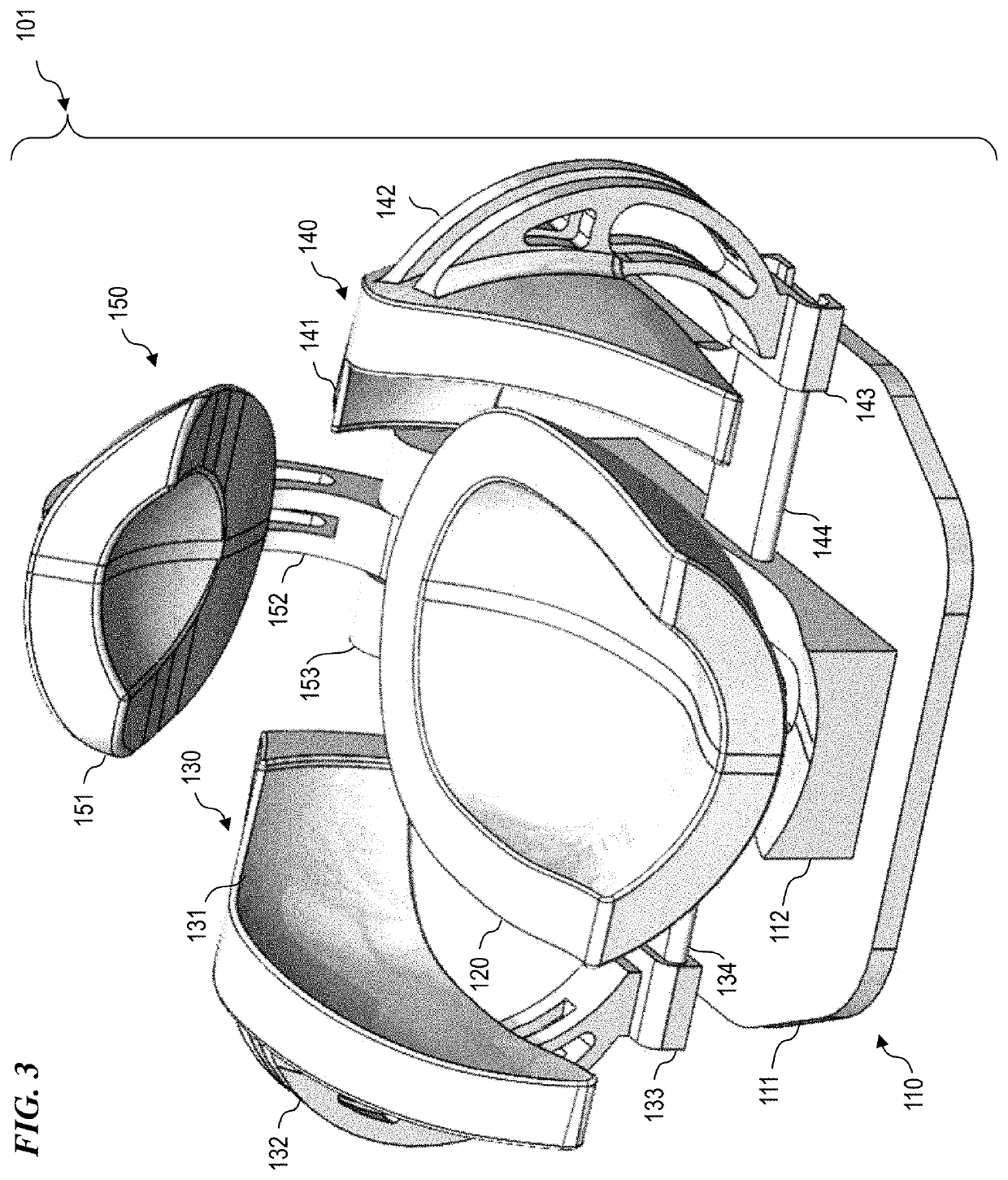

Semiconductor device

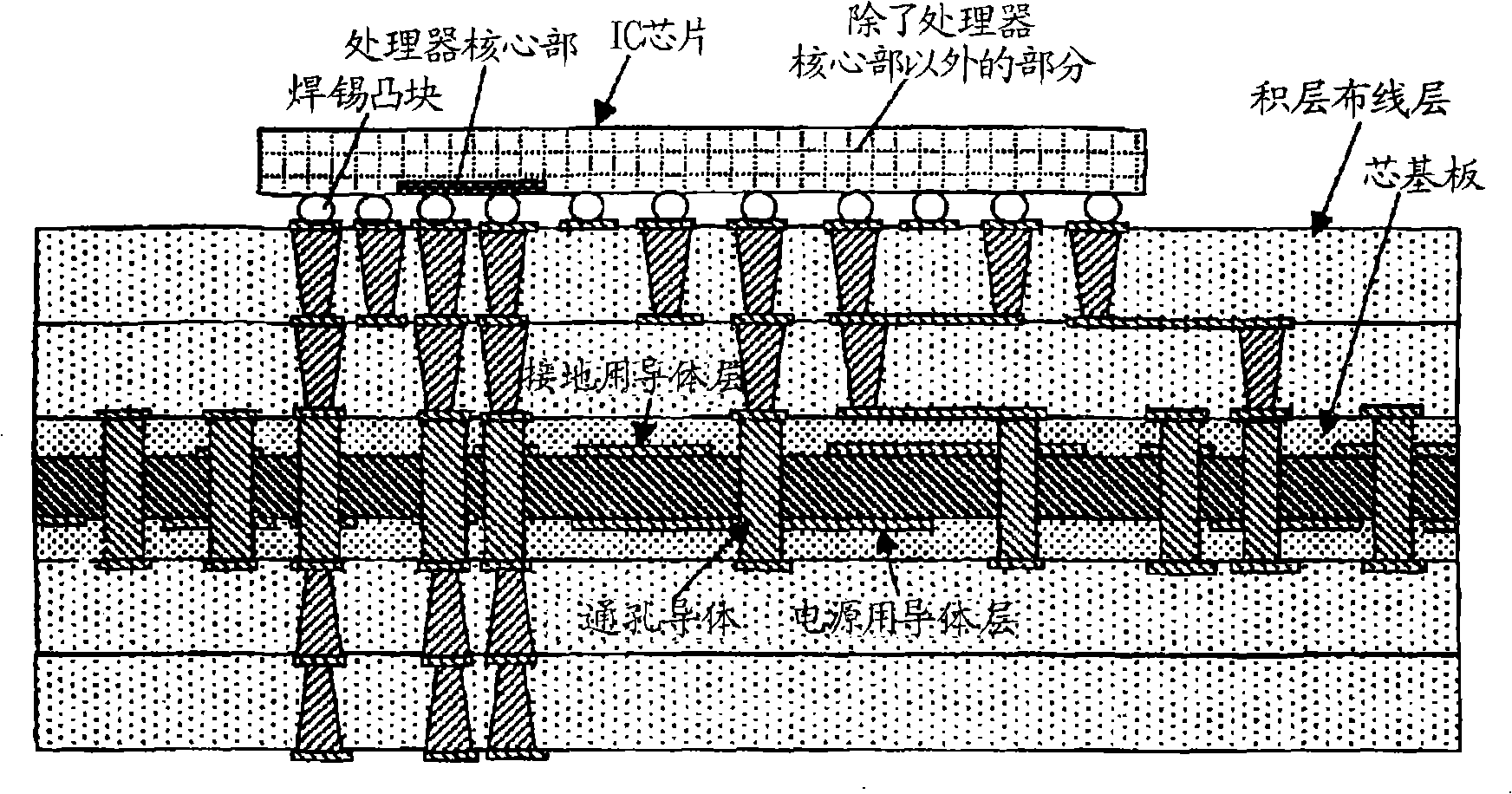

InactiveUS20070120245A1Reduce and suppress inductionReduce mutual inductanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

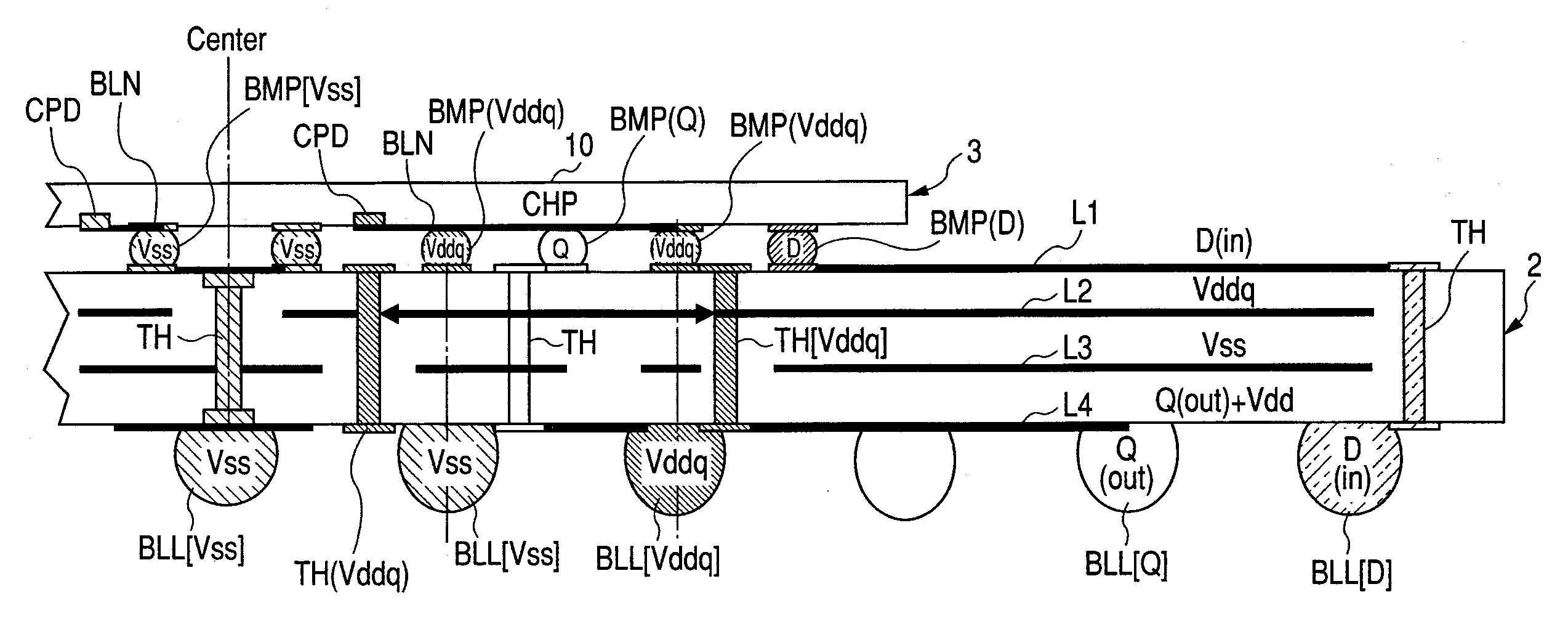

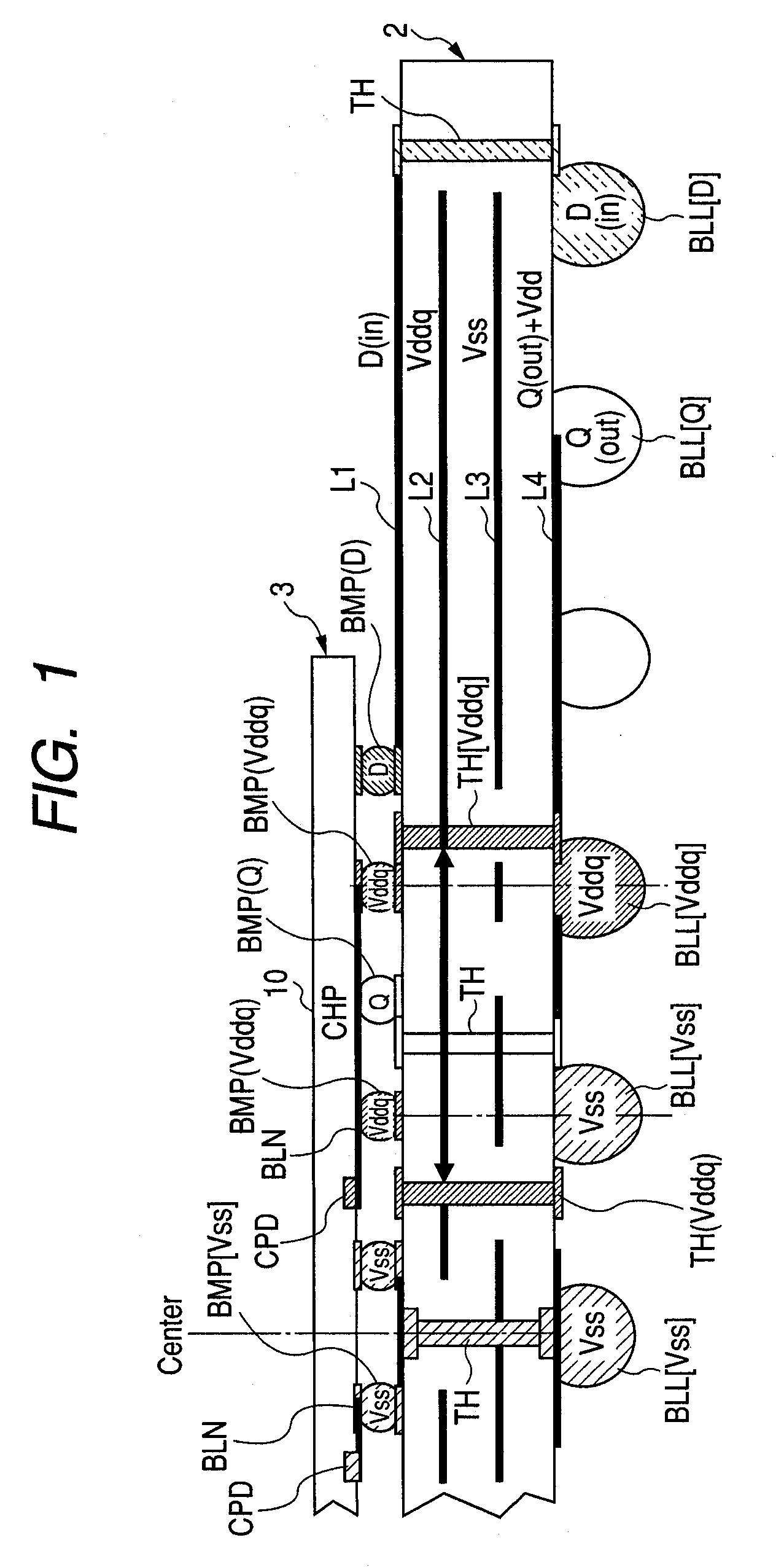

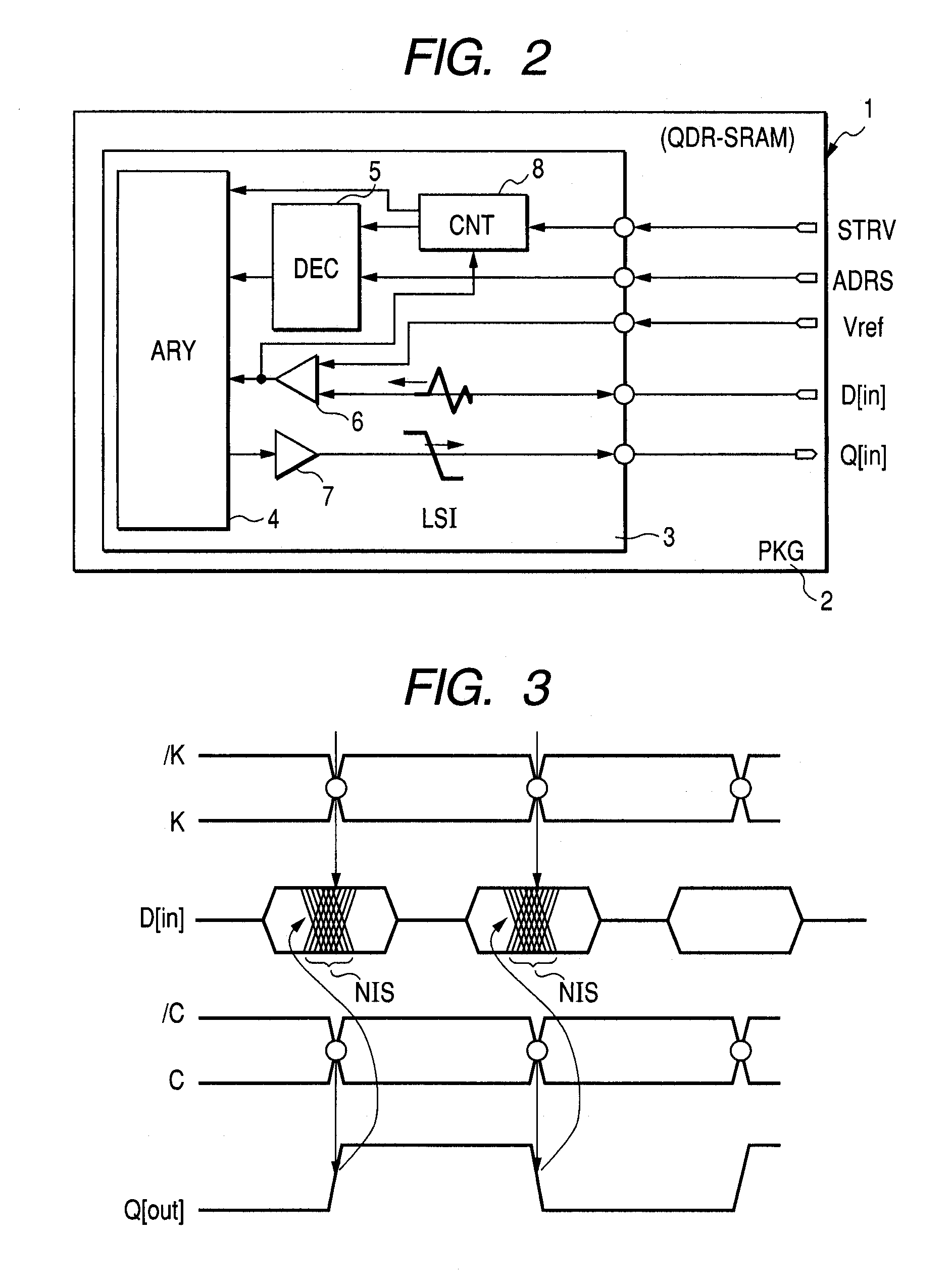

Mutual inductance from an external output signal system to an external input signal system, in which parallel input / output operation is enabled, is reduced. A semiconductor integrated circuit has a plurality of external connection terminals facing a package substrate, and has an external input terminal and an external output terminal, in which parallel input / output operation is enabled, as part of the external connection terminals. The package substrate has a plurality of wiring layers for electrically connecting between the external connection terminals and module terminals corresponding to each other. A first wiring layer facing the semiconductor integrated circuit has a major wiring for connecting between the external input terminal and a module terminal corresponding to each other, and a second wiring layer in which the module terminals are formed has a major wiring for connecting between an external output terminal and a module terminal corresponding to each other. A major signal wiring of an external output system connected to the external output terminal, which may be a noise source, is made to be in a wiring layer distant from the semiconductor integrated circuit.

Owner:RENESAS ELECTRONICS CORP

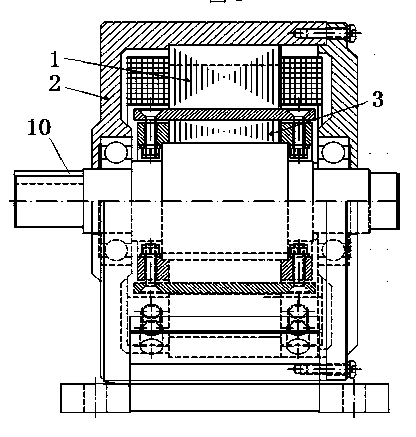

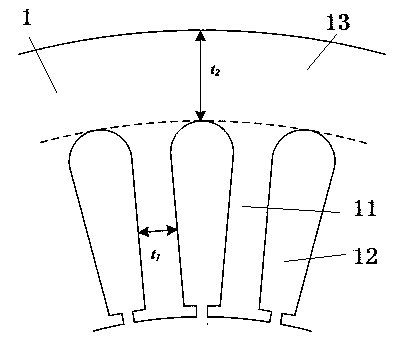

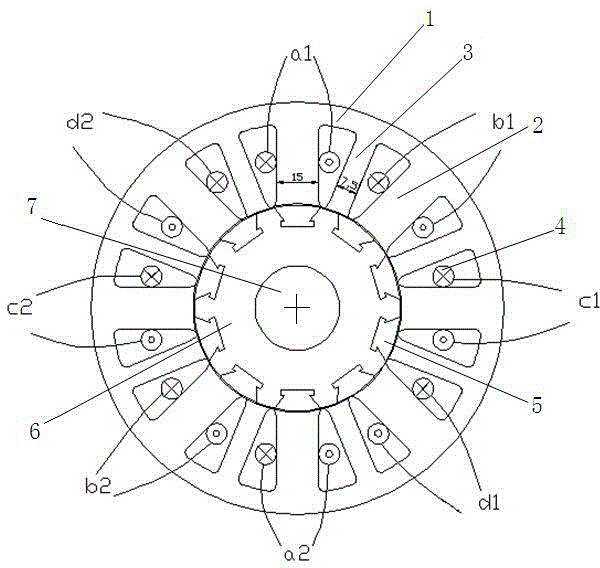

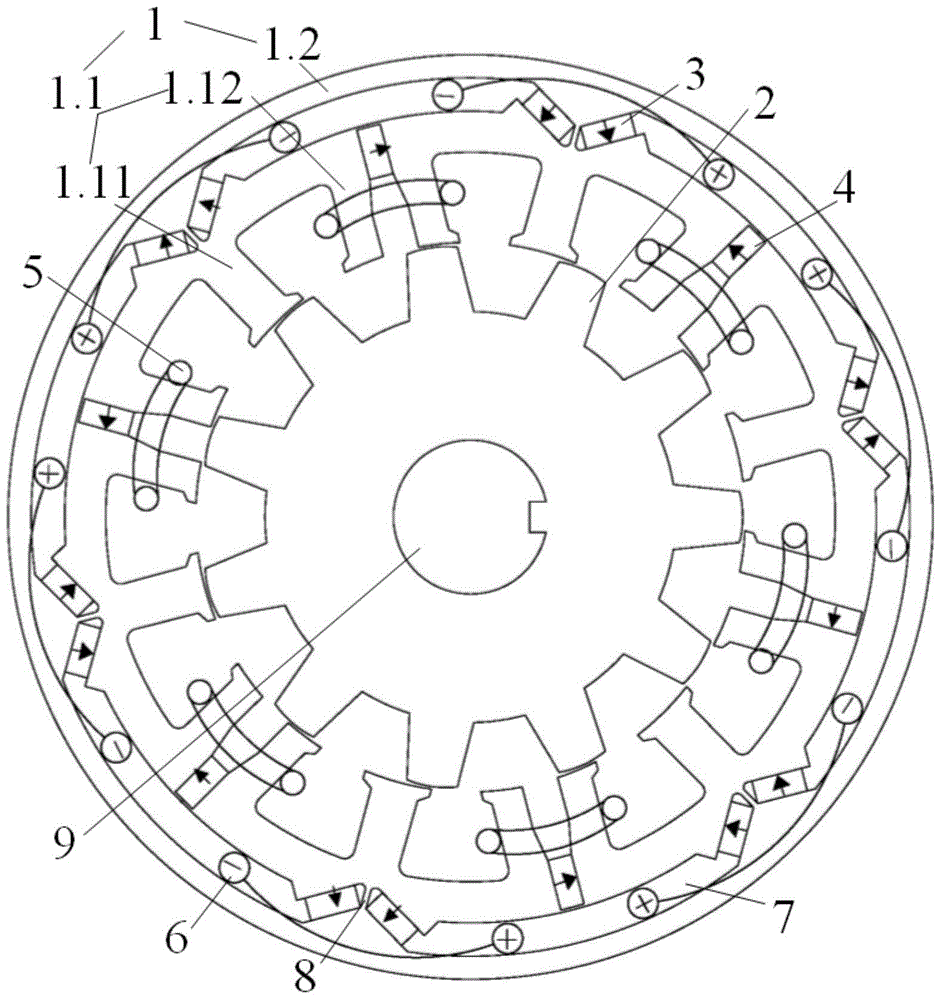

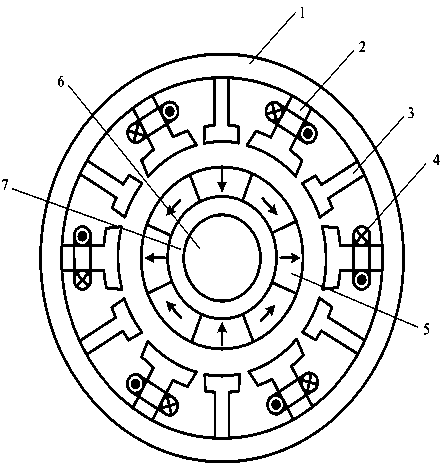

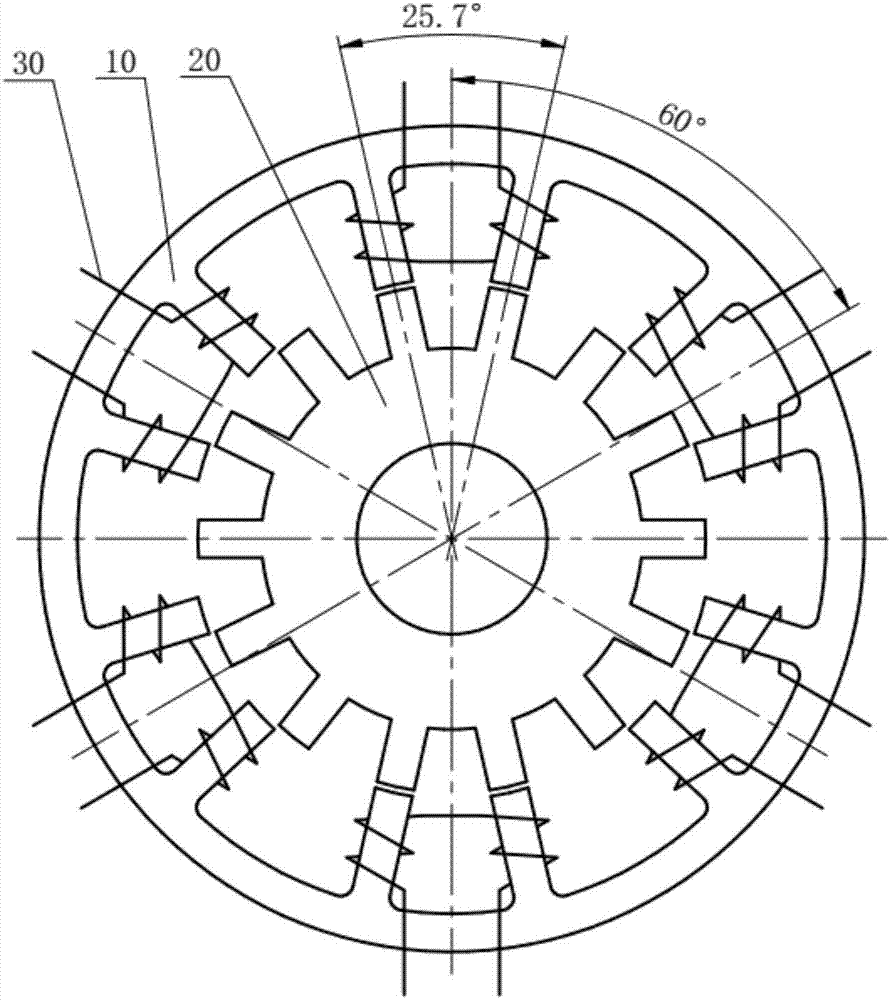

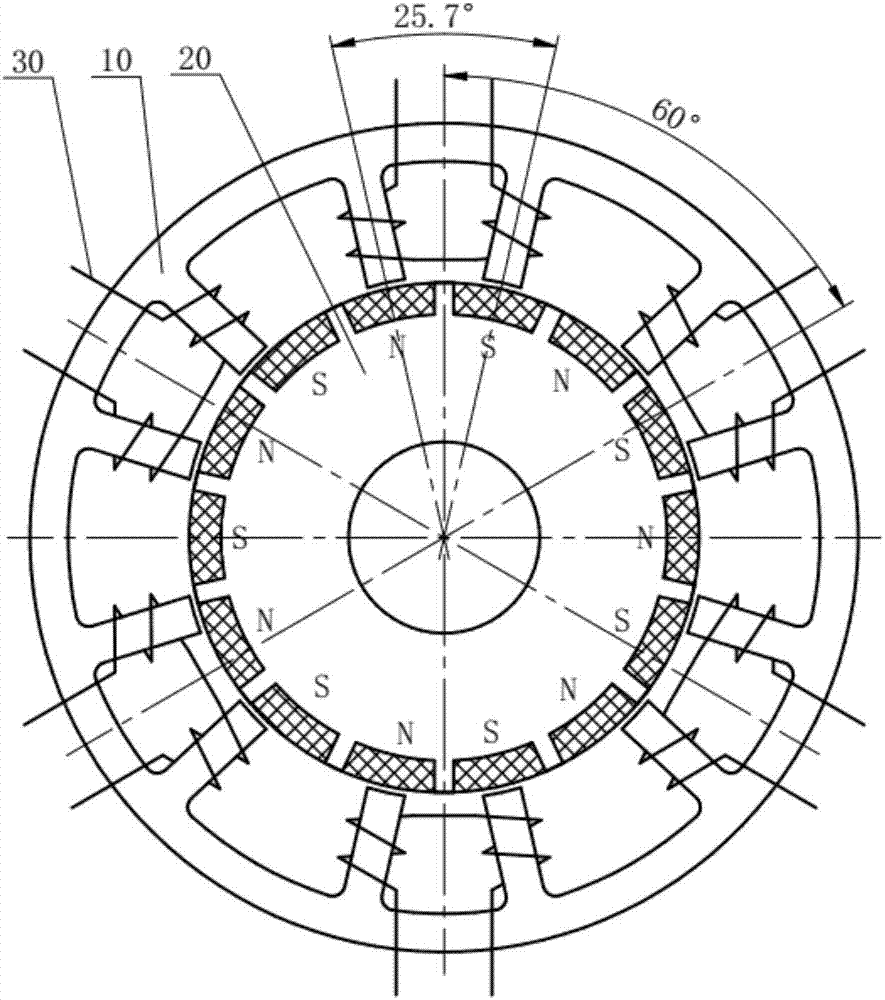

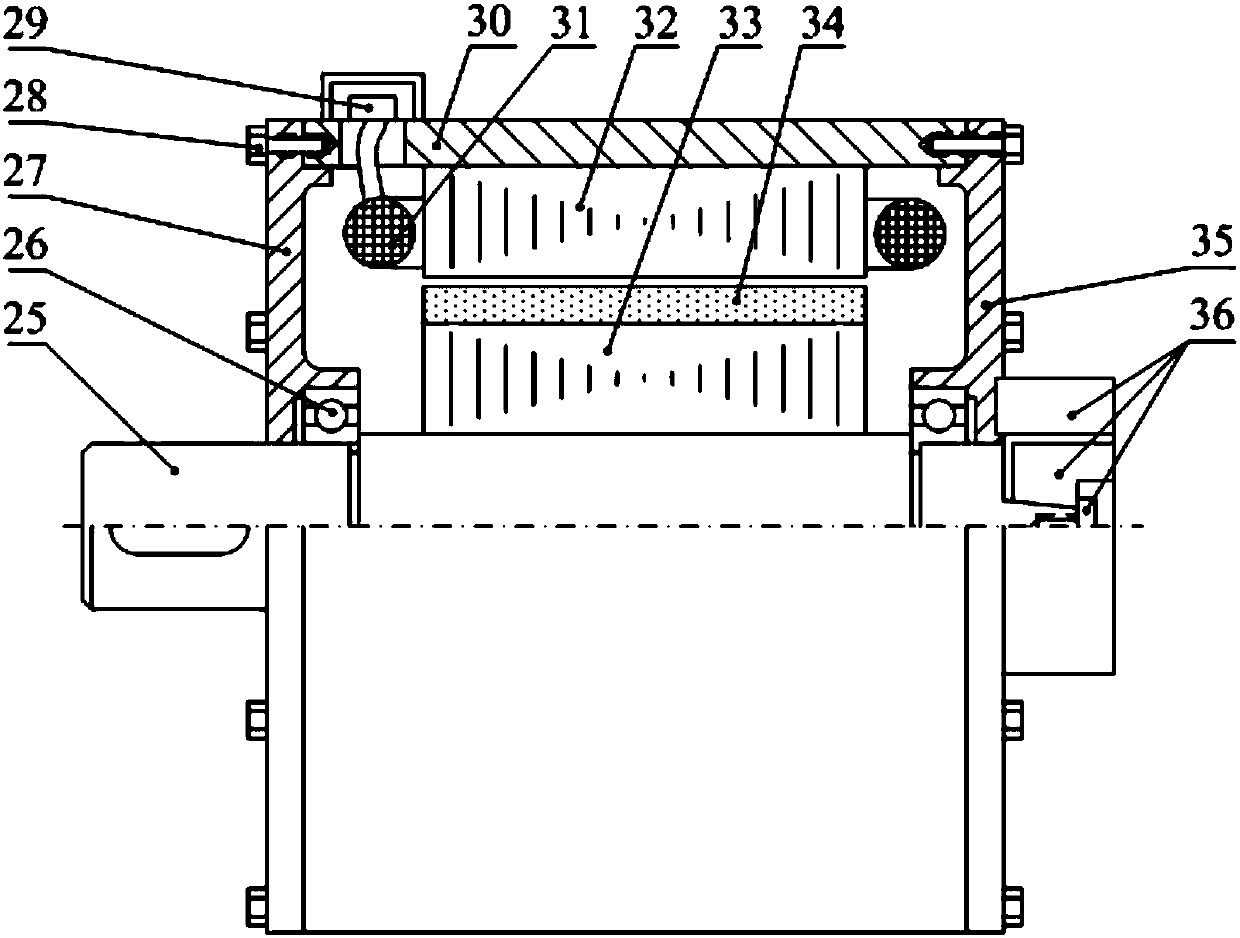

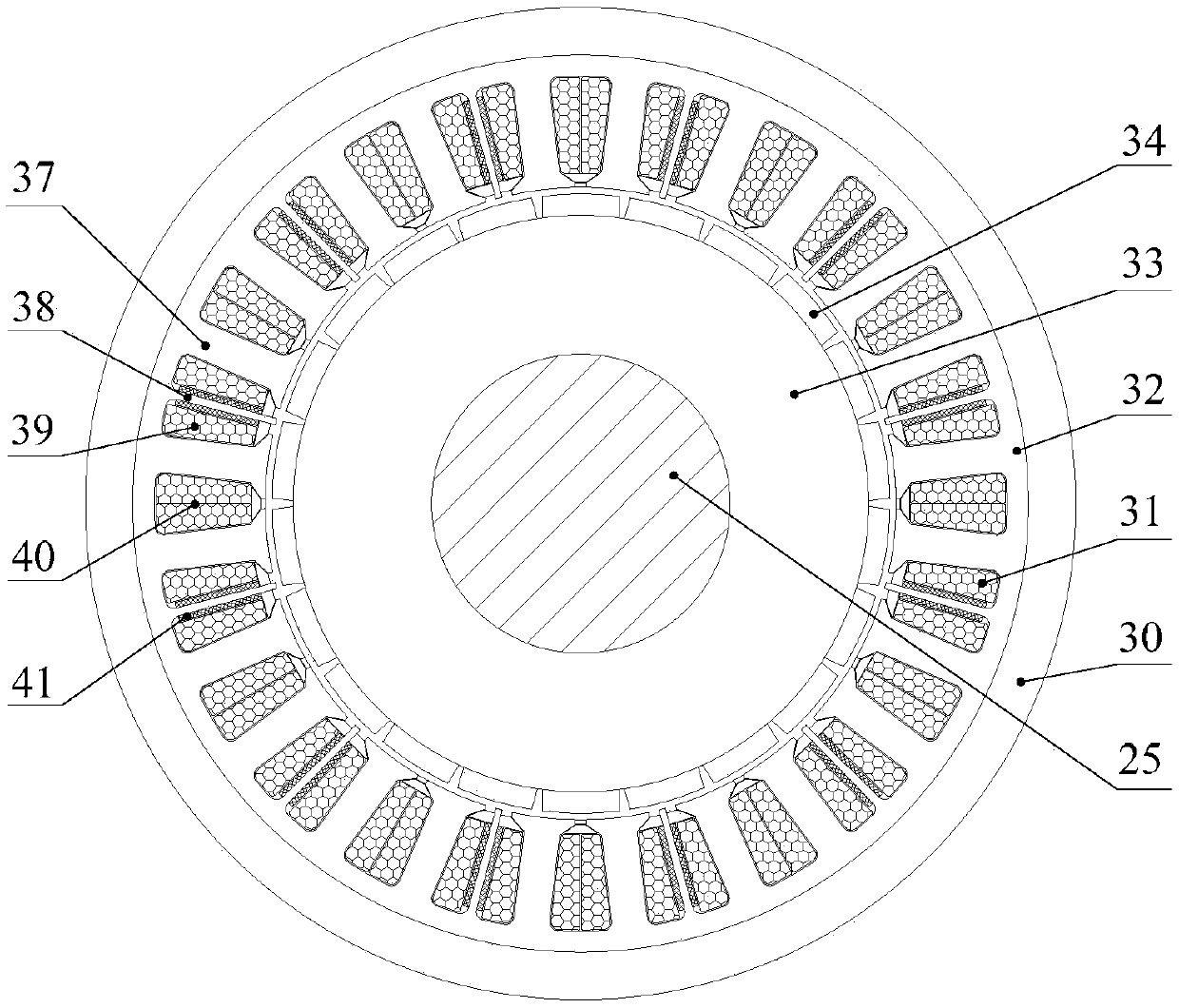

Mixed excitation permanent magnet flux switching motor

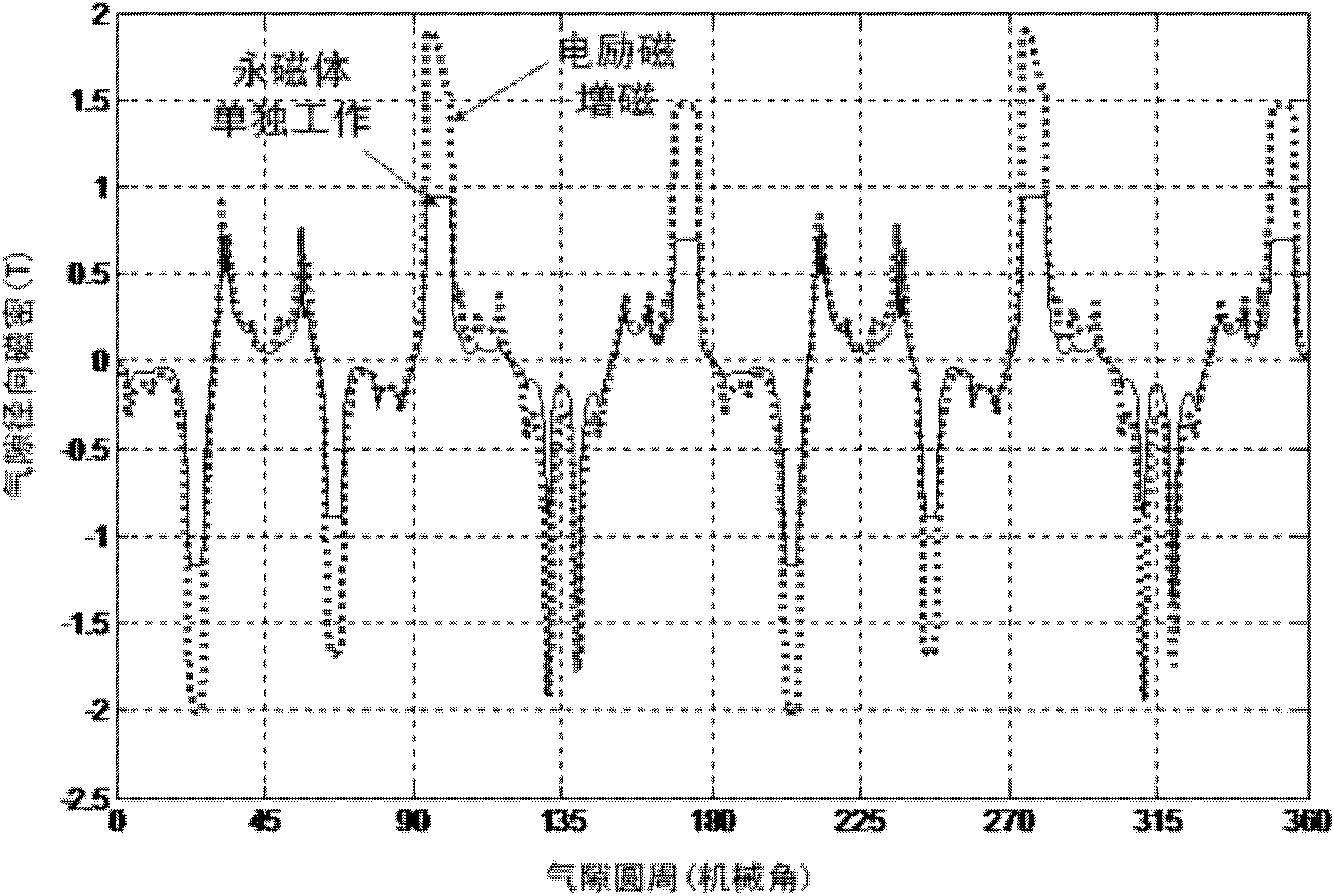

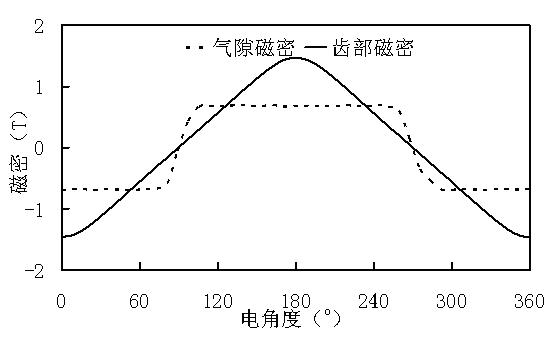

InactiveCN101820192AImprove tuning performanceReduced ampere-turnsMagnetic circuit rotating partsMagnetic circuit stationary partsTooth numberConductor Coil

The invention discloses a mixed excitation permanent magnet flux switching motor which comprises permanent magnets, three-phase armature windings and single-phase excitation windings, wherein the single-phase excitation windings are arranged on a stator, the tooth number of the stator is 4 times number of permanent magnets; and a rotor is in a salient pole structure and has no windings or permanent magnets, thereby having high mechanical strength and being suitable for high-speed operation. An air-gap field comprises an electric excitation magnetic field generated by the excitation windings and a magnetic field generated by the permanent magnets, and is flexibly adjusted by changing an excitation current. An electric excitation magnetic line of force is closed by using an iron core connecting magnetic bridge, which is beneficial to reducing the electric field ampere-turns and lowering the electric excitation copper loss. The armature windings and the excitation windings are distributed in different stator grooves at intervals, which is beneficial to increasing the self-inductance of the armature windings and the mutual inductance of the windings and effectively inhibiting the short circuit current of a motor.

Owner:CHANGZHOU INST OF TECH

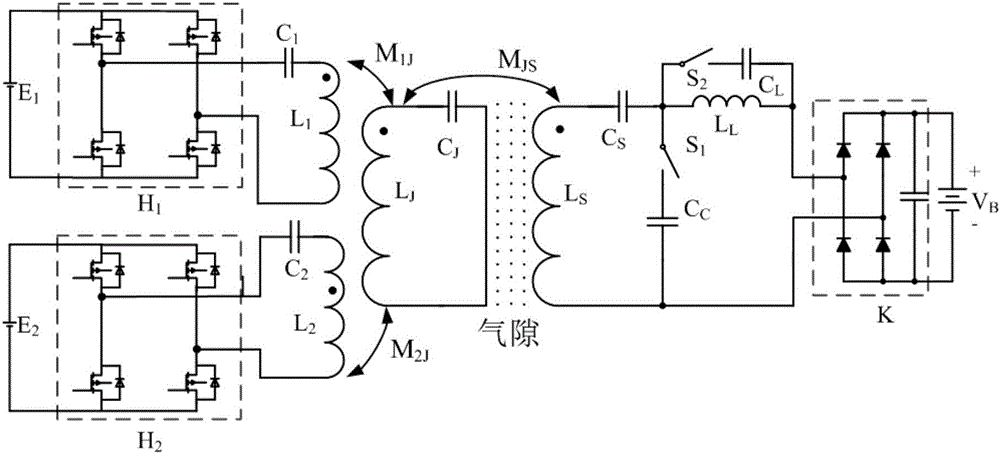

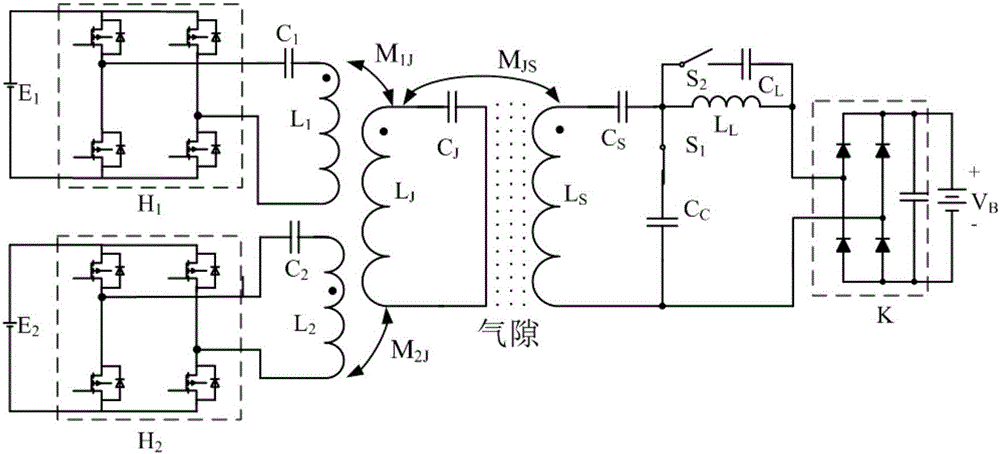

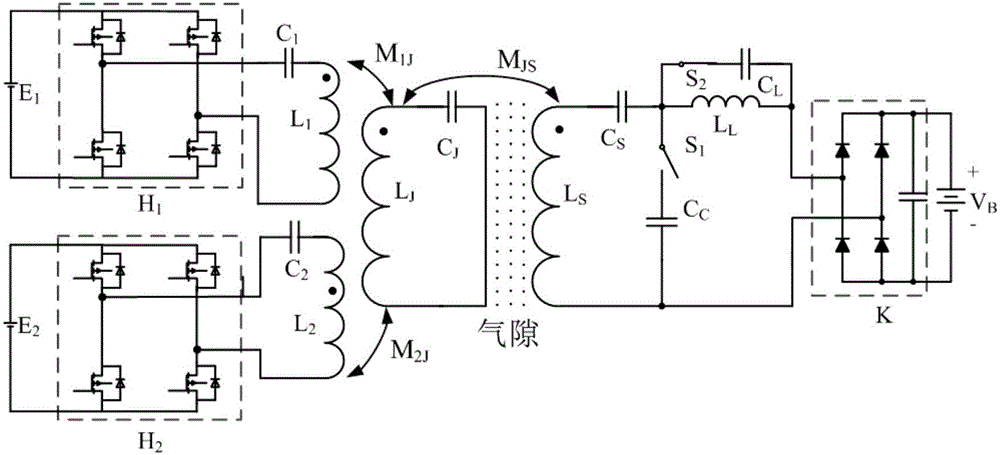

Multi-transmission-source enhanced wireless charging system

ActiveCN106828174AReduce mutual inductanceIncrease output power levelBatteries circuit arrangementsCharging stationsCapacitanceTransformer

The invention discloses a multi-transmission-source enhanced wireless charging system. The multi-transmission-source enhanced wireless charging system comprises an energy transmission part, a relay part and an energy receiving part; the energy transmission part comprises a plurality of energy transmission sources; each energy transmission source comprises a high frequency inverter, a compensation capacitor and a primary coil with a small number of turns; the relay part is a loop which is formed by connecting a relay coil with a large number of turns with a relay circuit compensation capacitor in series; the relay coil is close to each primary coil; the energy receiving part comprises a secondary coil with a large number of turns and a rectifying and filtering circuit; an output end of the rectifying and filtering circuit is connected with two ends of a charging battery; an air gap exists between the secondary coil and the relay coil. The multi-transmission-source enhanced wireless charging system disclosed by the invention has the advantages that the output power grade of the system is enhanced, dissonance problem of the system caused by decoupling and mutual inductance between the plurality of transmission coils is avoided; neither additional compensation capacitor nor compensation transformer needs to be additionally arranged; as the energy transmission part and the relay part are mounted on the ground and the energy receiving part is mounted at the bottom of the vehicle, the system has a simple structure and has low requirements on space.

Owner:SOUTHWEST JIAOTONG UNIV

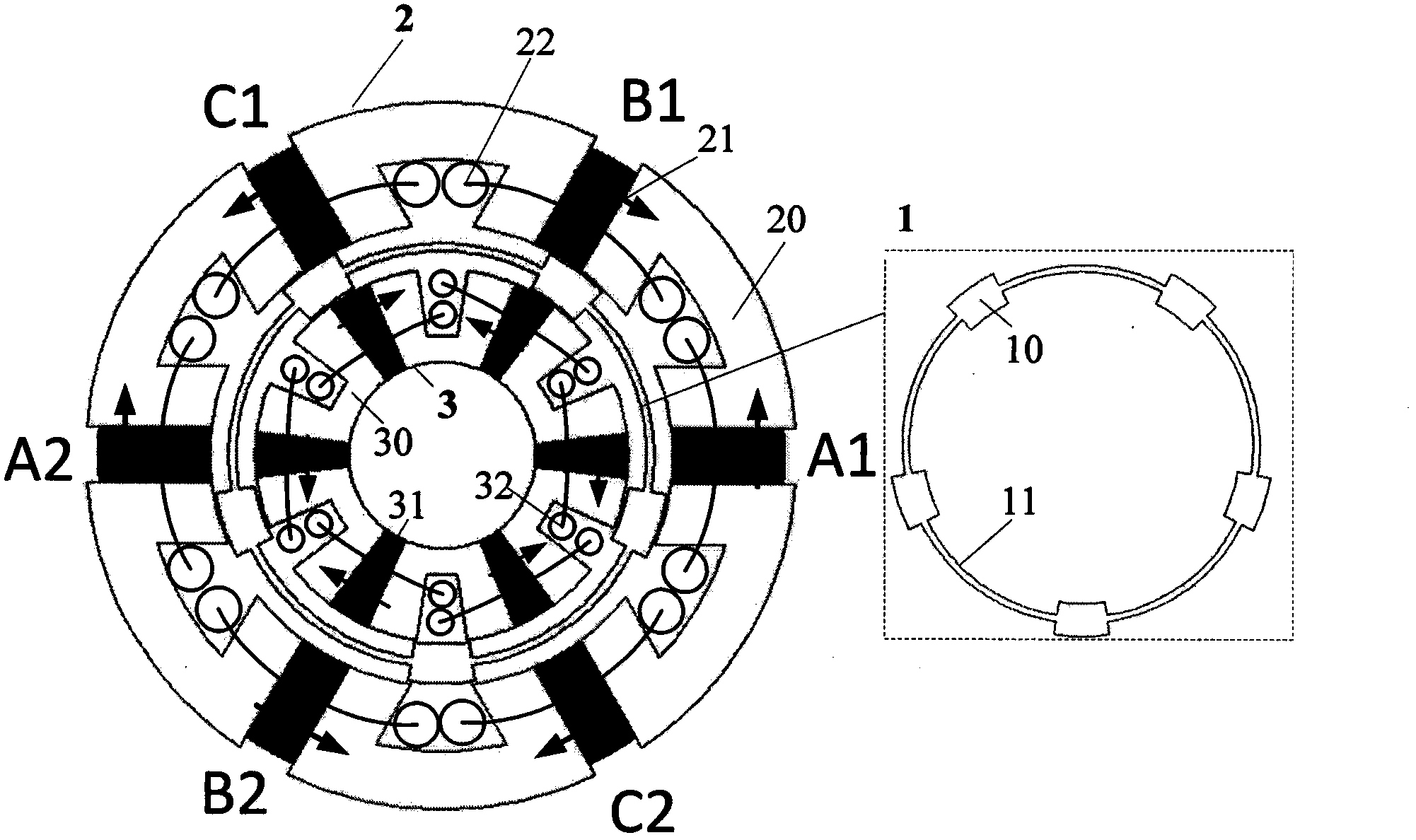

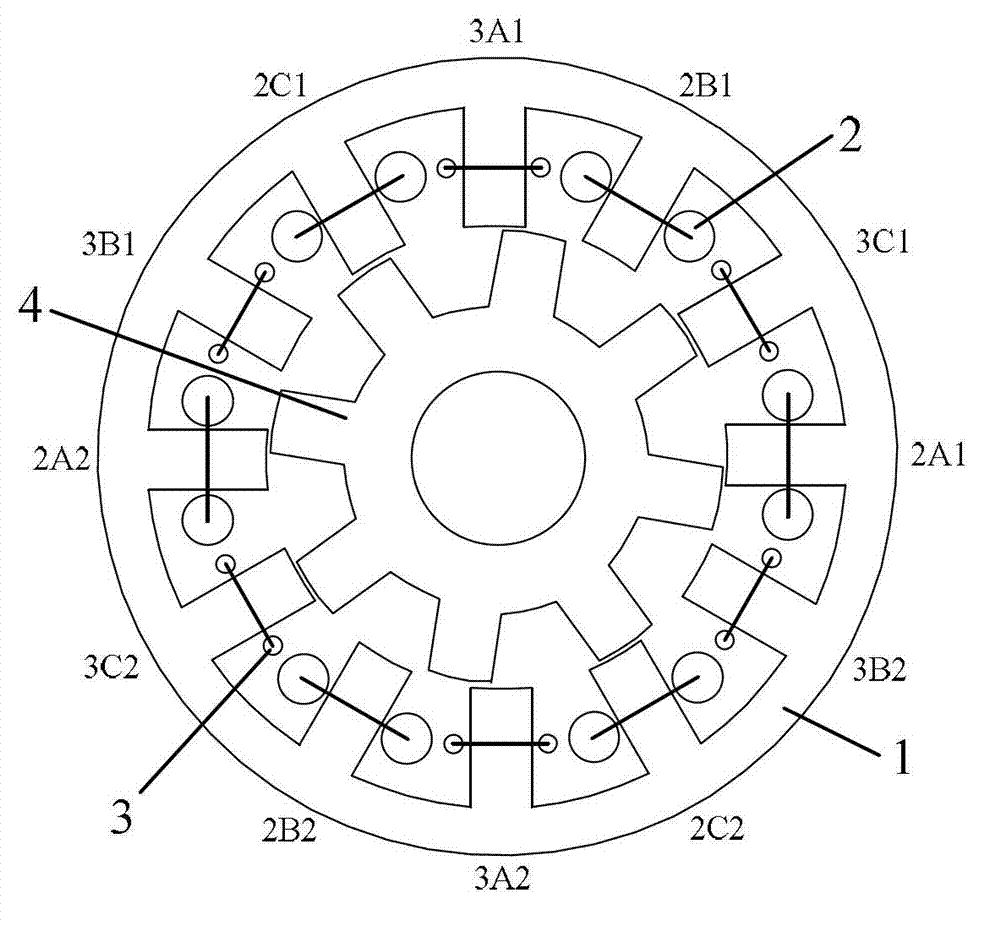

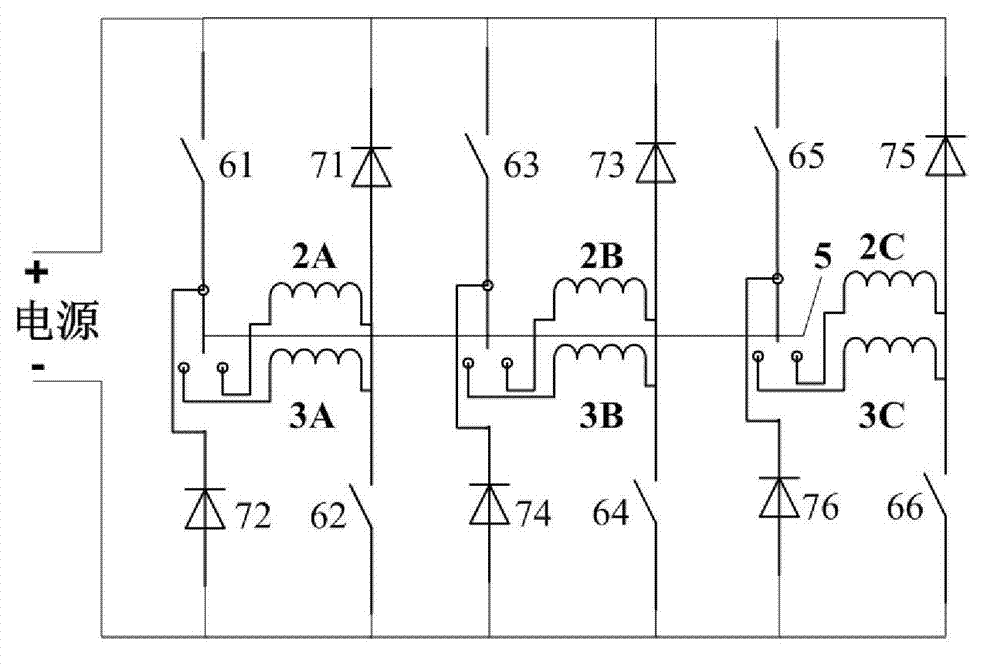

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

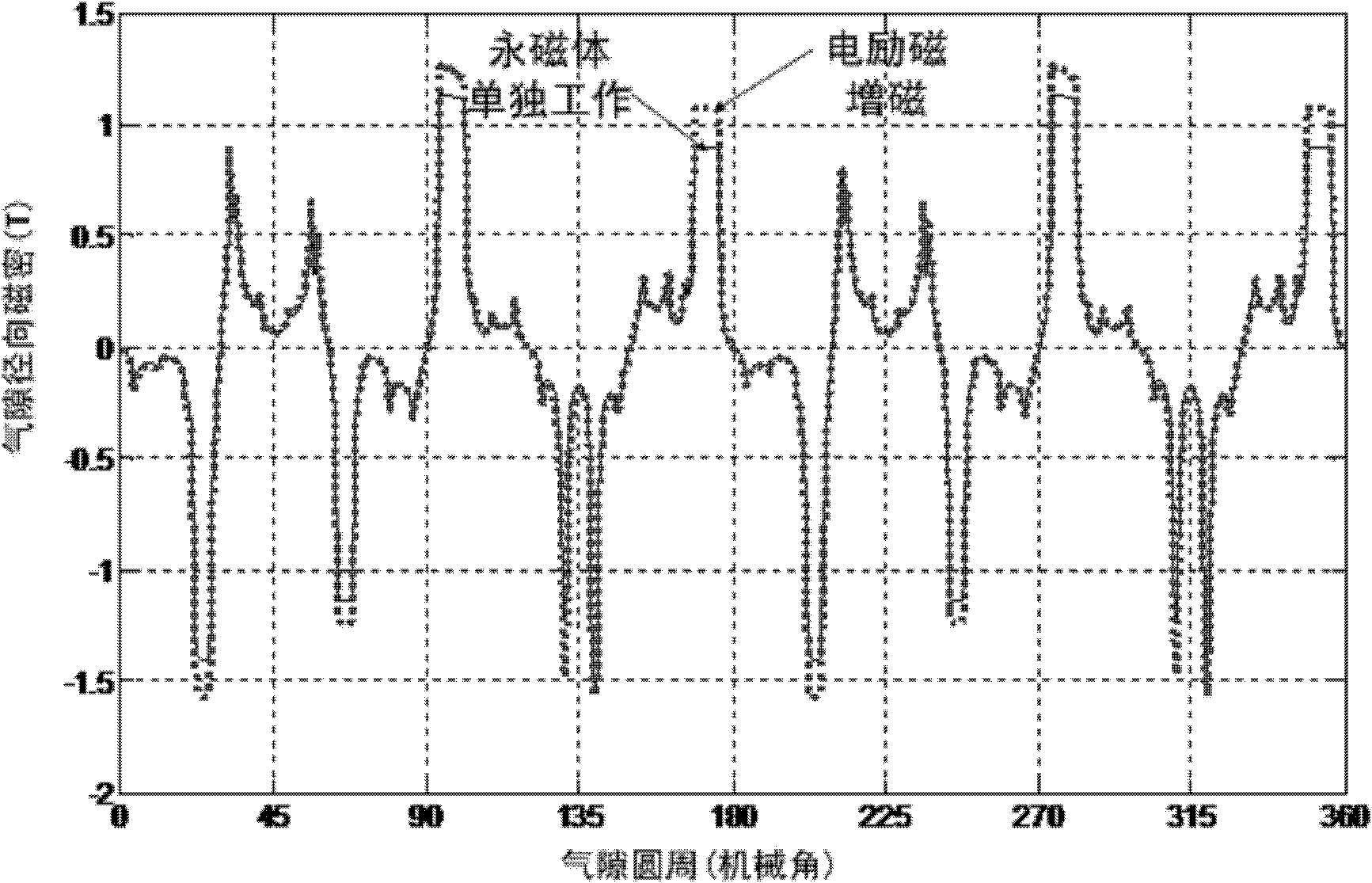

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

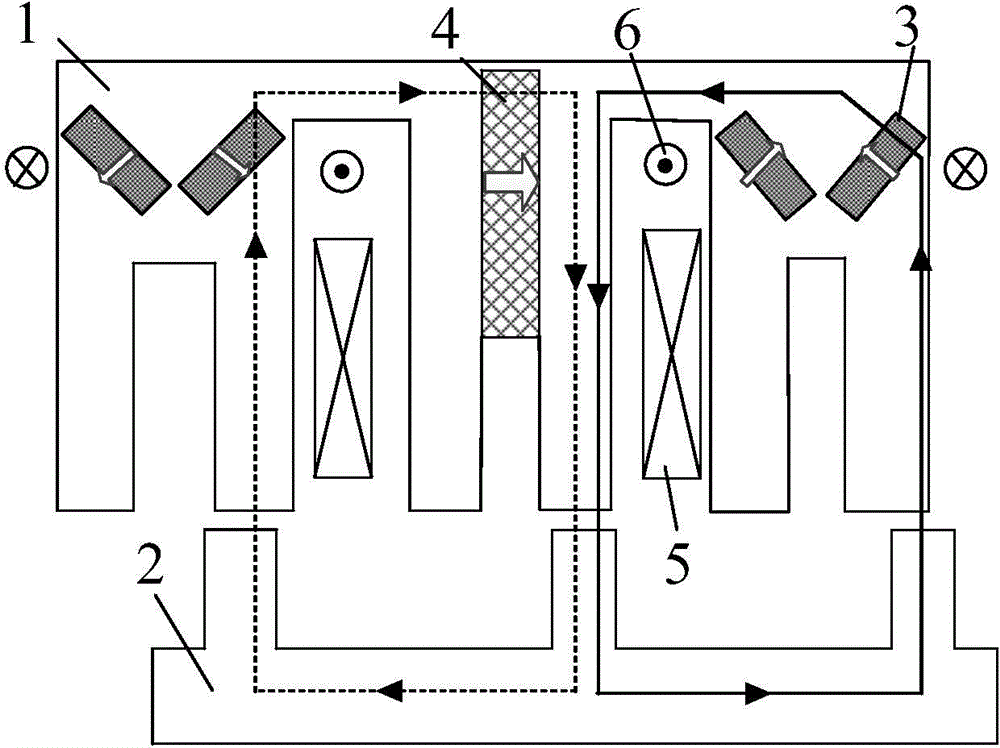

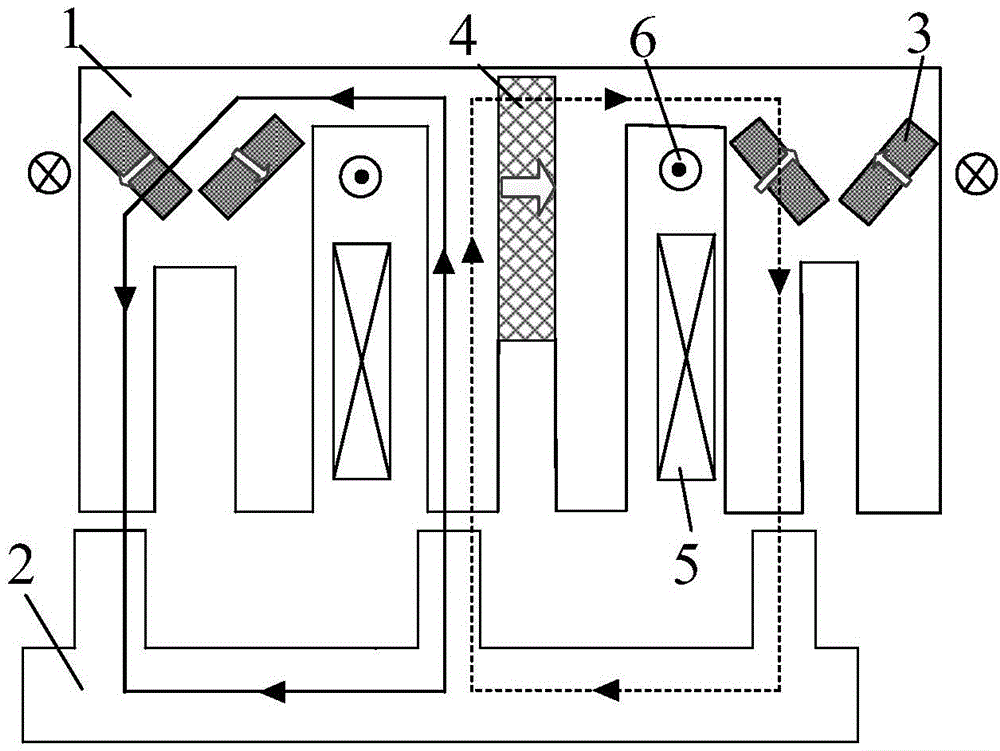

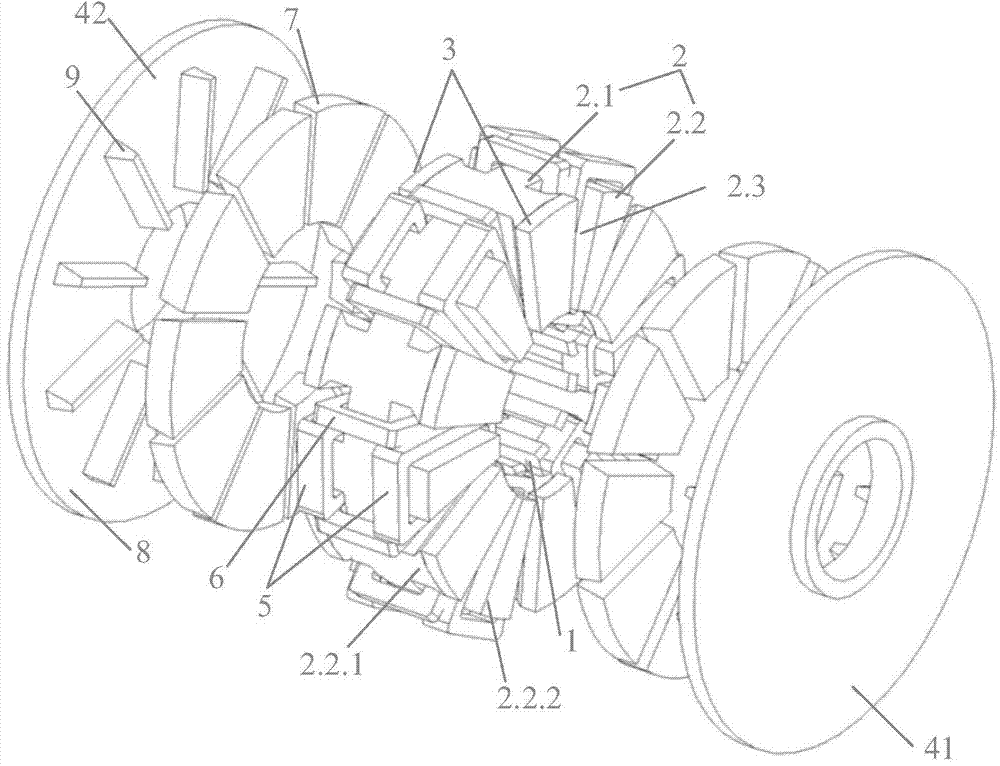

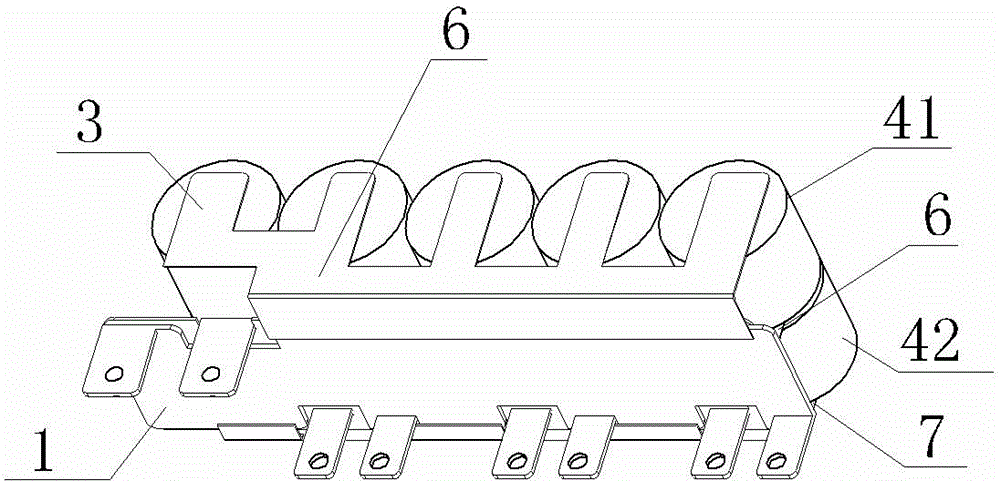

Axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor

ActiveCN103490573ASimple structureReduce wind resistanceMagnetic circuit rotating partsMagnetic circuit stationary partsSurface mountingElectric machine

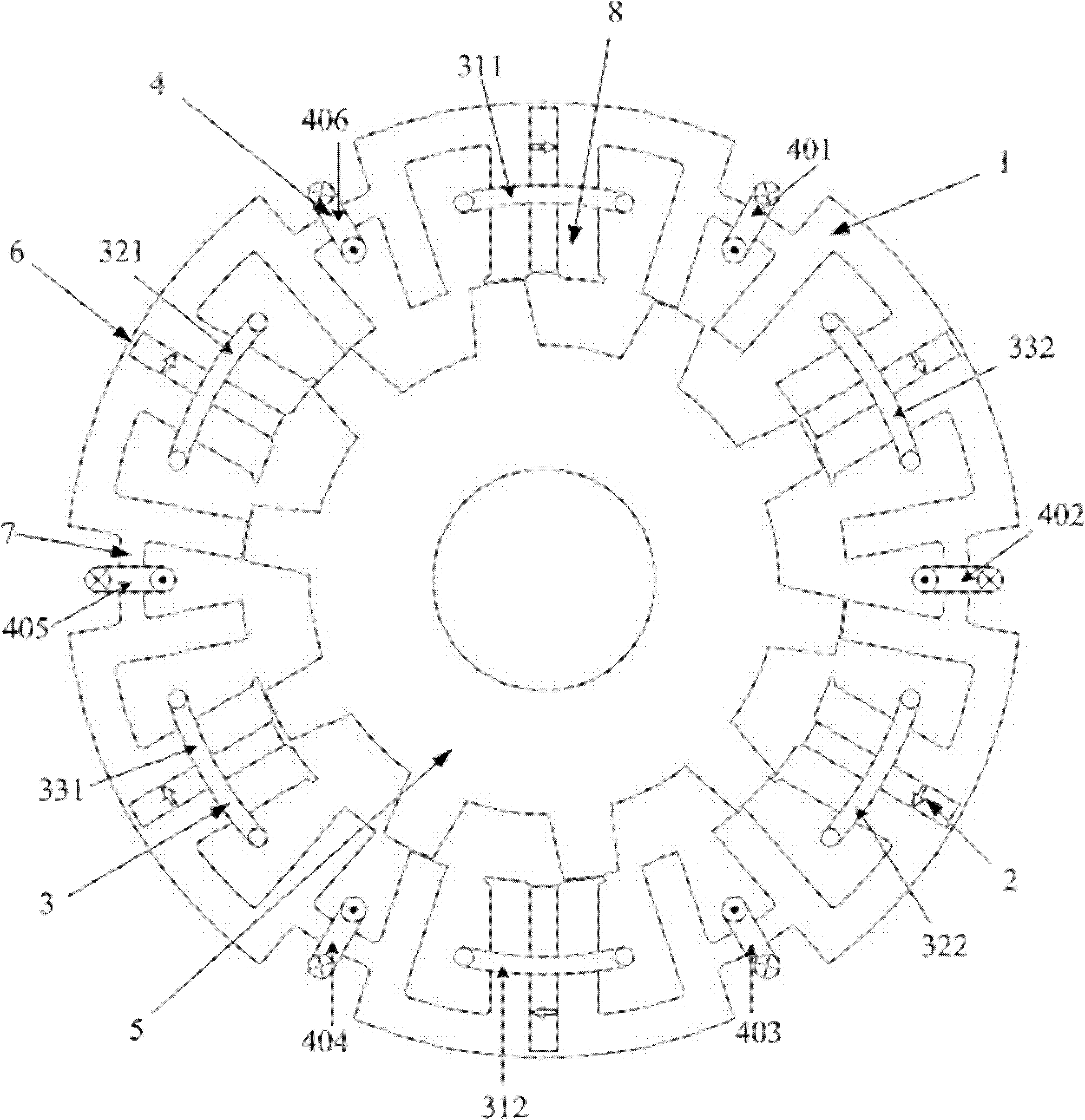

The invention discloses an axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor. The permanent magnet memory motor comprises a first rotor (41), a second rotor (42), a stator (1) and an installing shaft, wherein the stator (1) is arranged between the first rotor (41) and the second rotor (42) and of an axial two-side symmetrical structure, the installing shaft is used for coaxially installing the stator (1), the first rotor (41) and the second rotor (42), and the stator is located between the two rotors to form an axial two-air-gap motor. The stator (1) is of the two-side symmetrical salient pole structure and comprises a stator iron core (2), a plurality of permanent magnets (3), a three-phase armature winding (5) and a single-phase pulse winding (6). The stator iron core (2) comprises a stator yoke (2.1) and stator teeth (2.2), wherein the stator teeth (2.2) protrude in the center direction of the first rotor (41) and in the center direction of the second rotor (42) respectively from the stator yoke (2.1). By the adoption of the permanent magnet memory motor, power density of the motor is improved, and the wide rotating speed operation range is possessed.

Owner:SOUTHEAST UNIV

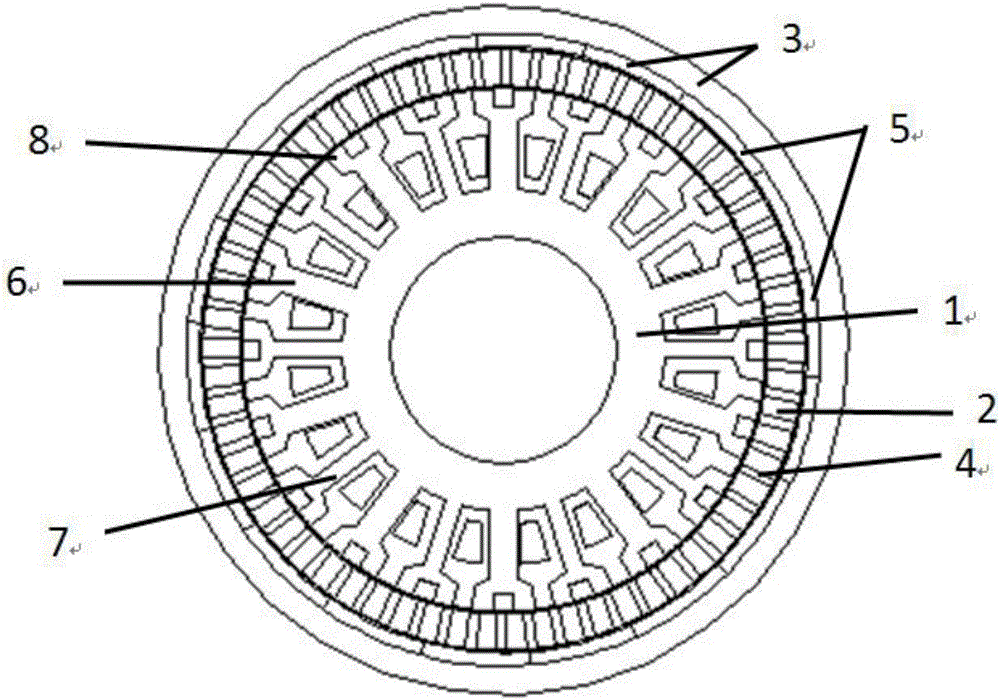

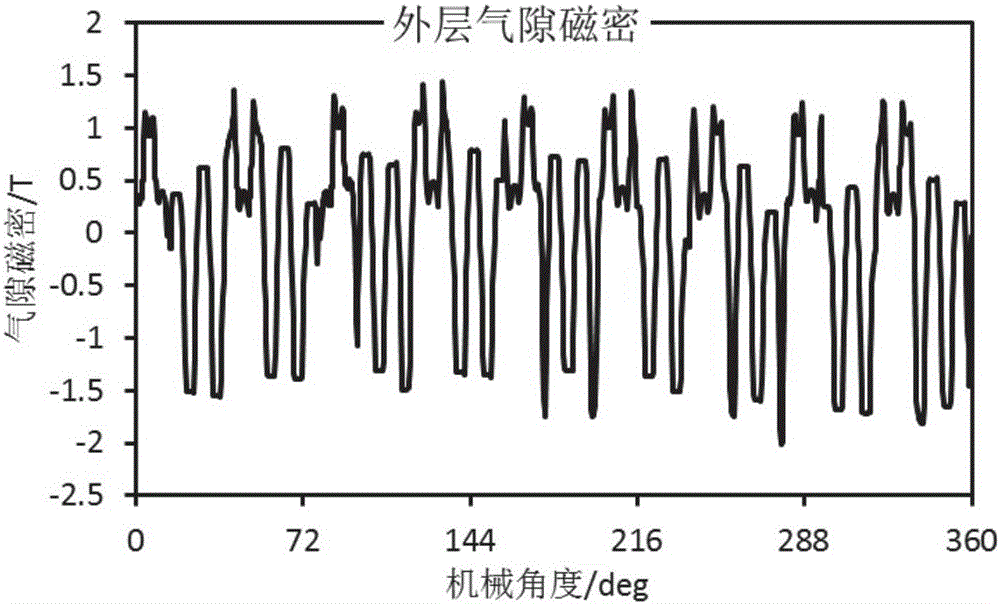

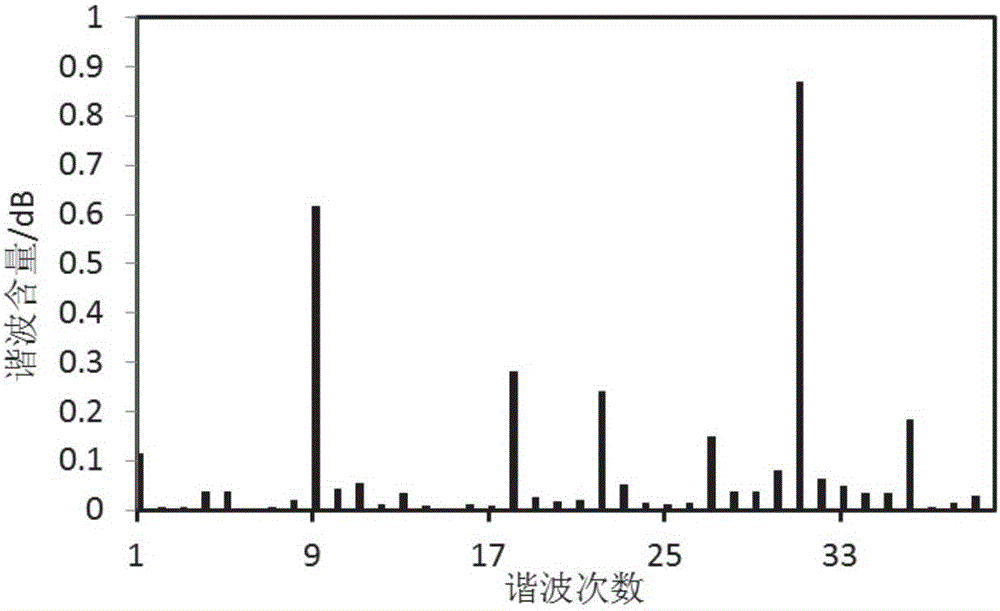

Double-stator high-power-density flux switching permanent magnet motor

ActiveCN103647382ASimple structureImprove reliabilityElectric machinesDynamo-electric machinesElectric machinePermanent magnet motor

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

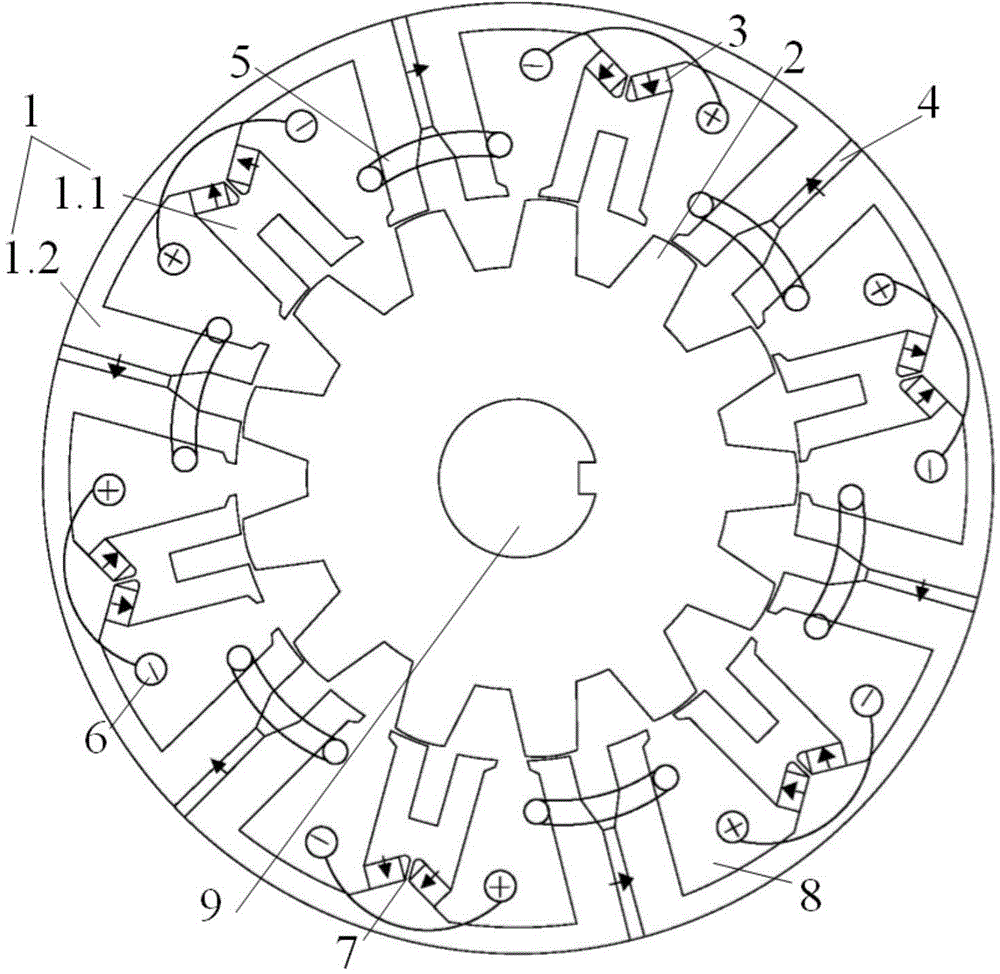

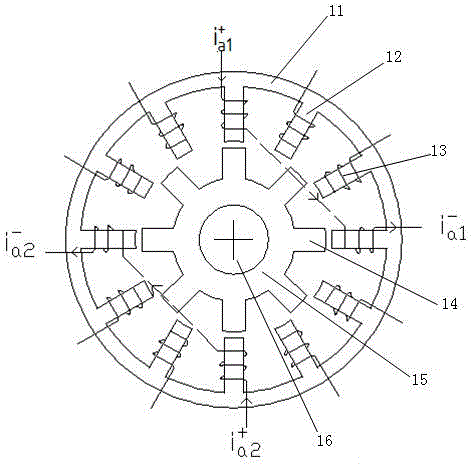

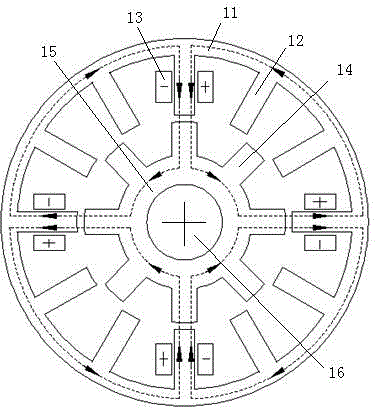

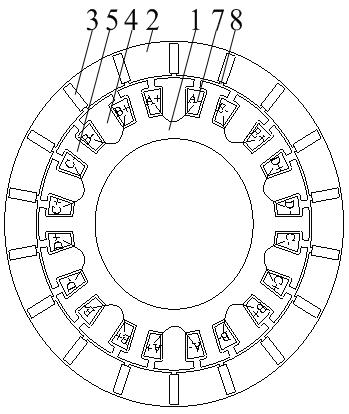

Multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine and fault-tolerance method thereof

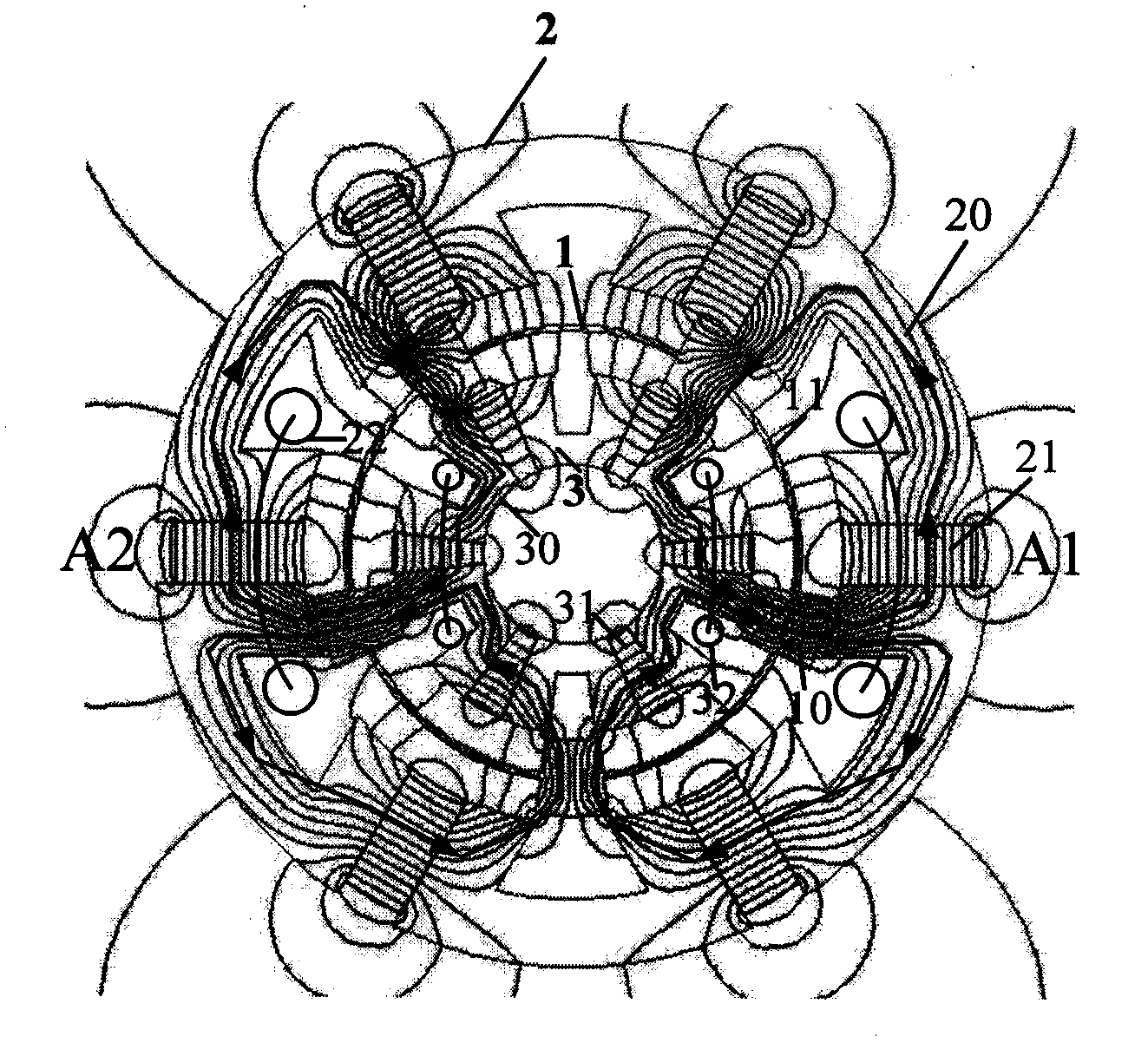

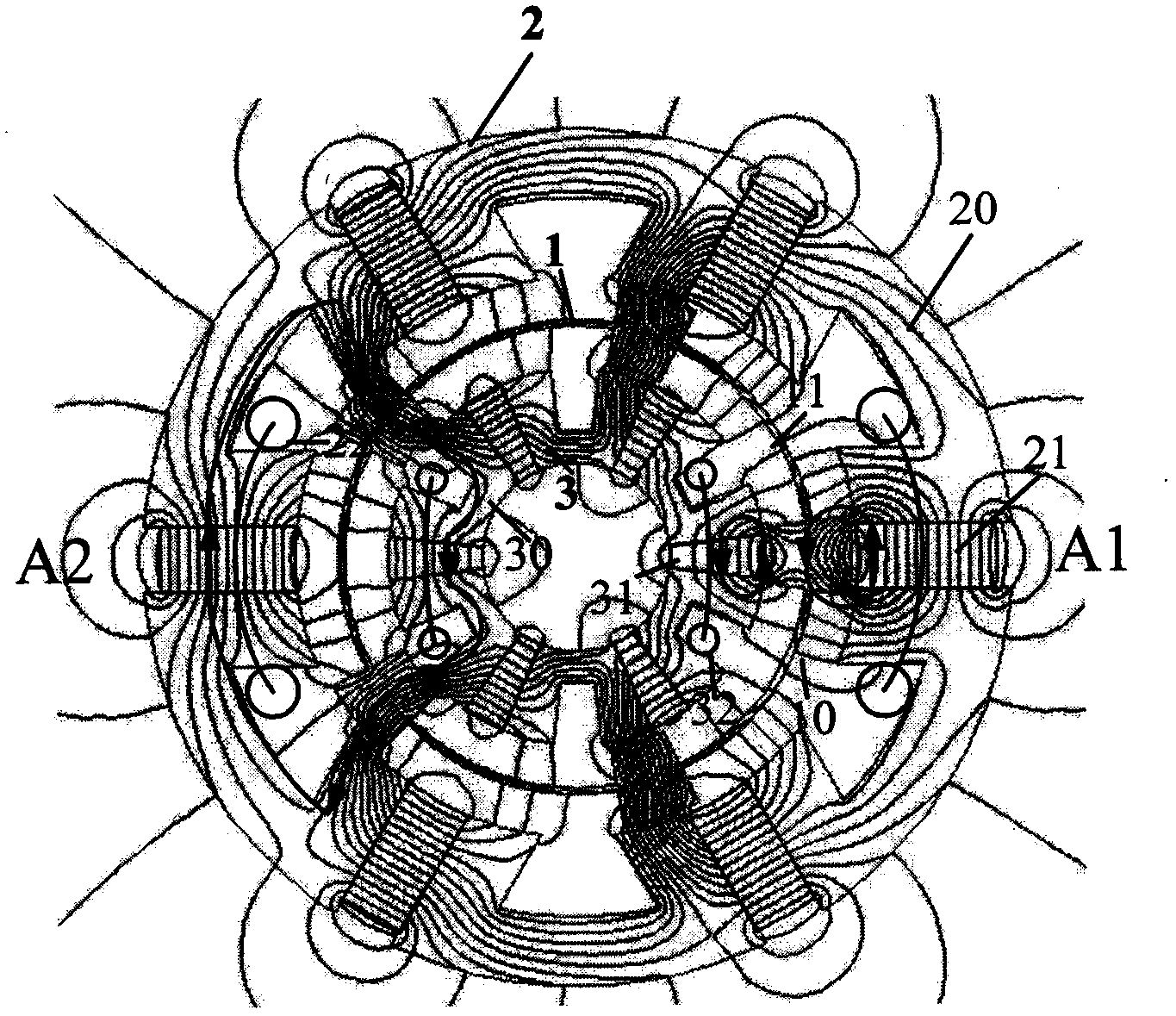

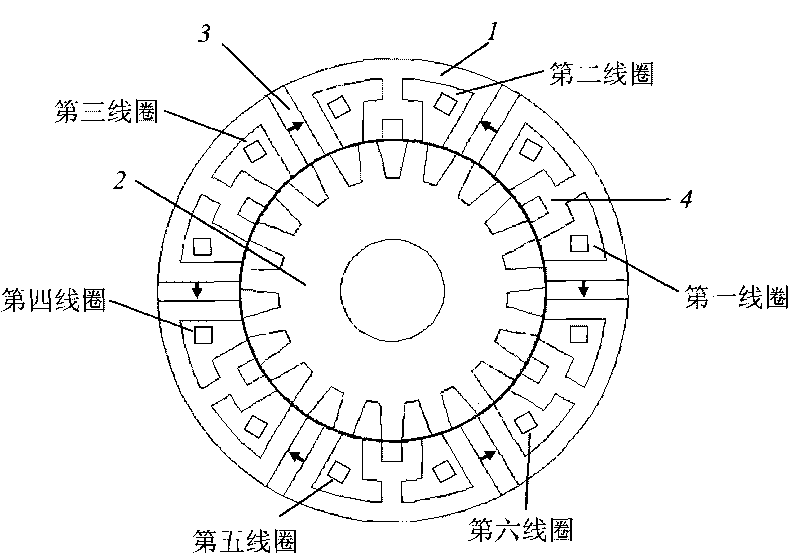

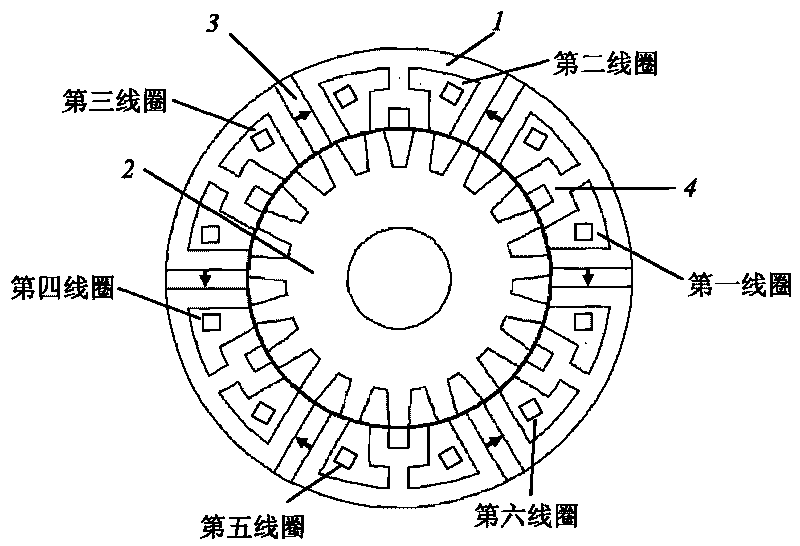

InactiveCN101697431AIncrease magnetic circuit permeabilityReduce mutual inductanceMagnetic circuit stationary partsPhysicsMagnetic flux

The invention discloses a multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine and a fault-tolerance method thereof, belonging to a permanent magnetism fault-tolerance electric machine and a method. The electric machine comprises a salient pole stator, an armature winding and a salient pole rotor. Stator salient poles are E-shaped stator iron blocks; bar-shaped permanent magnets are embedded into a gap between every two E-shaped stator iron blocks in sequence; and stator windings which are coils from a first coil to a sixth coil are wounded on two E-shaped arms connected with the bar-shaped permanent magnets. Since the method employs the multitooth fault-tolerance permanent magnetism magnetic flux switching electric machine, the self inductance of the armature winding is increased; when the multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine uses high-coercive force permanent magnets, the short circuit current if can be restrained within the rated current iL without considerably increasing the number of turns of the armature winding. The invention has high reliability; the armature magnetic field makes small impact on the permanent magnets; the multi-gear structures of the stator and the rotor of the electric machine enable the electric machine to have small mutual inductance, strong magnetism isolating capability, big electrical inductance, strong capability of restraining the short circuit current and reduced location torque.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

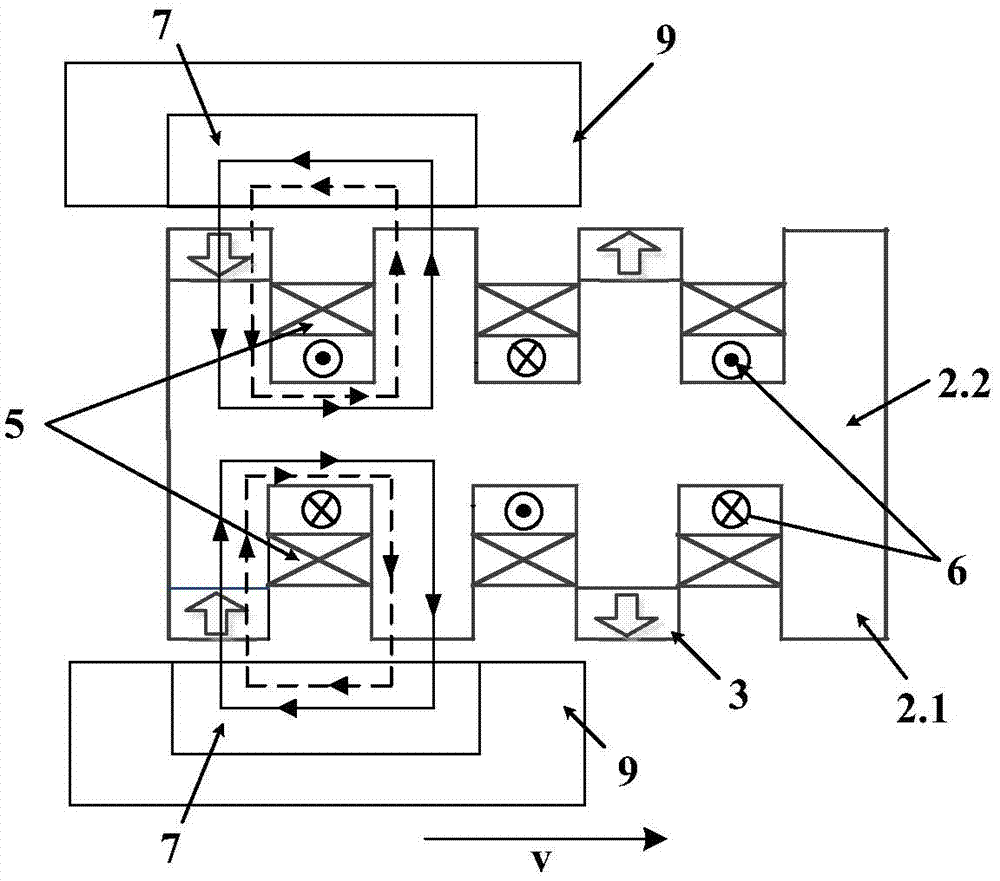

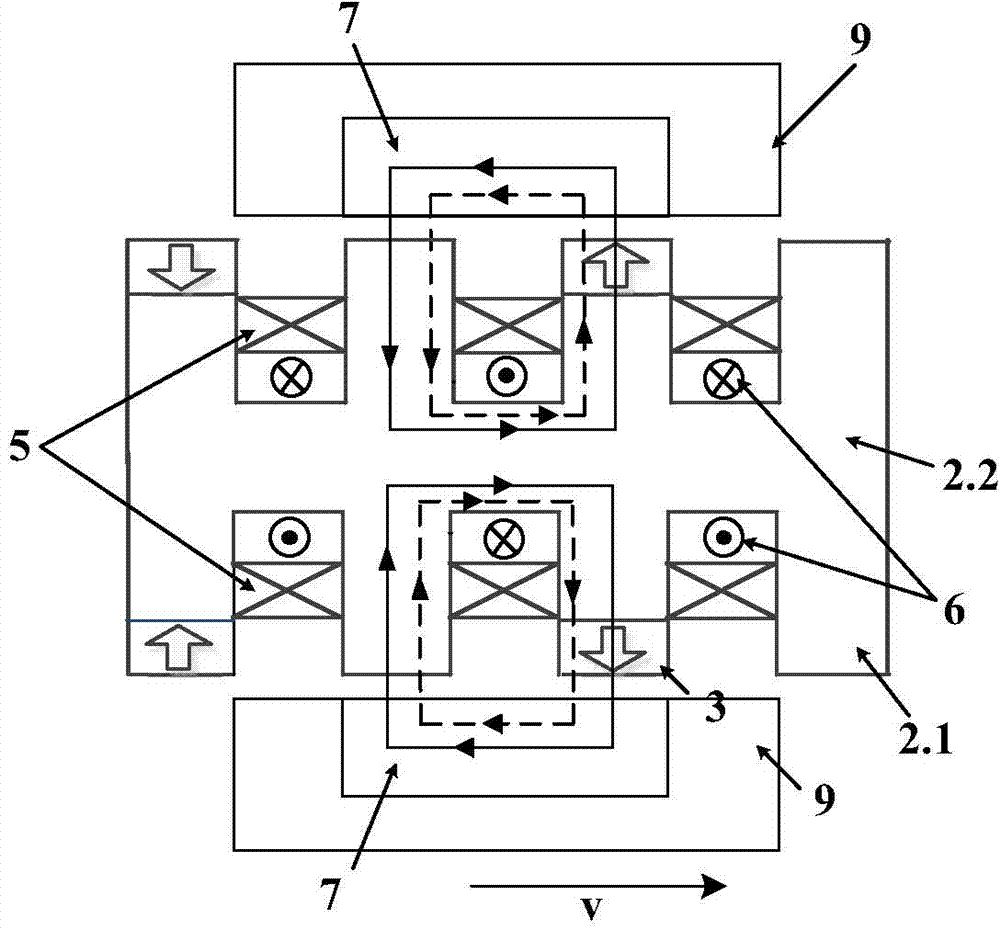

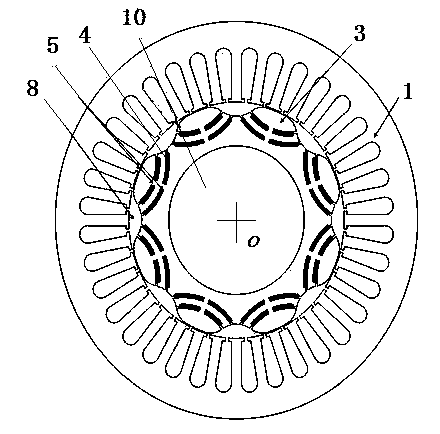

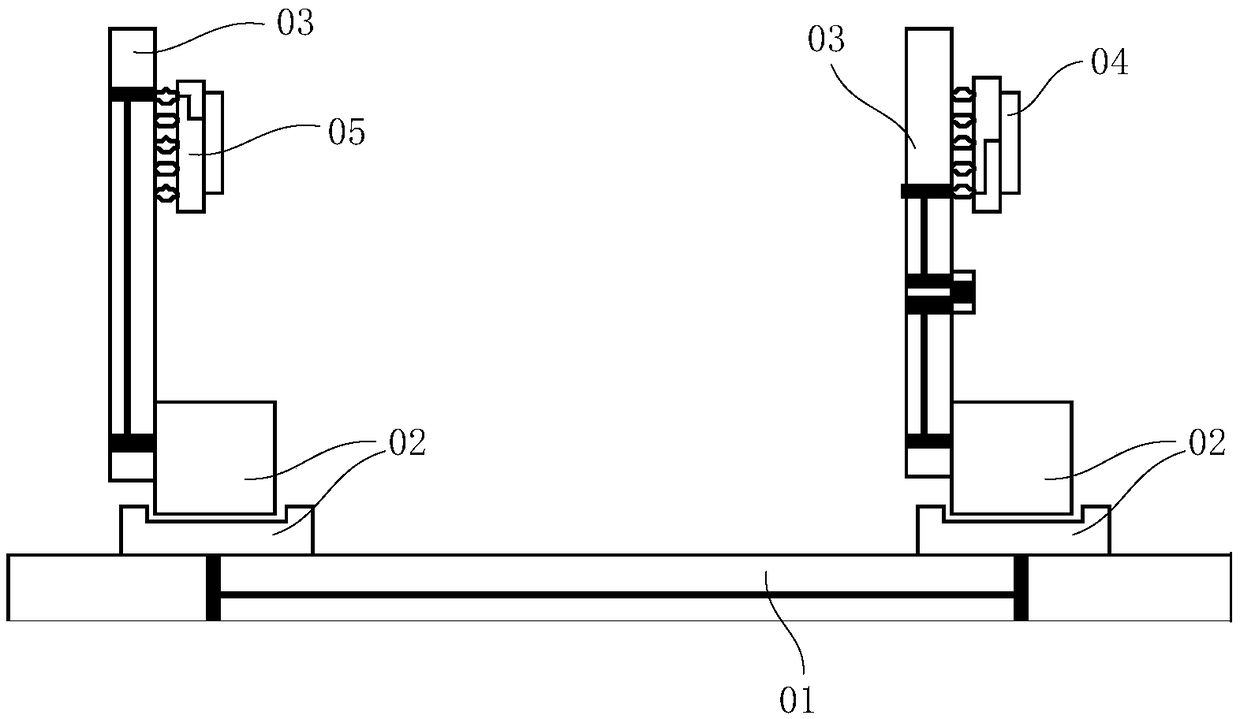

Modular vernier permanent magnetic linear motor based on Halbach permanent magnetic structure

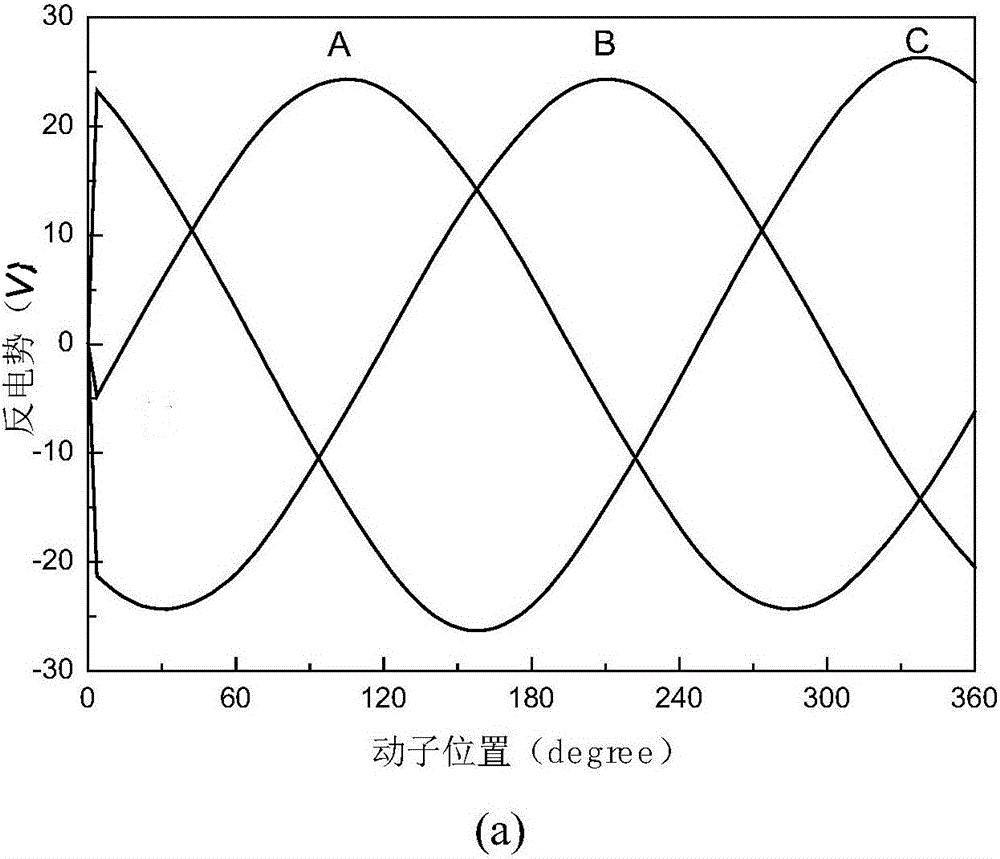

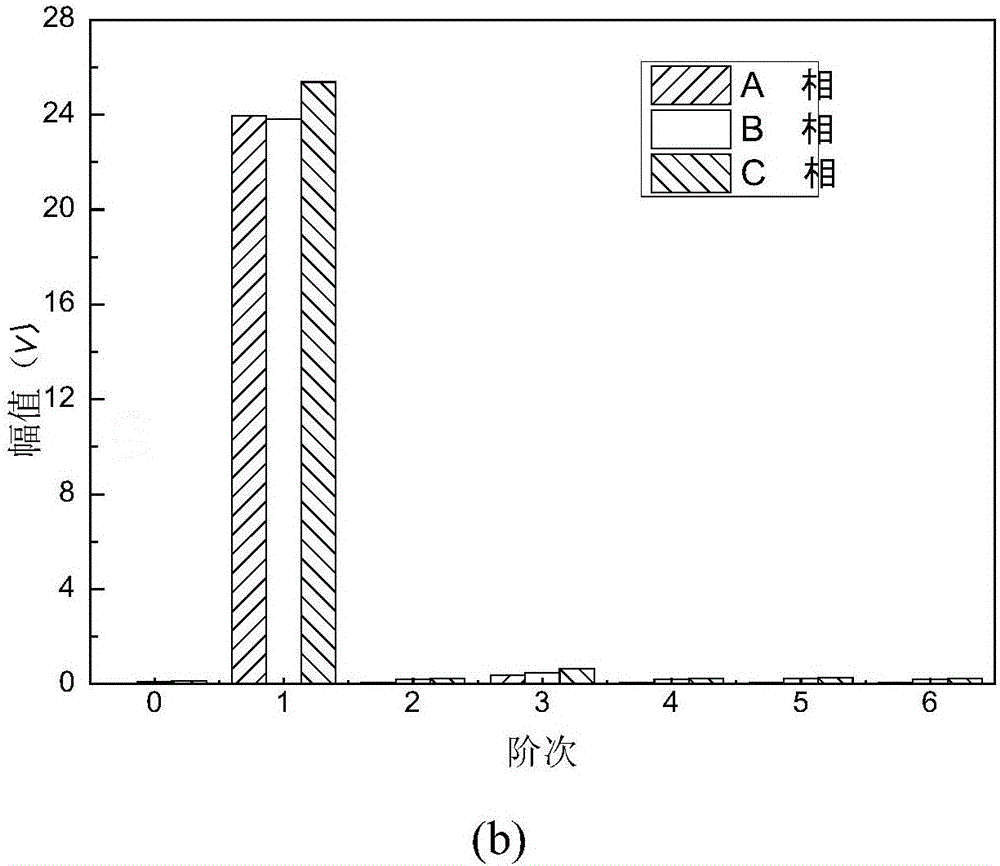

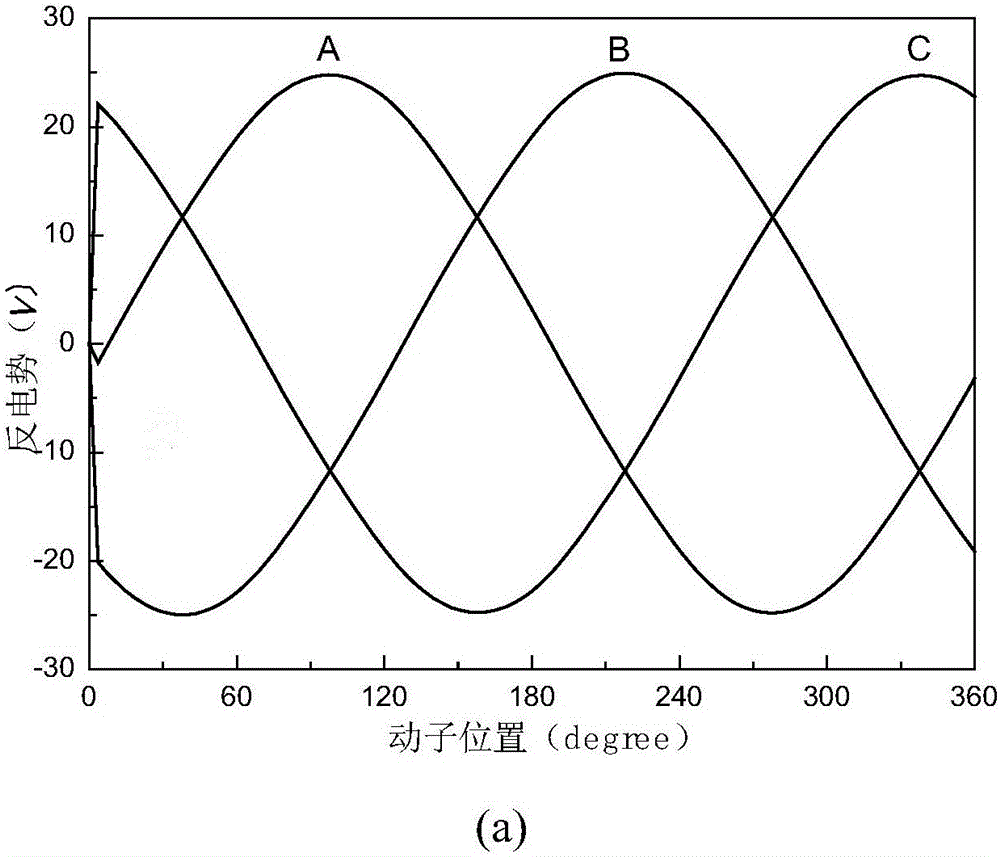

ActiveCN106411096AReduce thrust fluctuationImprove the unbalanced three-phase potential problemPropulsion systemsMagnetic barrierPhase difference

The invention discloses a modular vernier permanent magnetic linear motor based on a Halbach permanent magnetic structure. The modular vernier permanent magnetic linear motor comprises 3k mover modules and one stator, there are air gaps between the two, the stator comprises a permanent magnet which is provided with a stator core, is surface-mounted to the stator core and has a Halbach array structure, armature windings are arranged in grooves of the mover modules, positions of each phase of the armature windings in the different mover modules are different, positions of axles of the same phase of the armature windings in each module correspondingly relative to the stator permanent magnet are maintained consistent, each module can work as an individual complete vernier permanent magnetic linear motor, two adjacent mover modules are connected by use of a magnetic barrier made of a non-magnetic material, the different mover modules respectively generate push forces with certain phase differences with the stator, through modular combination of movers and variation of positions of the windings in the different modules, each phase of the windings is enabled to have a completely symmetric structure in an overall view, and thus the effect of offsetting and weakening thrust fluctuations is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for electric automobile

ActiveCN104253499AMeet high torque performance requirementsImprove driving abilityMagnetic circuit rotating partsElectric machinesMagnetic barrierBrushless motors

The invention discloses a direct-axis magnetic field enhanced type wide-range speed control permanent magnet brushless motor for an electric automobile. A magnetic barrier fills each slot of a rotor, and the magnetic barriers are symmetrical relative to a centerline, i.e., a quadrature axis, of slot parts of the rotor; four sections of arc-shaped permanent magnet steel are fixedly embedded on each tooth part of the rotor, the four sections of arc-shaped permanent magnet steel are divided into an inner layer and an outer layer, two sections are arranged on each layer, the two sections of permanent magnet steel on each layer are the same in structure and are symmetrical relative to a centerline, i.e., a direct axis of the tooth parts of the rotor, the two sections of permanent magnet steel on the same layer do not run through each other and are not connected with each other, and an arc-shaped magnetic bridge is formed between the two sections of permanent magnet steel; a circle center of each section of permanent magnet steel is located on the diameter of the rotor; the direct-axis inductance of the motor is larger than the quadrature-axis inductance, so that the motor can adopt a control method with zero direct-axis current and can also adopt a direct-axis magnetic field enhanced control method during low-speed operation or startup, and can adopt a coordinated control method of direct-axis magnetic field enhancement and slight direct-axis magnetic field weakening during high-speed operation, and the speed control range is wider.

Owner:JIANGSU UNIV

Fault-tolerant type four-phase switch reluctance motor used for driving of electric automobile

InactiveCN104821697AIncreased torque output capabilityImprove operational efficiencyMagnetic circuit rotating partsSynchronous motorsEngineeringNon magnetic

The invention discloses a fault-tolerant type four-phase switch reluctance motor used for driving of an electric automobile. A stator is composed of a stator yoke and stator teeth. The stator teeth are formed by eight wide teeth and eight narrow teeth which are distributed along the circumferential direction of the internal circle of the stator yoke in a mutually alternating way. A rotor is composed of rotor iron core blocks and a rotor sleeve. There are ten rotor iron core blocks which are evenly distributed along the circumferential direction of the external circle of the rotor sleeve and fixedly embedded in the rotor sleeve so that the cylindrical rotor is formed by the rotor iron core blocks and the rotor sleeve together. One stator winding is wound on the eight wide teeth in a concentrated way, and winding directions on the adjacent wide teeth are identical so that NNNNSSSS polar distribution is formed, and the windings on the two opposite wide teeth are forwardly connected in series into a phase. Torque output capability is enhanced under the situation that the motor is not aligned in position. The separated rotor iron core blocks are adopted to embedded in the non-magnetic-conductive rotor sleeve so that the magnetic circuit is shorter, magnetic leakage is reduced and wind resistance is low. The narrow teeth with no winding can be used as the loop of magnetic flux to realize a shorter magnetic circuit and can also be used for isolation.

Owner:JIANGSU UNIV

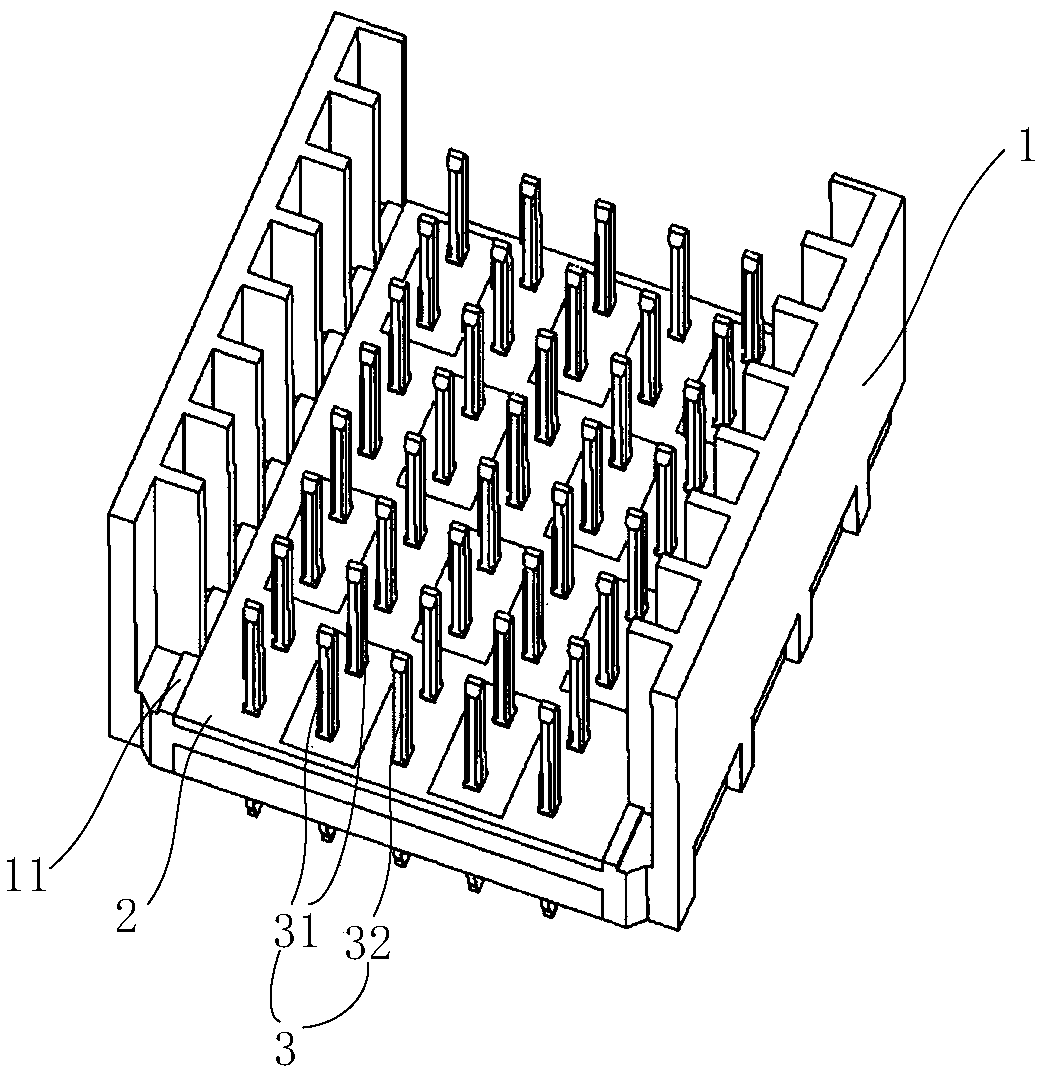

Connector and backplane interconnecting system

InactiveCN109473805AImprove shielding effectEasy to assembleSecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsDifferential signalingEngineering

The embodiment of the invention provides a connector and a backplane interconnecting system, and relates to the technical field of communication equipment. The connector comprises a connector shell, wherein the connector shell is an insulator, and comprises at least two connecting end faces; a shielding member is disposed at least one connecting end surface, wherein the shielding member has conductivity, and a plurality of isolation holes and a plurality of connecting holes are configured on the shielding member; the connector further comprises a plurality of plug-in terminals; the plurality of plug-in terminals include signal terminals for transmitting signals and ground terminals for grounding; one or more adjacent signal terminals constitute a signal terminal group; a plurality of signal terminal groups are used for transmitting different electrical network signals or different differential signals; the plurality of signal terminal groups penetrate through the plurality of isolationholes in a one-to-one correspondence mode, and the signal terminals in the signal terminal groups are not in contact with the hole walls of the corresponding isolation holes; and the plurality of ground terminals penetrate through the connecting holes in a one-to-one correspondence mode, and the ground terminals at least are partially in contact and conductive with the hole walls of the connecting holes.

Owner:HUAWEI TECH CO LTD

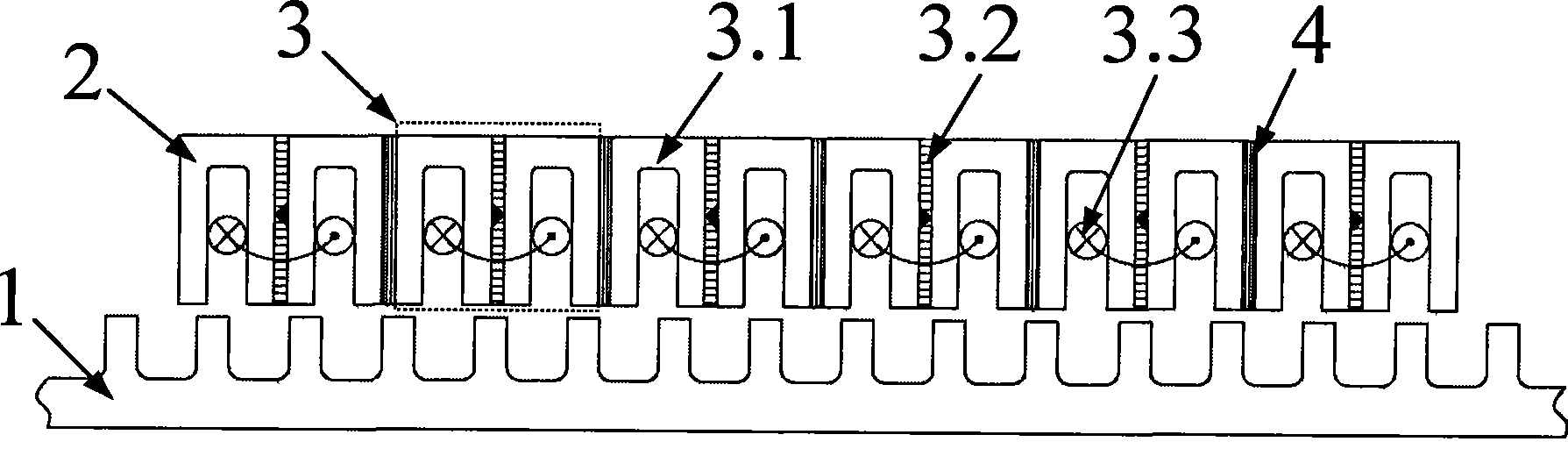

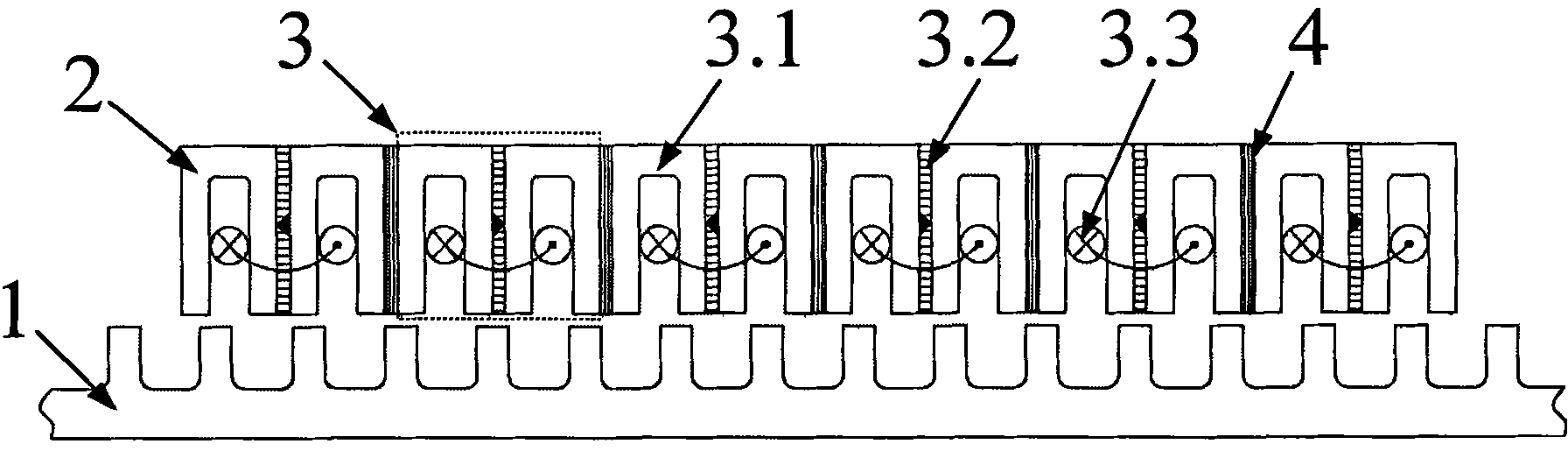

Modularization error-tolerance type permanent magnet switch magnetic linkage straight line motor

The invention discloses a modularized fault-tolerance type permanent-magnet switched magnetic linkage linear motor, comprising a stator and a mover, wherein the stator is a flat plate or a cylinder formed by a toothed groove type iron core, the mover is a flat plate or a cylinder formed by a plurality of modules and reluctance pieces which are arranged at intervals, each module comprises two reversed U-shaped iron cores, a permanent magnet clamped between the two U-shaped iron cores, and a three-phase armature winding, armature teeth are formed on the sides of the two U-shaped iron core for clamping the permanent magnet, auxiliary teeth are formed on the sides of the two U-shaped iron core sides for clamping the reluctance piece, the three-phase armature winding is wound on the armature teeth, the auxiliary teeth are not wound with a winding, and N poles and S poles of adjacent modules are arranged at intervals. In the linear motor, the coil and the permanent magnet are arranged on the mover part, the stator part only consists of an iron core lamination at low cost and is particularly suitable for a long-distance linear motion drive system; in addition, the modularized design brings convenience to the assembly and is easy to implement the large-scale production.

Owner:ZHEJIANG UNIV

Five-phase permanent magnet fault-tolerant motor with magnetic congregating effect for electric vehicle

InactiveCN102130559AEffective combinationImprove reliabilityMagnetic circuit rotating partsElectric machinesElectric machineElectric vehicle

The invention discloses a five-phase permanent magnet fault-tolerant motor with a magnetic congregating effect for an electric vehicle. An outer rotor is arranged on a stator outer ring, armature teeth and fault-tolerant teeth are uniformly distributed at intervals along the circumferential direction of the stator outer ring, permanent magnets are uniformly and radially embedded in the direction of the circumference in the outer rotor, a single-layer concentrated winding is wound on the armature teeth, radially opposite dipolar single-layer concentrated windings are serially connected to form one phase; total tooth quantity of the armature teeth and the fault-tolerant teeth is a multiple of 10 and is not equal to the quantity of permanent magnets, and the difference of the total tooth quantity of the armature teeth and the fault-tolerant teeth does not exceed + / -4; rotor grooves with same quantity as the permanent magnets are arranged on the outer rotor and positioned between each of the permanent magnets and the stator; and the width of the armature teeth is two times of that of the fault-tolerant teeth. The flux leakage of the permanent magnets is reduced while a magnetic-gathering effect is generated, the consumption of the permanent magnets is reduced, the motor cost is saved, the motor weight is reduced, and the reliability and the failure operation capacity of the motor is improved.

Owner:JIANGSU UNIV

Novel high torque density high power factor fault tolerant permanent magnet vernier machine and its modulation method

ActiveCN105958762AImprove winding factorImprove torque performanceElectronic commutation motor controlMagnetic circuit rotating partsHigh torquePower factor

The invention discloses a novel high torque density high power factor fault tolerant permanent magnet vernier machine and its modulation method. The vernier machine structure comprises a coaxial stator, an inner rotor and an outer rotor, wherein the permanent magnets of the inner rotor are distributed in a radial arrangement with their magnetization directions being tangential and their N poles and the S poles arranged in alternation. The permanent magnets of the outer rotor are arranged in a face embedding manner with their magnetization directions pointing to the center of circle. Ten smaller fault-tolerant teeth and ten bigger armature teeth are alternately arranged on the stator. The tops of each fault-tolerant tooth and the armature tooth are provided with a virtual slot, forming two virtual teeth. The armature windings adopt a single-layer concentrated winding manner in their winding. The invention utilizes the combination of a vernier machine, a magnetic gear and a fault-tolerant performance to further increase the motor torque outputting capacity on the basis of the vernier machine to achieve a more efficient utilization of the motor. This motor, with fault-tolerant performance, is ensured to provide reliable operations. Structured with a magnetic gear, the vernier machine can greatly enhance the motor power factor. The invention can increase the reliability of the motor operation and has great application prospects.

Owner:JIANGSU UNIV

E-shaped stator core flux switching type hybrid permanent magnet memory motor

InactiveCN104410180ASimple structureStable structureMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses an E-shaped stator core flux switching type hybrid permanent magnet memory motor and belongs to the field of flux-adjustable permanent magnet motors. Both rotor and stator cores of the motor adopt a salient pole structure. A stator of the motor comprises six E-shaped stator cores, V-shaped aluminum-nickel-cobalt permanent magnets, tangential-magnetizing rectangular neodymium iron boron permanent magnets and a whole layer of stator yokes, wherein adjacent neodymium iron boron permanent magnets with opposite polarities are inlaid between the two adjacent E-shaped stator cores, and a three-phase concentrated winding armature winding is wound across a sandwich-shaped unit composed of the core edges of adjacent E-shaped stator units and the neodymium iron boron permanent magnets; a groove between two adjacent V-shaped aluminum-nickel-cobalt permanent magnets is used for placing a concentrated single-phase pulse winding. The E-shaped stator core flux switching type hybrid permanent magnet memory motor greatly alleviates a space conflict between electromagnetic loading in the stator cores and pulse magnet-adjustment capacity, can realize flexible online magnet adjustment and has little loss of excitation, the torque density and the force and energy expression of the motor can be improved, and the fault-tolerant fault operation ability is good.

Owner:SOUTHEAST UNIV

Double-speed winding switch reluctance motor

ActiveCN103166337AWide speed rangeReduce the number of turnsMagnetic circuit stationary partsWindings conductor shape/form/constructionLow speedEngineering

Owner:SOUTHEAST UNIV

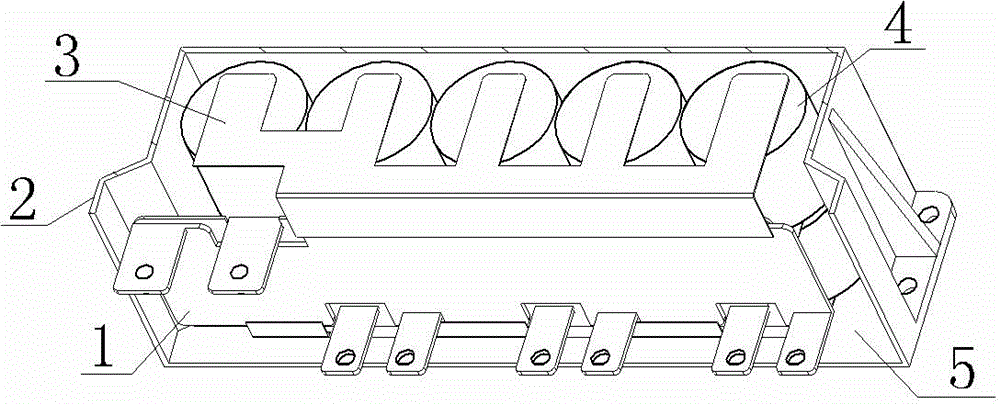

Thin-film capacitor for automobile

ActiveCN104934223ASmall ESRESL smallThin/thick film capacitorStacked capacitorsCapacitanceElectricity

The invention relates to the field of a new-energy electric automobile, in particular to a thin-film capacitor for an automobile. By the thin-film capacitor, a capacitor technological level can be enhanced, volume can be reduced, moreover, high-frequency induction eddy current can be effectively shielded due to electrical performance, current trend is reasonably distributed, the capacitor reaches minimum equivalent series resistance (ESR) and equivalent series inductance (ESL), the heating of the capacitor is greatly reduced, the heat dissipation capability of the capacitor is improved, and thus, a product possesses excellent performance and is more safe and reliable. The thin-film capacitor comprises a shell and is characterized in that a leading-out end composite copper bar is arranged in the shell, the leading-out end composite copper bar comprises an upper-layer copper bar, an intermediate insulation plate and a lower-layer copper bar, one end of a capacitor core is connected with the upper-layer copper bar via a welding copper plate, and the other end of the capacitor core is connected with the lower-layer copper bar via a welding copper plate.

Owner:WUXI CHENRUI NEW ENERGY TECH

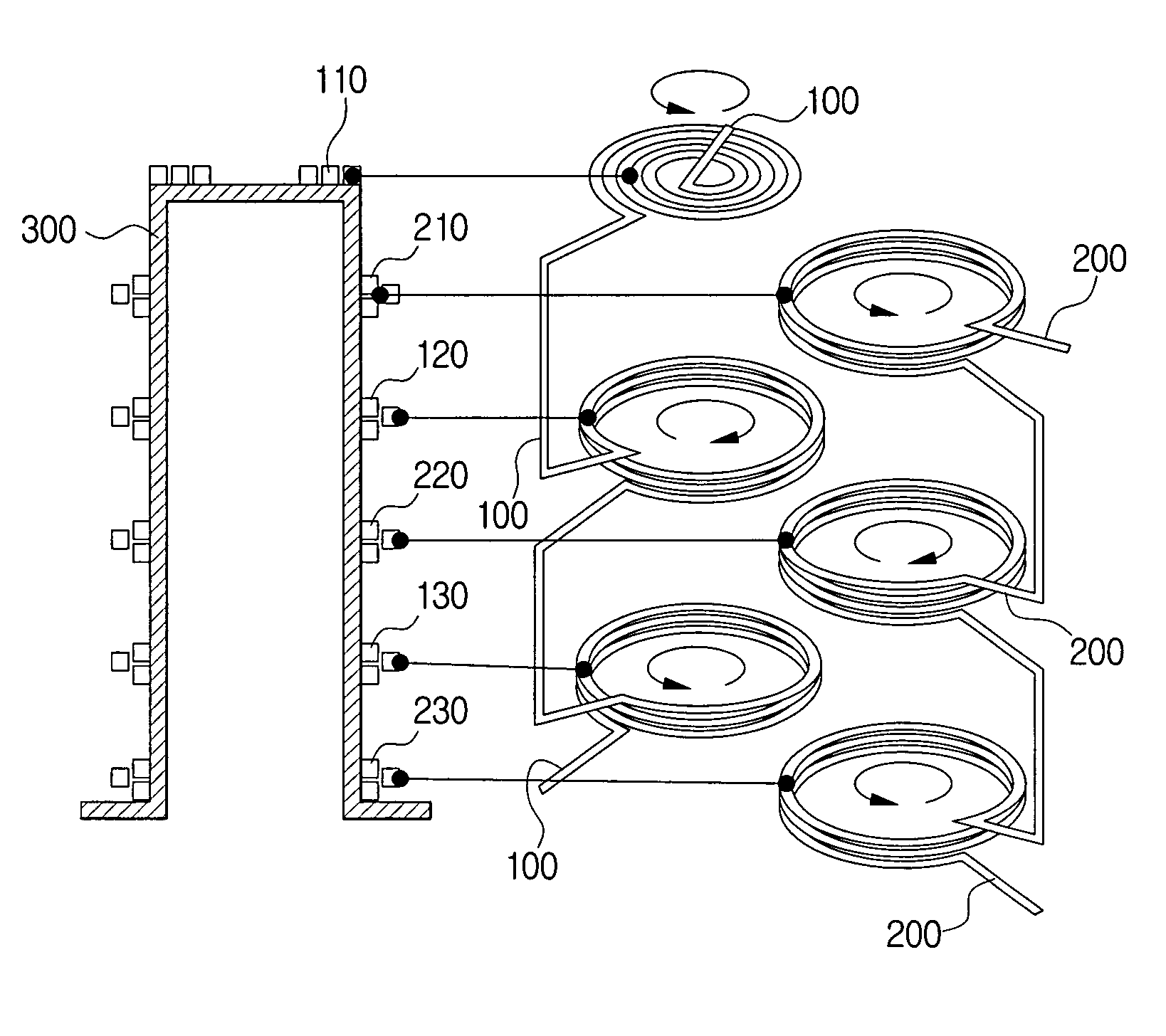

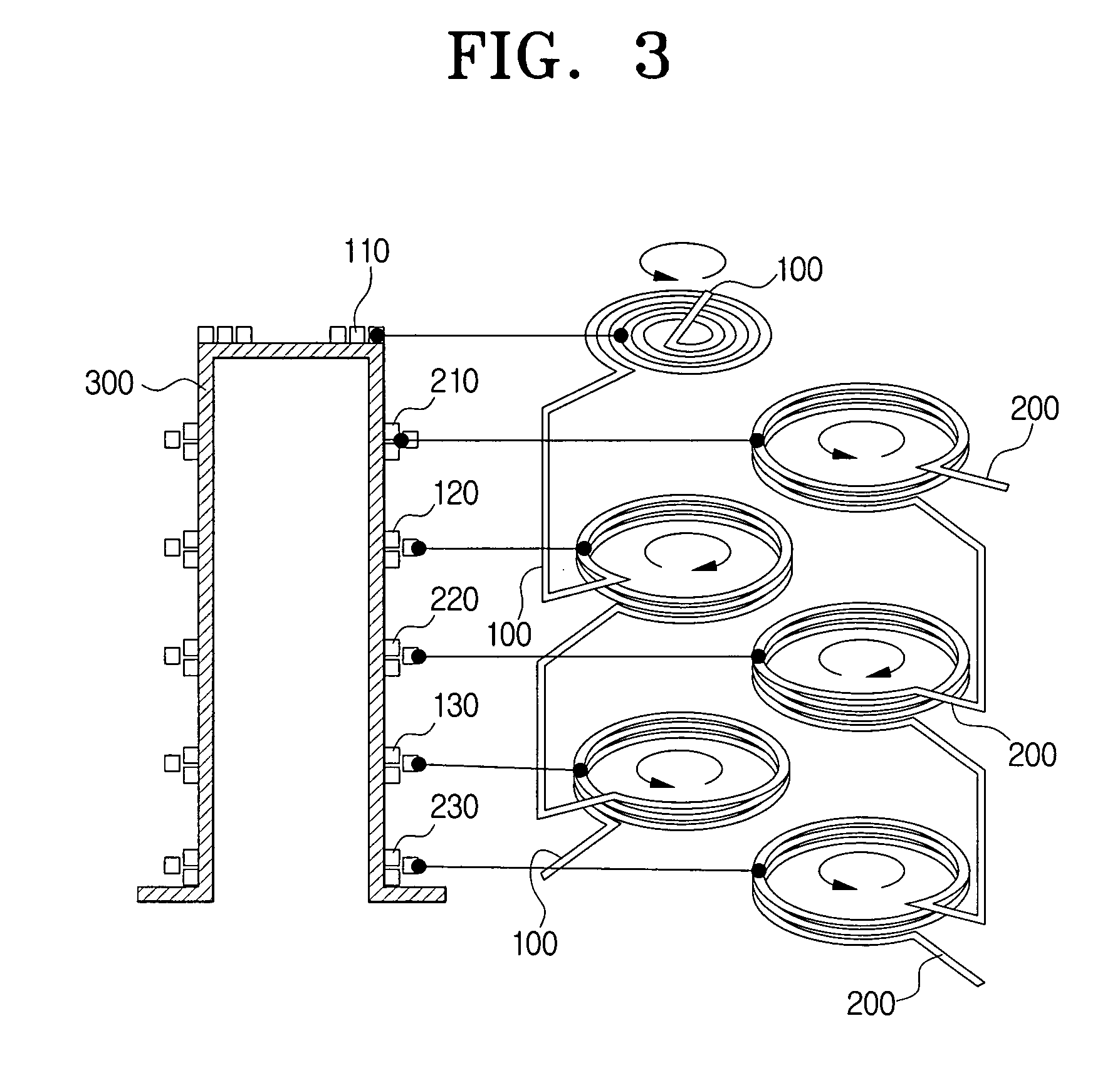

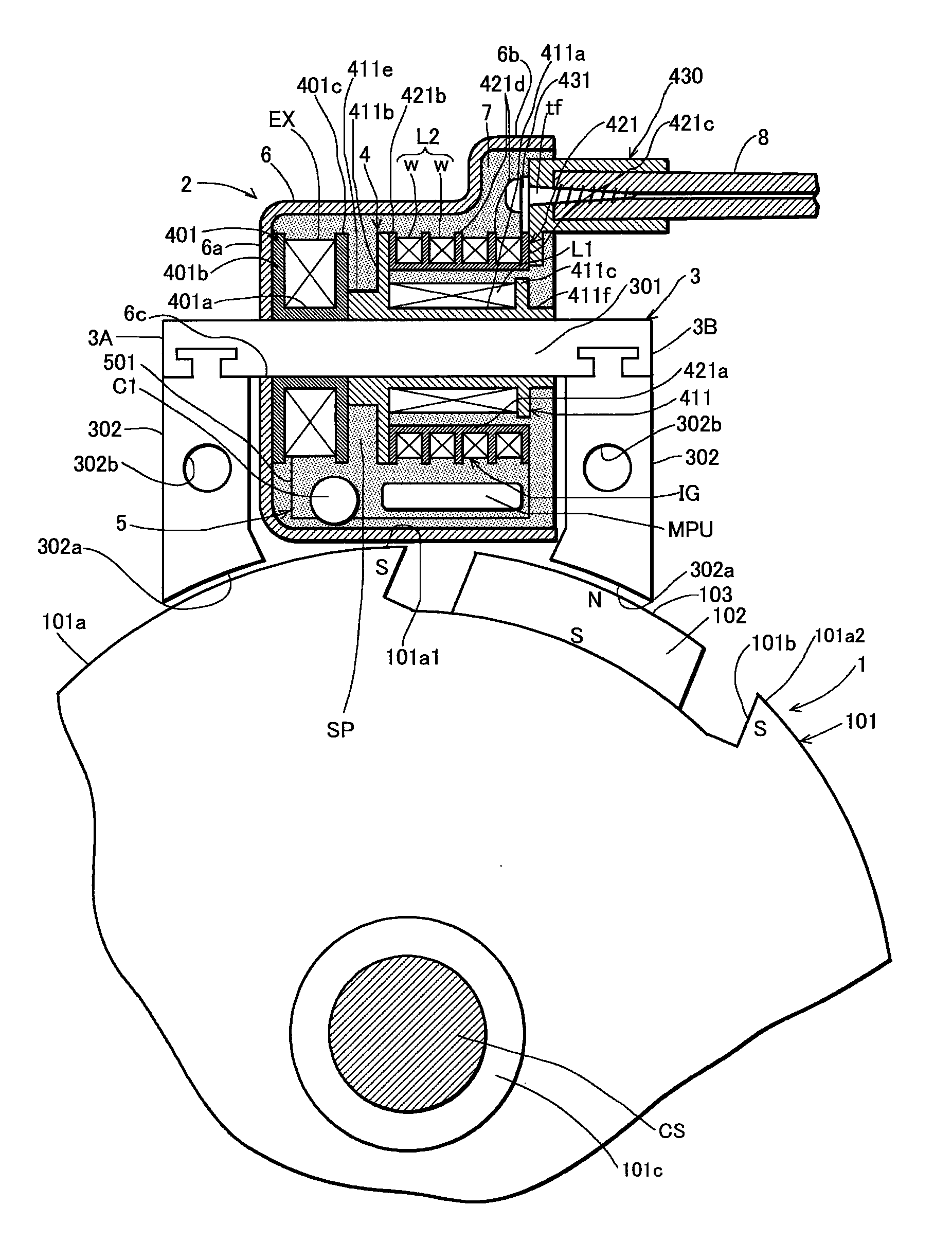

Plasma accelerator

ActiveUS7355357B2Reduce mutual inductanceAccurately differenceSemiconductor/solid-state device manufacturingLinear acceleratorsPlasma accelerationPhase difference

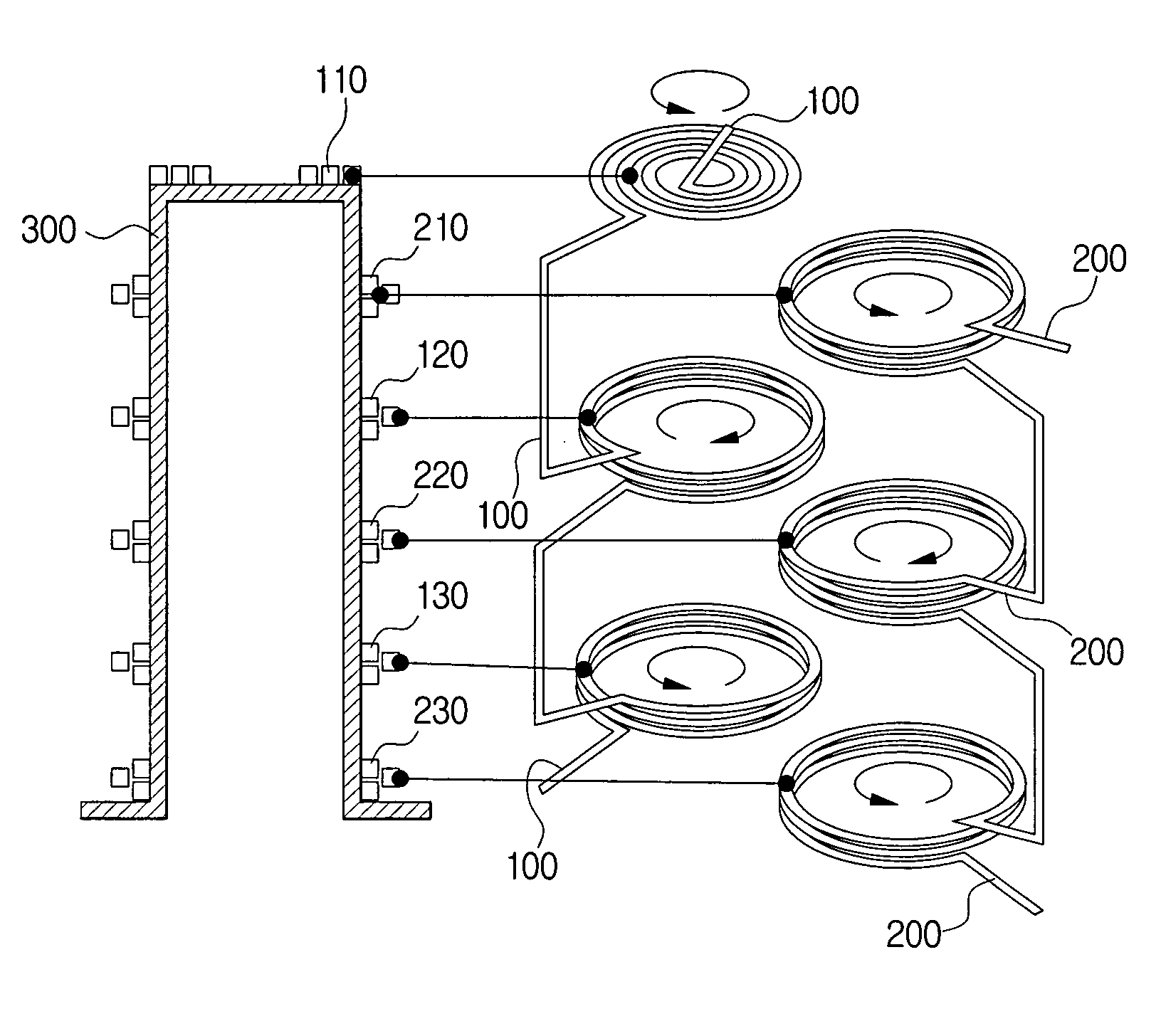

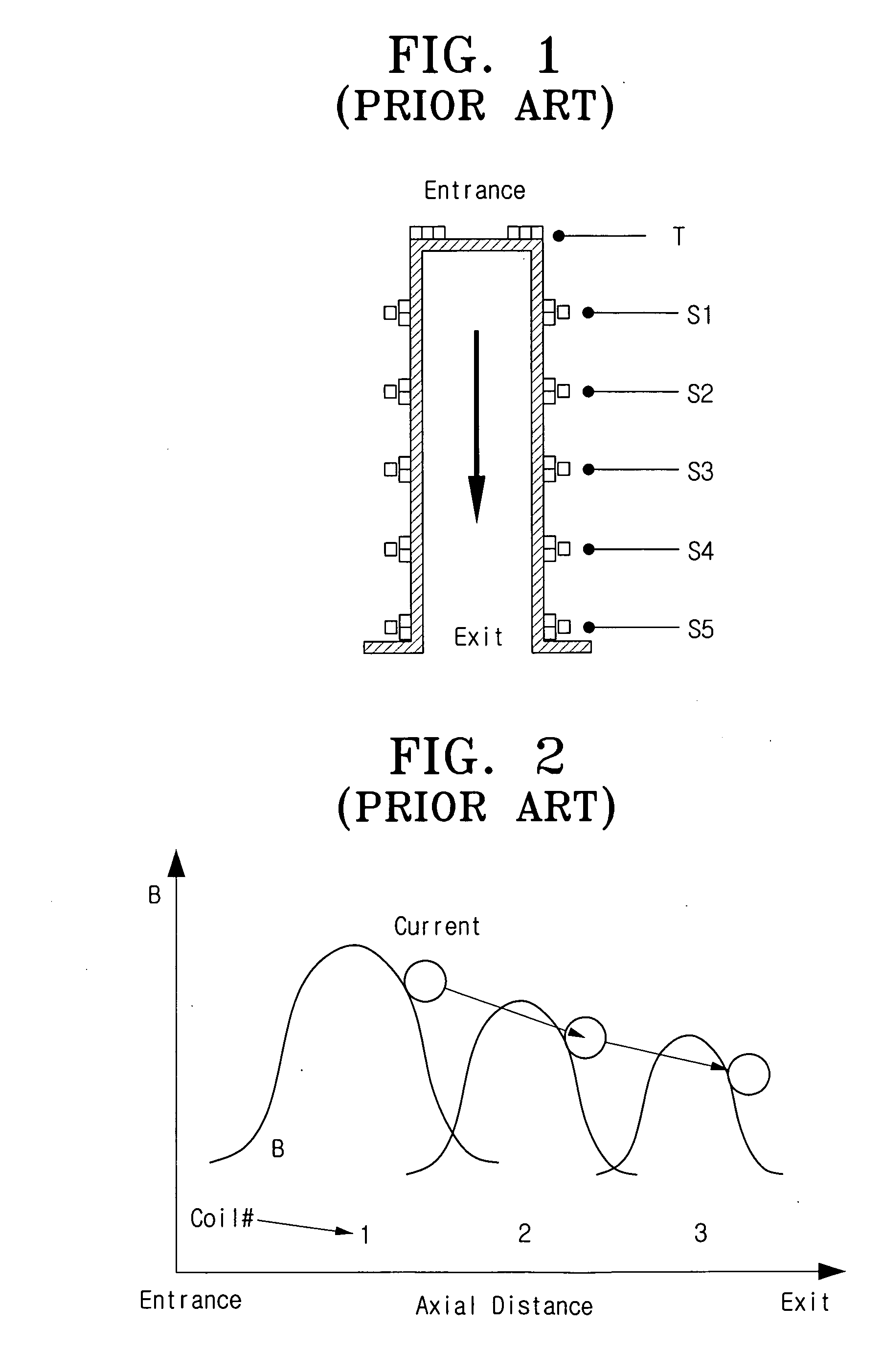

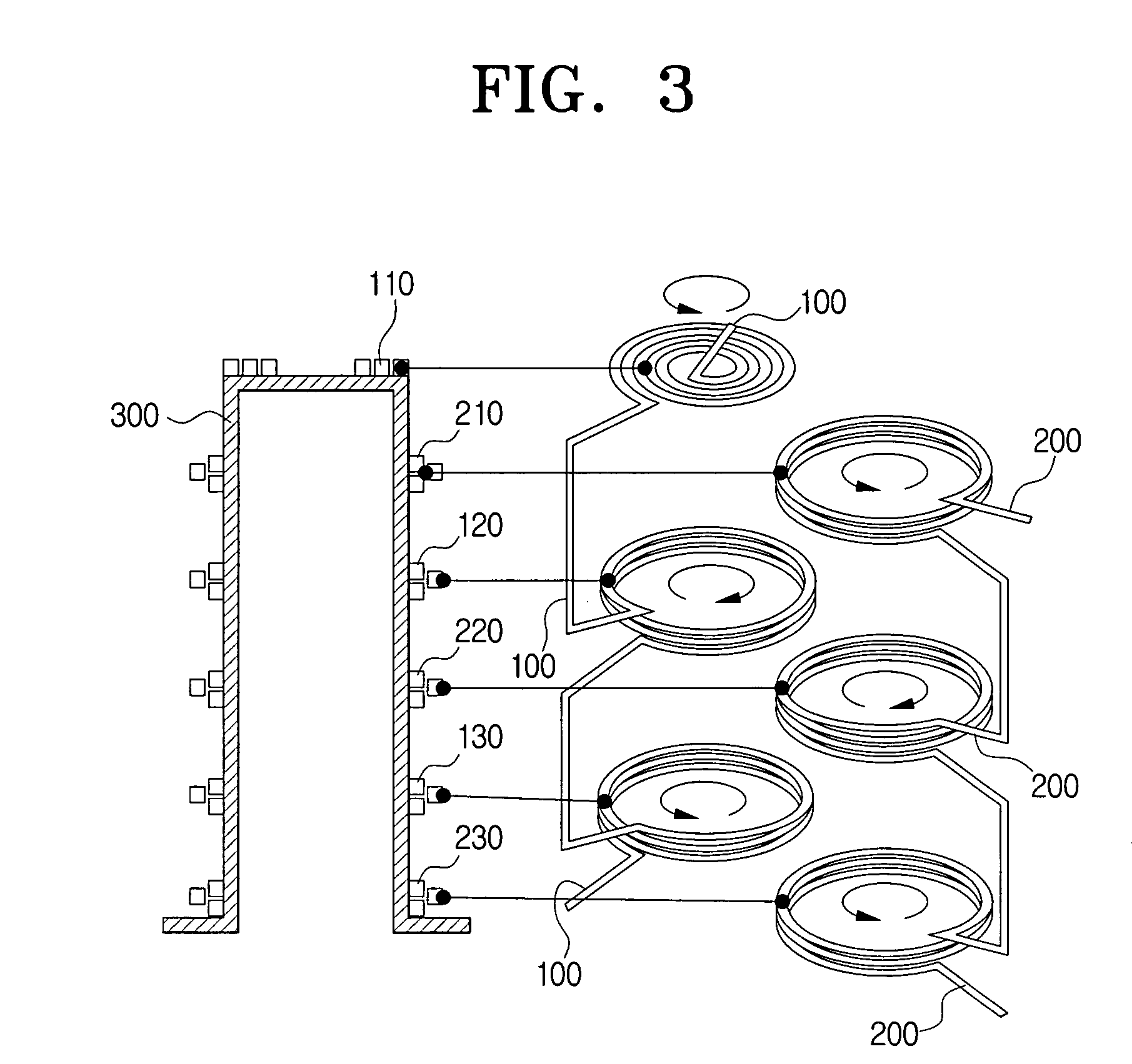

A plasma accelerator is provided. The plasma accelerator includes a chamber having a closed top, an opened bottom and a lateral surface, a first coil section comprising a plurality of coils that are connected to one another in series and are wound around the lateral surface of the chamber in opposite directions, and a second coil section comprising a plurality of coils that are wound around the lateral surface of the chamber between coils of the first coil section in opposite directions. Accordingly, it is possible to make the mutual inductance between the coils small, to accurately adjust levels and phase differences of currents to be applied to the coils, and also to simplify the driving circuit.

Owner:SAMSUNG ELECTRONICS CO LTD

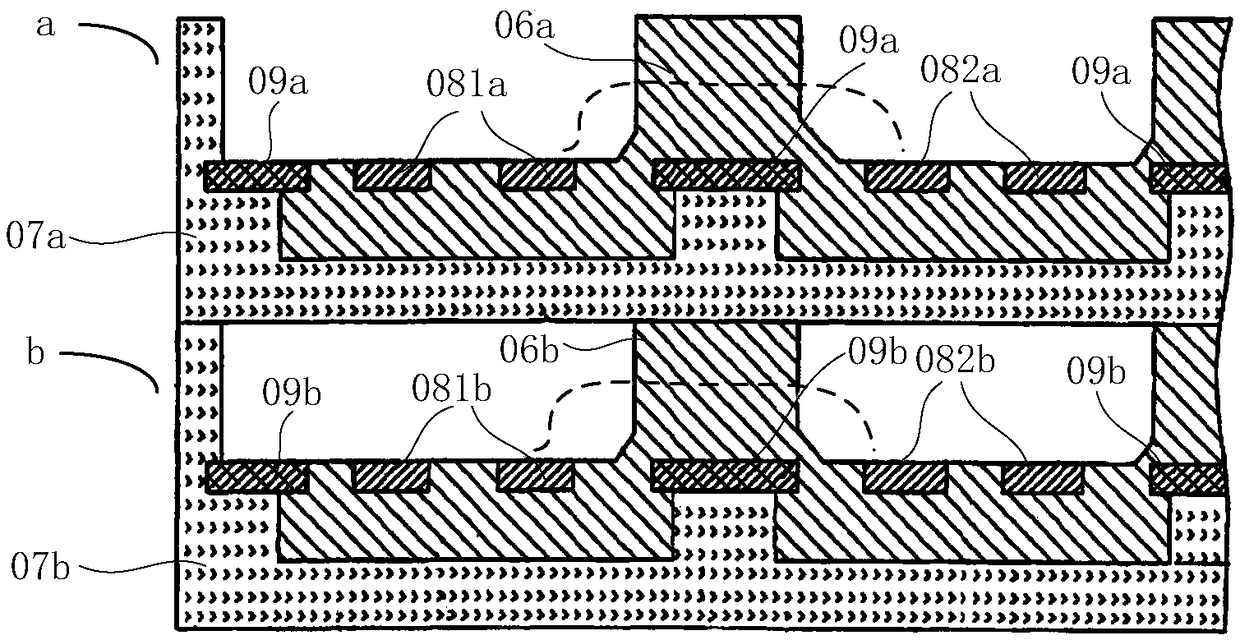

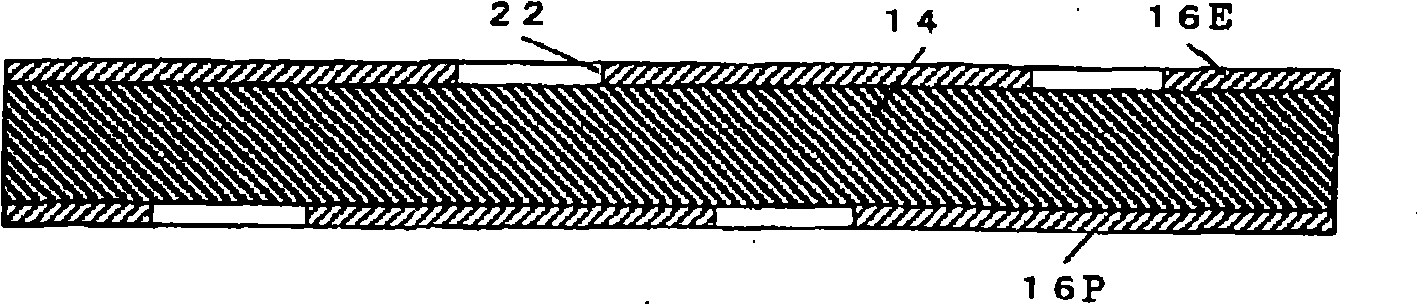

Multilayer printed wiring board

ActiveCN101278392ASuppression delayReduce mutual inductanceSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringSemiconductor components

A multilayer printed wiring board has a mounting section for mounting a semiconductor element such as an IC chip on a surface layer of a build up wiring layer. The pitch of a through hole conductors arranged in regions directly below regions whereupon semiconductor elements such as IC chips are mounted is permitted to be smaller than that of through hole conductors arranged in other regions. Thus, delay of power supply to the transistor of the processor core section of the mounted IC chip is suppressed and malfunctioning is prevented from being easily generated.

Owner:IBIDEN CO LTD

Fault-tolerant type single-winding bearing-less permanent magnet motor

InactiveCN103929035ACompact structureShort endsMagnetic holding devicesSynchronous machines with stationary armatures and rotating magnetsShortest distancePermanent magnet motor

The invention discloses a fault-tolerant type single-winding bearing-less permanent magnet motor. A stator magnet yoke is in a cylinder shape and is placed on the outermost portion of the permanent magnet motor. A rotating shaft and the stator magnet yoke are coaxial, the rotating shaft is placed in the middle in the stator magnet yoke, a rotor iron core coaxial with the rotating shaft is fixed on the outer periphery surface of the rotating shaft, and a plurality of permanent magnets which are evenly distributed on the outer surface of the rotor iron core in a Halbach array structure to form a cylinder shape are fixed on the outer periphery surface of the rotating shaft. Six armature teeth and six fault-tolerant teeth which are arranged in an alternating mode in the periphery direction are fixed evenly on the inner periphery face of the stator magnet yoke. Each armature tooth is provided with a set of an armature winding which generates torque and radial suspension force at the same time in a winding mode. Each set of armature winding is of a concentrating short-distance winding structure. Each phase control current is formed by overlapping of a torque winding control current component and a suspension force winding control current component. According to the fault-tolerant type single-winding bearing-less permanent magnet motor, only one set of armature winding is needed, the structure is simple, motor weight is lowered, and the suspension operation capacity with fault of the motor is improved.

Owner:JIANGSU UNIV

Plasma accelerator

ActiveUS20070068457A1Reduce mutual inductanceAccurately differenceSemiconductor/solid-state device manufacturingLinear acceleratorsInductanceAcoustics

Owner:SAMSUNG ELECTRONICS CO LTD

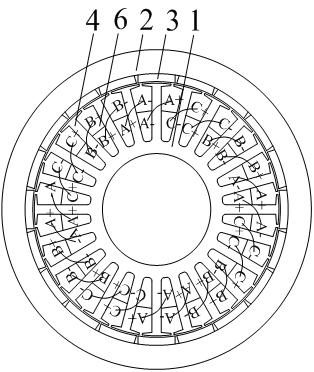

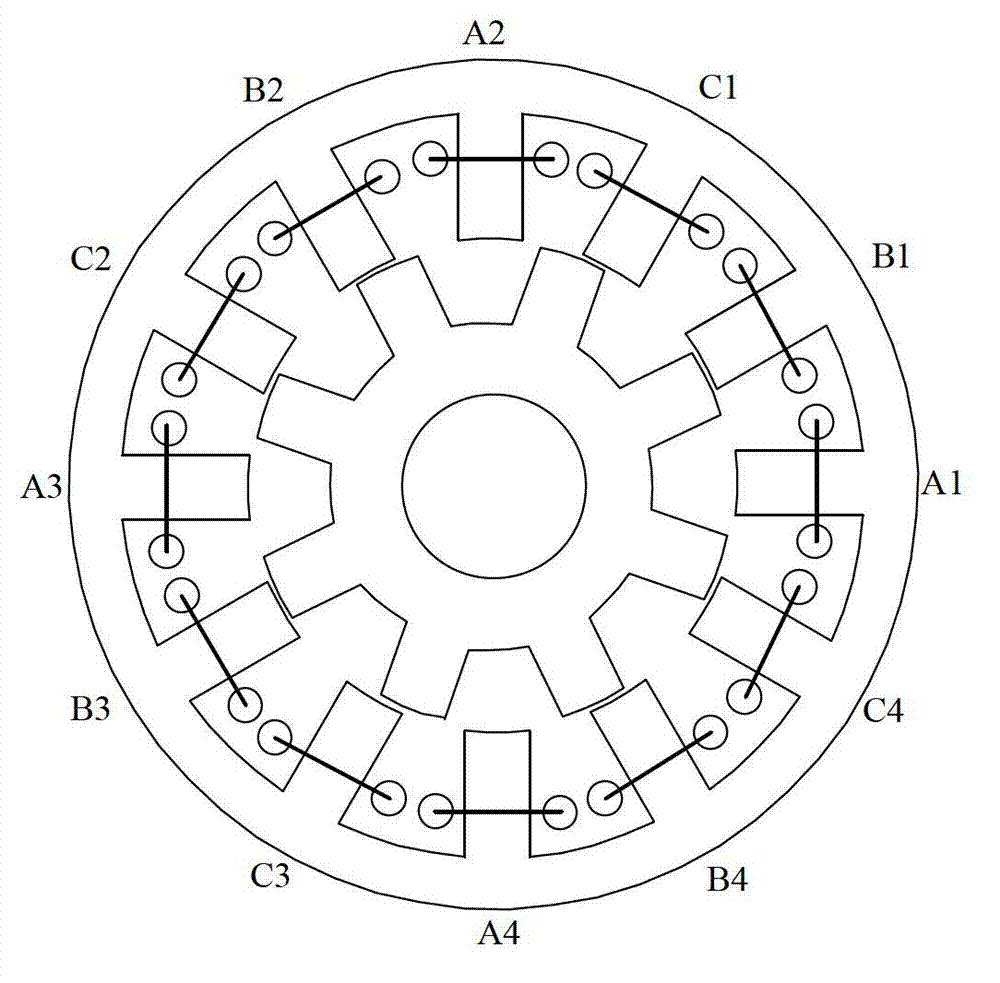

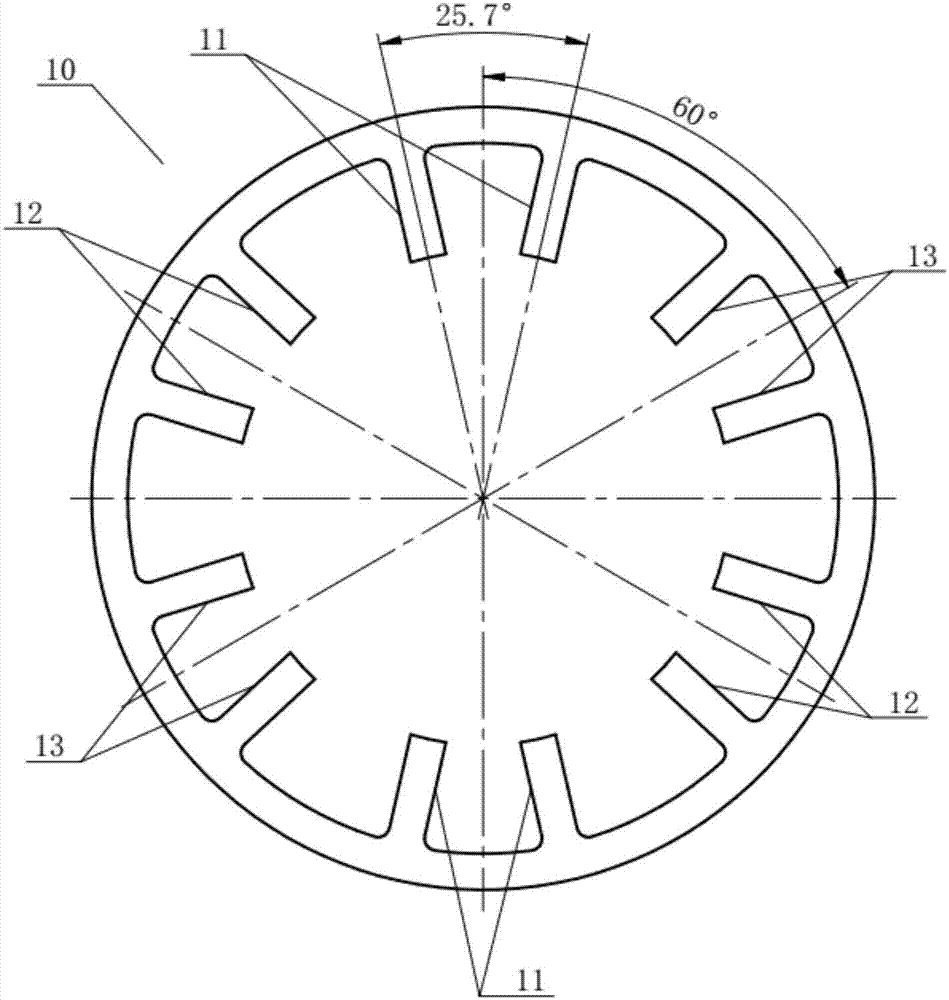

Stator iron core with all phases of salient poles in concentrated arrangement and motor with all phases of salient poles in concentrated arrangement

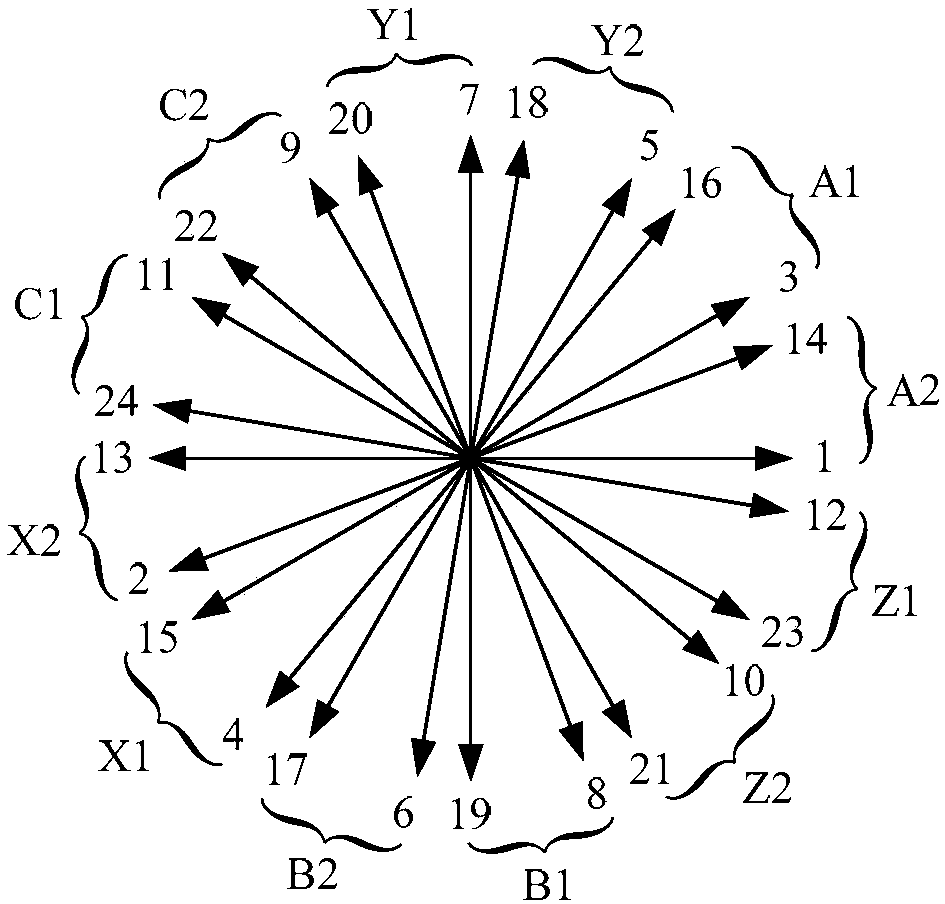

InactiveCN107171459ASimplifies the work of split-phase wiringReduce mutual inductanceMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

The invention discloses a stator iron core with all phases of salient poles in concentrated arrangement and a motor with all phases of salient poles in concentrated arrangement, which belongs to the motor field. The salient poles of the stator iron core are arranged in q-phase n groups. Each group has z salient poles in each phase, and z salient poles are in adjacent concentrated arrangement. q, n and z are natural numbers. q is equal to or greater than 2. z is equal to or greater than 2. The salient poles are arranged in the circumferential direction of the stator iron core in the order of the first group of salient poles, the second group of salient poles, ..., and the n-th group of salient poles. The salient poles in each group are arranged in the order of the first phase salient pole, the second phase salient pole, ..., and the q-th phase salient pole. The motor is a motor using the stator iron core with all phases of salient poles in concentrated arrangement. According to the invention, all phases of salient poles in the stator iron core are in concentrated arrangement, which can simplify the operation of the split-phase wiring and reduce interphase mutual inductance.

Owner:SHENZHEN HUAYIN POWER TECH CO LTD

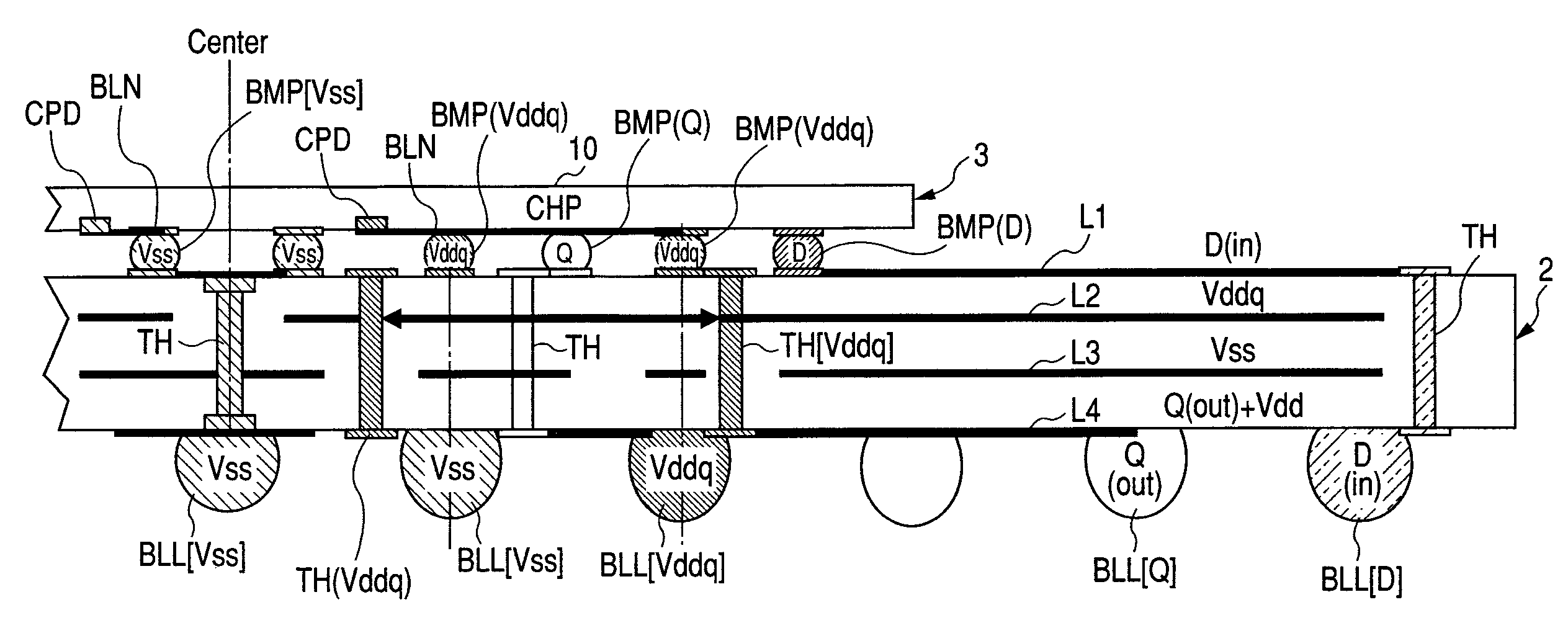

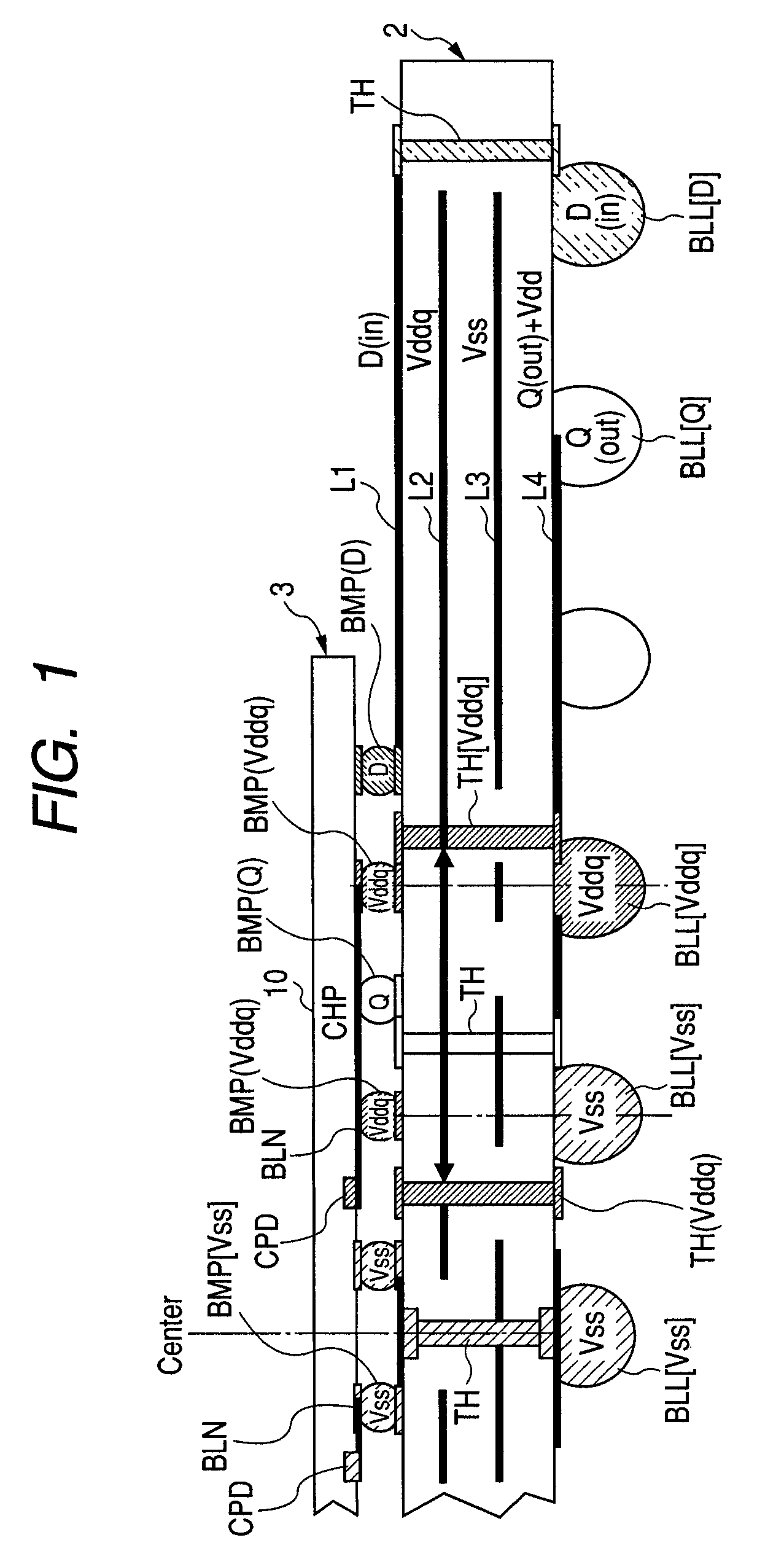

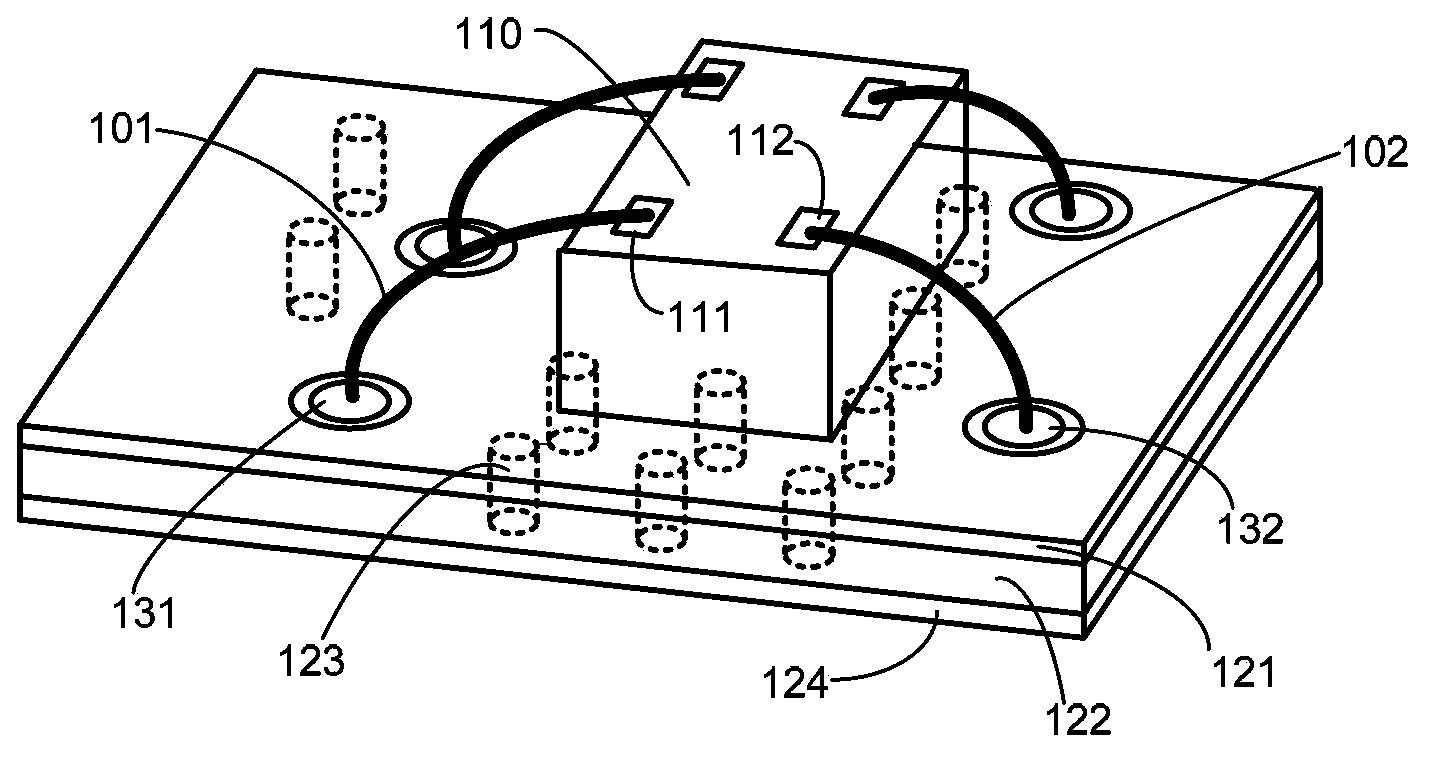

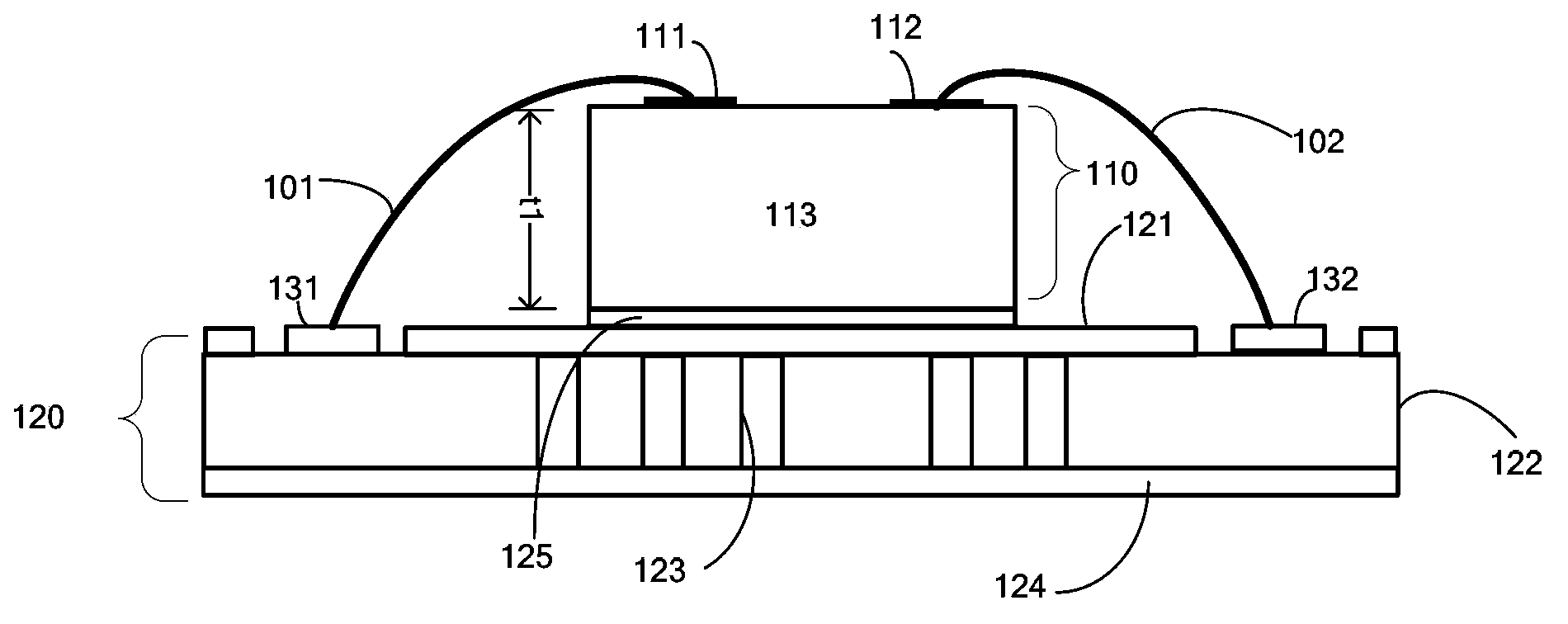

Semiconductor device

InactiveUS7800214B2Reduce and suppress inductionReduce mutual inductanceSemiconductor/solid-state device detailsSolid-state devicesSignaling systemInductance

Mutual inductance from an external output signal system to an external input signal system, in which parallel input / output operation is enabled, is reduced. A semiconductor integrated circuit has a plurality of external connection terminals facing a package substrate, and has an external input terminal and an external output terminal, in which parallel input / output operation is enabled, as part of the external connection terminals. The package substrate has a plurality of wiring layers for electrically connecting between the external connection terminals and module terminals corresponding to each other. A first wiring layer facing the semiconductor integrated circuit has a major wiring for connecting between the external input terminal and a module terminal corresponding to each other, and a second wiring layer in which the module terminals are formed has a major wiring for connecting between an external output terminal and a module terminal corresponding to each other. A major signal wiring of an external output system connected to the external output terminal, which may be a noise source, is made to be in a wiring layer distant from the semiconductor integrated circuit.

Owner:RENESAS ELECTRONICS CORP

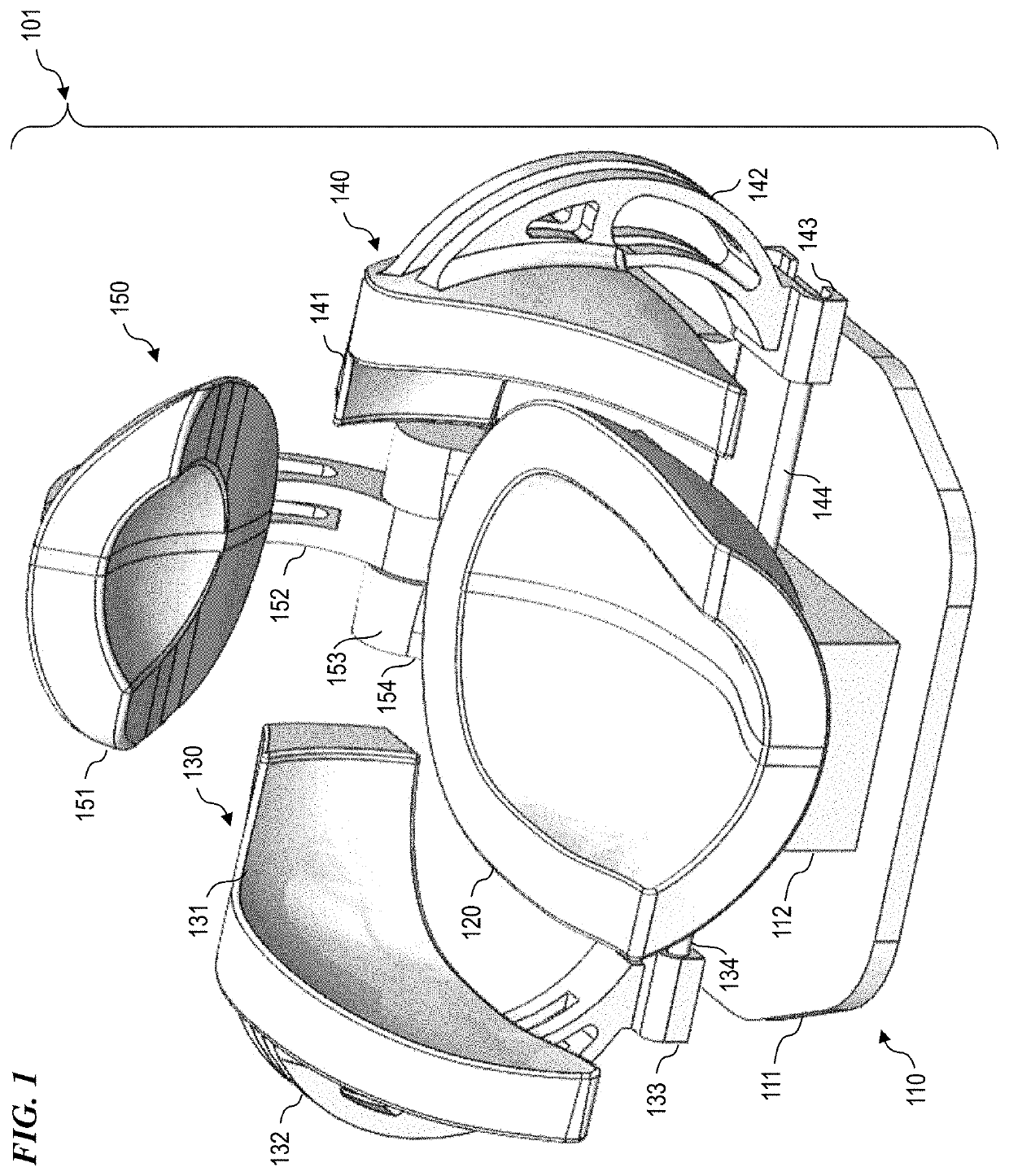

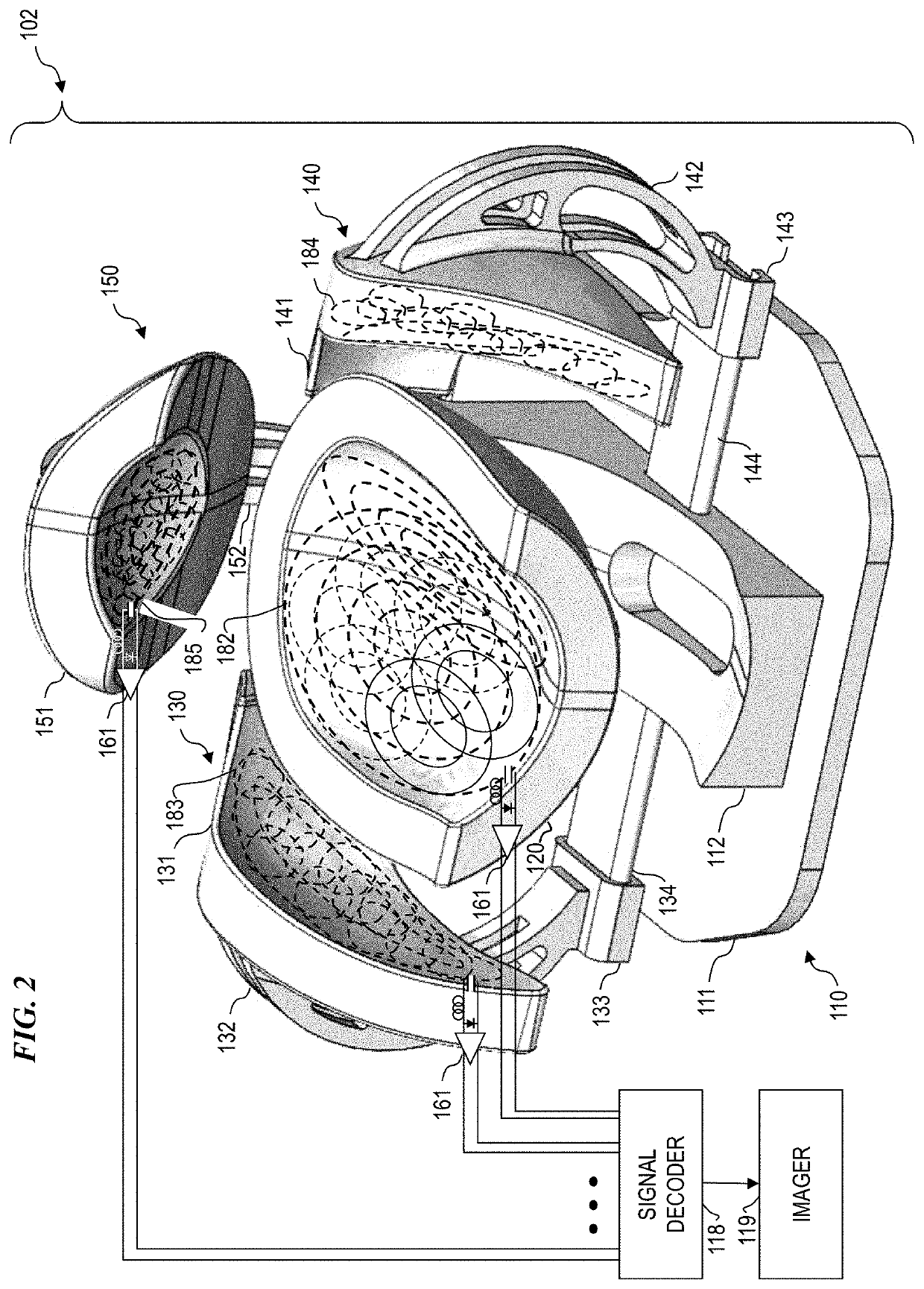

Method and apparatus for multi-part close fitting head coil

ActiveUS10827948B1Reduce mutual inductanceBetter signal to noise ratioSensorsTelemetric patient monitoringNuclear physicsNuclear magnetic resonance

A method and apparatus for receiving (RX) radio-frequency (RF) signals suitable for MRI and / or MRS from a plurality of MRI “coil loops” in each of a plurality of coil parts, each coil part having a subset of the total number of coil loops. In some embodiments, a first base part, optionally having no coils, is used to provide support of the plurality of coil parts, wherein the plurality of coil parts include a second part holding back-of-the-head coil loops, a third part holding right-side-of-the-head coil loops, a fourth part holding right-side-of-the-head coil loops, and a fifth part holding top-of-the-head coil loops. In some embodiments, the system provides for repeatable positioning, frequency tuning, and impedance matching such that experimental conditions can be replicated for later examinations of each of a plurality of patients having differing impacts on positioning, tuning and matching of the various coil parts.

Owner:LIFE SERVICES

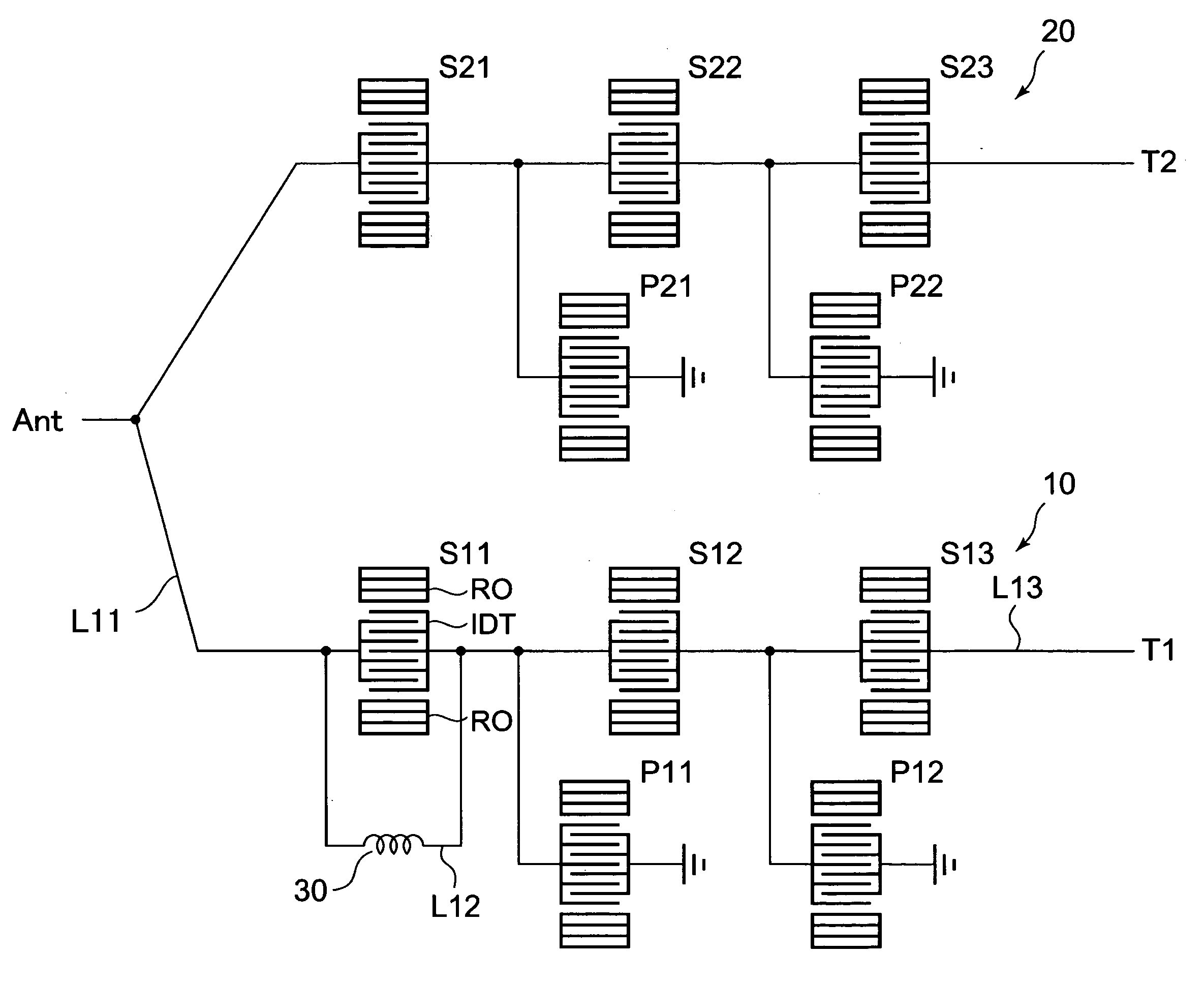

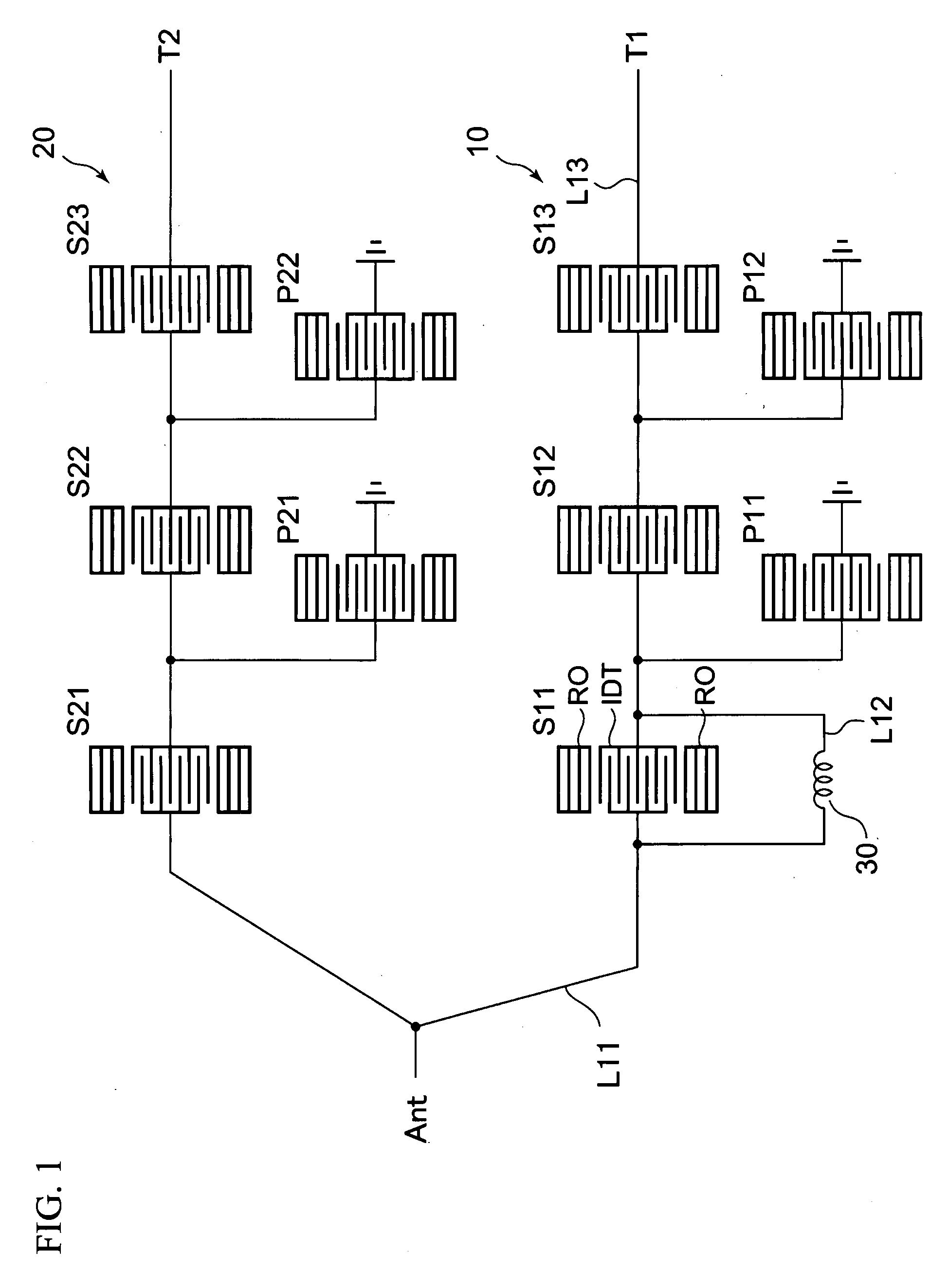

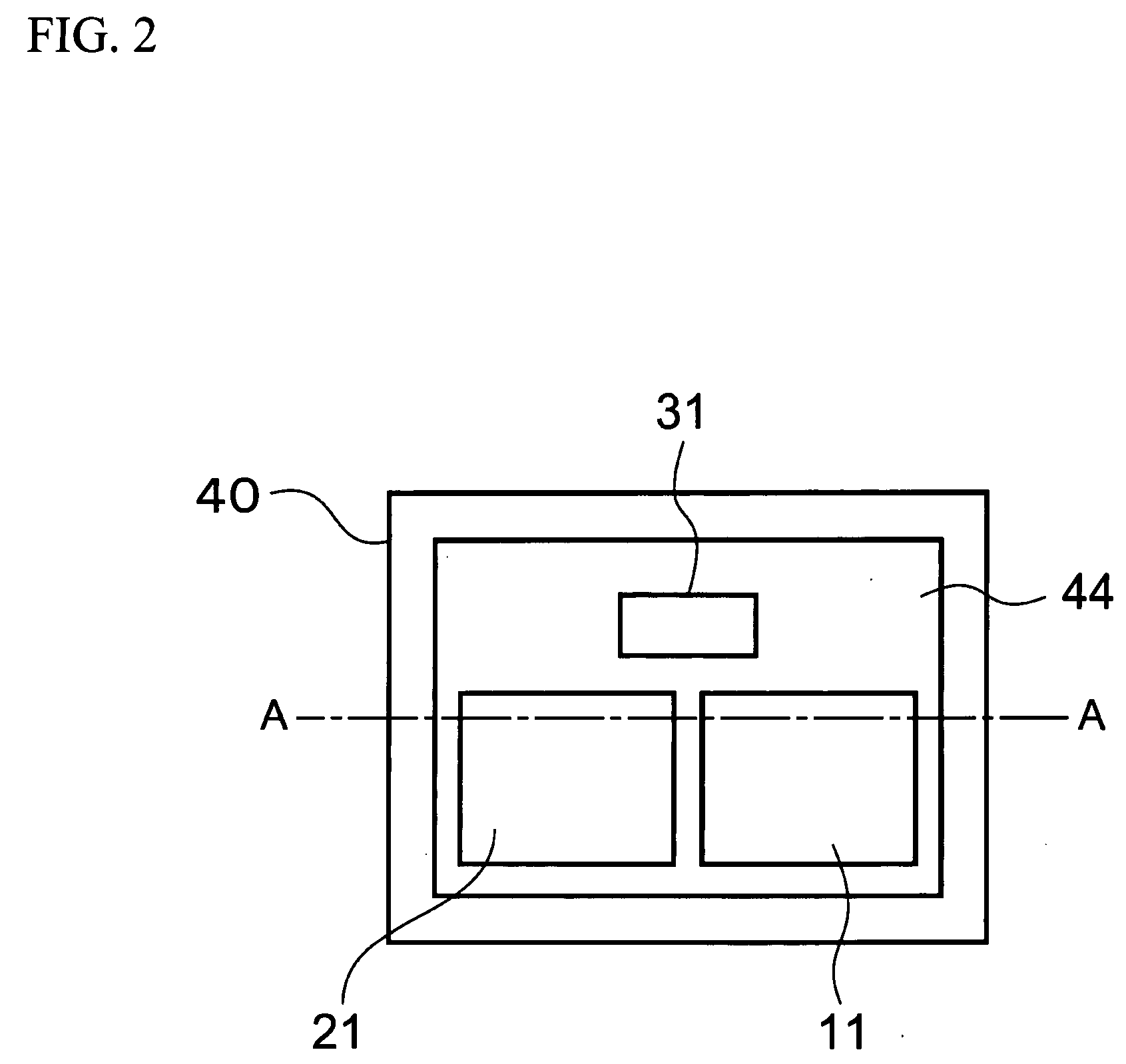

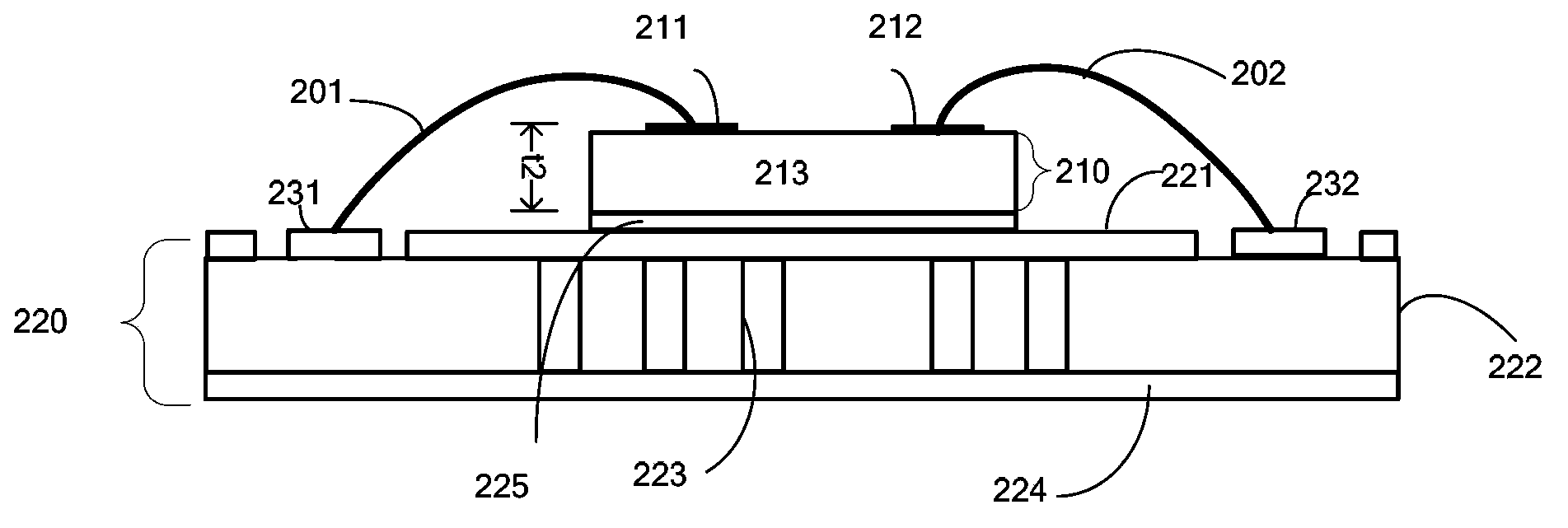

Filter and duplexer

ActiveUS20070268091A1Reduce mutual inductanceEnhanced inhibitory effectImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesInductorResonator

A duplexer includes: a first filter that is connected to a common terminal and a first terminal, and includes a first series-arm resonator; a second filter that is connected to the common terminal and a second terminal; a first inductor that is connected in parallel to the first series-arm resonator; a mounting unit that has the first filter and the second filter mounted thereon; a first inductor line that is provided on the mounting unit, and connects the first inductor and the first series-arm resonator; and a first terminal line that is provided on the mounting unit, and connects the first filter and the first terminal. In this duplexer, the directions of currents flowing through the first inductor line and the first terminal line cross each other.

Owner:TAIYO YUDEN KK

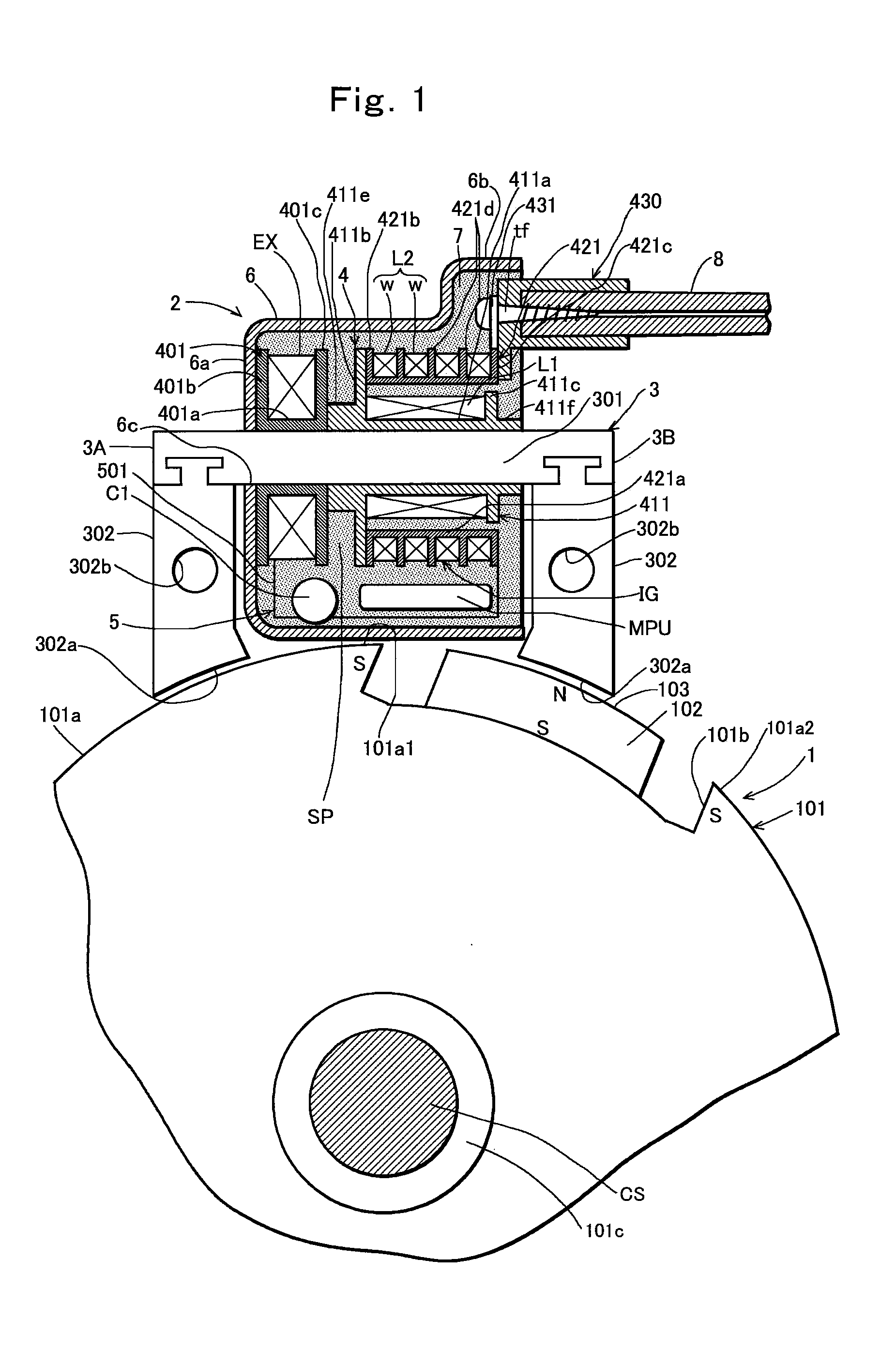

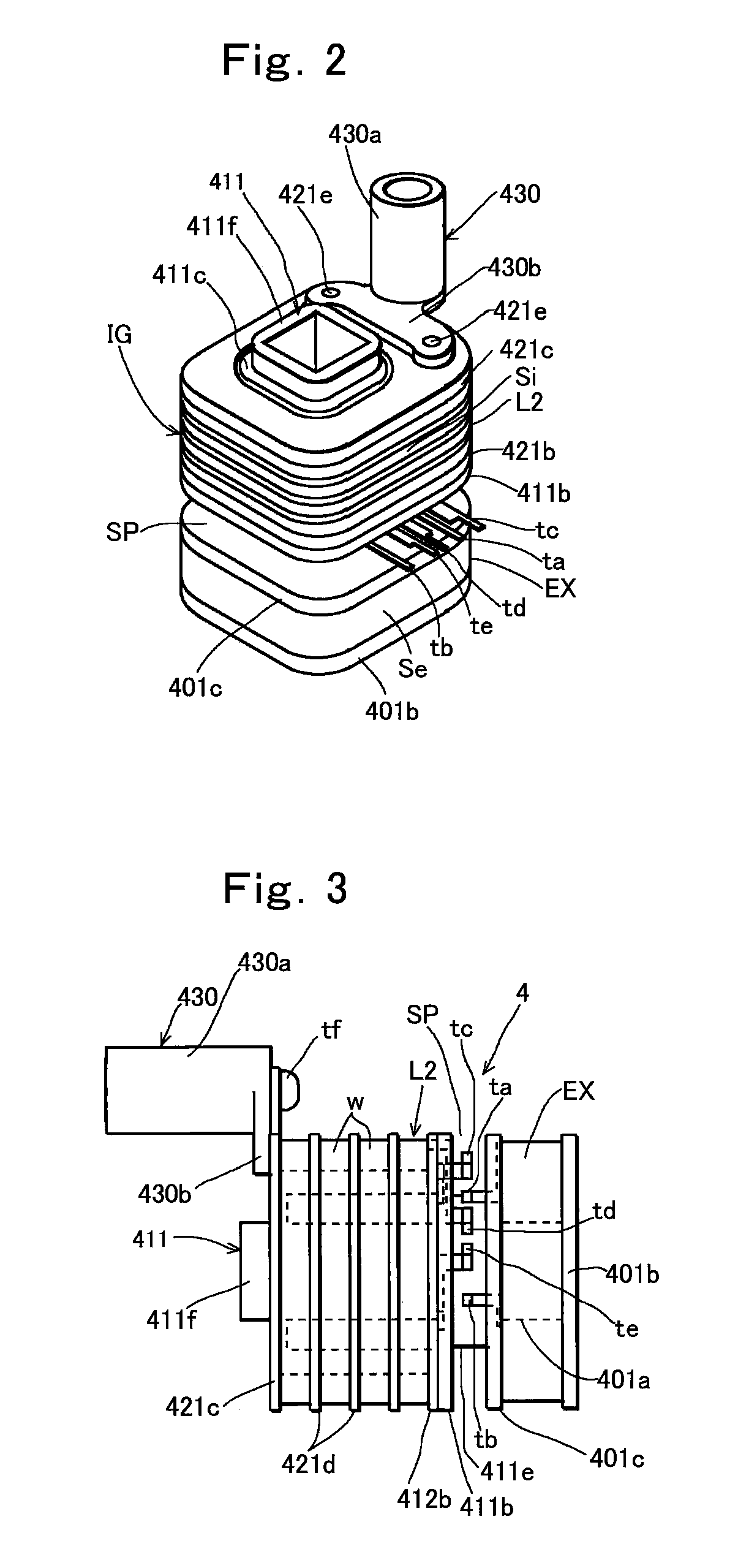

Capacitor discharge engine ignition device

ActiveUS20090126686A1Reduce mutual inductancePrevent reduction in high voltageGenerator generated ignition energyMachines/enginesCapacitanceEngineering

A capacitor discharge ignition device in which a coil unit including an ignition coil and an exciter coil wound around a common core, and an ignition unit including a circuit board and components of an ignition circuit mounted to the circuit board are housed in a case and molded with resin poured into the case, wherein the ignition coil and the exciter coil are placed axially with a spacing therebetween and a space is formed between the coils, the circuit board of the ignition unit is placed on a lateral side of the coil unit, and terminals for connecting the ignition coil and the exciter coil to the circuit board are all connected to the circuit board through the space between the ignition coil and the exciter coil.

Owner:MAHLE INT GMBH

Double-Y 30 DEG phase shift dual-redundancy permanent magnet synchronous motor without electromagnetic coupling between two phases of windings

ActiveCN107742930ASmall leakage mutual inductanceNo slot mutual leakage inductanceWindings conductor shape/form/constructionPhase shiftedSmall teeth

The invention discloses a double-Y 30 DEG phase shift dual-redundancy permanent magnet synchronous motor without electromagnetic coupling between two phases of windings. Two sets of independent three-phase symmetrical windings are placed on a stator core, the phase difference of the electromotive force between the corresponding phases of each three-phase symmetrical winding is 30 DEG electrical angle, the two sets of windings are powered by two controllers independently, and the two sets of windings can work simultaneously or separately. The coils of each phase of winding are concentrated windings, and the winding ends do not overlap. Moreover, by placing small teeth and placing high-temperature-resistant insulation materials on both sides of the small teeth, the two phases of windings areelectrically isolated from each other, the leakage mutual inductance between the two phases of windings corresponding to an end leakage magnetic field is extremely small, and there is no groove mutual leakage inductance, and at the same time, the thermal coupling between the two phases of windings is low. The mutual inductance between the two phases of windings corresponding to an armature reaction magnetic field is extremely small, and it can be assumed that there is no electromagnetic coupling between the two phases. During double redundancy operation, the armature reaction in the motor hasa low magnetomotive force harmonic component.

Owner:TIANJIN UNIV

Semiconductor device

InactiveCN103413821AReduce thicknessImprove performanceSolid-state devicesSemiconductor devicesElectromagnetic interferenceEngineering

The invention discloses a semiconductor device. The semiconductor device comprises a package substrate including a bonding area used for connecting bonding wires; and at least one die provided on the package substrate. Each die comprises a wafer substrate and a pin disposed on the wafer substrate. Each pin is used for connecting the bonding wire. The thickness of each wafer substrate is between 50um to 400um. By thinning the wafer and reducing the thicknesses of the dies, the semiconductor device can reduce the average height of the bonding wires from a ground plane, thereby improving the electrical isolation between the bonding wires and between the bonding wires and other sensitive components, lowering mutual inductance, solving the problem of electromagnetic interference and improving chip performance.

Owner:TIANJIN UNIV

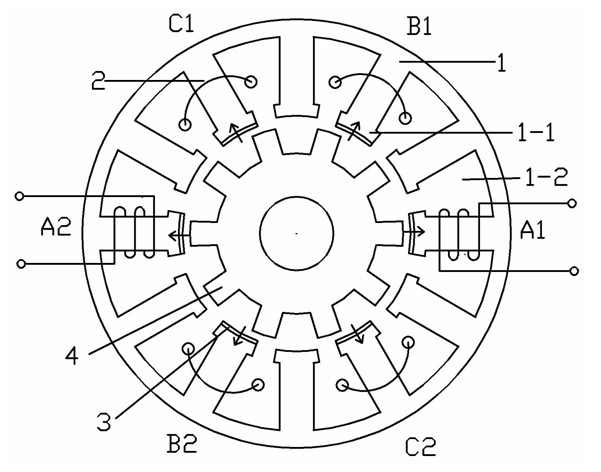

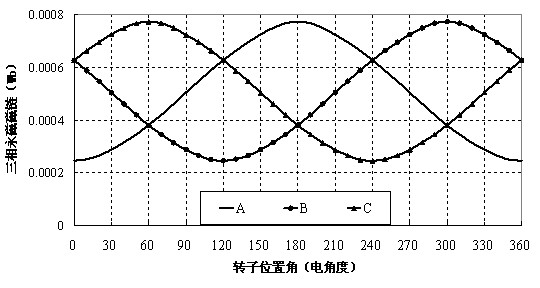

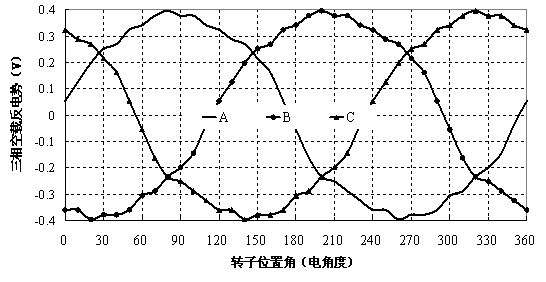

High-reliability half stator-tooth winded stator-surface mounted permanent magnet motor

InactiveCN102611219AImprove cooling conditionsGreat effortWindingsMagnetic circuit rotating partsElectric machineSurface mounting

The invention relates to a high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor which comprises a stator (1) and a rotor (4). The rotor (4) is arranged inside or outside the stator (1). The high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor is characterized in that: the stator (1) is in a salient pole structure and provided with stator teeth (1-1) which protrude from a yoke part; armature winding slots (1-2) are formed among the stator teeth (1-1), the stator teeth (1-1) and the armature winding slots (1-2) are distributed alternatively, the stator (1) is provided with a centralized armature winding (2) and permanent magnets (3), and only half of the stator teeth (1-1) are winded by armature winding coils and provided with the mounted permanent magnets so that half of permanent magnets is saved and the areas of the armature winding slots are increased. Only half of the stator teeth (1-1) are dotted with the permanent magnets (3), and the magnetizing directions of the permanent magnets (3) are same between the gap of the stator (1) and the rotor (4). The centralized armature winding (2) is arranged on the stator teeth (1-1) of the stator (1) provided with the permanent magnets. The high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor has the advantages of simple and firm structure, strong torque output capacity, large power density and high reliability.

Owner:SOUTHEAST UNIV

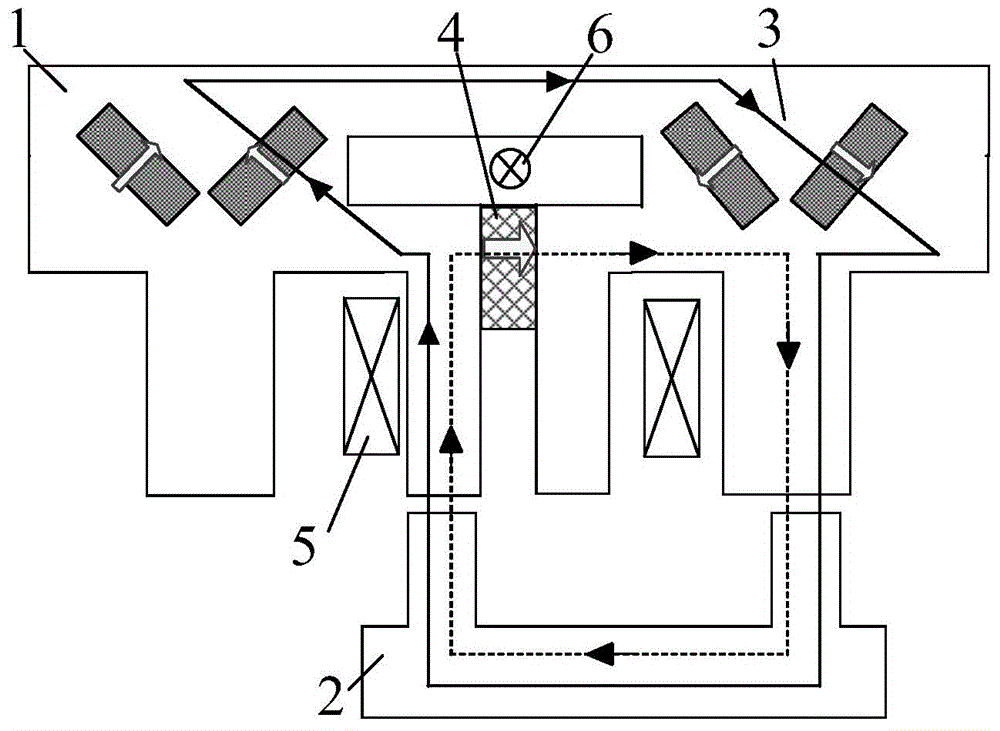

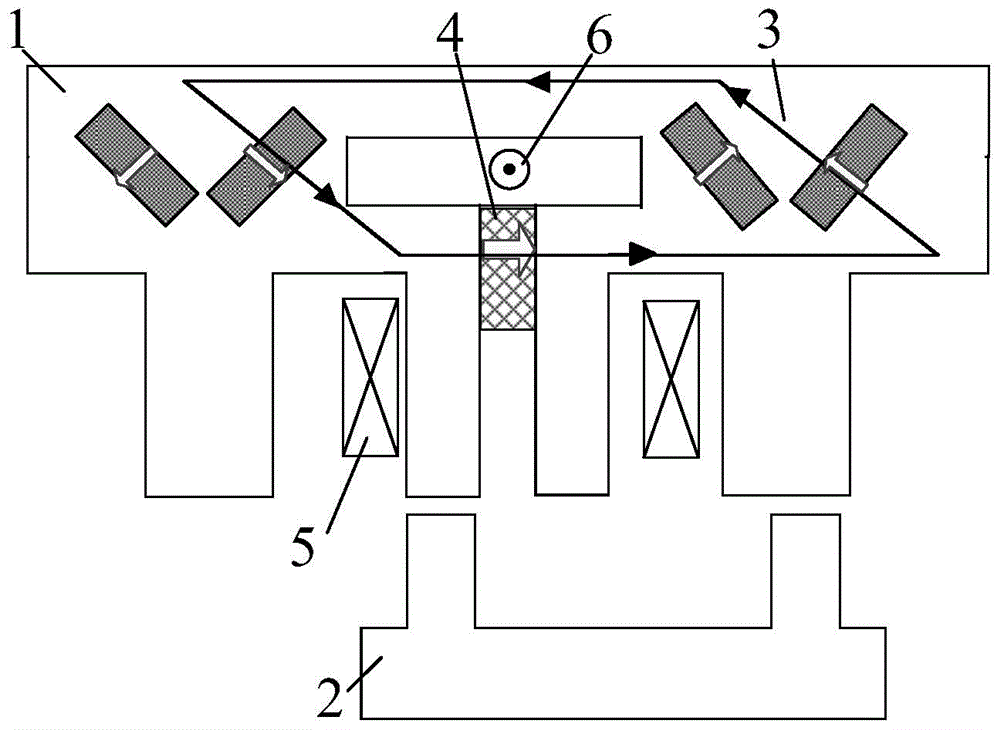

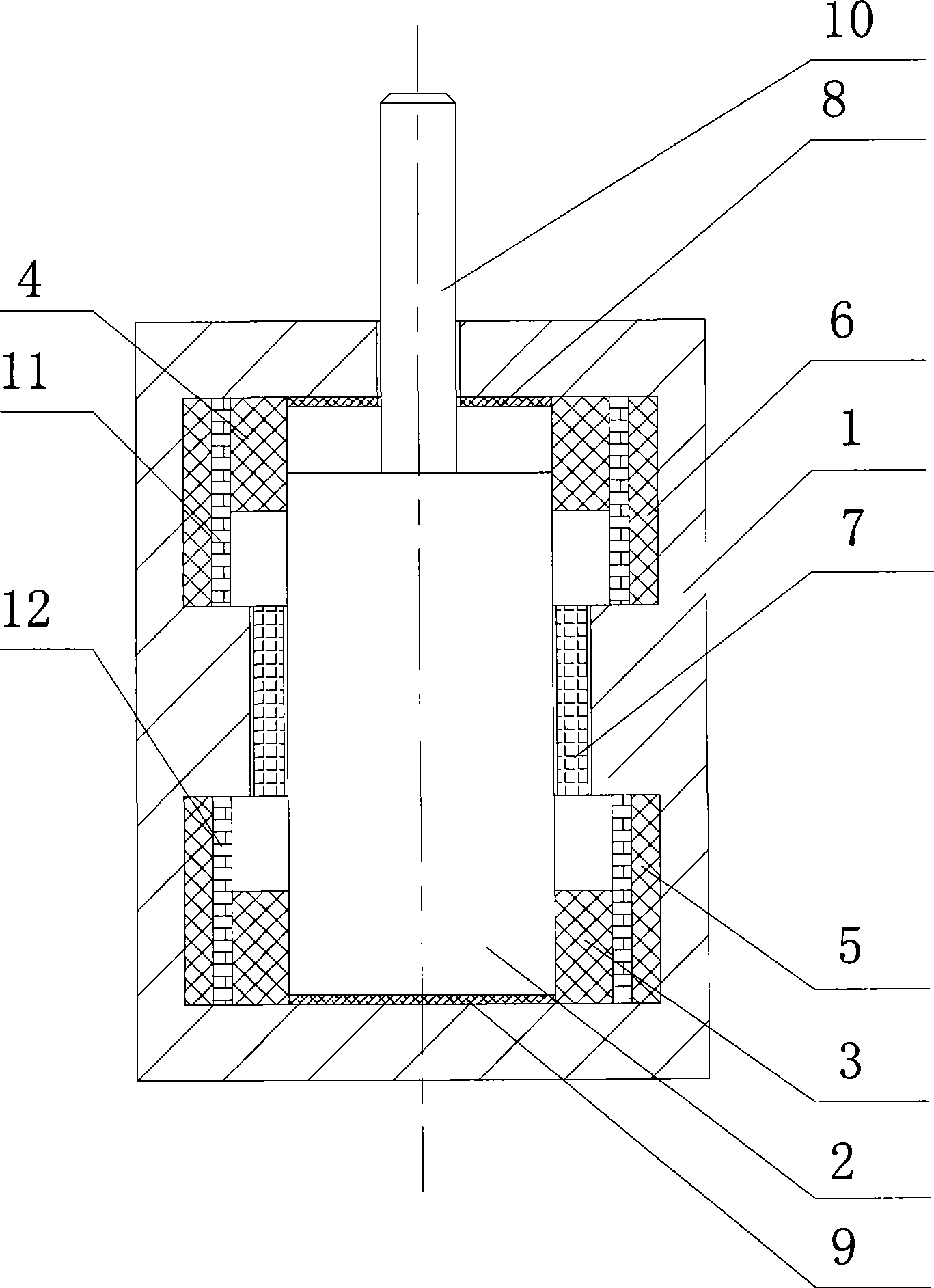

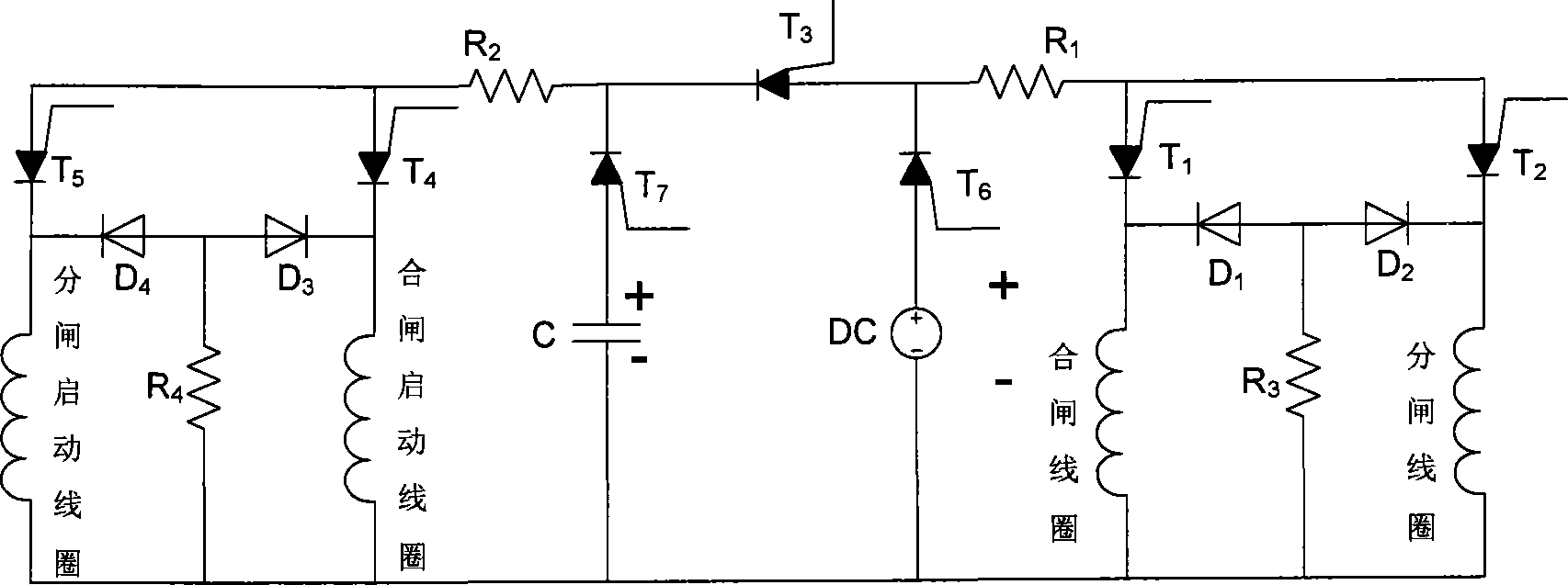

Rapid response permanent magnet control mechanism

InactiveCN101510474AReduce the starting ampere-turnsImprove the forceSwitch power arrangementsInsulation layerRapid response

The invention discloses a fast response permanent magnetic operating mechanism used for switch operation, which comprises a magnetic yoke (1), a movable core (2) and a push rod (10), wherein, the top of the movable core (2) is provided with the push rod (10); the movable core (2) is arranged in the magnetic yoke (1) which is internally provided with a switch-off coil (3), a closing coil (4), a switch-off starting coil (5), a closing starting coil (6), an annular permanent magnet (7), an upper buffer cushion (8), a lower buffer cushion (9), an upper insulation layer (11) and a lower insulation layer (12). The switch-off and closing coils are used for providing electromagnetic attraction for the movable core during switch-off and closing processes of the switch so as to offset the attraction of the annular permanent magnet to the movable core; and the switch-off and closing starting coils are used for providing electromagnetic attraction for the movable core at the initial stage of switch-off and closing of the switch so as to offset the attraction of the annular permanent magnet to the movable core. The annular permanent magnet is used for providing switch-off and closing power and keeping a movable contact of the switch to be in the switch-off and closing position. The magnetic yoke is used for providing a magnetic circuit; the movable core is used for driving the moving part of the switch to move; and the buffer cushions is used for absorbing the impact of vibration.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com